Abstract

The nature of the complexing agents used in the bioscouring process of cotton fabrics aiming to eliminate the non-cellulosic compounds (pectin, waxes, etc.) and to improve the hydrophilic and wetting properties influences the thermal behaviour and the FT-IR spectra of the textile materials. In this paper, we study the influence of the experimental conditions and complexing agent nature (sodium citrate or disodium EDTA salt) on the pectin elimination in bioscouring treatment of cotton fabric by FT-IR and TG/DTG/DTA analysis. The changes from FT-IR spectra of the specific bands (absorbance intensity at 2916, 2852, 1732 and 1640/1642 cm−1) were evaluated. The thermal behaviour of the investigated samples’ fabric by using TG/DTG/DTA analysis was studied at 30–600 °C temperature range, in air atmosphere. All samples showed three mass-loss steps due to the elimination of humidity, decomposition of the non-cellulosic and cellulosic components (main degradation stage of the samples) and thermo-oxidative decomposition of the formed degradation products. The Tonset values corresponding to the main decomposition step, the mass-loss values (%Δm) and the % residual mass (at 600 °C) were influenced by the complexing agent nature as well as the concentration and the action time of the commercial enzyme product. In addition, the calcium content of some samples treated with and without ultrasound was determined using atomic absorption spectroscopy method (AAS) in order to correlate the results with TG/DTG/DTA analysis. The obtained results have shown that the synergistic action of experimental conditions (enzyme concentration, pH, enzyme product action time, ultrasound) and the presence of sodium citrate as a biodegradable complexing agent led to the elimination of a higher amount of pectin from the cotton samples than that eliminated when using EDTA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cotton is the most important raw material for the textile industry, comprising over 38% of the fibres consumed [1]. It mainly consists of cellulose (86–96%) [2], but also contains a number of other non-cellulosic components, considered impurities, such as pectin (0.7–1.2%), waxes (0.4–1.2%), proteins (1.0–1.9%), minerals/ashes (0.7–1.6%), total sugars (0.1–1%), organic acids (0.5–1.0%) and other compounds (traces) [3, 4]. These components are present in the cuticle and in the primary wall of the cotton fibre which can reach up to ~ 24% [5, 6]. The non-cellulosic content is responsible for the non-wetting behaviour of cellulosic fibres by water, causing a number of technical problems during the dyeing and finishing processing [7,8,9,10] and by the relatively low thermal stability of the row cotton; therefore, its elimination becomes necessary.

Pectin is a polysaccharides complex that contains (1–4) poly-d-galacturonic acid molecules randomly distributed and is present in cotton as methyl ester or calcium salts form [11]. Because of the formation of Ca2+ bridges between pectin substances (non-esterified or little methyl-esterified galacturonan blocks with negative charge) by electrostatic interactions (“egg-box” model), pectin molecules crosslink with each other and form a network structure that plays a bonding role between cuticle and primary wall [12,13,14].

The bioscouring is the process of removing existing non-cellulosic compounds, especially pectin with a complex enzymes system consisting mainly of pectinases and pectinesterases which catalyse the methyl ester hydrolysis, respectively, exo- and endo-polygalacturonases which break the 1–4 carbohydrate bonds [15,16,17,18,19]. Besides the specific reagent for pectin removal, the bioscouring solution contains wetting substances and complexing agents, like EDTA—a non-biodegradable compound, which helps pectin elimination by destroying calcium bridges through the formation of coordination compounds with calcium ions [20]. The role and influence of EDTA as a complexing agent in biopreparation of cellulosic/lignocellulosic materials were also studied by Csiszar et al. [21,22,23]. The importance of EDTA utilization in rinsing step after bioscouring of cotton fabrics was reported by Lenting et al. [24].

In the present, the studies are focused on identifying new biodegradable complexing agents and on analysis of their influence on hydrophilic properties, wetting and thermal behaviour of bioscoured cellulosic fibres.

Our previous works have showed that the use of sodium citrate as biodegradable complexing agent in the cotton fabrics bioscouring may be a viable alternative to replace EDTA leading to an improvement in hydrophilic and wetting properties of the textiles [8, 15, 19, 25].

