Abstract

Optimization of microwave and infrared drying processes of nettle leaves was investigated using dependent variables of drying time and phenolic composition of nettle extracts. The response surface method was selected for design and optimization of the processes. Experiments were performed at different microwave power levels (180, 360, 540, 720 and 900 W) and infrared lamp distances to samples (4, 5.5, 7, 8.5 and 10 cm). The results showed that the drying time (t) decreased and the amount of total phenolic contents (TPC) of nettle extracts increased with an increase in microwave power and also increasing infrared lamp distance to the sample increased the drying time of the samples and decreased the amount of total phenolic contents of nettle extracts. Based on response surface and desirability functions, the optimum conditions for nettle leaves drying were: microwave power 900 W and infrared lamp distance 4 cm. At this point, t and TPC were obtained as 3.014 min and 38.81 mg/g for microwave dryer and 7.73 min and 36.45 mg/g for infrared dryer, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plants form a large part of nature and have long been considered by humans for food consumption and treatment of disease. Stinging nettle Urtica dioica L. belongs to the family of Urticaceae. In the past few years, nettle has been noted as a healing plant because of its considerable effects on human health. It is used as an expectorant, purgative, diuretic, hemostatic and vermifuge and for the treatment of eczema, rheumatism, hemorrhoids, hyperthyroidism, bronchitis and cancer [1]. Gallic acid, formic acid, carotene and vitamin A, potassium, iron, calcium, silicon and vitamin C are the chemical compounds of this plant [2, 3]. Nettle is one of the most important sources of antioxidants that reduces stroke and also prevents the development of cancers [4]. Antioxidant compounds, such as phenolic compounds, act through various mechanisms, such as scavenging of free radicals, compound-deactivating enzymatic activity and the chelation of metal ions [5]. Nettle is a vegetable that quickly fades after harvesting.

Drying is one of the storage methods, which has the capability of extending the consumption period of nettles. Different drying methods are used in the drying of fruits and vegetables. The drying operation could cause browning in vegetables due to enzymatic and nonenzymatic reactions, which may indicate a negative quality of product. To preserve the nutritional and sensorial quality of fresh nettle, choosing the best drying technique and optimization of the drying conditions are so important. In recent years, new drying methods such as microwave and infrared drying have been replaced with traditional drying methods. In order to prevent quality damage due to long drying time, microwave drying has been introduced. Microwave drying creates an effect for moisture transfer, leading to a water vapor pressure gradient between the bulk and the surface of the material, as in the conventional drying methods [6]. Ilknur Alibas dried nettle leaves by microwave, convective and vacuum drying and investigated the energy consumption and color parameters of the dried nettle leaves at these different drying conditions. The result showed that the optimum method in drying period, color and energy consumption was the microwave drying at 850 W [7]. Therdthai et al investigated the drying of mint leaves by microwave vacuum dryer and hot air dryer. They understood that microwave vacuum drying could reduce drying time of mint leaves by 85–90%, compared with the hot air drying. In addition, their result about color change during drying showed that lightness, greenness and yellowness of dried mint leaves by microwave vacuum dryer were higher than that of the hot air dryer [8]. Ayse Sarimeseli investigated the effect of microwave power output on effective moisture diffusivity, color parameters and rehydration characteristics of coriander leaves by using a microwave dryer. The result showed that there are not significant differences in the color parameters between the fresh and dried samples. They found out that microwave drying can be performed in very short times compared to other methods [9]. Drying with the infrared system has advantages such as high drying rate, high dry quality products and strong sterilization ability [10, 11]. The infrared radiation is absorbed directly by the material and does not need air to transmit heat. Infrared energy is transmitted to the surface of the product without heating the environment. Infrared drying can create more uniform heating and reduce the gradient of moisture during heating. In infrared drying, heat is generated inside the material and focuses on areas with higher humidity and, by increasing the vapor pressure, causes the moisture to propagate from those points to the outer layers. Boudhrioua et al compared the total phenol contents, the color and the moisture rate removal of fresh and infrared-dried olive leaves. The infrared drying causes a considerable moisture removal from the fresh leaves. Total phenol content of dried olive leaves enhanced if compared to fresh ones. Infrared drying preserves the greenness color of fresh leaves and increases their luminosity [12]. Torki Harchegani et al investigated the drying of saffron stigmas by infrared thin layer. The quality results showed that the total crocin content increased, when the temperature increased up to 90 but, in higher temperatures, the amount of crocin decreased slightly. Also, the amount of picrocrocin enhanced as the drying temperature increased from 60 to 100 °C [13]. Therefore, in this drying method, it seems that problems with the surface layer drying are reduced [14].

