Abstract

This study investigates the viscosity of CuO/EG:W (20:80 v/v) nanofluid in the solid volume fraction from 0 to 1% and temperatures between 15 and 50 °C. Examining the correlation between the shear stress and shear rate obtained from experiment test at different temperatures and solid volume fractions revealed that the investigated nanofluid behaves much very carefully like the Newtonian fluid behavior. Therefore, observing the independency of the viscosity to the shear rate was not unexpected in the results. During analyzing, the authors found that the viscosity of investigated nanofluid has a very low sensitivity to temperature changes but it is significantly influenced by changes in the solid volume fraction and nanoparticle concentration. In this research, a new experimental correlation was suggested to predict the viscosity of the investigated nanofluid in the expressed range of temperature and solid volume fraction to model the test results. In the mentioned correlation, the viscosity is expressed as the relative variable to independent variables (temperature and solid volume fraction). R2 (R-squared) value for the expressed correlation was 0.9850, which shows the accuracy in the presented experimental correlation to predict the nanofluid viscosity in the concentration and the temperature range.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A mixture of water and ethylene glycol (EG) is one of the current and traditional fluids in the heat transfer topics, and it is widely used in energy systems due to its high capability in improving the heat transfer rate at different temperatures and working conditions. These mixtures are widely used as they are a combination between the good thermal capabilities of water and the protection against corrosion using ethylene glycol. Many researchers investigated the effects of adding nanoparticles to the base fluid of water, ethylene glycol, or a mixture of them on thermophysical properties [1,2,3,4,5,6,7,8,9,10]. The effect of different nanoparticles like CuO [11], SiO2 [12], MWCNTs (experimentally and numerically) [13,14,15,16,17,18], TiO2 [19] on thermophysical properties of oil based [20, 21] and water based [22,23,24,25,26,27,28,29] nanofluids have been studied and some optimizations have been done [30,31,32,33].

