Abstract

The number of renewable-resource-based and inherently biodegradable poly(lactic acid) (PLA) products is growing in the market, resulting in an increasing demand to produce even small series of injection-molded PLA prototypes for testing purposes by using rapid molds. In our research, it was first demonstrated that it is possible to use epoxy-based molds made by PolyJet Rapid Prototyping technology for conventional injection molding to produce small series of PLA parts. The effect of mold material, namely conventional steel mold and epoxy-based PolyJet mold, was analyzed on the thermal and mechanical properties of the injection-molded products. PLA was used with no, moderate and high nucleating agent contents [talc and poly(ethylene glycol)] to obtain a model material with slow, moderate and high crystallization rates, respectively. It was demonstrated that the mold used and thus the thermal conductivity of the mold had significant effect on the crystallinity of the PLA parts and thus on its mechanical and thermomechanical properties. Finally, it was found that it is possible to mimic the thermomechanical properties of nucleated PLA injected into hot mold used for mass production by injecting it into the epoxy-based PolyJet mold used for small series production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As the rapid prototyping (RPT) or additive manufacturing (AM) technologies appeared on the market, the time for a product to reach the consumers significantly decreased, since these technologies assist simultaneous product design [1, 2]. Nowadays, the fluid-based AM technologies are the most spread, like Stereolithography (SLA) or PolyJet technologies, which apply typically curable polymers or like Fused Deposition Modeling (FDM) technology, which uses thermoplastic polymers in molten state. PolyJet implies one of the most accurate and versatile AM technologies with a layer thickness of only 16–30 and the possibility of using multicomponent manufacturing in the same step. During manufacturing with PolyJet technology, a light-sensitive polymer is sputtered onto the worktable and cured, thus solidified by using UV light and, finally, layer by layer, the prototype is built. In recent years, much research has been devoted to make prototypes with the same material and same technology as the latter products made by mass production (production intent material) to be able to perform functionality tests on the prototypes. Since one-third of the polymer parts are produced by using injection molding, where the most expensive phase is the manufacturing of the mold, thus the highest demand to produce prototypes came from this field. In order to produce prototypes by using injection molding, a solution is needed to dramatically reduce the costs of the mold manufacturing. This possibility is the rapid tooling technology (RT), where the main objective is to manufacture rapid tools, which corresponds in functionality to the molds manufactured by conventional machining from steel, but differ by its material and production [3, 4]. Recently, it was proved that it is possible to use PolyJet technology even to make rapid molds for injection molding to produce low series of prototypes.

Nowadays, due to environmental consciousness reasons, the need for bio-based and inherently biodegradable polymers (or biopolymers in short) has increased [5, 6], meaning that there is a growing demand to use biopolymer products as prototypes even for testing purposes before the final product enters the market. Making and testing of the prototypes are especially important in case of the biodegradable polymers to be able to predict the duration of applicability. Accordingly, there will be increasing number of attempts to injection-mold biopolymers into rapid molds for producing prototypes with the same processing technology and same material than in future production supporting product design, product analysis especially for time-dependent properties and future mass production of the given part. This injection molding into rapid mold technique can even be used to produce a small series of a unique product like biodegradable and at the same time bioabsorbable implants for instance for the medical industry (hard tissue repair) [7–10], since the geometry of these parts may highly vary in this field. Currently, one of the most promising biopolymers is poly(lactic acid) (PLA), which is a semicrystalline thermoplastic polyester [11]. It can be produced by its two enantiomers, namely l-Lactic Acid or d-Lactic Acid or their dimers called l-lactide or d-lactide from the fermentation of starch containing agricultural plants such as corn (maize), wheat, rice and potato. The d-lactide content modifies most importantly the crystallization and degradation properties; thus, PLA was commercialized with 0.5–12 % d-lactide content depending on the application. For instance, to achieve best crystallization rate low d-lactide, while for low degradation time (medical implants) high d-lactide content (50 m%) is used. Unfortunately, PLA has slow crystallization rate even at low d-lactide content compared to petrol-based semicrystalline polymers [12] and also has low glass transition temperature (T g) around 50 °C resulting in retarded usage in elevated heat applications. The case is even worse in injection molding conditions, where typically high cooling rate is applied giving almost no possibility for PLA to crystallize from melt [13]. Barrau et al. [14] measured by Differential Scanning Calorimetry (DSC) that a conventional PLA (4042D, NatureWorks, 4.3 % d-lactide content) has only a few percent of crystallinity when cooled over 5 °C min−1. As a result, even though PLA is a semicrystalline polymer, most injection-molded PLA products are almost totally amorphous (crystallinity is around 1–3 %) and thus transparent. In the last decade, much effort has been devoted to find effective nucleating agents for PLA to widen its applications, since highly crystalline PLA with a crystallinity of 40–50 % has a heat deflection temperature (HDT) of over 100 °C, while amorphous PLA has a HDT of only ~50 °C around its T g.

