Abstract

This contribution is devoted to thermoanalytical investigation of the mechanism of the formation of solid solutions of Li1+xCrxZr2−x(PO4)3. The samples were prepared by high-temperature solid-state reaction in the reaction mixtures of (0.5 + x/2)Li2CO3–(2 − x)ZrOCl2·8H2O–(x/2)Cr2O3–3(NH4)2HPO4. Thermal behaviour of the mixtures was characterised using STA analysis (RT-1200 °C); evolution of the phase composition during heating was analysed using powder XRD analysis. It is shown that with increase in substitution degree x from 0 to 2, the mechanism of the formation of the solid solutions changes dramatically. In general, it is influenced by the content of ZrOCl2·8H2O because its interaction with (NH4)2HPO4 is the dominant feature of the thermal transformation of the mixtures. However, with decrease in ZrOCl2·8H2O content and the corresponding increase in x, the indicated process becomes less dominant. On the other hand, unreacted amount of (NH4)2HPO4 is increased and the corresponding effect of elimination of its ammonia becomes more and more prominent. The mixture with x = 2 can be characterised with typical behaviour of the mixtures of (NH4)2HPO4 with oxides or carbonates. In general, the formation of solid solutions required calcination at 1200 °C during 6–12 h.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Complex zirconium phosphates are considered as technologically important class of compounds [1,2,3,4,5]. Various functional materials on basis of zirconium phosphates have been already found and adapted for actual technical needs as lasers, optical and magnetic materials, superconductors, ion conductors, semiconductors, sorbents, dielectrics, catalysts, pigments etc. Among their variability, complex zirconium phosphates of LISICON (lithium super ionic conductor) family have an important role. Area of their application constantly increases due to the characteristic unique spectra of valuable chemical and physical properties, which depend on their composition and crystal structure.

The crystal structure of common LISICONs embrace rhombohedral (\(R{\bar{3}}c\), \(R{\bar{3}}\)), orthorhombic (Pbcn), monoclinic (P21 /n) and triclinic (\(P{\bar{1}}\)) crystal systems. Rhombohedral and triclinic LISICONs are usually closely related to the original NASICON prototype, NaZr2P3O12, while monoclinic and orthorhombic LISICONs are structurally more related to scandium tungstate, Sc2W3O12 (SW). Both structure types are very flexible to co-substitutions. For example, the basic framework sites can be occupied ZrIV, TiIV, HfIV, GeIV, SnIV, MoIV, some LnIV and AnIV, CrIII, FeIII, ScIII, InIII or YbIII, as well as by NbV, while the interstitial sites besides being occupied by Li, can be partially or fully co-substituted by wide variety of s-, p-, d- and/or f-elements of oxidation state from 1+ to 3+ with radii ranges from H+ to Cs+ [6]. Attention in this study has been focused on preparation of zirconium-LISICONs.

Zirconium(IV) oxide (zirconia) and, in particular, its monoclinic modification is the basic compound for the solid-state synthesis of zirconium ceramics. However, usually the formation of single-phase product requires prolonged processing at high temperatures. In this view, other more reactive alternatives, such as tetragonal zirconia or ZrOCl, are adjusted to the synthesis of zirconium ceramics. At the same time, zirconium(IV) oxychloride octahydrate (ZrOCl2·8H2O) can be considered as well as a highly reactive alternative source of zirconium in solid-state reaction. Previously, ZrOCl2·8H2O was successfully used in preparation of different types of zirconium ceramics such as doped zirconia and its composites [7, 8], perovskite-type oxides [9], doped ZrP2O7 [10, 11], ZrC [12] and ZrB2 [13, 14], modified clay minerals [15, 16] as well as in role of catalyst in organic synthesis [17]. Within the studies at our department, ZrOCl2·8H2O was successfully used for the synthesis of ZrP2O7 ceramics [11, 18] and the mechanism of interaction between ZrOCl2·8H2O and (NH4)2HPO4 during calcination was explained in detail [18]. In this paper, we report results of our investigation on thermal behaviour of ZrOCl2·8H2O in more complex mixtures aiming the formation of complex LISICON solid solutions of Li1+xCrxZr2−x(PO4)3. Detailed characterisation of the properties of these solid solutions has been already published in our previous paper [19].