Li and Zou [34] have examined the experimental data of heat transfer and viscosity of SiC nanofluid with 1% solid volume fraction based on water/EG with 40:60 mass% in the temperature range of 10–50 °C. Results demonstrate that the viscosity of SiC nanofluid is decreased by increasing the temperature and increased by increasing the solid volume fraction. They identified two reasons for this phenomenon, (A) the viscosity of water and ethylene glycol mixture decreases with increasing the temperature, which can be considered as a natural feature. (B) When the temperature increases, the speed of individual molecules increases and the interaction between them is reduced, which helps to reduce viscosity. Esfe et al. [35] conducted a study on the viscosity, thermal conductivity, and heat transfer behavior of magnesium oxide nanofluid in water in a circular tube under turbulent flow with the particle solid volume fraction of 0.0625, 0.125, 0.25, 0.5, and 1% in the base fluid. They observed that many conventional models are not able to predict the thermal conductivity and viscosity of MgO nanofluid in water, particularly the viscosity. Thus, they proposed a new correlation based on their results of experiments. Suganthi et al. [36] evaluated the performance of heat transfer and nanofluid properties of zinc oxide–ethylene glycol (EG) and zinc oxide—a mixture of ethylene glycol and water as the coolant material. According to the results of Suganthi et al. [36], 33.4% increase in the thermal conductivity and 39.2% reduction in viscosity were reported for zinc oxide nanofluid with EG base fluid containing 4% nanoparticles by volume at 27 °C and 17.26% increase in the thermal conductivity and 17.34% reduction in viscosity were reported for zinc oxide fluid with a mixture of water and EG base fluid containing 2% nanoparticles by volume. Esfe et al. [37] studied the dynamic viscosity of Mg(OH)2–ethylene glycol (EG) nanofluid. They measured the mentioned nanofluid at different concentrations (0.1–2 solid volume fraction range) and at the temperature of 23–55 °C with the particle size diameter of 10 nm. They proposed a new correlation for the dynamic viscosity. Results indicated that the dynamic viscosity has been increased by increasing the solid volume fraction and this increase is much higher at lower temperatures than the higher temperatures. They also showed that increasing the solid volume fraction of nanoparticles at the temperature of 55 °C does not have much impact on the dynamic viscosity of the nanofluid. This subject can be considered as a major achievement in engineering and industrial applications. Yu et al. [38] surveyed the heat transfer and viscosity of water (55% solid volume fraction)—ethylene glycol (45%)-based Al2O3 nanofluid. They found that the viscosity of nanofluids has increased abnormally and it is beyond the expectations for the viscosity in the classic models. They have stated that increasing the concentration of nanoparticles directly affects the inner shear stress. They argued that reducing of viscosity with temperature is because of debilitating effect of temperature on the intermolecular forces and inner forces of particles. Increase in the viscosity of nanofluids in their tests is greater than the theoretical predictions of Einstein dilute suspension effective viscosity model because Einstein’s model only considers the solid volume fraction and ignores the particle–particle and particle–fluid interaction. Akbarzadeh et al. [39] evaluated the viscosity of zinc oxide in the ethylene glycol and propylene glycol in the form of a mixture of ethylene glycol and water (40:60 by mass) and a mixture of propylene glycol and water (40:60 by mass) at the temperature range of 25–60 °C. They revealed that the nanofluid viscosity decreases and the performance of nanofluid heat transfer increases with increasing temperature. Also they showed that zinc oxide has a higher thermal conductivity in the base fluid of ethylene glycol and water. Esfe et al. [40] conducted an experimental research on the effect of temperature and volumetric concentration of particles on the dynamic viscosity of zinc oxide nanofluid at a concentration of 0.25–5% in the base fluid of ethylene glycol at the room temperature of 50 °C. They found that the dynamic viscosity of fluid generally increases significantly by increasing the solid volume fraction of the particles, but no significant change was observed in the viscosity (reduction) by increasing the temperature. Azmi et al. [41] investigated the forced heat transfer of Al2O3 nanofluid in the base fluid of mixed water (W) and ethylene glycol (EG) in three volume ratios of 60:40, 50:50, and 40:60 (EG:W) under fixed heat flux and constant operating temperature of 30–70 °C and Reynolds number of 3000–25,000. Results of Azmi et al. [41] experimental study revealed that the dynamic viscosity of nanofluid increases by increasing the nanoparticle concentration and decreases by increasing the temperature. They found that nanofluids with the base fluid of EG/W with 60:40 ratio in 1% concentration of nanoparticle and a temperature of 70 °C have the best performance in order to improve the forced heat transfer coefficient with 24.6% increase. Yu et al. [42] studied the viscosity and thermal conductivity of ethylene glycol nanofluid containing copper nanoparticles. They showed that the viscosity of nanofluid increases at 10 °C with the solid volume fraction of 0.3 and 0.5% compared to the base fluid and reaches 3.5 and 4.2 times with pure EG viscosity. They also observed that the nanofluid viscosity decreases with increasing the temperature in the temperature range of 10–30 °C. Zakaria et al. [43] studied Al2O3 nanofluid with 0.1 and 0.5% concentration in the base fluid of mixed water and ethylene glycol by 60:40 and 50:50 mass% as a coolant fluid in the PEM fuel cell. They observed 26% increase in the viscosity of Al2O3 nanofluid with 0.5% concentration in the base fluid 50:50 (EG:W) as compared to the base fluid while they reported 45% increase compared with the base fluid for Al2O3 nanofluids with 0.5% concentration in the base fluid 40:60 (EG:W). They stated that the reason is the importance of the volume ratio of hybrid base fluid comprising fluids. Chiam et al. [44] analyzed the thermal conductivity and viscosity of dispersed Al2O3 nanoparticles in the base fluid with 40:60, 50:50, and 60:40 (W: EG) volume ratio of the mixture of water (W) and ethylene glycol (EG), in the temperature range of 30–70 °C and at the concentration of 0.2–1% by volume. They found that the maximum average increase in thermal conductivity is related to Al2O3 40:60 (W:EG). They concluded that Al2O3 nanofluid with 1% concentration in the base fluid with a ratio of 40:60 (W:EG) is suitable for heat transfer applications. According to their results under the mentioned conditions, increasing the thermal conductivity has the highest and increasing the viscosity has the lowest value, which is a huge advantage for heat transfer applications. Niknam et al. [45] evaluated the thermal conductivity and rheological properties of nanofluids containing copper nanoparticles with 0.4–1.6 mass% in the temperature range of 20–50 °C in the base fluid of diethylene glycol. 7.2% heat conductivity enhancement and 5.2% viscosity increase were reported for nanofluid containing 1.6 mass% of nanoparticles. They showed that the studied nanofluid has Newtonian behavior. This means that viscosity is independent of shear rate, which is an important criterion for using this type of nanofluid in the convective heat transfer. Li et al. [46] examined the natural and convective heat transfer characteristics of zinc oxide nanofluid with 5.25% concentration of the base fluid mixed with ethylene glycol and water with the solid volume fractions of 75:25, 85:15, and 95:5 (EG/DW) in the temperature range of 15–55 °C. They stated that the thermal conductivity of nanofluid with larger DW (deionized water) is greater because there is a significant thermal resistance in EG that makes restricted nuclear movement and thus, heat transfer. They also found that the fluid viscosity increases with increasing EG concentrations. The other result of their work is that increasing the temperature leads to an increase in thermal conductivity due to the failure of the relatively weak hydrogen bonds. They also stated that when the temperature rises, the intermolecular gap becomes larger and leads to reduction in viscosity, but the presence of EG can greatly reduce the fluidity of nanofluids increasing the viscosity of nanofluids. Table 1 presents some experimental correlations for ethylene glycol and water-based nanofluids viscosity. The presented correlations in Table 1 in some cases depend solely on the solid volume fraction and depend on the temperature and solid volume fraction in some other cases. The temperature range of the presented correlations performance proposed by different researchers is different from each other. For example in some research results there are some correlations for subzero temperatures for estimating the viscosity [47].