Response surface methodology (RSM) is a collection of statistical and mathematical techniques that has been successfully used for developing, improving and optimizing processes in which a response of interest is influenced by several variables and the objective is to optimize this response [15]. On the processes, it defines the effect of the independent variables, alone or in combination. Some examples of the RSM applications performed for optimization of food processes include optimization of microwave drying conditions of banana, processing parameter optimization for obtaining dry red currants and optimization of spray-drying process for developing guava powder [16,17,18].

The purpose of this study was to investigate the effect of microwave power and infrared lamp distance from the samples on drying time and total phenolic content of dried nettle extract and to find the best method of drying nettle leaves. In this study, two methods of drying nettle under a completely identical condition are investigated. Modeling and optimization of the two drying processes for the purpose of getting functional relationships between input and output parameters and getting values of input parameters that will either maximize or minimize the output parameters are necessary. This will ensure better understanding of the process which can be used as tools for further research and industrial production of dried nettle leaves. Using of microwave and infrared dryers in the same chamber to dry nettle leaves and optimize the process using the Design Expert software is the innovation of this research.

Materials and methods

Material

The leaves used in the drying experiments were 10 g in mass and were selected from healthy plants of fresh nettle provided from Babol (Iran). The moisture content of the samples was determined by the A & D MX-50 humidity meter on wet basis. The initial moisture content of all samples was approximately equal and its value was 83 ± 2% (w.b.).

Drying equipment

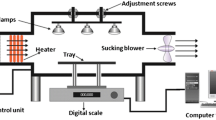

As it is shown in Fig. 1, the drying chamber was a 900 W, 2450 MHz microwave oven (Butan, M245, Iran) having an inside chamber with dimensions of 45(W)* 40(D)* 28(H) cm3. The microwave oven was operated by a control panel, which could control both microwave input power level and emission time (1 s–100 h). One dish, containing the sample, was placed on the center of a turntable fitted inside (bottom) the microwave cavity. Moisture loss was recorded at 1-min interval during drying by measuring and weighing the dish on the digital balance (AND EK-6000i, ± 0.01 g). To create the same conditions, a hole equipped with a movable metal cap was created at the top of the microwave with laser cutting. To use the infrared system, the metal cap was removed and an infrared lamp (250 W) was installed in the microwave. This system was able to adjust the infrared lamp distances to the samples by wire. The microwave or infrared was applied until the mass of the sample reduced to a level corresponding to moisture content of about 12 ± 2% (w.b.).

In order to calculate uncertainty analysis, Schultz and Cole method has been utilized [19]:

where \(U_{{{\text{V}}_{\text{i}} }}\) and UR are error of each parameter and total error, respectively. Table 1 shows the accuracy of measurement devices.

Determination of total phenolic contents

The total phenolic contents (TPC) of nettle leaves were determined by using the Folin–Ciocalteu method [20]. For the purpose of preparation of extracts, the 0.1 g of raw material was weighed and about 10 mL of an 20% (v/v) aqueous solution of ethanol was added. The samples were shook for 20 h at 70 rpm. The extract was filtered into a volumetric flask. Further, the total phenolic content in prepared extracts was determined with Folin–Ciocalteu’s reagent. For this purpose, a 10 mL of distilled water, 0.5 mL of herbal extract and 0.25 mL of Folin–Ciocalteu’s reagent were transferred into a 15-mL volumetric flask. After 5 min, a 2 mL of sodium carbonate solution (6% w/w) was added. Solution was mixed and left in the darkness for 1 h at a room temperature. The absorbance of every solution was measured in a spectrophotometer at 750 nm against a reagent blank (without extract). Gallic acid was used as a standard. The results were expressed as milligram gallic acid equivalent in 1 g of herbal extract. The TPC was obtained in mg/g of dry matter (d.m.).