Numerous nucleating agents were tested, and some of them were found very effective in nucleating PLA including zinc phenylphosphonate (PPZn) [15, 16], zinc citrate complex (ZnCC) [17], talc [18, 19], hydrazide compounds [20, 21], orotic acid [22], ethylene-bis-stearamide (EBS) [23], p-tert-butylcalix [8] and arene recrystallized from ethyl benzene (TBC8-eb) [24] to name a few. Moreover, the combination of nucleating agents and plasticizers were found to be more effective, since nucleating agents have their greatest impact at elevated temperatures where homogeneous nucleation is weak, while plasticizers [25] have their greatest impact on the lower-temperature regions, where crystallization is hindered by the lack of chain mobility [26]. One example is the joint usage of the rather cheap additives talc and poly(ethylene glycol) (PEG), which allows fast crystallization [27, 28]. Another possibility to highly increase crystallinity of PLA and thus its HDT is the 50–50 m% blending of optically pure PLLA and PDLA produced entirely by using l-lactide and d-lactide, respectively, to develop stereocomplex crystalline structure [29, 30]. Although this crystalline structure improves PLA with a HDT value of even 150 °C, the cost of producing PDLA is the bottleneck of this technology, since during fermentation almost entirely l-Lactic acid is generated making the price of d-Lactic Acid and PDLA high. Accordingly, by using either nucleating agents or stereocomplexation, the crystallization rate of PLA could be highly enhanced; however, during injection molding conditions due to the very high cooling rate, it is still challenging to develop high crystallinity. By using the generally applied cold mold (20–25 °C) to injection-mold nucleated PLA, in most cases, a PLA product with still too low crystallinity develops not enough for significantly increasing HDT. At the same time, hot mold (80–120 °C) can be used to lower the cooling rate and to crystallize the part within the mold if necessary [27, 28] by applying some sort of in-mold-annealing time as an extending of the cooling time. Although this annealing time or crystallization time increases the overall cycle time depending on the efficiency of the applied nucleating agents, but at least crystallinity can be controlled and highly crystalline PLA parts, and thus, PLA parts with high HDT (>100 °C) can be produced. Subsequently, the thermal conductivity of the mold and thus the extent of abstraction of heat from the part to the mold highly influence crystallinity and other material properties. There are only a few papers found in this field [31, 32], where the mold thermal conductivity was analyzed, but in most cases not on the crystalline structure but on mechanical properties [31] or warpage [32] of the final parts. Although the difference in thermal conductivity and heat transfer between a steel and PolyJet mold may not have a significant effect on polymers with fast crystallization rate such as polypropylene (PP) or high-density polyethylene (HDPE), it might have huge effect on the properties of polymers with low or moderate crystallization rate polymers such as PLA and nucleated PLA, respectively.

Since there are currently no scientific papers found in the literature dealing either with the injection molding of PLA into epoxy-based PolyJet molds to produce prototypes or with the differences in properties of the final part caused by the different thermal conductivity of these molds, thus in our work, pure PLA and nucleated PLA (with talc and PEG) were injected into epoxy-based Rapid Prototyped PolyJet mold as well as conventional steel mold (P20) and the effect of the difference in thermal conductivity of the two mold materials was investigated on the mechanical, thermal and thermomechanical properties of the final PLA product.

