Abstract

In this study, effective parameters on viscosity of a suitable oil for lubrication of heavy-duty engines (vehicles that are in use in construction, farm, and logging equipment, semi-trucks, delivery trucks, etc.) are studied. SAE50 as a single-degree engine oil is examined in present experimental work. The mentioned engine oil is enriched by MgO and MWCNT nanoparticles (NPs). The nanofluid was prepared in six solid volume fractions (SVF) and in temperature range of 25–50 °C. The results showed the viscosity dependence on shear rate, so nanolubricant has a non-Newtonian behavior. 2–4% Viscosity reduction in concentrations of 0.0625% and 0.125% reported in comparison with viscosity of pure fluid. Also sensitivity analysis of viscosity measurement was lower than 1% for all investigated conditions. To lower experimental costs, a mathematical correlation was proposed to predict the viscosity. The R2 was considered as criterion for accuracy of proposed correlation. Having amount of 0.9995 for R2 shows accommodation of correlation predictions with experimental results. Also maximum deviation of < 3% indicates that the proposed correlation has a high accuracy.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanofluids are an evolution in fluid science. NPs have unique mechanical, thermal, magnetic and electrical properties. Actually, nanofluids are obtained by suspending particles with sizes below 100 nm in common fluids such as water and oil. By adding insignificant amounts of nanoparticles into the base fluids, an improvement in thermophysical properties is considered. Nanofluids are the term used by Choi (1995) for first time. The purpose of nanofluids is a significant increment in thermal properties of fluids by adding small amounts of nanoparticles. So thermophysical properties such as thermal conductivity, viscosity and density were examined. In recent decades, many studies have been implemented to measure and study the thermophysical properties of nanofluids like viscosity [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26], thermal conductivity [27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60] and thermal convection [61,62,63,64,65,66,67,68,69,70,71,72]. Nanofluids are used in various fields such as air-conditioning [73], solar cell [74], automotive [75], nuclear reactors [76], lubrication [77], electrical systems [78], heat exchangers [79] and microchannels [80].

One of the important parameters in fluids is viscosity, which has important role in calculating Reynolds number, Prandtl number and heat transfer coefficient. Many studies have been conducted on the viscosity of nanofluids. Studies show that different parameters such as VF, particle size, temperature, base fluid properties, surfactant, etc., are affected on viscosity of nanofluids. Asadi et al. [81] examined the influence of temperature and particle volume concentration on the dynamic viscosity of MWCNT-MgO/SAE50 hybrid nanofluid. Results indicated that with increase in the temperature and concentration, the dynamic viscosity decreases and increases, respectively. They presented an empirical correlation for dynamic viscosity of nanofluid as a function of temperature and particle volume concentration. Hemmat et al. [82] examined the influence of temperature and particle volume concentration on the dynamic viscosity of SWCNTs-ZnO/EG nanofluid. This study determined that dynamic viscosity increases significantly by changing VF from 0.25 to 5%, while diameter of NP is 18 nm and temperature is 50 °C, whereas it does not change with increase in temperature. As well as, they presented an empirical correlation for dynamic viscosity of nanofluid as a function of temperature and particle volume concentration. Soltani and Akbari [83] examined the effect of temperature and particle volume concentration on the dynamic viscosity of MWCNT-MgO/EG hybrid nanofluid. This study conducted in volume concentration from 0 to 1% and temperature from 30 to 60 °C. Results of this study showed that hybrid nanofluid has the behavior such as Newtonian fluid in mentioned VFs and temperatures. The experiment indicated that with increase in the SVF from 0.1 to 1%, the relative viscosity increases up to 168%. Hemmat et al. [84] performed an experimental study on the dynamic viscosity of Mg(OH)2-EG nanofluids in VF range of 0.1–2.0% under the temperatures ranging from 23 to 55 °C. The results showed that the viscosity rises with growth in the concentration values and relative viscosity increases with rise in temperature. They also suggested a new correlation. Many studies have been done to predict a new correlation for nanofluid viscosity. Some correlations for predicting nanofluids viscosity are presented in Table 1.

In some cases, experts have tried to improve viscosity index of engine lubricants. Hemmat Esfe et al. [90] conducted an experimental study on a nanolubricant enriched by MWCNT and ZnO NPs to control viscosity of nanofluids after adding nanoparticles.

In regard to importance of the viscosity of oil, the viscosity of the hybrid nano-oils would be of great importance. Adding NPs into hybrid fluids of nano-oils in different temperatures and VFs has a major impact. In this study, rheological behavior of MWCNT-MgO (50–50%)/SAE50 hybrid nano-oil under the temperature and concentration variations examined exactly for first time. As well as, a new correlation was suggested to estimate relative viscosity of hybrid nano-oil.