Experimental

The synthesis of the samples was performed by solid state reaction (SSR) in the mixture of (0.5 + x/2)Li2CO3 [P.A., Lachema, CZ]–(2−x)ZrOCl2·8H2O [P.A., Merck, DE]–(x/2)Cr2O3 [P.A., Lachema, CZ]–3(NH4)2HPO4 [P.A., Lachema, CZ]. Calcination was performed in an electric furnace (heating rate of 5–10 °C min−1) in several steps in the temperature range from 150 to 1300 °C with exposure time of 1–12 h. Thermal behaviour of the reaction mixtures with the composition corresponding to x = 0, 0.5, 1.0, 1.5, 2.0 was investigated using simultaneous differential thermal and thermogravimetric analysis (Jupiter STA 449/C/6/F, Netzsch, DE, the measurement atmosphere: below 750 °C-air, above 750 °C-argon) using the following conditions: temperature intervals between 20 and 1200 °C; a heating rate of 10 °C min−1; α-Al2O3 was used as reference material; mass of the sample was 50–100 mg. Phase composition investigation of the calcined powders and intermediate products was performed by X-ray diffraction analysis: a diffractometer D8 Advance, monochromatic CuKα radiation and a scintillation detector, Bruker, GB, step scanning over 2θ range from 10° to 80° with a step size of 0.02° and 3 s counting time at each step; a diffractometer Rigaku Miniflex 600, continuous scanning over 2θ range from 10° to 80°, scanning speed—5° to 10° 2θ min−1, CuK β Ni filter, 1D detector D/teX Ultra.

Results and discussion

Background on thermal behaviour of the initial compounds and ZrOCl2·8H2O–(NH4)2HPO4 mixture

Thermal behaviour of the individual mixture components is shortly discussed below. Decomposition of (NH4)2HPO4 starts at 160 °C and takes place in several steps: melting and elimination of one molecule of ammonia with the formation of NH4H2PO4 (endothermic effect at 210 °C, step-like mass loss between 160 and 230 °C); elimination of the second molecule of ammonia and further dehydration start above 200 °C immediately after the formation of NH4H2PO4 and are accompanied with gradual mass loss; subsequent heating leads to the reaction of polycondensation yielding different polyphosphate acids and their dehydration [18]. Decomposition of ZrOCl2·8H2O starts at 70 °C with elimination of eight molecules of its crystalline water [18], while above 230 °C it undergoes thermal hydrolysis leading to elimination of HCl and formation of ZrO2. Chromium(III) oxide, Cr2O3, has a very high thermal stability, and its melting point is above 2000 °C. Lithium carbonate, Li2CO3, melts at 720 °C and decomposes above the melting point [20]. It is also worth to note, that the thermal behaviour of ZrOCl2·8H2O and (NH4)2HPO4 mixture changes dramatically in comparison with the typical behaviour of the individual compounds [18]. The typical features of thermal behaviour of this mixture are the following: dehydration of ZrOCl2·8H2O (endothermic effect at 160 °C, step-like mass loss between 70 and 230 °C) accompanied with interaction between ZrOCl2·8H2O and (NH4)2HPO4 in molar ratio 1:2 leading to the formation of NH4Cl, NH4H2PO4 and ZrO2; release of ammonia and dehydration of NH4H2PO4 starts above 200 °C (gradual mass loss); sublimation and decomposition of NH4Cl (endothermic effect at 350 °C, step-like mass loss between 310 and 410 °C). Thus, when additional carbonate and oxide are included in the mixture composition, its thermal behaviour becomes even more complex, and at the same time it still highly depends on the ratio between the ZrOCl2·8H2O and (NH4)2HPO4 components as it will be shown below.

Thermal behaviour of (0.5 + x/2)Li2CO3–(2−x)ZrOCl2·8H2O–(x/2)Cr2O3–3(NH4)2HPO4 mixtures