Experimental

Materials

Injection molding-grade PLA type 3052D from NatureWorks (Minnetonka, MN, USA) was used for the research with a d-lactide content of around 4 %. 3052D PLA has a density of 1.24 g cm−3, a glass transition temperature of 55 °C, a melting temperature of 145 °C and a melt flow index of 14 g 10 min−1 (at 210 °C, with 2.16 kg load). Talc particles were purchased with a mean value of 0.65 μm (type HTPultra5 from IMI Fabi Ltd., Italy). Poly(ethylene glycol) (PEG) was obtained from Molar Chemicals Ltd. (Hungary) with a molar mass of 1500 g mol−1.

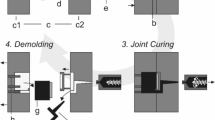

Rapid mold production

The rapid mold (mold cavity) was produced as the copy of an already existing steel mold by using a Connex 500 PolyJet machine with 16 μm layer thickness and RGD515 (“ABS like”) epoxy-acrylic photopolymer (UV curable) compound. Printing time was around 10 h followed by a post-heat-treatment to finalize curing and to increase heat deflection temperature above 100 °C. The post-heat-treatment consisted of increasing the temperature of the whole mold block gradually up to 100 °C and maintaining this temperature for 1 h. Both PolyJet mold and conventional steel mold used for the injection molding are cold runner molds with film-gate and 2 cavities capable of producing 80 × 80 mm area, 2-mm-thick flat specimens (Fig. 1).

Material preparation and processing

A LabTech Scientific twin-screw extruder (screw diameter = 26 mm, L/D = 40) was used for compounding PLA with talc and PEG by using zone temperatures of 175–180–185–190 °C from the hopper to the die and a screw rotational speed of 30 rpm. PLA was dried at 120 °C for 6 h prior to processing to avoid hydrolytical degradation. Besides pure PLA, two nucleated PLA compounds were extruded, namely PLA with 10 m% talc and 10 m% PEG as well as PLA with 20 m% talc and 10 m% PEG content. These three materials represent model materials with slow (pure PLA), moderate (10 m% talc and 10 m% PEG) and high (20 m% talc and 10 m% PEG) crystallization rate. The extrudates were pelletized and cold-crystallized at 100 °C for one hour to avoid pellet sticking caused injection molding problems as it was reported in our previous publication [13]. An Arburg Allrounder 370S 700-290 injection molding machine was used for specimen production equipped with a diameter 30 mm, L/D = 25 screw. Flat specimens with an area of 80 × 80 mm and a thickness of 2 mm were injection-molded by using an injection rate of 50 cm3 s−1, a holding pressure of 300 bars, a holding time of 20 s, a residual cooling time of 60 s and a melt temperature of 190 °C. Two different mold materials, P20 steel and RGD515 (“ABS like”) epoxy-acrylic photopolymer, were used to be able to analyze the effect of mold material and thus the heat transfer from the polymer melt to the mold. In order not to damage the PolyJet mold, only low clamping force (250 kN) was used also for the steel mold to keep the comparability. In case of the PolyJet mold, since its temperature cannot be controlled by simple cooling channels widely used in steel molds, room temperature mold (23 °C) was used. In every case, the next cycle of injection molding into the PolyJet mold only took place when the mold reached room temperature. By using steel mold, two different mold temperatures were used, namely 23 and 90 °C.

23 °C steel mold was used to mimic the initial thermal conditions making it comparable with PolyJet mold, while 90 °C steel mold was used to develop the possible maximum crystallinity, since nucleated PLA is usually injected into “hot” mold to develop significant crystallinity in case of industrial injection molding production. Accordingly, 8 types of specimens were injection-molded due to three materials (pure PLA, two kinds of nucleated PLA), three mold setups (23 and 90 °C steel mold, 23 °C PolyJet mold) and the fact that pure PLA was not injection-molded into 90 °C mold (it was not able to crystallize within this cycle time, and thus, it was rejected from the measurements). The abbreviation used to distinguish the specimens is xTyP_z°C_q, where x is the talc content/m%, y is the PEG content/m%, z is the mold temperature/°C and q is the type of mold used (S for steel and P for PolyJet). Accordingly, 20T10P_23 °C_S means a 20 m% talc and 10 m% PEG content PLA injection-molded into a 23 °C steel mold. Pure PLA specimens were simply abbreviated as PLA_z°C_q.