Experimentation

Sample preparation

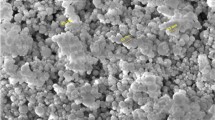

In this study, MWCNT and MgO NPs were blended in 50:50 volume percent and they were dispersed in SAE50 oil with VFs of 0%, 0.125%, 0.25%, 0.5%, 0.75% and 1% by the use of two-step method. MWCNT/MgO properties are presented in Table 2. For the purpose of identifying specifications of nanofluids, it is necessary to disperse nanoparticles in base oil uniformly and gain a stable nanofluid. To create stable nanofluid samples, a magnetic stirrer device was used for 2 h. An ultrasonic device (Ultrasonic Homogenizer Development of Ultrasonic Technology, Iran) was applied for 3 h to create a great dispersion and stop formation clusters of NPs. In this way, a stable nanofluid was made and deposition was not observed with the naked eye.

The size was measured using X-ray diffraction (XRD). The results of XRD pattern for MgO and MWCNT nanoparticles are displayed in Fig. 1.

Dynamic viscosity measurement

Dynamic viscosity of nano-oils samples of MWCNT-MgO (50–50%)/SAE50 hybrid nanofluids with SVFs of 0.0625, 0.125, 0.25, 0.75 and 1% was measured at temperatures between 25 and 50 °C by using Brookfield viscometer. Brookfield viscometer properties are listed in Table 3. SAE50 oil was used for calibrating the viscometer at room temperature. In order to ensure the results of the experiments, each experiment with different shear rates, temperatures and VFs was repeated several times, and then, the average of the measured data was recorded.

Results and discussion

In this study, the viscosity variations of MWCNT-MgO (50–50%) hybrid nanofluid are examined experimentally in SVFs between 0.0625 and 1% and in temperatures between 25 and 50 °C.

Newtonian behavior

In fluid mechanics, a non-Newtonian fluid is a fluid in which viscosity depends on shear rate. For determination of Newtonian, non-Newtonian and Bingham behavior usually uses Ostwald–de Waele equation that is considered as follows:

Figure 2 displays n as a function of different temperatures for all samples. A value n is close to unity indicates nanofluid behavior close to Newtonian behavior. By enhancing SVF, n values decreases. That means non-Newtonian behavior is clearer in concentrated samples.

In Fig. 3, consistency index (m) of hybrid nanofluids is displayed against temperature. The results show that the random motion of NPs in the base fluid increases by rising VF and van der Waals force causes major nanoclusters which prevent motion of fluid layers on each other. Therefore, m index of nanofluids increases to create a more viscous fluid. It has been reported that intermolecular interactions decrease with increase in temperature and it cause to decrease consistency index. It should be noted that some visible fluctuations in amounts of consistency index have no important reason. In this figure, the trend of changes is more important than fluctuations.

Effective parameters on viscosity

The viscosity of fluid is the measure of its resistance to relative motion. On the other hand, the viscosity is known as an inhibition force and measure of the frictional properties of fluid. The viscosity of fluids is due to intermolecular force which is the van der Waals force.

In Fig. 4, variations of MWCNT-MgO (50–50%) hybrid nanofluid versus shear rate are presented for different VFs. Temperature increment leads to viscosity reduction in nanofluids. Low viscosity variations at higher temperatures of SAE50 base oil and MWCNT-MgO nanofluid are more significant in all volume fractions. The variation of viscosity versus shear rate illustrates non-Newtonian behavior of nanofluids.

Concentration of NPs effect on viscosity at a certain temperature is investigated, and results are depicted in Fig. 5. In a specific temperature, while shear rate enhances and VF reduces, the viscosity of nanofluid decreases. It seems that intermolecular force decreases by increase in temperature and viscosity of nanofluid reduces accordingly. The variation trends illustrate dependency of viscosity to its shear rate and a non-Newtonian behavior of nanofluids.

Figure 6 displays the variation of relative viscosity of MWCNT-MgO (50–50%)/SAE50 nanofluid versus temperature in different VFs. As seen in Fig. 6, increase or decrease in shear rate at a constant temperature leads no noticeable change in relative viscosity. Considering low variations in relative viscosity of nanofluids by increasing temperature in a constant VF, the independency of the relative viscosity changes to temperature is possible. The optimum concentration of dispersed NPs in oil depends on the expected application by user. For applications that pressure drop in operating cycle is not important or applications with only heat transfer goals, higher SVFs are suitable. On the other hand to reach a fluid with improved thermal characteristics and also minimum enhanced pressure drop in comparison with basefluid, users can select lower solid VFs like 0.0625% or 0.125%. As it is clear in Fig. 6, SVF of 0.0625% caused viscosity reduction in comparison with pure basefluid that gives users a fluid with modified thermal characteristics and also reduced viscosity that causes pumping cost saving.