Few basic types of research have been conducted to determine the specific viscosity of CuO/EG:W nanofluid. In addition to conventional method of studying the rheological behavior of the aforementioned nanofluid, the present research has proposed suggestions to reduce costs in time and financial costs to achieve the general rheological behavior of CuO/EG:W nanofluid with fewer experiments using the sensitivity analysis. Choosing volume proportion of 80 to 20 for a mixture of water and ethylene glycol as a base fluid in this study because of the better properties of water to polyethylene glycol [36] was one of the cases that have led the present research to achieve more suitable and more efficient nanofluids in industries.

Experimental

In this work, a two-step method was used to prepare the nanofluid samples (0.05, 0.1, 0.2, 0.5, 1 vol%). To prepare the stable samples, suitable mechanisms such as mixing and sonication were used. In this way, after magnetic stirring for 2 h, the samples were exposed to an ultrasonic processor (Ultrasonic Homogenizer Development of Ultrasonic Technology, Iran). The photograph of all samples is displayed in Fig. 2. Also integrated temperature control is done with connecting the viscometer to a Brookfield TC series bath and AP controller. It should be noted that temperature information about experimental study is available at touch screen display of the viscometer.

In this study, model DV3T viscometer made by Brookfield Company was used. This device is based on a cone-plate geometry. Figure 1 shows the viscometer and nanofluids images. The cone is connected to the spindle drive, and the plate is mounted in the sample cup. As the spindle is rotated, the viscous drag of the fluid against the spindle is measured by the deflection of the calibrated spring. Thus, the digital system calculates the torque acting on the spindle with the help of a coil spring by entering the spindle rotational speed of the device.

Table 2 shows the technical specifications of viscometer used in this study. Considering the measurement range of DV3T viscometer, the viscometer is used for measuring the fluid viscosity with low viscosity (the viscosity range of water and ethylene glycol).

Validation of experimental results

In order to more accurately investigate on accuracy of viscometer, the measured data (water and mixture of ethylene glycol and water) by DV3T compared with Nist Data base [51] and Sunder et al. [48] and results are presented in Fig. 2.

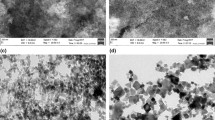

In order to achieve a characterization of the sample, the structural properties of the dry CuO nanoparticle were measured by using X-ray diffraction as shown in Fig. 3.

Results and discussion

Linear or nonlinear behavior

The fitness of linear and power functions on the values of shear stress and rate of shearing strain obtained from experimental test results were investigated in two stages, respectively, in order to determine the behavior of nanofluid in terms of Newtonian and non-Newtonian. R2 coefficient for fitted linear and power functions on shear stress and rate of shearing strain data is shown in Tables 3 and 4. It is clear that the values of R-squared for the linear function are closer to 1 compared to the values of R-squared for power functions in almost all cases. Accordingly, it can be said that the compliance linear curve data values with shear stress and shear rate are much better than the power curve data with shear stress and rate of shearing strain. Therefore, the investigated nanofluid has a Newtonian behavior due to the linear relation between the amount of shear stress and shear rate of shearing strain. Data in Table 5 have been provided in order to measure the similarity of the behavior of the investigated nanofluid in terms of Bingham fluid behavior, in which the value of the initial shear stresses, i.e., τ0 is given. As this table shows τ0 values are very small and close to zero in almost all cases. Given that the yield stress τ0 values are very close to zero at all investigated temperatures and solid volume fractions, the behavior of investigated nanofluid in the present study is very little similar to Bingham fluid behavior.

Figure 4 shows the shear stress curve based on the rate of shear strain at different temperatures and solid volume fractions. As the set of figures shows, the shear stress and the shear rate of shear strain have a linear relation with each other at all temperatures and solid volume fractions, and the passing line of the points of experiments passes the origin with a proper approximation. This is an intuitive reason for being a Newtonian fluid. The mixture of water and ethylene glycol is mentioned as Newtonian fluid in ASHRAE Handbook [52].