It is known that only in ionized form the organic acids and their salts can complex bivalent metal ions. The EDTA bonds calcium ions in 1:1 ratio [26] with the formation of a chelate. The citric acid and its sodium salts have different degrees of ionization depending on the pH value of reaction medium. Under acid and neutral conditions, only two of the carboxyl groups are ionized, while in alkaline conditions, all three of the carboxyl groups undergo ionization, providing a citric acid residue ion with three negative charges. In these conditions, the mechanism of complexation is different. In the first condition, the Ca2+ is bonded by one molecule of partial ionized citric acid or its sodium salt (1:1 ratio). In the second one, the Ca2+ is bonded by two molecules of complexing agent (1:2 ratio) [27].

In the continuation of the previous work, in this paper we present the results obtained from FT-IR and TG/DTG/DTA analysis in order to study the influence of the experimental conditions and complexing agent nature (disodium EDTA salt or sodium citrate) on the changes in the specific pectin bands (2916, 2852, 1732 and 1640/1642 cm−1) and on thermal behaviour of cotton fabric subjected to the bioscouring. The process was done in ultrasound in the presence of three different concentrations of commercial enzyme product (Beisol PRO) (1, 2 and 3% o.w.f) and at three different enzymes action times (15, 35 and 55 min), respectively. From thermal analysis recorded curves, the Tonset values (corresponding to the main decomposition step), the mass-loss values (%Δm) and the % residual mass (at 600 °C) were evaluated. These parameters provide useful information on the thermal stability of the cotton fabric samples and on the pectin content influence on thermal degradation of cellulosic polymer. In addition, the calcium content of some samples was determined using AAS method (atomic absorption spectroscopy) in order to correlate the results with TG/DTG/DTA analysis.

The TG/DTG/DTA thermal analysis is a most widely used technique to monitor the influence of the composition and structure on the thermal degradation of lignocellulosic or cellulosic fibres under oxidative or inert atmosphere [28,29,30,31,32].

The FTIR-attenuated total reflectance (ATR) spectroscopy has proven to be useful in the evaluation of the bioscouring process of the cotton fabric because it can highlight changes in the main non-cellulosic compounds by characterizing the carboxyl acids and esters bands that are present in pectin which do not exist in the cellulose structure [4, 10, 33,34,35,36].

Experimental

Materials

The following materials have been investigated:

-

Raw cotton fabric denoted as RWC—untreated woven cotton fabric without sizing agent, underwent preliminary washing and then conditioned.

-

Bioscoured cotton fabric in the presence of sodium citrate or EDTA complexing agents is denoted as BSCx-y orBSEx-y, respectively (where x is the concentration, % o.w.f, of enzyme product in the bioscouring bath and y-minutes of the enzyme product action time). BSC1-35, BSC2-15, BSC2-35, BSC2-55, BSC3-35 and BSE1-35, BSE2-15, BSE2-35, BSE2-55 and BSE3-35—cotton fabric samples, underwent preliminary washing, conditioned and then subjected to bioscouring process. After the biotreatments, the samples were washed with hot water at 85 °C (to eliminate all the reagents and products), cold water and then dried and conditioned.

Bioscouring process conditions distilled water reaction media; 1:20 liquid-to-fabric ratio; commercial enzyme Beisol PRO from CHT Bezema Company (a mixture of polygalacturonases and pectinesterases enzymes); pH 8.5 (assured by buffer CAS:7732-18-5); 55 °C treatment temperatures; 2 g L−1 (~ 10 mmol L−1) sodium citrate (monosodium citrate, CAS: 18996-35-5) or 2 g L−1 (~ 5 mmol L−1) EDTA (disodium ethylenedinitrilotetraacetic acid salt, CAS: 6381-92-6) as complexing agents from Sigma-Aldrich (The sodium citrate concentration was chosen to double that of EDTA because it was taken into account that the citrate bound Ca2+ in a 2: 1 ratio while EDTA bound this ions in a 1:1 ratio at the alkaline pH.); 0.5% surfactant Denimcol Wash-RGN detergent (from CHT Bezema Company). To improve the diffusion, mass and heat transfer, all treatments were carried out in an Elmasonic X-tra basic 2500 ultrasound bath from Elma Company, Germany at 45 kHz.