Figure 7 displays the variation of viscosity of MWCNT-MgO (50–50%)/SAE50 nanofluid versus different VFs. The results show that by rising temperature, the intermolecular van der Waals force decreases and it causes low viscosity. In higher temperatures, the variation of viscosity is fewer and it means that the viscosity has low dependency on effective parameters such as VF and temperature. The random motion of NPs in the base fluid increases by rising volume fraction and possibility of agglomeration in nanofluids increases. Therefore, the variation of viscosity is significant in higher volume fractions. The results show that the viscosity of nanofluid decreases to 329.6% by rising temperatures in a constant volume fraction of 1% and shear rate 200 1 s−1. As well as, the viscosity of nanofluid increases to 10.66% by rising VFs at a constant temperature of 25 °C and shear rate 200 1 s−1.

Proposed correlation

RSM method is used as a fast and economic method for prediction of viscosity of nanofluids based on mathematics. According to this method, a three variable mathematical correlation is proposed as a function of shear rate, SVF and temperature. By this formula, researchers can predict the viscosity of MWCNT-MgO (50–50%)/SAE50 nanofluid without needing any experimental setup.

The coefficients of correlation for desired nanofluid are shown in Table 4. The P value less than 0.05 shows non-removable parameters in proposed correlation. By removing these coefficients, the order of correlation is eliminated. As shown in F values, there is only 0.01% probability of variance in the correlation, which indicates a valid relation in determining viscosity of nanofluid. Also Table 5 gives some information about the accuracy of the proposed model.

To check the accordance of predicted results by RSM method with empirical results, Fig. 8 is drawn up. As seen in Fig. 8, experimental data are laid on the bisector line or at least deviating from it. According to Fig. 8, dynamic viscosity data are predicted well by proposed correlation (2) and the correlation error is acceptable.

Figure 9 displays mean square errors of two shear rates in different VFs and temperatures. As shown in Fig. 9, maximum deviation is less than 3% that shows high accuracy of the correlations.

Sensitivity analysis

Sensitivity analysis is performed to analyze the effect of adding unwanted amounts of NPs to base fluids (because of laboratory errors and human mistakes) on viscosity of nanolubricant. Change by 10% in each certain SVF and investigating the effect of this change on viscosity is studied for the introduced nanolubricant. Equation (3) was used for sensitivity analysis:

Sensitivity of viscosity in different temperatures and shear rates versus different VFs is illustrated in Fig. 10. At temperatures higher than 30 °C, the sensitivity of viscosity and their shear rates increases by adding VF and considering 10% extra NP to the sample. Increasing VF at a constant temperature resulted in increase in sensitivity of nanofluids. Increasing NPs collisions with base fluid molecule in higher VFs causes it to happen. The sensitivity rises more at 45 °C and 50 °C. Because of high sensitivity of viscosity at higher temperatures, more accuracy for supplying nanofluid is necessary.

Conclusions

In present experimental work, rheological behavior of MWCNT-MgO (50–50%) hybrid nanofluid based on SAE50 oil was examined experimentally. For this purpose, nanofluid samples were prepared in six solid VF under the temperatures ranging from 25 to 50 °C. According to results, adding NPs to base fluid causes viscosity dependency to shear rate and it is a sign of non-Newtonian behavior. Therefore, MWCNT-MgO (50–50%) hybrid nanofluid shows a non-Newtonian behavior. The examination of experiments shows below results:

- 1.

The results show that the viscosity of nanofluid decreases to 329.6% by rising temperatures in a constant VF of 1% and shear rate 200 1 s−1. As well as, the viscosity of nanofluid increases to 10.66% by rising VFs at a constant temperature of 25 °C and shear rate 200 1 s−1.

- 2.

Increase or decrease in shear rate at a constant temperature leads no noticeable change in relative viscosity.

- 3.

In higher temperatures, the variation of viscosity is fewer and it means that the viscosity has low dependency on effective parameters such as VF and temperature. This trend causes a better balance in the variation of viscosity versus temperature.

- 4.

By enhancing VF, power law index decreases and nanofluids behavior would become closer to non-Newtonian behavior.

- 5.

