Abstract

A semi-organic nonlinear optical single crystal of bis thiourea sodium iodide (BTSI) has been successfully grown from aqueous solution using the slow evaporation solvent technique (SEST) at room temperature. Obtained crystals using the SEST method were characterized by using different characterization techniques. Structural studies of the grown crystals have been carried out by single-crystal XRD to confirm the crystal system and functional groups by FT-IR spectroscopy. Single-crystal XRD reveals orthorhombic structure of semi-organic BTSI single crystals and its unit cell parameters. Metal complex coordination of the single crystal is studied by FT-IR spectroscopy. The optical absorption study revealed excellent optical transparency of BTSI crystal in the entire visible region with a sharp lower cutoff wavelength 298 nm. The energy band gap of BTSI is found to be 4.16 eV. Thermal stability and thermal decomposition of BTSI single crystals were investigated by TGA–DTA and DSC analysis. The surface appearance of BTSI crystals by scanning electron microscopy reveals the formation of layer growth pattern. The structural perfection and growth features of the grown crystal were analyzed by wet chemical etching studies. The above studies reveal the effect of incorporation of sodium iodide into the lattice of thiourea crystals. The as-grown BTSI single crystals can be used as a potential candidate for NLO material as well as in electronic and optoelectronic devices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

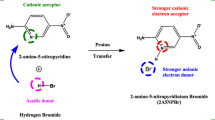

Recently, the strategy to design and develop new materials with suitable physiochemical properties is a prime factor to the research and scientists. Understanding the way in which molecules interact with each other through intermolecular forces is essential for new compounds and materials. Such new novel materials were obtained from semi-organics as it includes the properties of both organic and inorganic materials. Hence, more emphasis has been given by scientists to develop semi-organic crystals. Semi-organic complexes offer higher environmental stability combined with greater diversity of tunable electronic properties by virtue of the coordinated metal center [1]. Coordination compounds formed by thiourea with transition metal ions and halogen ion received renewed attention due to the following reasons (1) the nonlinear optical (NLO) properties of these compounds and (2) thiourea convenient preparation of semiconducting materials through thermal decomposition of such complexes [2–6]. Thiourea, a centrosymmetric molecule, which on coordination with a metal ion gives a non-centrosymmetric material [7]. Thiourea molecule is an interesting inorganic matrix modifier due to its large dipole moment and its ability to form an extensive network of hydrogen bonds [8]. In the present work, bis thiourea sodium iodide (BTSI), a desirable semi-organic single crystal, has been grown from aqueous solution using slow evaporation technique and reported. The grown crystals were subjected to various characterizations such as single-crystal XRD, FT-IR, optical absorption and thermal studies, and the results were discussed.

Experimental

Synthesis and crystal growth

Bis thiourea sodium iodide (BTSI) was synthesized by mixing aqueous solutions of thiourea and sodium iodide (99% Merck) in stoichiometric ratio of 2:1 with double distilled water as a solvent. To obtain high purity, the synthesized material was purified by successive recrystallization for several times in double distilled water.

Since thiourea has the coordination capacity to form different phases of metal thiourea complexes, the mixtures of the reactants are stirred well to avoid co-precipitation of multiple phases and also to get the homogeneous and transparent solutions [9]. BTSI single crystals were grown by solution growth technique at ambient condition. The solution was made saturated by dissolving the synthesized BTSI in double distilled water in good quality beaker by using 2MLH magnetic stirrer to make the solution more saturated. At ambient conditions, the solution was continuously stirred for more than 14–18 h to get the homogenous and transparent mixture of supersaturated solutions. After getting the supersaturated solution, the solution was filtered and kept at room temperature and optimally closed for controlled evaporation. After the period of 10–13 days, colorless, good quality hexagonal-shaped transparent crystals were harvested from the mother solution of size 10 mm × 13 mm × 10 mm as shown in Fig. 1.

Analysis techniques

For determining the crystal system and lattice parameters, single-crystal XRD was recorded by using with Enraf–Nonius CAD4 X-ray diffractometer. Functional group studies were carried out using FT-IR spectrometer (Model IFS BRUKER 66 V) in the range of 400–4000 cm−1. The optical absorption spectrum of the grown crystal of BTSI was recorded using Varian Cary 5E spectrophotometer with the range of 200–800 nm. Chemical wet etching technique is the simplest and proved to be one of the most powerful characterization techniques that can be employed to study the defects of single crystals. The chemical etching study was carried out using double distilled water using Metatech optical microscope. The morphology and structure of the cleaved cross section of single crystals was characterized with the help of a scanning electron microscope made in JEOL Japan (Model JSM-840). Thermal analyses were performed by using thermogravimetric analysis (TGA), differential thermal analysis (DTA) and differential scanning calorimetric (DSC) analyses using NETZSCH STA 409C thermal analyzer and NETZSCH DSC 204 instrument, respectively. TGA/DTA analyses of BTSI sample were carried out from room temperature to 1400 °C in nitrogen atmosphere at a heating rate of 20 °C min−1 flow rate to identify the thermal stability, purity and crystalline nature of the grown crystals.