Methods

To be able to measure the thermal conductivity of the epoxy-based PolyJet mold, an 80 × 80 mm area, 2-mm-thick flat specimen was printed by using the PolyJet technology. Single-specimen hot plate apparatus was used according to the publication of Suplicz et al. [33]. In this equipment, the heat flows in a single direction between the hot plate and the cold plate through the specimen, which is a simpler apparatus than a conventional two specimens. The more detailed structure of this equipment is described in the cited publication.

Injection molding simulations were performed to be able to investigate the thermal history of the PLA and PLA-based compound injection-molded into 23, 90 °C steel and 23 °C PolyJet mold. Autodesk Moldflow Insight 2015 software was used, and the model of the 80 × 80 mm area, 2–mm-thick flat specimen with cold runner was built and meshed with tetrahedral elements. PLA 3052D model material was selected from the material database, and the processing parameters used were taken from the real injection molding setups. According to the mold properties, the thermal conductivity measurement results of the PolyJet mold were used as an input parameter to simulate the injection molding into the PolyJet mold.

The mechanical properties of the compounds were analyzed by using tensile, flexural and Charpy tests. The tensile and the flexural tests were performed by using a Zwick Z020 universal testing machine (Ulm, Germany) equipped with a Zwick BZ 020/TN2S force measuring cell with a force limit of 20kN using a crosshead speed of 5 mm min−1. The Charpy impact tests were performed on unnotched samples by using a Ceast Resil Impactor (Torino, Italy) impact testing machine equipped with a 15-J impact energy hammer and a DAS8000 data collector unit. All of the tests were performed at room temperature at a relative humidity of 50 ± 10 %.

Differential Scanning Calorimetry measurements were taken on a TA Instruments Q2000 type calorimeter (New Castle, USA) by using 3–6 mg of samples taken from the middle of the cross section of the injection-molded specimens. The samples were tested in nonisothermal mode (heat/cool/heat) from 0 to 180 °C at a cooling rate of 10 °C min−1 to determine glass transition temperature (T g), cold crystallization temperature (T cc), enthalpy of cold crystallization (ΔH cc), melting temperature (T m), enthalpy of fusion (ΔH m) from the heating scan and crystallization temperature (T c), and enthalpy of crystallization (ΔH c) from the cooling scan. Crystallinity was calculated from the first heating scan of the injection-molded specimens by using Eq. (1):

where X/% is the calculated crystallinity, ΔH m/J g−1 and ΔH cc/J g−1 are the enthalpy of fusion and the enthalpy of cold crystallization, respectively, ΔH f/J g−1 is the enthalpy of fusion for 100 % crystalline PLA (93.0 J g−1 [19]) and α/− is the mass fraction of the sum of the additives (talc and PEG).

Dynamic Mechanical Analysis was performed on a TA Instruments type Q800 tester (New Castle, USA) by using the injection-molded flexural specimens. Dual cantilever layout was used to be able to gain storage modulus information above glass transition temperature (T g). A heating rate of 2 °C min−1 was used from 0 to 160 °C with a span length of 35 mm, an amplitude of 20 μm and a frequency of 1 Hz.

Vicat softening temperature tests were performed by using a Ceast 6505/000 HDT analyzer (Torino, Italy). In case of Vicat softening temperature, the applied load was 10 N, and the heating rate was 2 °C min−1. Vicat softening temperature was obtained when the standard loading needle with an area of 1 mm2 reached a penetration depth of 1 mm within the analyzed material.

Finally, wide-angle X-ray diffraction (WAXD) was applied to determine the crystallite size by using a Philips model PW 3710-based PW 1050 Bragg–Brentano parafocusing goniometer using CuKα radiation (λ = 0.15418 nm).