Dynamic viscosity of nanofluid is predicted by the mathematical model well. Maximum deviation is less than 3% that shows high accuracy of the correlations.

- 6.

Sensitivity of viscosity at higher temperatures is more than lower temperatures, because the sensitivity of viscosity to different VFs at higher temperatures rises.

- 7.

SVF of 0.0625% causes 2–4% viscosity reduction in comparison with pure 5W50.

- 8.

Concentrations of 0.0625% and 0.125% cause no excess pressure drop in operating cycle, and in some cases, it lowers the pumping cost.

References

Kwak K, Kim C. Viscosity and thermal conductivity of copper oxide nanofluid dispersed in ethylene glycol. Korea Aust Rheol J. 2005;17(2):35–40.

Kulkarni DP, Das DK, Chukwu GA. Temperature dependent rheological property of copper oxide nanoparticles suspension (nanofluid). J Nanosci Nanotechnol. 2006;6(4):1150–4.

Dehghani Y, Abdollahi A, Karimipour A. Experimental investigation toward obtaining a new correlation for viscosity of WO3 and Al2O3 nanoparticles-loaded nanofluid within aqueous and non-aqueous basefluids. J Therm Anal Calorim. 2019;135(1):713–28.

Esfe MH, Esfandeh S, Alirezaie A. A novel experimental investigation on the effect of nanoparticles composition on the rheological behavior of nano-hybrids. J Mol Liq. 2018:269:933–9.

Jabbari F, Rajabpour A, Saedodin S. Viscosity of carbon nanotube/water nanofluid. J Therm Anal Calorim. 2019;135(3):1787–96.

Phuoc TX, Massoudi M. Experimental observations of the effects of shear rates and particle concentration on the viscosity of Fe2O3–deionized water nanofluids. Int J Therm Sci. 2009;48(7):1294–301.

Aladag B, Halelfadl S, Doner N, Maré T, Duret S, Estellé P. Experimental investigations of the viscosity of nanofluids at low temperatures. Appl Energy. 2012;97:876–80.

Esfe MH, Saedodin S, Wongwises S, Toghraie D. An experimental study on the effect of diameter on thermal conductivity and dynamic viscosity of Fe/water nanofluids. J Therm Anal Calorim. 2015;119(3):1817–24.

Maddah H, Aghayari R, Ahmadi MH, Rahimzadeh M, Ghasemi N. Prediction and modeling of MWCNT/Carbon (60/40)/SAE 10 W 40/SAE 85 W 90 (50/50) nanofluid viscosity using artificial neural network (ANN) and self-organizing map (SOM). J Therm Anal Calorim. 2018;134(3):2275–86.

Koca HD, Doganay S, Turgut A, Tavman IH, Saidur R, Mahbubul IM. Effect of particle size on the viscosity of nanofluids: a review. Renew Sustain Energy Rev. 2018;82:1664–74.

Sekhar YR, Sharma KV. Study of viscosity and specific heat capacity characteristics of water-based Al2O3 nanofluids at low particle concentrations. J Exp Nanosci. 2015;10(2):86–102.

Esfe MH, Saedodin S, Rejvani M, Shahram J. Experimental investigation, model development and sensitivity analysis of rheological behavior of ZnO/10W40 nano-lubricants for automotive applications. Physica E: Low-dimens Syst Nanostruct. 2017;90:194–203.

Esfe MH, Kamyab MH, Afrand M, Amiri MK. Using artificial neural network for investigating of concurrent effects of multi-walled carbon nanotubes and alumina nanoparticles on the viscosity of 10 W-40 engine oil. Phys A Stat Mech Appl. 2018;510:610–24.

Esfe MH, Arani AAA. An experimental determination and accurate prediction of dynamic viscosity of MWCNT (% 40)-SiO2 (% 60)/5W50 nano-lubricant. J Mol Liq. 2018;259:227–37.

Ramezanizadeh M, Ahmadi MA, Ahmadi MH, Nazari MA. Rigorous smart model for predicting dynamic viscosity of Al2O3/water nanofluid. J Therm Anal Calorim. 2018;137(1):307–16.

Żyła G, Fal J. Experimental studies on viscosity, thermal and electrical conductivity of aluminum nitride–ethylene glycol (AlN–EG) nanofluids. Thermochim Acta. 2016;637:11–6.

Esfe MH, Rostamian H, Akbari M, Hassani M. An experimental study and new correlations of viscosity of ethylene glycol-water based nanofluid at various temperatures and different solid concentrations. Heat Transf Res. 2016. https://doi.org/10.1615/HeatTransRes.2016010502.