Viscosity analysis

Figure 5 shows the viscosity changes with temperature changes in the base fluid and CuO/EG:W (20:80 v/v) nanofluid at different solid volume fractions. According to 80:20 volume ratio of water to ethylene glycol in the base fluid and the greater share of water in the base fluid, the viscosity changes in the made nanofluid are very close to the viscosity of pure water in all solid volume fractions (volume fraction range of zero to 1%). In addition, the high sensitivity of ethylene glycol viscosity at lower temperatures up to 40 °C is evident. Ethylene glycol viscosity decreased with increasing temperature and became almost stable at temperatures from 40 to 50 °C. The heavy dependence of viscosity to external effective factors such as the solid volume fraction and temperature is an advantage in industrial applications. In order to achieve this importance in the present research, adding water to ethylene glycol as a part of the base fluid and forming a base fluid consisting of water and ethylene glycol (80% water–20% ethylene glycol) led to achieve a better balance in the process of change in viscosity with temperature. The mass ratio importance of the base fluid ingredients in past research has been widely studied [43, 44]. The lack of viscosity’s heavy dependence on the temperature of the base fluid (water + ethylene glycol) and nanofluid is evident in Fig. 3 in all solid volume fractions.

Figure 6 shows the relative viscosity changes in the investigated nanofluid CuO/EG:W (20:80 v/v) to the temperature at different solid volume fractions. As Fig. 6 shows, the relative viscosity changes can be ignored with temperature in all solid volume fractions because a little change has been created in the relative viscosity of nanofluid with increasing temperature at the fixed solid volume fraction that Esfe et al. [40] found in their study. The slight increase in the relative viscosity with increasing temperatures in the solid volume fractions can be due to less drop in the viscosity of nanofluids at different solid volume fractions compared with the base fluid as the temperature increases. Figure 7 also shows it in another way. In Fig. 7, the relative viscosity changes at different temperatures are shown in terms of the solid volume fraction. The figure shows the differences between the Lundgren [53] and Einestein [54] model estimation with the conducted experimental results. In fact, Lundgren and Einestein models considered the relative viscosity changes independent of solid volume fraction changes, while the results of this study showed significant changes in relative viscosity with temperature, which caused differences in the results. The reason for this difference is that Einstein’s theory model [54]only considers the solid volume fraction and ignores particle–particle and particle–fluid interactions.

According to the results in Fig. 7, the relative viscosity increased with increasing the solid volume fraction. The reason is that increasing the concentration of nanoparticles directly affects the inner shear stress. This increases friction and thus, viscosity [38].

The relative viscosity values of the nanofluid for all examined temperatures and solid volume fractions are shown in Fig. 8 for better assessment in 3D bar chart. It is observed that 1% volume nanofluid has the most viscosity and 0.05% volume nanofluid has the lowest viscosity. The relative independence of temperature is clearly visible at all solid volume fractions.

In Fig. 9, the dynamic viscosity changes in temperature and solid volume fraction are displayed. As is clear, increasing the solid volume fraction at all temperatures increases the viscosity. The reason is increasing the friction between the particles and nanofluid layers (due to the increasing the solid volume fraction and adding solid particles to the base fluid) compared to the base fluid. 30% increasing and changes in the Nanofluid viscosity with 1% solid volume fraction compared to the base fluid are evident in the figure below.

Thermal conductivity analysis

Also Esfe et al. [55]. conducted an experimental study on thermal conductivity of CuO/EG:W (40:60 v/v) at temperature range of 20–50 °C and solid volume fraction range of 0.1–2%. As it is clear in Fig. 10 at solid volume fraction of 2%, the thermal conductivity enhanced by 15.84 and 97.36% at temperatures of 20 and 50 °C, respectively. Considering low impact of temperature on viscosity of CuO/EG:W (40:60 v/v) nanofluid and highly remarkable thermal conductivity enhancement, CuO/EG:W (40:60 v/v) nanofluid could be introduced as one of the main candidates of working fluids in cooling systems.

Proposing a new two variable correlation

Obtaining a proper correlation in order to accurately predict nanofluid viscosity changes in different temperature and solid volume fraction is a favorite case of many scientific community and researchers. Therefore, the present study was performed on experimental data of the viscosity curve fitting, and a correlation was provided for the nanofluid viscosity in terms of the solid volume fraction and temperature independent variables, which is presented below (Table 1). R2 value in the mentioned correlation is 0.9850, and the R value is 0.9925. In addition, the tolerance of numerical parameters A, B, and C related to the proposed correlation is equal to 0.1 × 10−5.