Results and discussion

Thermal conductivity of the molds

According to the measurements, the thermal conductivity of the epoxy-based PolyJet mold material was found to be 0.28 W (mK)−1, which is a typical value for an insulating polymer, while the thermal conductivity of the P20 mold steel material was 20–25 W (mK)−1 (data taken from the literature), representing a thermally conductive material. As it can be observed, there is a two order of magnitude difference between the insulating epoxy-based polymeric and the conductive steel mold materials.

Thermal history of the injection-molded parts by using simulation

The thermal conductivity data of the molds were used in the injection molding simulations to be able to investigate the thermal history of the molded parts (Fig. 2).

As it can be seen when PLA is injection-molded into 23 °C steel mold, it can be cooled quickly below its T g (during 15 s) and thus its ejection temperature due to the high thermal conductivity of the mold. On the contrary, the much lower cooling rate can be observed when PLA is injection-molded into the PolyJet mold opening the possibility for the material to crystallize, since crystallization takes place only above T g and PolyJet mold allows for PLA to stay above T g for 66 s. Finally, by analyzing the temperature of the injection-molded PLA into 90 °C steel mold, it is visible that this temperature can be almost as quickly reached due to the high thermal conductivity of the steel mold as the 23 °C, and only the steady-state temperature is different again opening the possibility for crystallization.

Thermal properties of the injected parts

Prior to injection molding, the crystallization behavior of PLA and the PLA-based nucleated compounds was analyzed upon cooling from melt (Fig. 3).

One can see that during cooling from melt, pure PLA is not likely to crystallize, since there was no exothermic peak found related to crystallization. On the other hand, in case of both 10T10P and 20T10P nucleated PLA compounds, intensive crystallization was found with a peak temperature of around 105 °C for both compounds. This crystallization was so intensive that it was fully completed during cooling represented by a crystalline ratio of 34.3 and 36.1 % for 10T10P and 20T10P compounds, respectively. After analyzing the crystallization of the PLA-based compounds, these materials were injection-molded into 23 and 90 °C steel mold as well as 23 °C PolyJet mold and the crystallinity of these injection-molded samples were analyzed, by investigating the first heating scan related to the thermal history of the specimens (Fig. 4).

In case of pure PLA injected into 23 °C steel mold, a very typical curve can be seen with a T g around 60 °C, a cold crystallization between around 100–130 °C and a melting between around 145–158 °C. During melting, a bimodal peak is found related to the melting of the less ordered α′ crystalline structure as well as its recrystallization into the more ordered α in lower-temperature region (peak at 147 °C), and also related to the melting of α crystalline structure in the higher temperature region (peak at 154 °C). The presence of a significant cold crystallization exothermic peak indicates low crystalline ratio of the injection-molded PLA specimen. When pure PLA was injection-molded into 23 °C PolyJet mold, some changes occurred in the curve compared to the curve of PLA injected into 23 °C steel mold. Namely, after T g and enthalpy, relaxation was found related to aging. Since the only difference between PLA_23 °C_S and PLA_23 °C_P was the mold used, thus the explanation should be looked for in the processing and thermal history of the part. One explanation could be that during the much slower cooling of PLA injected into PolyJet mold compared to steel mold, PLA took more time at elevated temperature (Fig. 2) resulting accelerated aging. Cai et al. [34] analyzed the physical aging of PLA for various aging times and temperatures and found that PLA ages quickly when stored at temperatures near to T g, which was demonstrated by major enthalpy relaxation effect found in their curves. In our work, the other difference found between the curves of PLA injected into steel and PolyJet molds was their melting characteristic since the ratio of the α′ and α crystalline structure changed. This could also be explained by the slower cooling of PLA injected into PolyJet mold, since it had more time to crystallize; moreover, it stayed longer in the crystallization temperature region of >120 °C, where the more ordered α crystalline structure develops [26]. At the same time as it can be seen, the PLA injected into PolyJet mold had very low crystallinity, as indicated by the still significant cold crystallization exothermic peak, but nevertheless, it is still suggested that this minor crystallinity developed during cooling in the PolyJet mold is more likely the ordered α than the less ordered α′.