-

Control sample cotton fabric denoted as CSC—woven cotton fabric sample underwent preliminary washing, conditioned and then subjected to bioscouring process to 2% o.w.f commercial enzyme at 35 min, but without complexing agents. The sample was finally washed with hot water at 85 °C, cold water and then dried and conditioned.

Preliminary washing conditions hot water at 100 °C, 10 min aiming to remove dust (mechanical impurities) and soluble compounds (sugars, amino acids and low molecular weight peptides, proteins, etc.)

The dimension of all treated samples was 35 cm (weft direction)/65 cm (warp direction).

The FT-IR and TG/DTG/DTA experiments were performed on samples taken from different areas of conditioned samples (up to 105 °C on Sartorius MA 100 system), chopped and mechanically homogenized.

Methods

FT-IR analysis

The FT-IR spectra of all investigated samples were acquired using the Bruker Vertex 70 spectrophotometer equipped with the ATR cell, on the 600–3000/1500–1800 cm−1 wavelength range with a resolution of 4 cm−1 and 32 scans. The spectra were processed using the OPUS software. The recorded FT-IR spectra were normalized (611 cm−1 band/minim–maxim) and baseline corrected. The relative absorbance values (a.u.—absorbance units) for 1732 and 1642 cm−1 peaks were evaluated.

Thermal analysis

The TG/DTG/DTA experiments for the investigated cotton fabric samples were performed on a STA 409C Luxx system, produced by Netzsch, Germany. The experiments were conducted on 30–600 °C temperature range, at 10 K min−1 heating rates, using platinum crucibles in dynamic air atmosphere (50 Ml min−1, 20% O2). The samples’ mass was ~ 10 mg. The curves were processed using the Netzsch Proteus software.

Atomic absorption spectroscopy analysis

A Unicam 929 AA-Solar System ETAAS equipped with a Unicam GF-90 graphite furnace and FS-90 auto-sampler was used to evaluate the calcium content of the RWC, BSC2-35 and BSE2-35 samples treated with or without ultrasound. The samples’ preparation and operational conditions were presented in a previous work [8].

Results and discussion

FT-IR analysis

Figure 1a shows the FT-IR spectra of the RWC, CSC and BSC2-15, BSC2-55, BSE2-15 and BSE2-55 samples on the 600–3000 cm−1 wavelength range, while Fig. 1b shows the FT-IR spectra of the BSC1-35, BSC2-35, BSC3-35 and BSE1-35, BSE2-35 and BSE3-35 bioscoured samples on 1500–1800 cm−1 range.

Cellulosic fibres are usually characterized by several absorption bands. In the spectra from Fig. 1a, b, the band at 3000–3600 cm−1 can be assigned to the free OH stretching vibration and to the intra- and intermolecular hydrogen bond related to chemical structure of cellulose [4, 9, 35, 37]. The two narrower bands located at 2916 and 2852 cm−1 are attributed to the stretching vibration of CH2 and CH groups from pectin and waxes [4, 9, 37, 38]. The bands at around 1732 and 1640/1642 cm−1 are characteristic for pectin and can be assigned to the COOH and COOCH3 groups of polygalacturonic acid and to symmetrical/asymmetrical oscillations of ionized carboxyl groups COO−, respectively [4, 9, 18, 34, 37]. It should be noted that the characterization of the carboxyl ion band around 1550–1700 cm−1 by FT-IR is quite difficult because the OH bending of absorbed water (1642 cm−1) was also observed in these regions [4, 39].

In the 600–1400 cm−1 fingerprint area, specific and common bands appear and are assigned to cellulose (Fig. 1a). The 1426 cm−1 band was attributed to CH2 bending of cellulose [34, 36, 37]. Bands due to the deformation of OH group of cellulose were located at 1334 and 1368 cm−1, while the band at 1315 cm−1 is assigned to CH2 rocking vibration [34, 37]. The band at 1279 cm−1 is assigned to C=O and G ring stretching, while the bands at 1159 and 1202 cm−1 are for C–O–C symmetric and asymmetric stretching [37, 38]. The bands from 1029 to 1106 cm−1 indicated the C–O, C–C, C–H ring and side-group vibration in cellulose [37]. The observed band at 897 cm−1 indicates the presence of the β-glycosidic linkages between monosaccharides [35, 37]. The band at 611 cm−1 can be assigned to the OH out-of-plane bending in cellulose, it does not vary with the enzyme treatment, and this can be used to normalize the recorded spectra and to calculate the relative absorbance of the peaks [40].