Figure 11 shows the acceptable compliance of results and predictions with experimental results of the present study. The quality of results is clear in all solid volume fractions.

Margin of deviation

According to the proposed correlation to report the nanofluid viscosity in terms of temperature and solid volume fraction of nanoparticles, the margin of deviation from the experimental data is evaluated according to Eq. (2):

The margin of deviation in terms of solid volume fraction of nanoparticles at different temperatures is reported in Fig. 12. As shown in this figure, the maximum deviation from the predicted values by Eq. 1 is related to 0.05% solid volume fraction at 40 °C and water–ethylene glycol fluid (zero solid volume fraction) at 40 °C, which differs 3.5% from the predicted values. This difference is less than 3.5% in other investigated solid volume fractions and temperatures.

Sensitivity analysis of viscosity

Figure 13 shows the investigation of the nanofluid viscosity sensitivity in terms of the solid volume fraction of nanoparticles added to the base fluid and temperature parameter. For this purpose, the effect of 10% increase in the solid volume fraction of nanofluid was studied compared to the initial solid volume fraction on the viscosity and the viscosity change rate of the nanofluid was calculated. The viscosity sensitivity analysis is achieved by Eq. (3):

As can be seen in Fig. 13, the dynamic viscosity sensitivity of the nanofluid is almost the same at all temperatures compared to the small changes in the solid volume fraction (10% change). With increasing the volume fraction of nanoparticles, the dynamic viscosity sensitivity increases by small changes in the solid volume fraction, but as the low solid volume fractions, the nanofluid viscosity is much less sensitive to temperature changes, which is almost negligible at high solid volume fractions. In addition, calculations show the difference in viscosity sensitivity rates in the seventh or eighth decimal (in fixed solid volume fraction and different temperatures).

Accordingly, the nanofluid viscosity can be considered as a function of solid volume fraction in the feasibility process of industrial applications of investigated nanofluid in this study.

Conclusions

In the present study, the viscosity of CuO/EG:W (20:80 v/v) nanofluid was investigated in 0.05, 0.1, 0.2, 0.5, and 1% solid volume fraction and at 15, 20, 25, 30, 35, 40, 45, and 50 °C. A new correlation was proposed for the viscosity based on the independent variables of the volume fraction and temperature in order to predict the viscosity of the investigated nanofluid in the temperature and solid volume fraction range. According to the observations and surveys, the following results were obtained:

-

1.

The relation between shear stress and rate of shearing strain obtained from experiments at different temperatures and solid volume fractions reveals the Newtonian behavior of the investigated nanofluid and thus, the independence of the viscosity from the shear stress.

-

2.

The R2 value for the proposed correlation was as much as 0.9850, which reveals the proper accuracy of the proposed correlation to estimate the amount of viscosity based on the independent variables of temperature and solid volume fraction.

-

3.

The sensitivity analysis showed that the viscosity of CuO/EG:W nanofluid is very sensitive to changes in the solid volume fraction, but the viscosity of the mentioned nanofluid is very little sensitive to temperature changes at a fixed solid volume fraction.

-

4.

Because of imperviousness and very low sensitivity of the investigated nanofluid viscosity to temperature changes, the CuO/EG:W nanofluid has a very good performance in industrial applications with wide temperature ranges. The low sensitivity to temperature also makes the rheological behavior testable, observable, and predictable at high temperatures and ambient temperature conditions.

References

Esfe MH, Razi P, Hajmohammad MH, Rostamian SH, Sarsam WS, Arani AAA, Dahari M. Optimization, modeling and accurate prediction of thermal conductivity and dynamic viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids by NSGA-II using ANN. Int Commun Heat Mass Transf. 2017;82:154–60.

Esfe MH, Esfandeh S, Saedodin S, Rostamian H. Experimental evaluation, sensitivity analyzation and ANN modeling of thermal conductivity of ZnO–MWCNT/EG–water hybrid nanofluid for engineering applications. Appl Therm Eng. 2017;125:673–85.

Esfe MH. Designing a neural network for predicting the heat transfer and pressure drop characteristics of Ag/water nanofluids in a heat exchanger. Appl Therm Eng. 2017;126:559–65.

Esfe MH, Alirezaie A, Rejvani M. TTTd alterations gradient of thermal conductivity increases with the rise of volume fraction of up to 1%, and emmmy then, the sensitivity decreases. Generally, the current study is a combination of empirical studies along. Appl Therm Eng. 2017;111:1202–10.