In case of nucleated PLAs injected into 23 °C steel mold, T g was found to decrease to around 45–50 °C, which is obviously the effect of PEG plasticizer. Moreover, cold crystallization was shifted to lower temperatures and became much more intensive. Although this PLA compound contained high amount of nucleating agent and plasticizer, cold crystallization was still observable, indicating that cold steel mold highly decreased the rate of crystallization of PLA, compared to our previous findings that nucleated PLA could fully crystallize during the DSC scan at a rate of 5 °C min−1 (Fig. 3). It was also found that during melting only the presence of the more ordered α crystalline structure could be detected since the addition of PEG enhanced chain mobility and thus crystallization as well as recrystallization. When nucleated PLA compounds were injection-molded into PolyJet mold, T g was almost not detectable, which is the feature of highly crystalline PLA. This statement that highly crystalline PLA developed during processing is verified by the fact that only a minor or no cold crystallization exotherm was found in case of 10T10P_23 °C_P and 20T10P_23 °C_P compounds, respectively. Moreover, like in the all other cases of nucleated PLA, only the more ordered α crystalline structure developed. Finally, when the nucleated PLA compounds were injection-molded into 90 °C steel mold, cold crystallization was totally absent, indicating that the PLA fully crystallized during processing. The crystallinity of all of the investigated materials was calculated and presented in Table 1 as well as all other relevant calorimetric data.

As it can be seen, the calculated crystallinity values verify the previously discussed findings. Namely, pure PLA injected into 23 °C steel mold had almost no crystallinity, while without nucleating agent, pure PLA injected into PolyJet mold had slightly higher, but still only minor crystalline ratio. By using nucleating agents, still rather low crystallinity could only develop when the compound was injection molded into 23 °C steel mold. At the same time, when nucleated PLA was injected into PolyJet mold, in case of 10T10P compound almost the possible maximum, while in case of 20T10P compound the possible maximum crystalline ratio developed during processing. Also the possible maximum crystallinity developed when the nucleated PLA compound was injected into 90 °C mold.

Thermomechanical properties of the injected parts

As it was demonstrated, the amount of nucleating agents and moreover the mold material used had significant effect on the final crystallinity of the injection-molded parts. This crystalline ratio highly influences the thermomechanical properties and thus the applicability of the injection-molded PLA parts. In case of pure PLA injection-molded into 23 °C steel or PolyJet mold, typical storage modulus curves can be observed (Fig. 5).

As it can be seen, PLA has relatively high storage modulus of around 3 GPa, but when reaching T g, as a consequence of very low crystallinity, the modulus drops to a practically unacceptable level of 7 MPa and 17 MPa in case of PLA part injection-molded by using a steel or PolyJet mold, respectively. As it was previously found in the DSC measurements that the PLA injected into PolyJet mold has somewhat higher crystallinity compared to the PLA injected into 23 °C steel mold, which is manifested in the somewhat higher storage modulus especially in the critical temperature range above T g. However, as a result of negligible crystallinity, above T g, PLA begun to cold-crystallize, and thus, storage modulus increased until reaching maximum crystalline ratio. By further increasing the temperature, the storage modulus finally decreased since the melting of the material took place. When 10 m% talc and 10 m% PEG content PLA was injected into 23 and 90 °C steel as well as 23 °C PolyJet mold, the storage modulus curves significantly changed (Fig. 6).

In case of the 10T10P compound injected into 23 °C steel mold, the T g decreased as the effect of the added plasticizer, and as a result of still rather low crystallinity, storage modulus again significantly dropped above this temperature. Although the decrease in storage modulus above T g for this nucleated PLA compound was lower compared to pure PLA part produced by using 23 °C steel mold as the effect of slightly higher crystallinity (13,8 %), this drop was still very significant and unambiguously narrows the temperature range of applicability. On the other hand, when 10T10P compound was injection-molded into PolyJet mold, as the effect of significant crystalline structure developed during processing, the drop in storage modulus above T g was retarded and only a smaller decrease could be observed, which is typical for semicrystalline thermoplastics. This indicates that the applicability range of the part made by this compound was highly widened by injection molding it into not 23 °C steel but PolyJet mold. Finally, when this compound was injection-molded into 90 °C steel mold, the same storage modulus characteristic and modulus values could be observed. Since injection molding into 90 °C mold was used as a representation of the given material with the highest achievable crystallinity, the same storage modulus characteristic indicates that the highest possible modulus values for this compound were already reached when nucleated PLA was injected into PolyJet mold. Finally, the storage modulus of the 20 m% talc and 10 m% PEG content PLA compound injection-molded into 23 °C and 90 °C steel and well as 23 °C PolyJet mold was investigated (Fig. 7).