Results and discussion

Single-crystal XRD

The single-crystal XRD study indicated that the unit cell parameters of the as-grown BTSI crystals are a = 5.49 Å, b = 7.65 Å and c = 8.55 Å with α = β = γ = 90°, and thus the volume of the cell is 359 Å3. Hence, the BTSI crystal is an orthorhombic structure.

FT-IR analysis

The FT-IR spectra of BTSI are recorded in the range of 400–4000 cm−1 using IFS BRUKER 66 V spectrophotometer, and the resultant spectrum is shown in Fig. 2. A number of reports are available in the FT-IR studies of thiourea compounds. The observed bands along with their vibrational assignments are summarized and compared with thiourea in Table 1. The shift in the observed peaks of BTSI in comparison with the free thiourea molecule confirmed the metal coordination with thiourea. In the present complex, there are three possibilities by which the coordination of sodium with thiourea can occur, which may see either through nitrogen (N) or sulfur (S) of thiourea [10]. The peaks of 3378, 3275 and 3174 cm−1 are due to the NH vibrations of thiourea. The N–C–N vibration produces sharp peak at 1472 cm−1. The increase in frequency can be attributed to the greater double bond character of the cason to nitrogen bond or complex formation gets the shift in CS stretching from 740 to 730 cm−1 confirmed the bonding of sulfur with sodium iodide. Hence, the shift in the peak positions of thiourea clearly shows the formation of BTSI. It is established that the CN stretching vibration of thiourea (1082 and 1479 cm−1) is shifted to a higher wavenumber of BTSI (1084 and 1472 cm−1). This clearly indicates the coordination of thiourea with the alkali ion.

Optical absorption studies

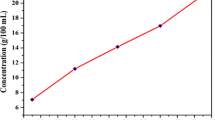

A good optical transmittance is very desirable in an NLO crystal since the absorptions, if any in an NLO material near the fundamental or the second harmonic, will lead to the loss of conversion efficiency in those wavelengths. It is well known that the parameters such as optical transmittance range and lower cutoff region are important to tailor the material for the specific application [11]. The optical absorption spectrum of the grown crystal of BTSI is shown in Fig. 3a. The spectrum shows very low absorbance in the entire visible and part of IR region. The lower cutoff wavelength for BTSI crystal is found to be 298 nm, which may be due to the excitation of electrons from the non-bonding to σ*. This very low absorption property with very low cutoff wavelength attests the usefulness of this material for second harmonic generation and other optoelectronic applications. Hence, it is suitable for frequency conversion applications [12, 13]. The optical band gap energy is yet another crucial factor which determines the transmittance in the visible region [14]. The optical band gap energy of BTSI single crystal can be determined using the relation

A plot was drawn between (αhν)1/2 and hν. The variation of α and (αhν)1/2 with reference to the energy (hν) is shown in Fig. 3b, c. From Fig. 3b, it is evident that the absorption coefficient (α) of the crystal almost remains a constant (about 6000 cm−1) up to incident energy of 4 eV. From Fig. 3c, the optical band gap energy is arrived by extrapolating the linear region of the curve to the hν axis. The band gap energy of BTSI obtained from the plot is 4.16 eV.

Etching studies

Etching studies is a very simple technique that can be employed to study the growth mechanism and also the presence of dislocations in the grown crystals. The chemical wet etching is an important tool for the identification of crystal defects, which is able to develop some of the features such as growth hillocks, etch spirals and rectangular etch pits on the crystal surface. The pattern of etch pits depends on the etchant, etching time and crystal faces. Etch pits are associated with dislocation and dislocation bundles and hence bring out the crystal quality [15]. In the present work, the etching studies were carried out on the BTSI crystals to study the distribution of structural defects in the grown crystals. BTSI crystal was etched in water for 5, 10 s. The etched surface was soaked with a filter paper and examined under an optical microscope in the reflection mode. The surface morphology of the as-grown single crystal is shown in Fig. 4a–c. Figure 4a–c shows the etch pattern of the grown crystal after etching for 5 s in water etchant, and it produces spiral-shaped well-defined etch pits. An increase in the etch time does not change the morphology of the etch pit. On successive etching for 5, 10 s, the spiral-shaped etch pits do not disappear, suggesting that the etch pits are due to dislocations. On increasing the duration of the etchant, deeper etch pits are observed.