In order to analyse the influence of the bioscouring process, which aims the elimination of a large amount of pectin from cellulosic fabrics, various authors recommend the investigation of the changes occurring in the absorbance intensity of the bands located at 2900–2919, 2850–2860 and around 1630–1640 cm−1 but especially of those at 1730–1734 cm−1, which is specific for the carboxylic group of polygalacturonic acid and COOCH3 [4, 9, 10, 37, 39].

From Fig. 1a analysis, it can be seen that the intensity of the two narrower bands located at 2916 and 2852 cm−1 decreases from RWC to CSC sample and bioscoured samples due to the elimination of waxes and of a pectin fraction, in bioscouring process, by breaking of the 1–4 carbohydrate bonds from d-galacturonic acid under polygalacturonases action.

Table 1 presents the relative absorbance values, A1732, A1642, of the carboxylic and COOCH3 groups from pectin, evaluated from recorded spectra, for all investigated samples.

It is noted that the relative absorbance values of the band at 1732 cm−1 decrease as follows: RWC > CSC > BSEx-y > BSCx-y, and those of the 1640/1642 cm−1 band increase as follows: RWC < CSC < BSEx-y < BSCx-y. Similar behaviour was reported in the literature by Wang et al. [4] in the characterization of bioscoured cotton fabrics using FT-IR ATR spectroscopy.

The differences that occur between the relative absorbance values obtained for the CSC and BSEx-y/BSCx-y samples can be attributed to the complexing agent action in the bioscouring process, while the differences between CSC and RWC samples are due to the action of the enzyme which, in optimal conditions, eliminate a fraction of pectin from the material even in the absence of the complexing agent.

In all cases, the BSEx-y samples had higher absorbance intensity values for 1732 cm−1 band and lower for 1640/1642 cm−1 band than those recorded for BSCx-y samples. This behaviour leads to the idea that sodium citrate complexing agent, along with the concerted action of the enzymes, in optimal pH conditions had higher efficacy than EDTA in the bioscouring process of cotton fabric.

It is mentioned that a change in the pH value compared to the initial one was observed during the bioscouring process for the BSEx-y samples (The pH value of the bath after the bioscouring process was ~ 7.8.). This behaviour has been mentioned in the literature by Timar-Balaszy and Eastop [27] and is due to the fact that, in the case of disodium EDTA salt, the metal ions replace the H+ which are released into the bioscouring bath and thus the pH decreases. In the case of BSCx-y samples, the pH value did not change during the bioscouring because the citrates can act as buffers and maintain the initial pH until the limit of their buffer capacity is reached [27]. In these conditions, the optimal pH value (pH = 8–9) for the maximum activity of the commercial enzyme product used was assured. This could explain the higher efficiency in pectin elimination in the case of BSCx-y samples.

Prolonging the enzymes’ action time from 15 min (BSE2-15 and BSC2-15) to 55 min (BSE2-55 and BSC2-55), the variations in the absorbance intensity of the specific COOH and COOCH3 bands become more pronounced.

With the increase in the enzymes’ concentration in the bioscouring bath, Fig. 1b and Table 1, the absorbance intensity of the 1732 cm−1 band varied in the following order: BSC1-35 > BSC2-35 > BSC3-35, and of the 1642 cm−1 band: BSC1-35 < BSC2-35 < BSC3-35. The same order has also been noticed in the case of BSEx-y samples.

The presented FT-IR results are in good agreement with the previously obtained data related to the influence of the complexing agent nature on the hydrophilic properties of the cotton fabric [19].

It is noted that the investigated bioscoured samples had approximately the same water content, as can be seen from the thermal analysis results; consequently, the observed variations in the absorbance intensity of 1640/1642 cm−1 band are due to the pectin content of the samples and not to the OH bending of absorbed water.

Thermal analysis

In Figs. 2 and 3, the TG/DTG/DTA curves recorded for the RWC, BSC2-35 and BSE2-35 samples in dynamic air atmosphere are presented.