Similar tendency of storage modulus can be seen compared to the 10T10P compounds, but in most cases due to the additional 10 m% talc content, all values are higher. In case of 20T10P compound injection-molded into 23 °C steel mold, its crystallinity of 14.9 % was still not enough to retard the significant modulus drop above T g. At the same time, naturally due to the effect of additional talc content, the lowest storage modulus in the temperature range between 40 and 80 °C was somewhat higher (22 MPa) compared to the storage modulus of 10T10P compound injection-molded into 23 °C steel mold (13 MPa). For the 20T10P PLA compounds injection-molded into PolyJet mold, high and at the same time the possible maximum crystallinity developed during processing, which retarded the modulus drop above T g, resulting in widened temperature range of applicability similarly to the 10T10P compound injected into PolyJet mold. Finally, 20T10P PLA compound was also injected into 90 °C steel mold to analyze the effect of possible maximum crystallinity, and since its storage modulus curve is almost coincident with the storage modulus curve of 20T10P PLA compound injected into PolyJet mold, it can be stated that the highest possible modulus values for this compound were already reached when it was injected into PolyJet mold.

Although the storage modulus values already indicate the temperature range of applicability of the injection-molded products, this property was also verified by Vicat softening temperature measurements (Fig. 8) as a more direct indication of the possible maximum allowable temperature.

As it can be observed, it was verified that the PLA-based injection-molded products with low crystallinity including PLA injection-molded into 23 °C steel and PolyJet mold as well as nucleated PLA injection-molded into 23 °C steel mold had a Vicat softening temperature of around 60–65 °C, while the nucleated PLA-based compounds injection-molded into either 23 °C PolyJet mold or 90 °C steel mold had much higher, 118–124 °C Vicat softening temperature. Subsequently, it was demonstrated that by using nucleated PLA and PolyJet mold, injection-molded prototype products with the same thermomechanical properties and the also the same high heat resistance could be produced as if 90 °C steel mold was used like in the industrial mass production of high-heat-resistant PLA parts. This also means that it is possible to mimic the crystallization of nucleated PLA injection-molded into and annealed in hot steel mold by injection molding it into epoxy-based PolyJet mold due to the slow-cooling-rate-induced crystallization caused by low thermal conductivity of the polymeric mold.

Mechanical properties of the injected parts

It was discussed previously that the mold used had significant effect on the thermal and thermomechanical properties of pure PLA and PLA-based nucleated compounds, but from the point of view of applicability, the effect of mold used on the mechanical properties is also important. All of the mechanical properties of the produced PLA parts are mainly influenced by the amount of talc and PEG used as well as the developed crystalline ratio. Basically, talc, as a flake shaped filler, increases strength, more preferably stiffness, and in case of rigid polymers like PLA, it usually also increases impact strength, while PEG as a plasticizer decreases both strength and stiffness, but usually increases deformability and impact strength. Crystallinity in turn generally increases strength and stiffness and usually decreases impact properties depending on the crystallite size, but its effect is much less significant than the typical fillers, reinforcements or plasticizers used. Accordingly, the effect of talc, PEG and crystalline ratio can in most cases be found in the mechanical properties (Figs. 9–14) of the produced PLA samples.