Scanning electron microscope studies

The surface morphology and dislocation on the surface of the grown crystal were magnified and analyzed using scanning electron microscope. The transparent growth plane of BTSI crystal was coated with gold to discharge the charge of particles and scanned at two different magnifications. The resultant images of magnifications 40× and 70× are shown in Fig. 5a, b. From the image, it is clear that the surface of BTSI depicts layer growth and steps-oriented morphology. At higher magnification, apart from layer growth morphology, some microcrystallines are also observed on the surface of BTSI (Fig. 5b).

Thermal studies

Thermogravimetric analysis (TGA), differential thermal analysis (DTA) and differential scanning calorimetry (DSC) data have been reported for the synthesized BTSI single crystals. Mass decomposition, melting points, exothermic and endothermic peaks observed has been reported. Here, our aim is to see the effect of NaI doping on the thermal stability or melting point of thiourea crystals and we have to use DSC technique to examine the same. DSC technique measures the temperature and heat flow associated with transitions in materials as a function of temperature and time. Hence, provide the researchers’ quantitative and qualitative information about physical and chemical changes which include endothermic/exothermic processes or any change in heat capacity [16].

Thermal stability and physiochemical changes of BTSI single crystal were studied by thermogravimetric analysis (TGA), differential thermal analysis (DTA) and differential scanning calorimetric (DSC) analyses using NETZSCH STA 409C thermal analyzer and NETZSCH DSC 204 instrument. TGA and DTA analyses of BTSI sample were carried out from room temperature to 1400 °C in nitrogen atmosphere at a heating rate of 20 °C min−1. The TGA, DTA, DSC spectra of BTSI are shown in Figs. 6–8. In TGA, it is observed that there is no mass loss up to 179 °C, which shows the absence of physically adsorbed or lattice water in the crystal. The DTA curve in Fig. 7 shows the first endothermic peak at 179 °C shows the melting point of the sample, and the second endothermic peak at 251.9 °C may be due to the liberation of two molecules of thiourea in BTSI. The corresponding TGA curve shows no mass loss, and hence this can be regarded as the melting point of BTSI. It is observed that the BTSI decomposes into two stages. First stage occurs at 200 °C and the mass loss is 80%. Second stage starts at 250 °C and the mass loss is 30%. Above 700 °C, there is no peak in TGA spectrum. This indicates that the residue of BTSI was stable one. The thermal analysis by TGA/DTA technique of thiourea cadmium iodide indicates the inclusion of cadmium iodide in the thiourea complex. The fine thermal stability and good crystalline behavior of the crystal advocate the prospective NLO applications in devices [17]. The DSC curve shows that the sample melts at 181.2 °C as shown in Fig. 8. Earlier reported melting point of thiourea-doped compounds such as BTCC and BTCI is ~ 143 °C [18] and CCZTS is 240 °C [19]. The sharpness of the peaks also confirms the good crystallinity of the grown crystals. The thermal stability and the good crystallinity of the grown crystals indicate that these are useful for NLO applications.

Conclusions

Optically transparent good quality single crystals of bis thiourea sodium iodide (BTSI) were grown from aqueous solutions by solvent evaporation technique. Bright, transparent, well-defined external appearance and colorless crystals were obtained. The unit cell parameters and the space group were determined using single-crystal data. The orthorhombic crystal system and lattice parameters were evaluated from single-crystal X-ray diffraction analysis. FT-IR analysis confirms all the necessary functional groups to form the BTSI compounds and thus clearly indicates the coordination of thiourea with the alkali ion. The UV cutoff wavelength of BTSI is found to be about 298 nm; it is suitable for frequency conversion applications. Thus, low absorption region shows its suitability for fabricating the optically active devices. The optical band gap energy of BTSI obtained from the plot is 4.16 eV. The etchings studies reveal the formation of spiral-shaped etch patterns. The layer growth morphology of BTSI single crystal has been observed SEM. Further, the thermal analysis of bis thiourea sodium iodide indicates the inclusion of sodium iodide in the thiourea complex. DSC studies pointed out that the melting point of the sample is 181.2 °C. The above experimental results such as the bulk size, optical transparency implicate BTSI as a potential candidate for NLO material as well as in electronic and optoelectronic devices.