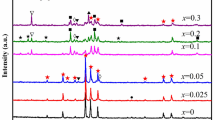

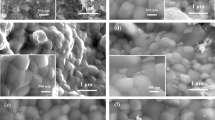

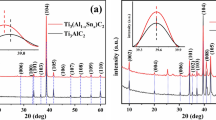

The results of thermal analysis of the (0.5 + x/2)Li2CO3–(2−x)ZrOCl2·8H2O–(x/2)Cr2O3–3(NH4)2HPO4 mixtures of 5 different compositions are presented in Fig. 1. Accordingly, with increase in substitution degree x from 0 to 2, the main features at the thermoanalytical curves changed dramatically indicating considerable changes in the mechanism of the formation of the studied solid solutions. The mixtures with x < 2 undergo similar interaction as two-component ZrOCl2·8H2O-2(NH4)2HPO4 mixture leading to the formation of NH4Cl, NH4H2PO4 and ZrO2 at low temperatures (< 160 °C), which with increase in x and corresponding decrease in ZrOCl2·8H2O content involves lesser and lesser part of the mixture. On the other hand, ‘unreacted’ amount of (NH4)2HPO4 is increased, and the corresponding effect of elimination of its ammonia became more and more prominent. The mixture with x = 2 can be characterised with typical behaviour of the mixtures of (NH4)2HPO4 with metal oxides or carbonates. Evolution of the phase composition of the mixtures is given in Table 1. Observed thermoanalytical effects and theoretical description of the corresponding processes taking place in the mixtures during heating are given in Table 2, while thermal behaviour of each of the studied mixture is described below. The discussion is started with the mixture which does not contain ZrOCl2·8H2O (x = 2) and is continued in order of the increasing content of ZrOCl2·8H2O component (decreasing x).

As it was already mentioned, thermal behaviour of the mixture with x = 2, in our opinion, is typical for (NH4)2HPO4 in mixture with anhydrous oxides or carbonates. In particular, elimination of ammonia started at 120 °C which initiated interaction with Li2CO3 and release of CO2. It is connected with a strong endothermic effect centred at 186 °C; a shoulder at high-temperature side reveals a multiple character of the process. According to the observed step-like mass loss accompanying this effect, both molecules of ammonia as well as full release of carbonate should be accomplished below 225 °C where the mass loss reached 25.5%. It was also confirmed with XRD analysis of the intermediate products. So, after calcination at 200 °C during 1 h, the main crystalline product in the mixture was Cr2O3; NH4H2PO4 and Li2CO3 were also detected; however, after longer heating or with increase in the calcination temperature, both phases disappeared. The gradual mass loss at higher temperature as well as weak endothermic effect should be connected with further dehydration of phosphate component. In comparison with pure (NH4)2HPO4 [18], the corresponding endothermic effect is shifted to lower temperature from 380 to 270 °C which should be connected with active interaction between the mixture components. The mass decrease in this sample stopped at 400 °C. The recorded total mass loss reached 37.5%, which closely approaches the theoretical value of 37.8%. At this temperature (400 °C, 1 h exposure time), besides Cr2O3 and the residues of Li2CO3, the sample also contained Li4P2O7 and complex chromium phosphates of Li9Cr3(PO4)2(P2O7)3 and LiCrP2O7. With short exposure time (1 h), Li2CO3 completely decomposed at 600 °C while Cr2O3 was fully reacted only by reaching 800 °C; pure rhombohedral LISICON phase was formed at 1150 °C. General reaction of the formation of Li3Cr2(PO4)3 is presented with Scheme 1.

Addition of ZrOCl2·8H2O to the mixture, as expected, complicates its thermal behaviour. For the mixture with x = 1.5, two additional thermoanalytical effects are observed. The first endothermic effect at 122 °C and the associated mass loss should correspond to dehydration of ZrOCl2·8H2O and its interaction with (NH4)2HPO4. The theoretical mass loss value corresponding to this process is 9.45% which is reached at 145 °C. Because the added amount of zirconium oxychloride is sufficient for the reaction with only one-third of (NH4)2HPO4, the latter is transformed into NH4H2PO4 at this reaction stage only partially. Therefore, (NH4)2HPO4 phase was detected in the samples composition below 200 °C; besides it, the products of interaction between ZrOCl2·8H2O and (NH4)2HPO4, i.e. NH4H2PO4 and NH4Cl, also appeared in the phase composition. The next endothermic effect between 150 and 250 °C is attributed to elimination of ammonia of the rest of (NH4)2HPO4, which, similar to the sample with x = 2, is followed with decomposition of lithium carbonate and elimination of ammonia of NH4H2PO4. In total the described processes should result in additional 18.3% of mass loss which was reached at 270 °C. After 1 h calcination at 270 °C, the sample contained only NH4Cl, Cr2O3 and the residues of Li2CO3, which disappeared after 2.5 h calcination at this temperature. Although Li4P2O7 and ZrP2O7 can hypothetically start to form at this reaction stage, however, their presence was confirmed by XRD analysis only after calcination at higher temperatures. The next process that is reflected with the endothermic effect at 328 °C is attributed to decomposition/sublimation of NH4Cl which formed during the initial stage of heating. Mass loss of this sample completely stopped at 550 °C. The total mass loss constituted 43.7% that correlates well with the theoretical value of 44.2%. Phase composition of the sample at this step was similar to the sample with x = 2. Additional phase of ZrP2O7 appeared at 600 °C and LISICON-related monoclinic SW modification (isostructural to scandium tungstate)—at 800 °C. At higher temperature, the monoclinic SW modification transformed into orthorhombic, and its pure phase product was detected after 6 h calcination at 1200 °C. The corresponding reaction of the formation of Li2.5Zr0.5Cr1.5(PO4)3 solid solution is presented with Scheme 2.