The analysis of the TG/DTG/DTA curves (Figs. 2, 3) shows that the non-isothermal degradation, in dynamic air atmosphere, of the investigated cotton fabric samples occurs through three successive decomposition processes accompanied by mass losses. In the first endothermic process (around 80–120 °C), denoted by STAGE I, the humidity from samples was completely eliminated. From 120 to 200 °C, the samples were quite stable. The next decomposition process, denoted by STAGE II, is exothermal and was recorded in the 200–400 °C temperature range being the main decomposition step of the samples. In this stage, the thermal degradation of non-cellulosic components structure takes place which overlapped and influenced the cellulose decomposition reactions. At a higher temperature (400–600 °C), the last exothermal process, denoted by STAGE III, was recorded and is due to the thermo-oxidative decomposition of the degraded un-volatile products formed in the STAGE II. In all cases, a % residual mass at 600 °C was noticed due to the formation of the carbonaceous residues from polymeric compounds degradation and to the ashes, naturally present in cotton fibres.

Some major differences could be noticed when comparing the TG/DTG/DTA curves from Figs. 2 and 3 as follows: the Tonset value of the STAGE II which is lower for RWC sample than for bioscoured samples (i.e. Tonset BSE2-35 = 343.0 °C); the temperature relating to minimum peak of DTG curves (lower value for RWC, TDTG RWC = 347.3 °C, than for bioscoured samples, TDTG BSC2-35 = 359.8 °C); temperatures relating to maximum exothermal peaks of DTA curves (lower values for RWC and higher for BSE2-35); the mass-loss value for STAGE II, %ΔmII (lower value for RWC and higher for BSC2-35); and the amount of % residual mass at 600 °C which diminishes on RWC > BSE2-35 > BSC2-35 order.

This behaviour is due to the high content of non-cellulosic components present in RWC which decompose at lower temperatures than cellulose. The by-products generated in the degradation reactions of non-cellulosic components can influence the decomposition of the cellulosic polymer leading to the formation of a large amount of residual mass (char) [28]. It is well known from the literature that cotton cellulose has a complex gradual degradation which involves: depolymerization reactions with the formation of oligomers and volatile products; dehydration reactions; and char formation [28,29,30,31,32]. At a higher temperature, a rapid decomposition occurs often accompanied by levoglucosan formation which breaks down to given low molecular mass volatile compounds like ketones, aldehydes, furans and pyrans. A re-polymerization of the volatiles compounds can lead to the carbonaceous residues formation especially in inert atmosphere decomposition [30, 32]. Small amounts of metallic ions, like calcium pectin ions from network structure which bonds cuticle and primary wall, could influence the char quantity produced in cellulose degradation [28].

The thermal parameters resulting from the TG/DTG curves of the investigated cotton fabric samples are shown in Table 2.

It can be seen that the investigated cotton fabric samples have approximately the same humidity and the mass-loss values for the STAGE I were around ΔmI = 3.08–3.94%.

Removal of non-cellulosic components (waxes, pectin, etc.) from the cuticle of cotton fibres leads to increases in the bioscoured samples thermal stability (Tonset) and to decreases in the % residual mass values.

The % residual mass at 600 °C obtained for the CSC sample was close to RWC sample but the Tonset value was ~ 20 °C higher, which means that the action of the enzyme in the absence of the complexing agent leads to the elimination of a pectin fraction and waxes that influence the values of the main thermal parameters.

For equal concentrations of commercial enzyme product in the bioscouring bath and at the same action time of the enzyme on cotton fabric substrate, the obtained Tonset values were higher for the BSEx-y samples (Tonset BSEx-y = 342.2–345.7 °C) than those obtained for BSCx-y (Tonset BSCx-y = 336.2–338.8 °C). These values suggest that BSCx-y samples have a lower thermal stability than BSEx-y samples but are more stable than the RWC sample (Tonset RWC = 299.7 °C). The mass-loss values (%ΔmII) showed an increase from the RWC sample (ΔmII RWC = 59.90%) to BSEx-y samples by ~ 4% (ΔmII BSEx-y = 60.44–64.34%) and a higher increase, by ~ 11%, to the BSCx-y samples (ΔmII BSCx-y = 65.88–71.22%). For all analysed samples, the (%ΔmIII) values were around ΔmIII = 23–25%. Important changes also occurred in % residual mass values that diminished from 11.5% for RWC to 8.01–10.62% for BSEx-y samples. This decrease has become more accented for BSCx-y samples that showed values between 1.06 and 5.66%.