Esfe MH, Behbahani PM, Arani AAA, Sarlak MR. Thermal conductivity enhancement of SiO2–MWCNT (85:15%)–EG hybrid nanofluids. J Therm Anal Calorim. 2017;128(1):249–58.

Alirezaie A, Hajmohammad MH, Ahangar MRH, Esfe MH. Price-performance evaluation of thermal conductivity enhancement of nanofluids with different particle sizes. Appl Therm Eng. 2018;128:373–80.

Esfe MH, Esfandeh S, Rejvani M. Modeling of thermal conductivity of MWCNT-SiO 2 (30: 70%)/EG hybrid nanofluid, sensitivity analyzing and cost performance for industrial applications. J Therm Anal Calorim. 2018;131(2):1437–47.

Esfe MH, Amiri MK, Alirezaie A. Thermal conductivity of a hybrid nanofluid. J Therm Anal Calorim. 1–10 (in press).

Raei B, Shahraki F, Jamialahmadi M, Peyghambarzadeh S. Experimental investigation on the heat transfer performance and pressure drop characteristics of γ-Al2O3/water nanofluid in a double tube counter flow heat exchanger. Transp Phenom Nano Micro Scales. 2016;5(1):64–75. https://doi.org/10.7508/tpnms.2017.01.007.

Abbasian Arani A, Abbaszadeh M, Ardeshiri A. Mixed convection fluid flow and heat transfer and optimal distribution of discrete heat sources location in a cavity filled with nanofluid. Transp Phenom Nano Micro Scales. 2016;5(1):30–43. https://doi.org/10.7508/tpnms.2017.01.004.

Esfe MH, Zabihi F, Rostamian H, Esfandeh S. Experimental investigation, model development of the non-Newtonian behavior of CuO-MWCNT-10w40 nano-lubricant for lubrication purposes. J Mol Liq. 2018;249:677–87.

Esfe MH, Wongwises S, Esfandeh S, Alirezaie A. Development of a new correlation and post processing of heat transfer coefficient and pressure drop of functionalized COOH MWCNT nanofluid by artificial neural network. Curr Nanosci. 2018;14(2):104–12.

Alirezaie A, Saedodin S, Esfe MH, Rostamian SH. Investigation of rheological behavior of MWCNT (COOH-functionalized)/MgO-engine oil hybrid nanofluids and modelling the results with artificial neural networks. J Mol Liq. 2017.

Nadooshan AA, Esfe MH, Afrand M. Prediction of rheological behavior of SiO2-MWCNTs/10W40 hybrid nanolubricant by designing neural network. J Therm Anal Calorim. 1–8.

Esfe MH, Naderi A, Akbari M, Afrand M, Karimipour A. Evaluation of thermal conductivity of COOH-functionalized MWCNTs/water via temperature and solid volume fraction by using experimental data and ANN methods. J Therm Anal Calorim. 2015;121(3):1273–8.

Esfe MH, Karimpour R, Arani AAA, Shahram J. Experimental investigation on non-Newtonian behavior of Al2O3-MWCNT/5W50 hybrid nano-lubricant affected by alterations of temperature, concentration and shear rate for engine applications. Int Commun Heat Mass Transf. 2017;82:97–102.

Esfe MH, Sarlak MR. Experimental investigation of switchable behavior of CuO-MWCNT (85%–15%)/10W-40 hybrid nano-lubricants for applications in internal combustion engines. J Mol Liq. 2017;242:326–35.

Salari M, Malekshah EH, Esfe MH. Three dimensional simulation of natural convection and entropy generation in an air and MWCNT/water nanofluid filled cuboid as two immiscible fluids with emphasis on the nanofluid height ratio’s effects. J Mol Liq. 2017;227:223–33.

Esfe MH, Rostamian H, Sarlak MR, Rejvani M, Alirezaie A. Rheological behavior characteristics of TiO2-MWCNT/10w40 hybrid nano-oil affected by temperature, concentration and shear rate: An experimental study and a neural network simulating. Phys E Low Dimens Syst Nanostruct. 2017;94:231–40.

Esfe MH, Esfandeh S. Investigation of rheological behavior of hybrid oil based nanolubricant-coolant applied in car engines and cooling equipments. Appl Therm Eng. 2018;131:1026–33.

Esfe MH, Saedodin S, Rejvani M, Shahram J. Experimental investigation, model development and sensitivity analysis of rheological behavior of ZnO/10W40 nano-lubricants for automotive applications. Phys E Low Dimens Syst Nanostruct. 2017;90:194–203.

