Abstract

The aim of this work has been the assessment of the thermo-oxidative, hydrothermal and crystalline zone stabilities of several leather samples taken by the conservators from a military coat dated sixteenth–seventeenth centuries, belonging to the History Museum of Braşov—Romania. For this purpose, the thermo-gravimetry/derivative thermo-gravimetry (TG/DTG), differential scanning calorimetry (DSC) and micro hot table (MHT) methods have been employed. The thermo-oxidative damage of leather has been characterized by the rate of the first thermo-oxidation process highlighted in TG/DTG curves recorded in static air atmosphere. The hydrothermal denaturation of leather has been characterized by MHT method and DSC analysis in excess water conditions. The damage of crystalline zone of collagen in leather has been determined by DSC analysis in nitrogen flow. The qualitative damage for each leather sample and each kind of deterioration has been evaluated using the criteria resulted by thermal analysis of a large number of collagen-based materials (pure collagens, new and old parchments and leathers). The obtained results could facilitate the choice of the restoration and conservation procedures applicable for the investigated military coat.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The animal skin products (clothing, footwear, furniture, upholstery, storage vessels, writing support, book bindings, etc.) have been useful materials since the dawn of human history. Tanning has been described as man’s first manufacturing process [1].

Museums, libraries, archives and religious institutions preserve significant collections of leather and parchment objects with historic, artistic and documentary value. It is therefore vital to ensure their longevity.

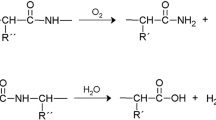

Deterioration of collagen-based materials (parchment and leather) appears at all levels of structural hierarchy (from molecular to microscopic levels) and can be categorized as: chemical damage due to oxidation, environmental chemical pollutants such as NO x and SO2, hydrolysis, photochemical degradation; physical–mechanical damage due to frequent stretching and shrinkage of the material that appear when fluctuations in relative humidity occur; biological damage induced by bacteria, fungi, insects, molds. The investigation of collagen-based materials deterioration is very important for conservators involving some problems, including the achievement of suitable preservation and restoration of historical objects.

The development of the analytical techniques improves the procedure to identify the patrimonial objects made from leathers as well as the methods to highlight the impact of environmental factors on them. Among these techniques, the thermal analysis methods, especially thermo-gravimetry (TG) [2–7], differential thermal analysis (DTA) [5], differential scanning calorimetry (DSC) [2, 6–13], thermo-mechanical analysis (TMA) and dynamic mechanical analysis (DMA) [2, 11, 12, 14–17], and micro hot table (MHT) [2, 6, 13, 18–22] are potentially useful to conservation scientists.

In this work, we will focus on the application of TG/DTG, DSC and MHT methods for assessment of hydrothermal stability, crystalline zone deterioration and thermo-oxidative deterioration of several leather samples taken by conservators from a military coat dated sixteenth–seventeenth century belonging to the History Museum of Braşov—Romania.

The applied criteria for the damage assessment of old leathers

In some previous papers [3–6, 10, 11], the results obtained by thermal analysis of some collagen-based materials (sorts of collagen, new and old parchments and leathers) were presented and discussed. The comparison of the results led to some qualitative criteria of degradation level of vegetable tanned leathers which will be briefly presented below.

Stability at thermo-oxidation

The TG/DTG analyses performed in air static atmosphere show [3–6] that the degree of thermo-oxidative degradation of a collagen-based material is characterized by the rate of the first process of thermo-oxidation put in evidence in non-isothermal conditions. The analysis of the obtained data shows that two main complex processes occur during the natural aging of leathers by decomposition, hydrolysis, oxidation and/or biological damage, namely the breaking of cross-linking bonds resulted by tanning of native leathers, and the splitting off of collagen macromolecules. When the breaking of cross-linking bonds is prevalent, the rate of the first process of thermo-oxidation of natural aged leather highlighted in DTG curve is between the rates corresponding to new and old parchments and those corresponding to new leathers manufactured by vegetable tanning. A higher deterioration of old leather consisting in splitting off of collagen macromolecules determines the increase in thermo-oxidative rate to a value higher than those corresponding to new leathers manufactured by vegetable tanning. These statements led to the qualitative criteria of degradation level of vegetable tanned leathers given in Table 1.

Hydrothermal stability

MHT and DSC analyses were performed in water excess [10] for determination of the shrinkage temperature (T s). For natural aged leathers, T s exhibits values comparable with those of parchments, but lower than those corresponding to new leathers manufactured by vegetable tanning. This could be explained by the process of breaking of cross-linking bonds, which occurs during natural aging. The obtained results led to the qualitative criteria of degradation level of vegetable tanned leathers listed in Table 1.