In the bioscouring process, the complexing agents destroy calcium bridges through the formation of coordination compounds with Ca2+, thus favouring the elimination of pectin by enzymes. Consequently, under the concerted action of complexing agents and the other treatment conditions (enzyme concentration and action time, alkaline pH, ultrasound) the pectin molecules crosslinking and the network structure between pectin and cellulose are destroyed and the cellulose, especially from primary wall, is thermally less stable with the formation of a larger amount of volatile compounds in the STAGE II. Also, the quantity of the carbonaceous residues (char) from residual mass is considerably diminished. In addition, the elimination in the bioscouring process of other non-cellulosic constituents like waxes, localized in the cuticle, determines the destruction of this external layer and cellulose is more exposed to the thermal degradation. This behaviour can explain the data obtained by thermal analysis of the cotton fabric samples shown in Figs. 2, 3 and Table 2.

The data from Table 2 show that, in the case of the same bioscouring agent, the increase in the enzyme product concentration from 1 to 2% o.w.f in the treatment bath and the increase in the enzyme action time from 15 to 35 min led to a larger amount of pectin removed, respectively. In contrast, increasing the enzyme concentration from 2 to 3% o.w.f and the bioscouring time from 35 to 55 min did not significantly affect the results.

A similar behaviour was reported by Lenting et al. [24] which studied the influence of the enzyme concentration and incubation time on the pectin elimination in bioscouring treatment of 100% cotton-woven fabric.

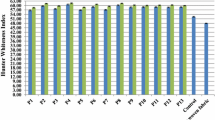

Atomic absorption spectroscopy analysis

The AAS results obtained for RWC and the bioscoured samples BSE2-35 and BEC2-35 treated with or without ultrasound are presented in Fig. 4. A decrease in calcium content from the RWC sample to those bioscoured in the presence of the complexing agents can be noticed in both cases with a more pronounced decrease for samples treated in the presence of ultrasound. It can also be seen that where ultrasound was used, the sample treated in the presence of sodium citrate had a lower amount of calcium than that treated with EDTA.

The lower amount of calcium determined in the samples treated with sodium citrate could be attributed to the diffusion process of complexing agent molecules favoured by the presence of ultrasound. Thus, even if EDTA has a higher binding constant (logKf = 10.7), the sodium citrate molecules having a lower molecular volume can easily diffuse into the “egg-box” structure, thus leading to more advanced complexation of the calcium.

In agreement with FT-IR and AAS results, the TG/DTG/DTA data showed that the sodium citrate (a biodegradable compound) may be a viable complexing agent, being in optimal enzymatic conditions more efficient than EDTA (a non-biodegradable compound) for cotton fabrics’ bioscouring process.

Conclusions

The influence of the experimental conditions and complexing agent nature (sodium citrate or disodium EDTA salt) on the pectin elimination from bioscouring cotton fabric was investigated by FT-IR, AAS and TG/DTG/DTA thermal analysis.

The FT-IR spectra showed changes in the absorbance intensity of the specific pectin bands (2916, 2852, 1732 and 1640/1642 cm−1) correlated to the amount of pectin removed from the cotton fabric. The most important changes in the relative absorbance values were noticed in the case of sodium citrate as complexing agent.

TG/DTG/DTA thermal analysis data showed that the removal of non-cellulosic components (waxes, pectin, etc.) from the cotton fabric leads to increases in the bioscoured samples thermal stability (Tonset) and to diminishes of the % residual mass values. The smallest % residual mass values were obtained for the samples bioscoured in the presence of sodium citrate complexing agent.

The AAS results showed lower calcium content for the sample treated in the presence of sodium citrate and ultrasound than that treated with EDTA.