Esfe MH, Esfandeh S. Investigation of rheological behavior of hybrid oil based nanolubricant-coolant applied in car engines and cooling equipments. Appl Therm Eng. 2018;131:1026–33.

Sarafraz MM, Arya A, Nikkhah V, Hormozi F. Thermal performance and viscosity of biologically produced silver/coconut oil nanofluids. Chem Biochem Eng Q. 2016;30(4):489–500.

Esfe MH, Arani AAA, Esfandeh S, Afrand M. Proposing new hybrid nano-engine oil for lubrication of internal combustion engines: preventing cold start engine damages and saving energy. Energy. 2019;170:228–38.

Esfe MH, Rostamian H, Sarlak MR. A novel study on rheological behavior of ZnO-MWCNT/10w40 nanofluid for automotive engines. J Mol Liq. 2018;254:406–13.

Hemmat Esfe M, Rostamian H, Afrand M, Wongwises S. Examination of effects of multi-walled carbon nanotubes on rheological behavior of engine oil (10W40). J Nanostruct. 2016;6(4):257–63.

Ahammed N, Asirvatham LG, Wongwises S. Effect of volume concentration and temperature on viscosity and surface tension of graphene–water nanofluid for heat transfer applications. J Therm Anal Calorim. 2016;123(2):1399–409.

Esfe MH, Rostamian H, Rejvani M, Emami MRS. Rheological behavior characteristics of ZrO2-MWCNT/10w40 hybrid nano-lubricant affected by temperature, concentration, and shear rate: an experimental study and a neural network simulating. Phys E Low Dimens Syst Nanostruct. 2018;102:160–70.

Esfe MH, Esfandeh S, Niazi S. An experimental investigation, sensitivity analysis and RSM analysis of MWCNT (10)-ZnO (90)/10W40 nanofluid viscosity. J Mol Liq. 2019;288:111020.

Afrand M, Nadooshan AA, Hassani M, Yarmand H, Dahari M. Predicting the viscosity of multi-walled carbon nanotubes/water nanofluid by developing an optimal artificial neural network based on experimental data. Int Commun Heat Mass Transf. 2016;77:49–53.

Esfe MH, Esfandeh S, Saedodin S, Rostamian H. Experimental evaluation, sensitivity analyzation and ANN modeling of thermal conductivity of ZnO-MWCNT/EG-water hybrid nanofluid for engineering applications. Appl Therm Eng. 2017;125:673–85.

Xuan Y, Li Q, Hu W. Aggregation structure and thermal conductivity of nanofluids. AIChE J. 2003;49(4):1038–43.

Esfe MH, Saedodin S, Biglari M, Rostamian H. Experimental investigation of thermal conductivity of CNTs-Al2O3/water: a statistical approach. Int Commun Heat Mass Transf. 2015;69:29–33.

Esfe MH, Ahangar MRH, Toghraie D, Hajmohammad MH, Rostamian H, Tourang H. Designing artificial neural network on thermal conductivity of Al2O3–water–EG (60–40%) nanofluid using experimental data. J Therm Anal Calorim. 2016;126(2):837–43.

Esfe MH, Arani AAA, Firouzi M. Empirical study and model development of thermal conductivity improvement and assessment of cost and sensitivity of EG-water based SWCNT-ZnO (30%: 70%) hybrid nanofluid. J Mol Liq. 2017;244:252–61.

Soltanimehr M, Afrand M. Thermal conductivity enhancement of COOH-functionalized MWCNTs/ethylene glycol–water nanofluid for application in heating and cooling systems. Appl Therm Eng. 2016;105:716–23.

Chon CH, Kihm KD, Lee SP, Choi SU. Empirical correlation finding the role of temperature and particle size for nanofluid (Al2O3) thermal conductivity enhancement. Appl Phys Lett. 2005;87(15):153107.

Esfe MH, Rejvani M, Karimpour R, Arani AAA. Estimation of thermal conductivity of ethylene glycol-based nanofluid with hybrid suspensions of SWCNT–Al2O3 nanoparticles by correlation and ANN methods using experimental data. J Therm Anal Calorim. 2017;128(3):1359–71.

Esfe MH, Hajmohammad MH. Thermal conductivity and viscosity optimization of nanodiamond-Co3O4/EG (40: 60) aqueous nanofluid using NSGA-II coupled with RSM. J Mol Liq. 2017;238:545–52.

Sundar LS, Ramana EV, Singh MK, Sousa AC. Thermal conductivity and viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids for heat transfer applications: an experimental study. Int Commun Heat Mass Transf. 2014;56:86–95.