References

Siddheswaran R, Sankar R, Rathnakumari M, Jayavel R, Murugakoothan P, Sureshkumar P. Growth and characterization of tris allylthiourea mercuric chloride crystals. Cryst Res Technol. 2006;41:771–4.

Wang XQ, Yu WT, Xu D, Lu MK, Yuan DR. catena-poly [[bis(thiocyanate-kN) cadmium(II)]-di-μ-thiourea-k4S:S]. Acta Crystalloger. 2002;C58:m336–7.

Kumari RG, Ramakrishnan V, Carolin ML, Kumar J, Sarua A, Kuball M. Raman spectral investigation of thiourea complexes. Spectrochim Acta Part A Mol Biomol Spectrosc. 2009;73:263–7.

Bhaskaran A, Ragavan CM, Sankar R, Mohankumar R, Jayavel R. Growth and characterization of semiorganic nonlinear optical tetrakis thiourea nickel chloride single crystals. Cryst Res Technol. 2007;42(5):477–82.

Selvaraju K, Valluvan R, Kumararaman S. A new metal organic crystal: potassium thiourea chloride. Mater Lett. 2007;67:751–3.

Senthilmurugan G, Ramasamy P. Growth and characterization of metal organic crystal: tetra thiourea cobalt chloride. J Cryst Growth. 2009;311:585–8.

Krishnakumar V, Ramachandraraj C, Sundrarajan RS. Crystal growth and vibrational spectroscopic studies of the semiorganic non-linear optical crystal—bisthiourea magnesium sulphate. Spectochim Acta A. 2007;68:113–6.

Kannan V, Rajesh NP, Bairava Ganesh R, Ramasamy P. Growth and characterization of Bisthiourea-zinc Acetate, a new nonlinear optical material. J Cryst Growth. 2004;269:565–9.

Singh P, Hasmuddin M, Abdullah MM, Shkir M, Wahab MA. Observation of crystallization and characterizations on thiourea cadmium iodide: a semi-organic optical material. Mater Res Bull. 2013;48:3926–33.

Ushasree PM, Muralidharan R, Jayavel R, Ramasamy P. Metastable zonewidth, induction period and interfacial energy of zinc tris(thiourea) sulfate. J Cryst Growth. 2007;210:741–5.

Nithya N, Mahalakshmi R, Sagadevan Suresh. Investigation on physical properties of semiorganic nonlinear optical glycine zinc sulfate single crystal. Mater Res. 2015;18:581–7.

Sagadevan S. Studies on optical, mechanical, dielectric properties of bisthiourea nickel bromide NLO single crystal. Opt Int J Light Electr Opt. 2014;125:6746–50.

Sagadevan S. Growth, optical and electrical studies of the nonlinear optical crystal: glycine thiourea. Opt Int J Light Electr Opt. 2014;125:950–3.

Sagadevan S. Growth, optical, mechanical, dielectric and theoretical properties of picolinium maleate NLO single crystal. Opt Int J Light Electr Opt. 2014;125:2826–9.

Singh P, Hasmuddin M, Shakir M, Vijayan N, Abdullah MM, Ganesh V, Wahab MA. Investigation on structural, optical, thermal, mechanical and dielectric properties of L-proline cadmium chloride monohydrate single crystals: an efficient NLO material. Mater Chem Phys. 2013;142:154–64.

Hasmuddin M, Singh P, Shkir M, Abdullah MM, Vijayan N, Ganesh V, Wahab MA. Study of pure and l-tartaric acid doped ammonium dihydrogen phosphate single crystals: a novel nonlinear optical non-centrosymmetric crystal. Mater Chem Phys. 2014;144:293–300.

Hasmuddin M, Abdullah MM, Singh P, Shkir M, Vijayan N, Wahab MA. Ab-initio study of L-tartaric acid (LTA) single crystal for NLO application. Opt Laser Technol. 2015;74:53–9.

Prameela Kumari IS, Mahadevan CK. Formation and characterization of mixed crystals based on Bis (Thiourea) cadmium chloride and bis (Thiourea) cadmium iodide. Int J Eng Res Appl. 2014;4:125–44.

Gopinath S, Palanivel R, Rajasekaran R. Growth and studies of pure and cadmium chloride-doped zinc tris-thiourea sulphate (CCZTS) crystals. Int J Pure Appl Sci Technol. 2010;1:104–13.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Subashini, A., Rajarajan, K., Sagadevan, S. et al. Preparation and characterization of a bis thiourea sodium iodide (BTSI). J Therm Anal Calorim 131, 2179–2186 (2018). https://doi.org/10.1007/s10973-017-6829-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6829-8