Experimental

Response surface method (RSM) was applied to study the effects of microwave powers (P) in microwave drying and infrared lamp distances (d) from samples in infrared drying on the dependent variables drying time (t) and total phenolic contents (TPC) of extracts. The experiments were established based on the one-factor design due to having only one independent variable in each dryer. The P levels are 180–900 w, and the d levels are 4–10 cm. The Design Expert software (Version 7) was used for experimental design matrix, data analysis and optimization procedure. First step in RSM is to find a suitable approximation for the true functional relationship between response and the set of independent variables. Designed experiments and their results are presented in Tables 2 and 3 for microwave and infrared dryers, respectively. According to R2, the behavior of the response surface was studied for the response function (y) using the polynomial (Eq. 2) and cubic (Eq. 3) regression equation. The generalized response surface models are given as follows:

where y is response calculated by the model; \(\beta_{0}\) is a constant; βi, βii, βiii and (βijβijk) are linear, squared, cubic and interaction coefficient, respectively. x1 and x2 are independent variables.

To calculate the sum of square error and the lack of fitness for the developed regression equation between the dependent and independent variables, replications are performed.

Results and discussion

The effect of drying methods on drying time

Results of analysis of variance (ANOVA) related to the drying time of the microwave and infrared dryers are presented in Tables 4 and 5, respectively. The coefficient of determination, R2, is the proportion of variation in the response attributed to the model rather than to random error. When R2 is close to unity, the model is suitable for fitting the actual data. A lower value of R2 indicates that the model is inappropriate for explaining the relation between variables. According to R2, a quadratic model was selected for this response in microwave dryer (R2 = 0.9998) and cubic model in infrared dryer (R2 = 0.9996). The F value indicates the effect of the variable on the response and the more it is, the greater the effect of that variable on the response. For any of the terms in the model, a large regression coefficient and a small p value would indicate a more significant effect on the respective response variables. The p value of less than 0.05 represents that the variables are significant.

Equations 4 and 5 are obtained to predict the drying time of samples in microwave and infrared dryers, respectively.

Figure 2a and b represents the predicted values of the drying time by the model at the experimental design points in terms of the actual drying time, in microwave and infrared dryers, respectively.

As seen in Fig. 2, the model has a good ability to predict the drying time of samples, and it is clear that the experimental results of drying time and the predicted values obtained using Eqs. (4) and (5) are not significantly different. Figure 3a shows the effect of microwave power on the drying time of the samples. The increase in microwave power led to the decrease in drying time. The time required to dry nettle samples from the initial moisture content of 83 ± 2% (w.b.) to the final moisture content of 12 ± 2% (w.b.) was 19 min at 180 W, which reduced to 3 min at 900 W. Microwave power had an important effect on drying time. The results indicated that mass transfer within the sample was more rapid during higher microwave power heating because more heat was generated within the sample creating a large vapor pressure difference between the center and the surface of the product due to characteristic microwave volumetric heating [21]. The effect of infrared lamp distance from sample (d) on drying time is shown in Fig. 4b. With the increase in d, the drying time of the samples also increases. Using infrared heating, the radiation penetrated the processed material and converted into heat, energy is transferred to the product without heating the air surrounding the material. Therefore, the moisture removal efficiency of infrared drying is higher than that of experienced conventional drying methods [22]. In our experiments, the drying time to achieve 12 ± 2% final moisture content of nettle can be reduced to approximately 75% when infrared intensity was applied in d = 4 cm instead of d = 10 cm. As expected at higher microwave power and lower infrared distance, the higher heat absorption resulted in higher product temperatures, higher mass transfer and faster drying rates with less drying time [23,24,25,26]. By comparing microwave and infrared drying methods, it can be concluded that the effects of power intensity in microwave drying process were stronger than that of experienced in infrared drying. By increasing the P, the rate of dehydration was higher, and the time demand for drying has been reduced in a larger extent than observed in under infrared drying.

The effect of drying methods on the amount of total phenolic contents (TPC)

Phenolic compounds, which are part of the plant’s antioxidant activities, were affected by drying methods. The results of the ANOVA related to TPC of the dried samples extracted under microwave and infrared drying are shown in Tables 6 and 7, respectively. The cubic model with high R2 (> 0.99) was selected for TPC in microwave and infrared dryers. Nonsignificant lack of fit is good as this strengthens the fitness of the models.

Regression models relating TPC and independent variables are presented in Eqs. 6 and 7.

Predicted versus actual values of TPC are shown in Fig. 4 for microwave and infrared dryers. As seen in Fig. 4, the model has a good ability to predict the values of TPC, and it is clear that the experimental results of TPC and the predicted values obtained using Eqs. (6) and (7) are not significantly different.