Esfe MH, Saedodin S, Mahian O, Wongwises S. Thermophysical properties, heat transfer and pressure drop of COOH-functionalized multi walled carbon nanotubes/water nanofluids. Int Commun Heat Mass Transf. 2014;58:176–83.

Esfe MH, Saedodin S, Mahian O, Wongwises S. Heat transfer characteristics and pressure drop of COOH-functionalized DWCNTs/water nanofluid in turbulent flow at low concentrations. Int J Heat Mass Transf. 2014;73:186–94.

Fereidoon A, Saedodin S, Hemmat Esfe M, Noroozi MJ. Evaluation of mixed convection in inclined square lid-driven cavity filled with Al2O3/water nano-fluid. Eng Appl Comput Fluid Mech. 2013;7(1):55–65.

Afrand M, Esfe MH, Abedini E, Teimouri H. Predicting the effects of magnesium oxide nanoparticles and temperature on the thermal conductivity of water using artificial neural network and experimental data. Phys E Low Dimens Syst Nanostruct. 2017;87:242–7.

Raei B, Shahraki F, Jamialahmadi M, Peyghambarzadeh S. Experimental investigation on the heat transfer performance and pressure drop characteristics of γ-Al2O3/water nanofluid in a double tube counter flow heat exchanger. Transp Phenom Nano Micro Scales. 2016;5(1):64–75. https://doi.org/10.7508/tpnms.2017.01.007.

Hemmat Esfe M, Akbar Abbasian Arani A, Aghaie A, Wongwises S. Mixed convection flow and heat transfer in an up-driven, inclined, square enclosure subjected to DWCNT-water nanofluid containing three circular heat sources. Curr Nanosci. 2017;13(3):311–23.

Esfe MH, Rostamian H, Shabani-samghabadi A, Arani AAA. Application of three-level general factorial design approach for thermal conductivity of MgO/water nanofluids. Appl Therm Eng. 2017;127:1194–9.

Esfe MH, Saedodin S, Biglari M, Rostamian H. An experimental study on thermophysical properties and heat transfer characteristics of low volume concentrations of Ag–water nanofluid. Int Commun Heat Mass Transf. 2016;74:91–7.

Esfe MH, Hajmohammad H, Moradi R, Arani AAA. Multi-objective optimization of cost and thermal performance of double walled carbon nanotubes/water nanofluids by NSGA-II using response surface method. Appl Therm Eng. 2017;112:1648–57.

Esfe MH, Hajmohammad MH, Razi P, Ahangar MRH, Arani AAA. The optimization of viscosity and thermal conductivity in hybrid nanofluids prepared with magnetic nanocomposite of nanodiamond cobalt-oxide (ND-Co3O4) using NSGA-II and RSM. Int Commun Heat Mass Transf. 2016;79:128–34.

Esfe MH, et al. Multi-objective optimization of nanofluid flow in double tube heat exchangers for applications in energy systems. Energy. 2017.

Esfe MH, Hajmohammad MH. Thermal conductivity and viscosity optimization of nanodiamond-Co3O4/EG (40: 60) aqueous nanofluid using NSGA-II coupled with RSM. J Mol Liq. 2017;238:545–52.

Li X, Zou C. Thermo-physical properties of water and ethylene glycol mixture based SiC nanofluids: an experimental investigation. Int J Heat Mass Transf. 2016;101:412–7. https://doi.org/10.1016/j.ijheatmasstransfer.2016.05.089.

Esfe MH, Saedodin S, Mahmoodi M. Experimental studies on the convective heat transfer performance and thermophysical properties of MgO–water nanofluid under turbulent flow. Exp Therm Fluid Sci. 2014;52:68–78. https://doi.org/10.1016/j.expthermflusci.2013.08.023.

Suganthi KS, Vinodhan VL, Rajan KS. Heat transfer performance and transport properties of ZnO–ethylene glycol and ZnO–ethylene glycol–water nanofluid coolants. Appl Energy. 2014;135:548–59. https://doi.org/10.1016/j.apenergy.2014.09.023.

Esfe MH, Saedodin S, Asadi A. An empirical investigation on the dynamic viscosity of Mg(OH)2–ethylene glycol in different solid concentrations and proposing new correlation based on experimental data. Int J Nat Eng Sci. 2014;8(3):29–34.

Yu W, Xie H, Li Y, Chen L, Wang Q. Experimental investigation on the heat transfer properties of Al2O3 nanofluids using the mixture of ethylene glycol and water as base fluid. Powder Technol. 2012;230:14–9. https://doi.org/10.1016/j.powtec.2012.06.016.