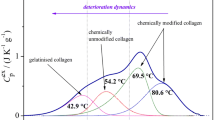

Crystalline zone stability

The DSC analyses of collagen-based materials, performed in nitrogen flow [10] show a melting process that occurs in the temperature range 200–240 °C. The temperature value of the DSC peak corresponding to this process (T m) is the melting temperature of the crystalline zone and characterized the deterioration by natural aging of this zone [10]. For natural aged leathers, T m exhibits values between those corresponding to parchments and to new vegetable tanned leathers. The obtained results led to the qualitative criteria of degradation level of vegetable tanned leathers listed in Table 1.

Experimental

Materials

Six leather samples were taken by conservators from different places of an oriental military coat dated sixteenth–seventeenth century belonging to the History Museum of Braşov—Romania (Figs. 1, 2). The leather coat is made of skins of different qualities. The collar is from sheep leather and exhibits orange ornaments made from lamb or untanned sheep leather. The sleeves are from bovine leather with thick structure that was tanned with vegetable extracts. The front of coat is decorated with sheep leather and parchment. The cuffs are from sheep leather. The piece has undergone repair interventions during which the interior was almost completely doubled with goat leather pieces bound together and the heavily degraded areas were covered with pieces of leather of various qualities, using a yellow–brown adhesive which had degraded over time. Based on the visual assessment made by conservators, the military coat is well preserved.

The investigated leather samples of the military coat are presented in Table 2.

Thermal analysis

For thermal characterization of leathers, the following techniques were used: TG/DTG, DSC and MHT.

TG/DTG analyses were performed with STA 409PC Luxx apparatus produced by Netzsch, Germany, in static air atmosphere, in the 20–600 °C temperature range, at a heating rate of 10 K min−1. The mass of analyzed samples was in the range 4–6 mg, and the heating of each sample was performed in a cylinder shape α-Al2O3 sample holder.

The following kinds of DSC measurements were performed by using DSC 204 F1 Phoenix apparatus produced by Netzsch, Germany:

-

DSC analysis of the sample (1–5 mg) immersed in water (35 μL deionized water), hermetically sealed in an aluminum pan and stocked for 24 h. Each sample was heated from 25 to 110 °C, at a heating rate of 10 K min−1.

-

DSC analysis of the sample (1–5 mg) in nitrogen flow (nitrogen purity was 99.999 %; 20 mL min−1), in an open aluminum pan, at the heating rate of 10 K min−1 and the temperature range 25–260 °C.

MHT analyses were performed with homemade equipment made of a CALORIS hot table controlled by a temperature processor and coupled with a Leica S4E stereomicroscope. The magnification used was 40×. A sample of about 10–15 fibers was thoroughly wetted with deionized water for 10 min on a microscope slide. The fibers were then separated under the microscope using needles, covered with a second microscope slide, placed on the hot table and heated with a 2 °C min−1 rate. A FLTK. 1.1.X homemade software was used for data collection. The shrinkage activity of collagen fibers is monitored, taking into account the following ranges [19, 20]:

-

A 1 and A 2—shrinkage activity is noticed in individual fibers (T first is the temperature at which the first contraction occurs and coincides with the start of A 1 interval, while T last is the temperature to which the last contraction occurs and marks the end of the A 2 interval);

-

B 1 and B 2—the contraction of a fiber is immediately followed by the contraction of another fiber;

-

C—the main shrinkage interval during which most collagen fibers shrink (shrinkage temperature—T s marks the beginning of this interval).

Shrinkage intervals occur in the following order:

Results and discussion

The thermo-oxidative deterioration, hydrothermal stability and crystalline zone deterioration of the leather samples taken from military coat mentioned in Table 3 were determined by TG/DTG, DSC and MHT methods and the criteria given in Table 1 were applied for estimation of their qualitative deterioration levels.

Stability at thermo-oxidation

The TG and DTG curves obtained for the sample 3 extracted from military coat are shown in Fig. 3; similar curves were obtained for all analyzed samples as well as for all kinds’ collagen-based materials which were analyzed for obtaining the deterioration criteria given in Table 1. The non-isothermal degradation of the leather occurs through three processes accompanied by mass losses. In the first process, denoted by I in Fig. 3, which occurs at <150 °C, the water contained by material was evolved. The next two steps, denoted by II and III in Fig. 3, consist in pyrolytic thermo-oxidation and decomposition of the material.

It was pointed out [3–6] that the main characteristic parameter, which could be correlated with the leather damage is the rate (\( - \frac{{{\text{d}}\%\Delta m}}{{{\text{d}}t}} \)) of the first process of thermo-oxidation (process II in Fig. 3), at 310 °C (the average temperature of DTG minimum obtained for the collagen-based materials, which were analyzed in air at 10 K min−1 for obtaining the qualitative degradation criteria given in Table 1). Table 3 lists also the qualitative degree of degradation of each analyzed sample. The inspection of this table shows:

-

Samples 1, 2, 3 and 6 exhibit high degree of thermo-oxidative degradation consisting mainly in splitting off of cross-linking bonds as a result of natural aging.