Response surface plots of the variability of TPC with the change in microwave power levels and infrared lamp distances from sample are shown in Fig. 5a and b.

As it is shown in Fig. 5a, by increasing the power of the microwave from 180 to 900 w, the amount of TPC extracts increases from about 29–38 mg/g d.m. By increasing the drying time in the microwave power spectrum, the TPC of the samples decreased dramatically. This decrease is probably due to increased activity of enzymes proportional to the drying time, and the degradation of polyphenols. The results of this study are consistent with the results of other researchers who have worked on the effect of microwave power on antioxidant activity. They considered the increase in the TPC by increasing microwave power due to the shortening of the drying time, as well as the increase in the propagation of polyphenolic components from cell walls due to increased microwave heating [27,28,29]. Figure 5b shows that with the increase in the infrared lamp distance to the sample, the amount of TPC decreases. This decrease is probably due to increased activity of enzymes proportional to the drying time, and the degradation of polyphenols [30].

Process optimization

Optimum conditions for microwave and infrared drying of nettle were determined to obtain minimum t and maximum TPC. By applying desirability function method, the solutions were proposed for the optimum covering the criteria. It was 900 W for microwave power in microwave drying and 4 cm for infrared lamp distance in infrared drying. At this point, t and TPC were obtained as 3.0145 min and 38.8769 mg/g for microwave and 7.7 min and 36.44 mg/g for infrared, respectively. The software-generated values were close to the experimental values, hence confirming the validity of the optimized results and consistency of the regression models generated by the RSM software. Desirability of the obtained optimum conditions was 1.000 and 0.994 for microwave and infrared, respectively. The optimization results are shown in Fig. 6a and b.

Conclusions

This study characterized the influence of drying conditions on the drying time and amount of total phenolic contents (TPC) of nettle using microwave drying and infrared radiation. In microwave drying, as the microwave drying power increased the drying time decreased and TPC increased. The same results were obtained in infrared dryer by reducing the distance between infrared lamp and samples. The response surface method (RSM) was applied for optimization of the process. Regression models were developed to effectively predict quality parameters at any given microwave power and infrared distance in microwave and infrared dryers, respectively. Optimal condition in microwave dryer at desirability parameter of 1.000 was microwave power of 900 W, while generated model predicted obtaining of dried nettle with following properties: drying time 3.0145 min and TPC 38.8769 mg/g. And also for infrared dryer, the optimal distance was obtained 4 cm at desirability parameter of 0.994. The predicted drying time and TPC in this condition were 7.7 min and 36.44 mg/g, respectively. Response surface methodology was effective in optimizing process parameters for microwave and infrared drying of nettle. By comparing these two dryers, it was concluded that the lowest drying time (3.0145 min) and the highest amount of TPC (38.8769 mg/g) were related to microwave treatment with the power of 900 W.

References

Kavalalı G, Tuncel H, Göksel S, Hatemi H. Hypoglycemic activity of Urtica pilulifera in streptozotocin-diabetic rats. J Ethnopharmacol. 2003;84(2):241–5.

Önal S, Timur S, Okutucu B, Zihnioğlu F. Inhibition of α-glucosidase by aqueous extracts of some potent antidiabetic medicinal herbs. Prep Biochem Biotechnol. 2005;35(1):29–36.

Hojnik M, Škerget M, Knez Ž. Isolation of chlorophylls from stinging nettle (Urtica dioica L.). Sep Purif Technol. 2007;57(1):37–46.

Noguchi N, Niki E. Phenolic antioxidants: a rationale for design and evaluation of novel antioxidant drug for atherosclerosis. Free Radic Biol Med. 2000;28(10):1538–46.

Bzducha A, Wołosiak R. Synergistic effect of antioxidant activity of casein and its enzymatic hydrolysate in combination with ascorbic acid and β-carotene in model oxidation systems. Acta Sci Pol Technol Aliment. 2006;5(1):113–33.

Maskan M. Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J Food Eng. 2001;48(2):177–82.

Alibas I. Energy consumption and colour characteristics of nettle leaves during microwave, vacuum and convective drying. Biosys Eng. 2007;96(4):495–502.

Therdthai N, Zhou W. Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen). J Food Eng. 2009;91(3):482–9.

Sarimeseli A. Microwave drying characteristics of coriander (Coriandrum sativum L.) leaves. Energy Convers Manag. 2011;52(2):1449–53.