Esfe MH, Hajmohammad H, Moradi R, Arani AAA. Multi-objective optimization of cost and thermal performance of double walled carbon nanotubes/water nanofluids by NSGA-II using response surface method. Appl Therm Eng. 2017;112:1648–57.

Godson L, Raja B, Lal DM, Wongwises S. Experimental investigation on the thermal conductivity and viscosity of silver-deionized water nanofluid. Exp Heat Transf. 2010;23(4):317–32.

Aybar HŞ, Sharifpur M, Azizian MR, Mehrabi M, Meyer JP. A review of thermal conductivity models for nanofluids. Heat Transf Eng. 2015;36(13):1085–110.

Esfe MH, Firouzi M, Afrand M. Experimental and theoretical investigation of thermal conductivity of ethylene glycol containing functionalized single walled carbon nanotubes. Phys E Low Dimens Syst Nanostruct. 2018;95:71–7.

Esfe MH, Esfandeh S, Amiri MK, Afrand M. A novel applicable experimental study on the thermal behavior of SWCNTs (60%)-MgO (40%)/EG hybrid nanofluid by focusing on the thermal conductivity. Powder Technol. 2019;342:998–1007.

Sundar LS, Singh MK, Ramana EV, Singh B, Grácio J, Sousa AC. Enhanced thermal conductivity and viscosity of nanodiamond-nickel nanocomposite nanofluids. Sci Rep. 2014;4:4039.

Esfe MH, Esfandeh S, Rejvani M. Modeling of thermal conductivity of MWCNT-SiO2 (30: 70%)/EG hybrid nanofluid, sensitivity analyzing and cost performance for industrial applications. J Therm Anal Calorim. 2018;131(2):1437–47.

Esfe MH, Arani AAA, Rezaie M, Yan WM, Karimipour A. Experimental determination of thermal conductivity and dynamic viscosity of Ag–MgO/water hybrid nanofluid. Int Commun Heat Mass Transf. 2015;66:189–95.

Rostamian SH, Biglari M, Saedodin S, Esfe MH. An inspection of thermal conductivity of CuO-SWCNTs hybrid nanofluid versus temperature and concentration using experimental data, ANN modeling and new correlation. J Mol Liq. 2017;231:364–9.

Sundar LS, Singh MK, Sousa AC. Investigation of thermal conductivity and viscosity of Fe3O4 nanofluid for heat transfer applications. Int Commun Heat Mass Transf. 2013;44:7–14.

Esfe MH, Afrand M, Yan WM, Akbari M. Applicability of artificial neural network and nonlinear regression to predict thermal conductivity modeling of Al2O3–water nanofluids using experimental data. Int Commun Heat Mass Transf. 2015;66:246–9.

Esfe MH, Yan WM, Afrand M, Sarraf M, Toghraie D, Dahari M. Estimation of thermal conductivity of Al2O3/water (40%)–ethylene glycol (60%) by artificial neural network and correlation using experimental data. Int Commun Heat Mass Transf. 2016;74:125–8.

Sundar LS, Farooky MH, Sarada SN, Singh MK. Experimental thermal conductivity of ethylene glycol and water mixture based low volume concentration of Al2O3 and CuO nanofluids. Int Commun Heat Mass Transf. 2013;41:41–6.

Afrand M, Esfe MH, Abedini E, Teimouri H. Predicting the effects of magnesium oxide nanoparticles and temperature on the thermal conductivity of water using artificial neural network and experimental data. Phys E Low Dimens Syst Nanostruct. 2017;87:242–7.

Esfe MH, Saedodin S, Naderi A, Alirezaie A, Karimipour A, Wongwises S, Bin Dahari M. Modeling of thermal conductivity of ZnO-EG using experimental data and ANN methods. Int Commun Heat Mass Transf. 2015;63:35–40.

Hadadian M, Goharshadi EK, Youssefi A. Electrical conductivity, thermal conductivity, and rheological properties of graphene oxide-based nanofluids. J Nanopart Res. 2014;16(12):2788.

Branson BT, Beauchamp PS, Beam JC, Lukehart CM, Davidson JL. Nanodiamond nanofluids for enhanced thermal conductivity. ACS Nano. 2013;7(4):3183–9.

Esfe MH, Saedodin S, Mahian O, Wongwises S. Thermal conductivity of Al2O3/water nanofluids. J Therm Anal Calorim. 2014;117(2):675–81.