-

Sample 5 exhibits a good conservation. This means the natural aging of this sample does not determine the destruction of the sites of material that are active in oxidation.

-

Sample 4 exhibits a relatively high value of V 310. This is recent vegetable tanned leather and has a relatively high cross-linking degree.

Hydrothermal stability

The hydrothermal stability is characterized by the shrinkage temperature (T s), which was determined by MHT and DSC methods.

The values of the temperature at which the first contraction occurs (T first) and shrinkage temperature (T s) determined by MHT method are listed in Table 3. A strong correlation between these temperatures was found (Fig. 4). A similar dependence was also obtained by Larsen et al. [21] for parchments.

Figure 5 shows the DSC curve for the sample 4 extracted from military coat, immersed in water, which exhibits an extrapolated onset temperature (T onset) of 60.4 °C and a peak temperature (T min) at 64.4 °C; similar DSC curves were obtained for all analyzed leather samples. Extrapolated onset temperature could be influenced by the base line applied to thermograms. However, the DSC curves obtained for numerous leathers and parchments [6, 10] exhibit a linear region in the temperature range T onset–10 °C–T onset, and therefore, T onset can be determined with an accuracy of ±0.3 °C. On the other hand, it was pointed out [6, 10] that the value of T onset, and not the value of T min, is practically equal with the value of shrinkage temperature (T s) that is a marker of deterioration. The linear correlation between T onset and T min (Fig. 6) shows that T min could be also used as marker of deterioration. This linearity will be checked for some sorts of parchments and leathers in a future work. One notes that the value of enthalpy cannot be used as a marker of deterioration because the value of this quantity is reported to 1 g of leather that is a complex material for which we do know the quantitative composition. The values of T onset and T min as well as the corresponding qualitative deteriorations of the analyzed samples are listed in Table 3.

The inspection of Table 3 shows:

-

There is a good agreement between the values of T s determined by MHT method and T onset determined by DSC method.

-

Different samples of old leathers (samples 1, 2, 3, 5 and 6) exhibit different deteriorations.

-

As is expected, the sample 4 exhibits a relatively high value of shrinkage temperature.

Crystalline zone stability

DSC curves associated with thermal transitions which typically occur in parchment and leather samples measured in open crucibles and gas flow display a broad endothermic peak followed by one or two smaller endotherms (Fig. 7). The samples 2 and 3 exhibit DSC curves similar to those from Fig. 7a, while the samples 3 and 7 exhibit DSC curves similar to those from Fig. 7b. The broad peak in the temperature range (50–120) °C is associated with thermal dehydration. The first endotherm at T m(1) ≈ 170 °C was related to collagen matrix thermal denaturation [6, 10], whereas the second peak at T m(2) > 190 °C was ascribed to melting of the crystalline collagen zone embedded in the amorphous matrix [10]. The temperature T m(2) is characteristic parameter for deterioration of the crystalline zone [6, 10]. The values of these temperatures as well as the corresponding qualitative deteriorations for the investigated samples are listed in Table 3.

The inspection of this table shows:

-

The old leathers (samples 1, 2, 3, 5 and 6) exhibit high degree of deterioration of the crystalline zone.

-

The DSC curve obtained for sample 4 does not exhibit a melting peak. This is explained by the high degree of cross-linking of this leather that determined the overlap of melting process with the first process of thermo-oxidation.

Conclusions

A multi-scale investigation was performed to characterize degradation and evaluate damage of a military coat dated sixteenth–seventeenth centuries belonging to History Museum of Braşov—Romania. The coat is a complex object with collar manufactured from sheep leather, the inner sleeve—from bovine leather, and front and back—from goat leather. Six different micro-samples of leather extracted from each of these parts of coat were analyzed by TG/DTG, DSC and MHT methods. The characteristic non-isothermal parameters of thermo-oxidation, denaturation in excess water and melting of crystalline zone were determined, and the qualitative criteria for assessment of thermo-oxidative deterioration, hydrothermal stability and crystalline zone deterioration were applied. Differences between the degradation levels of investigated old samples could be attributed to different degree of splitting of cross-linking bonds as a result of natural aging.

The obtained results could be used for finding the best possible procedures for preservation and/or restoration of the investigated heritage object.

References

Forbes RJ. Studies in ancient technology, vol. V. Leiden: Brill Academic Publishers; 1966. p. 22.

Odlyha M. The application of thermoanalytical techniques to the preservation of art and archaeological objects. In: Brown ME, Gallager PK, editors. Handbook of thermal analysis and calorimetry, Chap. 2, vol. 2. Amsterdam: Elsevier; 2009.