Krishnamurthy K, Khurana HK, Soojin J, Irudayaraj J, Demirci A. Infrared heating in food processing: an overview. Compr. Rev. Food Sci. Food Saf. 2008;7(1):2–13.

Hamanaka D, Dokan S, Yasunaga E, Kuroki S, Uchino T, Akimoto K. The sterilization effects of infrared ray on the agricultural products spoilage microorganisms. 2000:1–9.

Boudhrioua N, Bahloul N, Slimen IB, Kechaou N. Comparison on the total phenol contents and the color of fresh and infrared dried olive leaves. Ind Crops Prod. 2009;29(2–3):412–9.

Torki-Harchegani M, Ghanbarian D, Maghsoodi V, Moheb A. Infrared thin layer drying of saffron (Crocus sativus L.) stigmas: mass transfer parameters and quality assessment. Chin J Chem Eng. 2017;25(4):426–32.

Afzal T, Abe T, Hikida Y. Energy and quality aspects during combined FIR-convection drying of barley. J Food Eng. 1999;42(4):177–82.

Hinkelmann K. Design and analysis of experiments, volume 3: special designs and applications. New York: Wiley; 2011.

Omolola AO, Jideani AIO, Kapila PF, Jideani VA. Optimization of microwave drying conditions of two banana varieties using response surface methodology. Food Sci Technol. 2015;35(3):438–44.

Šumić Z, Vakula A, Tepić A, Čakarević J, Vitas J, Pavlić B. Modeling and optimization of red currants vacuum drying process by response surface methodology (RSM). Food Chem. 2016;203:465–75.

Patil V, Chauhan AK, Singh RP. Optimization of the spray-drying process for developing guava powder using response surface methodology. Powder Technol. 2014;253:230–6.

Schultz R, Cole R, editors. Uncertainty analysis in boiling nucleation. AIChE symposium series; 1979.

Singleton V, Rossi JA. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic. 1965;16(3):144–58.

Zarein M, Samadi SH, Ghobadian B. Investigation of microwave dryer effect on energy efficiency during drying of apple slices. J Saudi Soc Agric Sci. 2015;14(1):41–7.

Çağlar A, Toğrul İT, Toğrul H. Moisture and thermal diffusivity of seedless grape under infrared drying. Food Bioprod Process. 2009;87(4):292–300.

Alibas I. Drying of thin layer mango slices with microwave technique. Anadolu Tarim Bilimleri Dergisi. 2015;30(2):99.

Tirawanichakul Y, Kaseng S, Tirawanichakul S. Infrared and hot air drying of mullet fish: drying kinetics, qualities and energy consumption. Thai J Agric Sci. 2011;44(5):384–90.

Ponkham K, Meeso N, Soponronnarit S, Siriamornpun S. Modeling of combined far-infrared radiation and air drying of a ring shaped-pineapple with/without shrinkage. Food Bioprod Process. 2012;90(2):155–64.

Darvishi H, Azadbakht M, Rezaeiasl A, Farhang A. Drying characteristics of sardine fish dried with microwave heating. J Saudi Soc Agric Sci. 2013;12(2):121–7.

Wojdyło A, Figiel A, Lech K, Nowicka P, Oszmiański J. Effect of convective and vacuum–microwave drying on the bioactive compounds, color, and antioxidant capacity of sour cherries. Food Bioprocess Technol. 2014;7(3):829–41.

Kubra IR, Jagan Mohan Rao L. Microwave drying of ginger (Zingiber officinaleRoscoe) and its effects on polyphenolic content and antioxidant activity. Int J Food Sci Technol. 2012;47(11):2311–7.

Chan E, Lim Y, Wong S, Lim K, Tan S, Lianto F, et al. Effects of different drying methods on the antioxidant properties of leaves and tea of ginger species. Food Chem. 2009;113(1):166–72.

Doymaz İ, Karasu S, Baslar M. Effects of infrared heating on drying kinetics, antioxidant activity, phenolic content, and color of jujube fruit. J Food Meas Charact. 2016;10(2):283–91.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Movagharnejad, K., Vahdatkhoram, F. & Nanvakenari, S. Optimization of microwave and infrared drying process of nettle leaves using design of experiments. J Therm Anal Calorim 135, 1677–1685 (2019). https://doi.org/10.1007/s10973-018-7511-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7511-5