Saleh R, Putra N, Prakoso SP, Septiadi WN. Experimental investigation of thermal conductivity and heat pipe thermal performance of ZnO nanofluids. Int J Therm Sci. 2013;63:125–32.

Nasiri A, Shariaty-Niasar M, Rashidi AM, Khodafarin R. Effect of CNT structures on thermal conductivity and stability of nanofluid. Int J Heat Mass Transf. 2012;55(5–6):1529–35.

Mariano A, Pastoriza-Gallego MJ, Lugo L, Camacho A, Canzonieri S, Piñeiro MM. Thermal conductivity, rheological behaviour and density of non-Newtonian ethylene glycol-based SnO2 nanofluids. Fluid Phase Equilib. 2013;337:119–24.

Warrier P, Teja A. Effect of particle size on the thermal conductivity of nanofluids containing metallic nanoparticles. Nanoscale Res Lett. 2011;6(1):247.

Esfe MH, Naderi A, Akbari M, Afrand M, Karimipour A. Evaluation of thermal conductivity of COOH-functionalized MWCNTs/water via temperature and solid volume fraction by using experimental data and ANN methods. J Therm Anal Calorim. 2015;121(3):1273–8.

Yiamsawasd T, Dalkilic AS, Wongwises S. Measurement of the thermal conductivity of titania and alumina nanofluids. Thermochim Acta. 2012;545:48–56.

Salari E, Peyghambarzadeh SM, Sarafraz MM, Hormozi F, Nikkhah V. Thermal behavior of aqueous iron oxide nano-fluid as a coolant on a flat disc heater under the pool boiling condition. Heat Mass Transf. 2017;53(1):265–75.

Salari E, Peyghambarzadeh M, Sarafraz MM, Hormozi F. Boiling heat transfer of alumina nano-fluids: role of nanoparticle deposition on the boiling heat transfer coefficient. Period Polytech Chem Eng. 2016;60(4):252–8.

Esfe MH, Arani AAA, Niroumand AH, Yan WM, Karimipour A. Mixed convection heat transfer from surface-mounted block heat sources in a horizontal channel with nanofluids. Int J Heat Mass Transf. 2015;89:783–91.

Hemmat Esfe M, Akbar Abbasian AA, Aghaie A, Wongwises S. Mixed convection flow and heat transfer in an up-driven, inclined, square enclosure subjected to DWCNT-water nanofluid containing three circular heat sources. Curr Nanosci. 2017;13(3):311–23.

Esfe MH, Esforjani SSM, Akbari M, Karimipour A. Mixed-convection flow in a lid-driven square cavity filled with a nanofluid with variable properties: effect of the nanoparticle diameter and of the position of a hot obstacle. Heat Transf Res. 2014;45(6):563–78. https://doi.org/10.1615/HeatTransRes.2014007271.

Yadav D, Lee D, Cho HH, Lee J. The onset of double-diffusive nanofluid convection in a rotating porous medium layer with thermal conductivity and viscosity variation: a revised model. J Porous Med. 2016;19(1):31–46. https://doi.org/10.1615/JPorMedia.v19.i1.30.

Mahmoodi M, Esfe MH, Akbari M, Karimipour A, Afrand M. Magneto-natural convection in square cavities with a source-sink pair on different walls. Int J Appl Electromag Mech. 2015;47(1):21–32.

Hemmat Esfe M, Abbasian Arani AA, Wei-Mon YAN, Aghaie A, Afrand M, Sina N. Mixed convection of functionalized dwcnt-water nanofluid in baffled lid-driven cavities. Therm Sci. 2018;22(6):2503–14.

Arya A, Sarafraz MM, Shahmiri S, Madani SAH, Nikkhah V, Nakhjavani SM. Thermal performance analysis of a flat heat pipe working with carbon nanotube-water nanofluid for cooling of a high heat flux heater. Heat Mass Transf. 2018;54(4):985–97.

Fereidoon A, Saedodin S, Hemmat Esfe M, Noroozi MJ. Evaluation of mixed convection in inclined square lid-driven cavity filled with Al2O3/water nano-fluid. Eng Appl Comput Fluid Mech. 2013;7(1):55–65.

Sarafraz MM. Experimental investigation on pool boiling heat transfer to formic acid, propanol and 2-butanol pure liquids under the atmospheric pressure. J Appl Fluid Mech. 2013;6(1):73–9.

Sarafraz MM, Hormozi F. Application of thermodynamic models to estimating the convective flow boiling heat transfer coefficient of mixtures. Exp Therm Fluid Sci. 2014;53:70–85.