In agreement with FT-IR and AAS results, the TG/DTG/DTA data showed that the sodium citrate (a biodegradable compound) may be a viable complexing agent, being in optimal enzymatic conditions (enzyme concentration, pH, enzyme product action time, ultrasound) more efficient than EDTA (a non-biodegradable compound) for cotton fabrics bioscouring process.

References

Wakelyn PJ, Bertoniere NR, French AD, Thibodeaux DP, Triplett BA, Rousselle MA, Goynes WR, Edwards JV Jr, Hunter L, McAlister DD, Gamble GR. Cotton fibers. In: Menachem L, editor. Handbook of fiber chemistry. 3rd ed. New York: Taylor and Francis Group; 2007. p. 523.

Li Y, Hardin IR. Treating cotton with cellulases and pectinases: effects on cuticle and fiber properties. Text Res J. 1998;68:671–9.

Lin C, Hsieh YL. Direct scouring of greige cotton fabrics with proteases. Text Res J. 2001;71:425–34.

Wang Q, Fan X, Gao W, Chen J. Characterization of bioscoured cotton fabrics using FTIR ATR spectroscopy and microscopy techniques. Carbohydr Res. 2006;341:2170–5.

Gamble GR. Variation in surface chemical constituents of cotton (Gossypium hirsutum) fibre as a function of maturity. J Agric Food Chem. 2003;51:7995–8.

Clarke AJ. Biodegradation of cellulose: enzymology and biotechnology. Lancaster: Printing House, Technomic Publ; 1997.

Wang Q, Fan X, Hua Z, Gao W, Chen J. Influence of combined enzymatic treatment on one-bath scouring of cotton knitted fabrics. Biocatal Biotransform. 2007;25:8–15.

Dochia M, Stanescu MD, Constantin C. Calcium content indicator of scouring efficiency. Fibers Text East Europe. 2013;21(3 (99)):22–5.

Vigneswaran C, Ananthasubramanian M, Anubumani N. Effect of sonification on bioscouring of organic cotton through mixed enzymatic system—neutral network approach. Indian J Fibers Text Res. 2013;38:44–56.

Abdel-Halim ES, Fahmy HM, Fouda Moustafa MG. Bioscouring of linen fabric in comparison with conventional chemical treatment. Carbohydr Polym. 2008;74:707–11.

Ridley BL, O’Neill MA, Mohnen D. Pectins: structure, biosynthesis, and oligogalacturonide-related signalling. Phytochemistry. 2001;57(6):929–67.

Bertoniere NR, Zeronian SH. Chemical characterization of cellulose. In: Atalla RH, editor. The structures of cellulose. ACS Symposium Series, No. 340. Washington: American Chemical Society; 1987. p. 255.

Heldt HW, Piechulla B. Plant biochemistry. 4th ed. London: Academic Press; 2011.

Dey PM, Harborne JB. Plant biochemistry. San Diego: Academic Press; 1997.

Stanescu MD, Fogorasi M, Mihuta S, Dochia M, Lozinsky VI. Biotechnology for textile waste valorization. Rev. Chim. (Bucharest). 2009;60:59–62.

Calafell M, Garriga P. Effect of some process parameters in the enzymatic scouring of cotton using an acid pectinase. Enzym Microb Technol. 2004;34:326–31.

Araujo R, Casal M, Cavaco-Paolo A. Application of enzymes for textile fibers processing. Biocatal Biotransform. 2008;26(5):332–49.

Chung C, Lee M, Choe EK. Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr Polym. 2004;58(4):417–20.

Stanescu MD, Dochia M, Radu D, Sirghie C. Green solution for cotton scouring. Fibers Text East Europe. 2010;18((3 (80))):109–11.

Kalantzi S, Mamma D, Christakopoulos P, Kekos D. Effect of pectate lyase bioscouring on physical, chemical and low-stress mechanical properties of cotton fabrics. Bioresour Technol. 2008;99:8185–92.

Csiszár E, Losonczi A, Szakács G, Rusznák I, Bezúr L, Reicher J. Enzymes and chelating agent in cotton pretreatment. J Biotechnol. 2001;89(2–3):271–9.

Csiszár E, Losonczi A, Szakács G, Bezúr L, Kustos K. Influence of EDTA complexing agent on biopreparation of linen fabric. Biocatal Biotransform. 2004;22(5–6):369–74.