With increase in ZrOCl2·8H2O content in the mixture, the effect corresponding to its dehydration is shifted to slightly higher temperature (minimum is observed at 127 °C), and its intensity is increased (Fig. 1, x = 1). The theoretical mass loss corresponding to the dehydration of ZrOCl2·8H2O in this mixture is increased to 16.6%; at TG curve this value is reached at 150 °C. In opposite, the intensity of the following effect associated with elimination of ammonia of (NH4)2HPO4 is decreased, which can be explained with the fact that due to the higher content of ZrOCl2·8H2O in the mixture, more (NH4)2HPO4 is involved in the transformation leading to the formation of NH4Cl. Thus, because this reaction is accomplished at lower temperature, by reaching the decomposition temperature of (NH4)2HPO4, its initial content is decreased; the process should be followed by elimination of ammonia of NH4H2PO4 and decomposition of Li2CO3. The content of Li2CO3 in the mixture in comparison with the previous one is lower, which also contributes to lower intensity of the second endothermic effect. Also for this mixture, a shape of this effect, which is clearly dual, testifies in favour of several overlapped processes. Considering the mass loss, it is difficult to separate clearly this complex effect from the previous one on TG curve; in total all these processes including the dehydration should yield 29.5% what is reached at 275 °C. The last effect at 330 °C accompanied with the step-like mass loss of 12.3% between 280 and 350 °C is attributed to decomposition/sublimation of NH4Cl. In general, the interaction path and the detected intermediate products in this reaction mixture are similar to the described above for the mixture with x = 0.5. The mass loss in this mixture stopped at 650 °C. Its total amount constituted 49% that matches with the theoretical value of 49.1%. Scheme 3 represents the reaction of the formation of Li2ZrCr(PO4)3 which pure orthorhombic SW modification was detected after repeated calcination at 1200 °C during 6 h.

For the next mixture with x = 0.5, due to increasing content of ZrOCl2·8H2O, the endothermic effect of its dehydration and interaction with (NH4)2HPO4 became the most intensive one. Its minimum was observed at 137 °C, and the step-like mass loss of 22.2% is observed at 55–155 °C. Also because the ratio between ZrOCl2·8H2O and (NH4)2HPO4 in this mixture is 1:2, it was expected that (NH4)2HPO4 will be fully transformed into NH4H2PO4 and NH4Cl at the initial heating stage. Therefore, the effect of elimination of NH3 of (NH4)2HPO4 which should appear just below 200 °C is absent, while the effect connected with elimination of NH3 of NH4H2PO4 and CO2 of Li2CO3 appears as a very weak shoulder above 200 °C that gradually transforms into the next strong effect of decomposition/sublimation of NH4Cl. Its minimum is observed at 328 °C and the step-like mass loss of 16.5% is observed at TG curve between 260 and 360 °C. Similar to the mixtures with x = 1 and 0.5, NH4H2PO4, NH4Cl, Li4P2O7, ZrP2O7, LiCrP2O7 and Li9Cr3(PO4)2(P2O7)3 were detected as intermediate products. As final product, a mixture of orthorhombic SW and triclinic LISICON phases were detected. Mass loss of this mixture stopped at 650 °C which is similar to the previous one. Total mass loss constituted 52.8%, the theoretical value is 52.9%. The reaction of the formation of Li1.5Zr1.5Cr0.5(PO4)3 is given below (Scheme 4).

Finally, thermal behaviour of the reaction mixture with x = 0 is very similar to the previous mixture. In this case, endothermic minimum of dehydration of ZrOCl2·8H2O and its interaction with (NH4)2HPO4 is observed at the same temperature of 137 °C; corresponding 26.7% of the mass loss is reached on TG curve at 170 °C. At this stage, (NH4)2HPO4 is fully transformed into NH4H2PO4 and NH4Cl. Thus, the next effect, which appears as a very weak shoulder above 200 °C, corresponds to the elimination of NH3 of NH4H2PO4 and CO2 of Li2CO3. Decomposition/sublimation of NH4Cl is another dominating effect which endothermic minimum appears at 328 °C, while the corresponding mass loss of 19.9% appears on TG curve in broader range of 250–385 °C 19%. The mass loss stopped at 900 °C by reaching 55.8% of theoretical 56%. The single-phase product of rhombohedral modification of LISICON was obtained after 6 h calcination at 1300 °C. The reaction of the formation of double phosphate of LiZr2(PO4)3 is presented with Scheme 5.