Budrugeac P, Miu L, Bocu V, Wortmann FJ, Popescu C. Thermal degradation of collagen-based materials that are supports of cultural and historical objects. J Therm Anal Calorim. 2003;72:1057–65.

Budrugeac P, Miu L, Popescu C, Wortmann FJ. Identification of collagen-based materials that are supports of cultural and historical objects. J Therm Anal Calorim. 2004;74:75–85.

Budrugeac P, Miu L, Soukova M. The damage in the patrimonial books from Romanian libraries. Thermal analysis methods and scanning electron microscopy. J Therm Anal Calorim. 2007;88:693–9.

Budrugeac P, Cucos A, Miu L. The use of thermal analysis methods for authentication and conservation state determination of historical and/or cultural objects manufactured from leather. J Therm Anal Calorim. 2011;104:439–50.

Budrugeac P, Cucos A, Miu L. Use of thermal analysis methods to asses the damage in the book bindings of some religious books from XVIII century, stored in Romanian libraries. J Therm Anal Calorim. 2014;116:141–9.

Chahine C. Acid deterioration of vegetable tanned leathers. In: Calcan C, Haines B, editors. Leather, its composition and changes with time. Northampton: The Leather Conservation Centre; 1991. p. 75–87.

Chahine C. Changes in hydrothermal stability of leather and parchment with deterioration: a DSC study. Thermochim Acta. 2000;365:101–10.

Budrugeac P, Miu L. The suitability of DSC method for damage assessment and certification of historical leathers and parchments. J Cult Herit. 2008;9:146–53.

Cucos A, Budrugeac P, Miu L, Mitrea S, Sbarcea G. Dynamic mechanical analysis (DMA) of new and historical parchments and leathers. Correlations with DSC and XRD. Thermochim Acta. 2011;516:19–28.

Cucos A, Budrugeac P, Miu L. DMA and DSC studies of accelerated aged parchment and vegetable-tanned leather samples. Thermochim Acta. 2014;583:86–93.

Carşote C, Budrugeac P, Decheva R, Haralampiev NS, Miu L, Badea E. Characterization of a Byzantine manuscript by infrared spectroscopy and thermal analysis. Rev Roum Chim. 2014;56:429–36.

Cohen NA, Odlyha M, Foster G. Measurement of shrinkage behaviour in leather and parchment by dynamic mechanical thermal analysis. Thermochim Acta. 2000;365:111–7.

Odlyha M, Foster GM, Cohen NS, Larsen R. Characterisation of leather samples by non-invasive dielectric and thermomechanical techniques. J Therm Anal Calorim. 2000;59:587–600.

Jeyapalina S, Attenburrow GE, Covington AD. Investigation of leather drying by dynamic mechanical thermal analysis (DMTA). J Soc Leather Technol Chem. 2007;91:102–7.

Cucos A, Budrugeac P. The suitability of DMA method for the characterization of recent and historical parchments and leathers. Int J Conserv Sci. 2010;1:13–8.

Larsen R, Vest M, Nielsen K. Determination of hydrothermal stability (shrinkage temperature) of historical leather by the Micro Hot Table technique. J Soc Leather Technol Chem. 1993;77:151–6.

Larsen R, Vest M, Nielsen K. STEP leather project—protection and conservation of european cultural heritage. Research report no. 1, 1994, pp. 151–164.

Larsen R. Experiments and observations in the study of environmental impact on historical tanned leathers. Thermochim Acta. 2000;365:85–99.

Larsen R, Sommer PDV, Axelsson KM. Scientific approach in conservation and restoration of leather and parchment objects in archives and libraries. In: Engel Patricia, Schirò Joseph, Larsen René, editors. New approaches to book and paper conservation—restoration. Elisaveta Moussakova and Isván Kecskeméti: Horn/Wien Verlag Berger; 2011. p. 239–55.

Vest M. White tawed leather—aspects of conservation. Preprint of ninth International Congress IADA, Copenhagen, August 15–21, 1999.

Acknowledgements

The work was supported by the Romanian National Authority for Scientific Research, CNCS—UEFISCDI research projects—Intelligent System for Analysis and Diagnosis of Collagen-Based Artefacts (COLLAGE, PNII 224/2012) and Intelligent System for Movable Cultural Heritage Monitoring in a Changing Environment (INHERIT, PN II 325/2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Budrugeac, P., Carşote, C. & Miu, L. Application of thermal analysis methods for damage assessment of leather in an old military coat belonging to the History Museum of Braşov—Romania. J Therm Anal Calorim 127, 765–772 (2017). https://doi.org/10.1007/s10973-016-5343-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5343-8