Hatami M, Domairry G, Mirzababaei SN. Experimental investigation of preparing and using the H2O based nanofluids in the heating process of HVAC system model. Int J Hydrog Energy. 2017;42(12):7820–5.

Javadi M, Abdi Y, Arzi E. Local collection efficiency in the nano-crystalline solar cells. Sol Energy. 2016;133:549–55.

Hemmat EM, Noroozi M. Numerical simulation of mixed convection of fluid flow and heat transfer within car radiator with an inside hot obstacle filled with nanofluid. J Model Eng. 2011;9(25):33–47.

Ansarifar GR, Ebrahimian M. Design and neutronic investigation of the Nano fluids application to VVER-1000 nuclear reactor with dual cooled annular fuel. Ann Nucl Energy. 2016;87:39–47.

Esfe MH, Sarlak MR. Experimental investigation of switchable behavior of CuO-MWCNT (85%–15%)/10 W-40 hybrid nano-lubricants for applications in internal combustion engines. J Mol Liq. 2017;242:326–35.

Li Y, Yang J, Song J. Structure models and nano energy system design for proton exchange membrane fuel cells in electric energy vehicles. Renew Sustain Energy Rev. 2017;67:160–72.

Jafari SM, Saremnejad F, Dehnad D. Nano-fluid thermal processing of watermelon juice in a shell and tube heat exchanger and evaluating its qualitative properties. Innov Food Sci Emerg Technol. 2017;42:173–9.

Ho CJ, Chen WC. An experimental study on thermal performance of Al2O3/water nanofluid in a minichannel heat sink. Appl Therm Eng. 2013;50(1):516–22.

Asadi A, Asadi M, Rezaei M, Siahmargoi M, Asadi F. The effect of temperature and solid concentration on dynamic viscosity of MWCNT/MgO (20–80)–SAE50 hybrid nano-lubricant and proposing a new correlation: an experimental study. Int Commun Heat Mass Transf. 2016;78:48–53.

Esfe MH, Saedodin S. An experimental investigation and new correlation of viscosity of ZnO–EG nanofluid at various temperatures and different solid volume fractions. Exp Therm Fluid Sci. 2014;55:1–5.

Soltani O, Akbari M. Effects of temperature and particles concentration on the dynamic viscosity of MgO-MWCNT/ethylene glycol hybrid nanofluid: experimental study. Phys E Low Dimens Syst Nanostruct. 2016;84:564–70.

Esfe MH, Afrand M, Wongwises S, Naderi A, Asadi A, Rostami S, Akbari M. Applications of feedforward multilayer perceptron artificial neural networks and empirical correlation for prediction of thermal conductivity of Mg (OH) 2–EG using experimental data. Int Commun Heat Mass Transf. 2015;67:46–50.

Esfe MH, Saedodin S, Asadi A. An empirical investigation on the dynamic viscosity of Mg (OH) 2-ethylene glycol in different solid concentrations and proposing new correlation based on experimental data. Int J Nat Eng Sci (IJNES). 2014;5(3):29–34.

Esfe MH, Saedodin S, Mahmoodi M. Experimental studies on the convective heat transfer performance and thermophysical properties of MgO–water nanofluid under turbulent flow. Exp Therm Fluid Sci. 2014;52:68–78.

Moghaddam MA, Motahari K. Experimental investigation, sensitivity analysis and modeling of rheological behavior of MWCNT-CuO (30–70)/SAE40 hybrid nano-lubricant. Appl Therm Eng. 2017;123:1419–33.

Esfe MH, Afrand M, Rostamian SH, Toghraie D. Examination of rheological behavior of MWCNTs/ZnO-SAE40 hybrid nano-lubricants under various temperatures and solid volume fractions. Exp Therm Fluid Sci. 2017;80:384–90.

Esfe MH, Karimpour R, Arani AAA, Shahram J. Experimental investigation on non-Newtonian behavior of Al2O3-MWCNT/5W50 hybrid nano-lubricant affected by alterations of temperature, concentration and shear rate for engine applications. Int Commun Heat Mass Transf. 2017;82:97–102.

Esfe MH, Arani AAA, Esfandeh S. Improving engine oil lubrication in light-duty vehicles by using of dispersing MWCNT and ZnO nanoparticles in 5W50 as viscosity index improvers (VII). Appl Therm Eng. 2018;143:493–506.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hemmat Esfe, M., Kamyab, M.H. Viscosity analysis of enriched SAE50 by nanoparticles as lubricant of heavy-duty engines. J Therm Anal Calorim 140, 79–93 (2020). https://doi.org/10.1007/s10973-019-08698-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08698-4