In high-temperature range, DTA curves of all studied samples also show some other low intensity endothermic and exothermic effects (Fig. 1), which can be connected with melting or crystallisation of the intermediate products, respectively. In most cases, calcination at 1200 °C during 6 h was sufficient for the formation of solid solutions; formation of LiZr2(PO4)3 required calcination at 1300 °C, Li3Cr2(PO4)3-1150 °C. Under the studied conditions, LiZr2(PO4)3 and Li3Cr2(PO4)3 were obtained in their rhombohedral modification, solid solutions of Li1+xZr2−xCrx(PO4)3 with the substitution degree x = 0.5 are identified as a mixture of triclinic LISICON and orthorhombic SW types, while with higher substitution range with x = 1 and 1.5—orthorhombic SW type.

In general, the main processes taking place in the studied reaction mixtures are schematically presented in Fig. 2, where the molar interrelations between the mixture components are ignored.

General description of the process taking place in the reaction mixtures of (0.5 + x/2)Li2CO3–(2 − x)ZrOCl2·8H2O–(x/2)Cr2O3–3(NH4)2HPO4 during heating (* indicates unreacted (NH4)2HPO4 remaining after interaction with ZrOCl2·8H2O which takes place in molar ration 1:2; thus, unreacted (NH4)2HPO4 remains only in the mixtures with Zr/P < 0.5 (x > 0.5); ** indicates the residue of Li2CO3 (> 275 °C) which disappeared under prolonged heating)

In addition, it is interesting to note, that in one of the previous studies it was reported, that during heating of the related mixtures, uncontrolled lithium losses and deviation from stoichiometry were observed [21]. Instead of ZrOCl2·8H2O with (NH4)2HPO4, the authors of this publication used less reactive Zr(HPO4)2·H2O. It can be the reason why we did not observed this phenomenon in our study: mainly due to high reactivity of the both reagents used in our study, the reaction involving lithium carbonate takes place at lower temperature, also Li oxide is immediately transformed into phosphate that prevents its losses at higher temperatures.

Conclusions

Thermal transformation of the reaction mixture of (0.5 + x/2)Li2CO3–(2 − x)ZrOCl2·8H2O–(x/2)Cr2O3–3(NH4)2HPO4 was studied with the purpose to find out the mechanism of the formation of solid solutions of Li1+xCrxZr2−x(PO4)3. It is shown that the mechanism of interaction in the mixtures highly depends on the ratio between the ZrOCl2·8H2O and (NH4)2HPO4 component, and with increase in substitution degree x from 0 to 2 it changes dramatically. In particular, in the mixtures with x = 0 and 0.5, the dominant interaction between ZrOCl2·8H2O and (NH4)2HPO4 leading to the formation of NH4Cl, NH4H2PO4 and ZrO2 determines their thermal behaviour. With increase of x to 1 and 1.5 the indicated process becomes less dominant while unreacted amount of (NH4)2HPO4 is increased and the corresponding effect of elimination of its ammonia becomes more and more prominent. The mixture with x = 2 can be characterised with typical behaviour of the mixtures of (NH4)2HPO4 with oxides or carbonates. Thus, it can be concluded, when both ZrOCl2·8H2O and (NH4)2HPO4 are present in the reaction mixture, the interaction between these two components became the dominant feature of the thermal transformation, while other processes play the minor role.

References

Gorodylova N, Kosinová V, Šulcová P, Bělina P, Vlček M. Cr1/3Zr2P3O12 with unusual tetrahedral coordination of Cr(III): peculiarities of the formation, thermal stability and application as a pigment. Dalton Trans. 2014;43(41):15439–49.

Gorodylova N, Kosinová V, Dohnalová Ž, Bělina P, Šulcová P. New purple-blue ceramic pigments based on CoZr4(PO4)6. Dyes Pigm. 2013;98:393–404.

Oikonomou P, Dedeloudis Ch, Stournaras CJ, Ftikos C. [NZP]: a new family of ceramics with low thermal expansion and tunable properties. J Eur Ceram Soc. 2007;27:1253–6.