Losonczi A, Csiszár E, Szakács G, Bezúr L. Role of the EDTA chelating agent in bioscouring of cotton. Text Res J. 2005;75(5):411–7.

Lenting HBM, Zweir E, Nierstrasz VA. Identifying important parameters for a continuous bioscouring process. Text Res J. 2002;72(9):825–31.

Stanescu MD, Fogorasi M, Bucur MS, Pustianu M, Dochia M. Enzymes in cotton bio-scouring. UPB Sci Bull Series B. 2010;72(3):21–8.

Keowmaneechai E, McClements DJ. Influence of EDTA and citrate on physicochemical properties of whey protein-stabilized oil-in-water emulsions containing CaCl2. J Agric Food Chem. 2002;50(24):7145–53.

Timar-Balaszy A, Eastop D. Chemical principles of textiles conservation. 1st ed. London: Taylor and Francis Group; 2012. p. 221.

Cabrales L, Abidi N. On the thermal degradation of cellulose in cotton fibers. J Therm Anal Calorim. 2010;102:485–91.

Corradini E, Teixeira EM, Paladin PD, Agnelli JA, Silva ORRF, Mattoso LHC. Thermal stability and degradation kinetic study of white and colored cotton fibers by thermogravimetric. J Therm Anal Calorim. 2009;97(2):415–9.

d’Almeida ALFS, Barreto DW, Calado V, d’Almeida JRM. Thermal analysis of less common lignocellulose fibers. J Therm Anal Calorim. 2008;91(2):405–8.

Saafan AA, Habib AM. Influence of changes in fine structure on thermal properties of cotton fibers. J Therm Anal Calorim. 1987;32:1511–9.

Tian CM, Shi ZH, Zhang HY, Xu JZ, Shi JR, Guo HZ. Thermal degradation of cotton cellulose. J Therm Anal Calorim. 1999;55:93–8.

Zhang L, He J, Wanh SY. Structure and thermal properties of colored cottons and bombax cotton. J Thermal Anal Calorim. 2009;2:653–9.

Alix S, Philippe E, Bessadok A, Lebrun L, Morvan C, Marais S. Effect of chemical treatments on water sorption and mechanical properties of flax fibers. Bioresour Technol. 2009;100:4724–9.

Perincek S, Duran K. Optimization of enzymatic and ultrasonic bio-scouring of linen fabrics by aid of Box-Behnken experimental design. J Clean Prod. 2016;135:1179–88.

Bílková L. Application of infrared spectroscopy and thermal analysis to the examination of the degradation of cotton fibers. Polym Degrad Stab. 2012;97:35–9.

Kovačević Z, Bischof Vukušić S, Zimniewska M. Comparison of Spanish broom (Spartium junceum L.) and flax (Linum usitatissimum) fibre. Text Res J. 2012;82(17):1786–98.

Subramanian K, Senthil Kumar P, Jeyapal P, et al. Characterization of ligno-cellulosic seed fiber from Wrightia Tinctoria plant for textile applications—an exploratory investigation. Eur Polym J. 2005;41:853–61.

Čopiková J, Synytsya A, Černá M, Kaasová J, Novotá M. Application of FT-IR spectroscopy in detection of food hydrocolloids in confectionery jellies and food supplements. Czech J Food Sci. 2001;19(2):51–6.

Song KH, Obendorf SK. Chemical and biological retting of kenaf fibers. Text Res J. 2006;76:751–6.

Acknowledgements

This work was supported by a grant of the Romanian National Authority for Scientific Research and Innovation, CNCS—UEFISCDI, Project Number PN-II-RU-TE-2014-4-1370 and “Centru de Cercetare în Stiinte Tehnice si Naturale—CESTN” co-funded by European Union through European Regional Development Fund Structural Operational Program “Increasing of Economic Competitiveness” Priority axis 2. Operation 2.2.1. POSCCE Nr. 621/2014 POS-CCE.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dochia, M., Chambre, D., Gavrilaş, S. et al. Characterization of the complexing agents’ influence on bioscouring cotton fabrics by FT-IR and TG/DTG/DTA analysis. J Therm Anal Calorim 132, 1489–1498 (2018). https://doi.org/10.1007/s10973-018-7089-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7089-y