Akbarzadeh S, Farhadi M, Sedighi K, Ebrahimi M. Experimental investigation on the thermal conductivity and viscosity of ZnO nanofluid and development of new correlations. Trans Phenom Nano Micro Scales (Summer–Autumn). 2014;2(2):149–60. https://doi.org/10.7508/tpnms.2014.02.007.

Esfe MH, Saedodin S, Sharafi T. An experimental investigation and new correlations of viscosity of ZnO–EG nanofluid at various temperatures and different solid volume fractions. Exp Therm Fluid Sci. 2014. https://doi.org/10.1016/j.expthermflusci.2014.02.011.

Azmi WH, Usri NA, Mamat R, Sharma KV, Noor MM. Force convection heat transfer of Al2O3 nanofluids for different based ratio of water: ethylene glycol mixture. Appl Therm Eng. 2017;112:707–19. https://doi.org/10.1016/j.applthermaleng.2016.10.135.

Yu W, Xie H, Chen L, Li Y. Investigation on the thermal transport properties of ethylene glycol-based nanofluids containing copper nanoparticles. Powder Technol. 2010;197:218–21. https://doi.org/10.1016/j.powtec.2009.09.016.

Zakaria I, Azmi WH, Mamat AMI, Mamat RB, Saidur R, Abu Talib SF, Mohamed WANW. Thermal analysis of Al2O3–water ethylene glycol mixture nanofluid for single PEM fuel cell cooling plate: an experimental study. Int J Hydrog Energy. 2016;41:5096–112. https://doi.org/10.1016/j.ijhydene.2016.01.041.

Chiam HW, Azmi WH, Usri NA, Mamat R, Adam NM. Thermal conductivity and viscosity of Al2O3 nanofluids for different based ratio of water and ethylene glycol mixture. Exp Therm Fluid Sci. 2016. https://doi.org/10.1016/j.expthermflusci.2016.09.013.

Nikkam N, Ghanbarpour M, Saleemi M, Haghighi EB, Khodabandeh R, Muhammed M, Palm B, Toprak MS. Experimental investigation on thermo-physical properties of copper/diethylene glycol nanofluids fabricated via microwave-assisted route. Appl Therm Eng. 2014;65:158–65. https://doi.org/10.1016/j.applthermaleng.2014.01.003.

Li H, He Y, Hu Y, Jiang B, Huang Y. Thermophysical and natural convection characteristics of ethylene glycol and water mixture based ZnO nanofluids. Int J Heat Mass Transf. 2015;91:385–9. https://doi.org/10.1016/j.ijheatmasstransfer.2015.07.126.

Namburu PK, Kulkarni DP, Misra D, Das DK. Viscosity of copper oxide nanoparticles dispersed in ethylene glycol and water mixture. Exp Therm Fluid Sci. 2007;32:397–402. https://doi.org/10.1016/j.expthermflusci.2007.05.001.

Sundar LS, Ramana EV, Singh MK, Sousa ACM. Thermal conductivity and viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids for heat transfer applications: an experimental study. Int Commun Heat Mass Transf. 2014;56:86–95. https://doi.org/10.1016/j.icheatmasstransfer.2014.06.009.

Nguyen C, et al. Temperature and particle-size dependent viscosity data for water-based nanofluids–hysteresis phenomenon. Int J Heat Fluid Flow. 2007;28(6):1492–506.

Kulkarni DP, Das DK, Chukwu GA. Temperature dependent rheological property of copper oxide nanoparticles suspension (nanofluid). J Nanosci Nanotechnol. 2006;6(4):1150–4.

National Institute of Standards and Technology US Department of Commerce. https://www.nist.gov/.

ASHRAE Handbook. Fundamentals, American society of heating. Atlanta: Refrigerating and Air-Conditioning Engineers Inc.; 1985.

Lundgren TS. Slow flow through stationary random beds and suspensions of spheres. J Fluid Mech. 1972;51:273. https://doi.org/10.1017/S002211207200120X.

Einstein A. Eine neue bestimmung der moleküldimensionen. Ann Phys. 1906;324:289–306.

Esfe MH, Saedodin S, Akbari M, Karimipour A, Afrand M, Wongwises S, Safaei MR, Dahari MB. Experimental investigation and development of new correlations for thermal conductivity of CuO/EG–water nanofluid. Int Commun Heat Mass Transf. 2015. https://doi.org/10.1016/j.icheatmasstransfer.2015.04.006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hemmat Esfe, M., Esfandeh, S. Rheological behavior of CuO/EG:W (20:80 v/v) nanofluid from a thermal perspective. J Therm Anal Calorim 135, 61–72 (2019). https://doi.org/10.1007/s10973-018-7082-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7082-5