Zhang Y, Chen K, Shen Y, Lin Y, Nan C-W. Enhanced lithium-ion conductivity in a LiZr2(PO4)3 solid electrolyte by Al doping. Ceram Int. 2017; ahead of print.

Mutter D, Urban DF, Elsaesser Ch. Systematic search for lithium ion conducting compounds by screening of compositions combined with atomistic simulation. MRS Adv. 2017;2(9):483–9.

Orlova AI. Isomorphism in d-and f-element phosphates having framework crystal structure and crystallochemical conception of NZP matrix for radionuclide immobilisation. Czech J Phys. 2003;53A:649–55.

Wang T, Yu Q, Kong J, Wong Ch. Synthesis and heat-insulating properties of yttria-stabilized ZrO2 hollow fibers derived from a ceiba template. Ceram Int. 2017;43(12):9296–302.

Xiao L, Xu L-F, Hua K-H, Shui A-Z. Preparation of Al2O3–ZrO2 composite nanopowders by co-precipitation method. J Synth Cryst. 2015;44(10):2751–5.

Thananatthanachon T. Synthesis and characterization of a perovskite barium zirconate (BaZrO3): an experiment for an advanced inorganic chemistry laboratory. J Chem Educ. 2016;93(6):1120–3.

Zhao D, Deng X, Ding Z, Wang H, Ma G. Intermediate temperature ionic conduction in Mg2+-doped ZrP2O7 ceramics. Solid State Ion. 2012;229:33–7.

Gorodylova N, Šulcová P, Bosacka M, Filipek E, Vlček M. Heterovalent Zr4+–Cu2+ substitution in zirconium pyrophosphate: from theoretical models to synthesis and utilisation. J Eur Ceram Soc. 2015;35:4293–305.

Tao X, Xiang Zh, Zhou Sh, Zhu Y, Qiu W. Synthesis of a soluble preceramic polymer for ZrC using 2-hydroxybenzyl alcohol as carbon source. Adv Appl Ceram. 2016;115(6):342–8.

Liu Y, Geng R, Cui Y, Peng S, Chang X, Han K, Yu M. A novel liquid hybrid precursor method via sol-gel for the preparation of ZrB2 films. Mater Des. 2017;128:80–5.

Patra N, Nasiri NA, Jayaseelan DD, Lee WE. Synthesis, characterization and use of synthesized fine zirconium diboride as an additive for densification of commercial zirconium diboride powder. Ceram Int. 2016;42(8):9565–70.

Guo Ch. Preparation and applications of kaolin ZrO2/ZnO loaded photo-catalytic functional materials. Mater Res Appl. 2015;9(3):162–5.

Bhattacharyya KG, Sen Gupta S. Adsorption of Fe(III), Co(II) and Ni(II) on ZrO-kaolinite and ZrO-montmorillonite surfaces in aqueous medium. Colloids Surf A Physicochem Eng Asp. 2008;317(1–3):71–9.

Nikoofar K, Khademi Z. A review on green Lewis acids: zirconium(IV) oxydichloride octahydrate (ZrOCl2·8H2O) and zirconium(IV) tetrachloride (ZrCl4) in organic chemistry. Res Chem Intermed. 2016;42(5):3929–77.

Gorodylova N, Šulcová P, Bosacka M, Filipek E. DTA–TG and XRD study on the reaction between ZrOCl2·8H2O and (NH4)2HPO4 for synthesis of ZrP2O7. J Therm Anal Calorim. 2014;2014(118):1095–100.

Gorodylova N, Kosinová V, Šulcová P. Interrelations between composition, structure, thermal stability, and chromatic characteristics of new NASICON-related solid solutions of Li1+x Cr x Zr2−x (PO4)3. Ceram Int. 2017;. doi:10.1016/j.ceramint.2017.07.135.

Kim JW, Lee HG. Thermal and carbothermic decomposition of Na2CO3 and Li2CO3. Metallurg Mater Trans B. 2001;32:17–24.

Stenina IA, Velikodnyi YuA, Ketsko VA, Yaroslavtsev AB. Synthesis of NASICON-type lithium zirconium phosphate. Inorg Mater. 2004;40:967–70.

Acknowledgements

The authors would like to thank for the financial support to Grant Agency of Czech Republic (No. 16-06697S).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gorodylova, N., Šulcová, P. DTA–TGA and XRD study of the formation of LISICON-type Li1+xCrxZr2−x(PO4)3 ceramic using ZrOCl2·8H2O as precursor. J Therm Anal Calorim 133, 405–411 (2018). https://doi.org/10.1007/s10973-017-6736-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6736-z