According to tensile and flexural strength (Figs. 9, 10), it can be seen that there was no significant difference found in case of PLA injection-molded into 23 °C steel and PolyJet mold, since there was practically no difference in crystallinity, while 10 m% talc and 10 m% PEG compound had more or less half of the strength of pure PLA injection-molded into 23 °C steel mold, demonstrating that the plasticizer effect of PEG was dominant. This plasticizing effect was slightly compensated by the further addition of talc as demonstrated by the strength of 10T10P and 20T10P compounds injection-molded into 23 °C steel mold. In case of 10T10P compound, somewhat higher strength was found for the compound injected into PolyJet mold compared to 23 °C steel mold as a consequence of the developed crystalline ratio during slow cooling. Finally, in the case of 20T10P compound injection-molded into PolyJet and 90 °C steel mold, there was no significant difference found in strength values, indicating that the developed crystallinity was more or less the same at the same time the possible maximum.

For the measured stiffness including tensile and flexural modulus (Figs. 11, 12), the same findings were found to be also valid made for the strength values, but the modulus was found to be more sensitive for the addition of talc and the developed crystalline ratio.

Accordingly, there was practically no difference between the stiffness of PLA injection-molded into 23 °C steel and PolyJet mold, while the stiffness of 10T10P compound injection-molded into 23 °C steel mold decreased compared to pure PLA injection-molded into 23 °C steel mold; at the same time, by adding additional 10 m% talc (20T10P_23 °C_S), the modulus increased. Moreover, in case of 10T10P and 20T10P compounds, the stiffness values were in all cases higher, when the compounds were injection-molded into PolyJet mold (10T10P_23 °C_P and 20T10P_23 °C_P) compared to 23 °C steel mold (10T10P_23 °C_S and 20T10P_23 °C_S) as a clear indication of higher crystalline ratio. Finally, the stiffness of 10T10P compound injected into PolyJet mold was lower compared to the same compound injected into 90 °C steel mold due to its not fully crystallized structure, while there was practically no difference between the stiffness of 20T10P compound injection-molded into either PolyJet or 90 °C steel mold as the result of the developed possible maximum crystalline ratio for both materials.

The effect of the additives as well as the crystalline ratio was also observable for the strain at break values representing deformability of the specimens (Fig. 13).

PLA has low elongation at break, usually around 2–3 %, which is validated by our measurements in case of pure PLA injection-molded into either 23 °C steel or PolyJet mold. When 10 m% talc and 10 m% PEG was added and the compound was injection-molded into 23 °C steel mold, thus the crystalline ratio was kept low, and the deformability was highly enhanced (9.4 %) due to the plasticizing effect of PEG. On the contrary, when the same 10T10P compound was injected into either PolyJet or 90 °C steel mold, the strain at break decreased to 3.2 % and 2.7 %, respectively, as the effect of highly increased crystalline ratio. Deformability of the specimens also decreased when as additional 10 m% talc was added to the compound (20T10P). Accordingly, due to high talc content and crystalline ratio, strain at break was found only around 2.2–2.5 % for all of the 20T10P compounds independently from the mold used. Finally, impact strength of the specimens was also investigated by Charpy impact tests with unnotched specimens (Fig. 14).

As it is observable, mold material did not have significant effect on the impact strength of pure PLA, and at the same time, impact strength increased when 10 m% talc and 10 m% PEG was added; however, by adding a further 10 m% of talc to this compound, impact strength already decreased, representing that too high talc content has contradictory effect; it brittles PLA. When 10T10P compound was injection-molded not into 23 °C steel, but into 90 °C steel or 23 °C PolyJet mold the impact strength values surprisingly enormously increased to 71.4 kJ m−2 and 65.3 kJ m−2, which is a 131 % and 111 % increase, respectively, compared to the impact strength of the same material injection-molded into 23 °C steel mold. Since the only difference in these materials is the crystalline ratio, thus this phenomenon can be explained by the effect of crystalline content and most probably its hybrid effect with talc and PEG content. It is also interesting to note, that this compound containing 10 m% talc and 10 m% PEG had the highest strain when it was injection-molded into cold mold (10T10P_23 °C_S) and crystallinity was kept rather low, and the same material had at the same time the highest impact strength, when it was injection-molded into 90 °C steel mold (10T10P_90 °C_S) and it was fully crystallized during processing. Since the compound used was the same and only the mold material was varied, thus the main difference in the final injection-molded parts was the crystallinity meaning that it was responsible for having either a high strain (low crystallinity) or high impact strength (high crystallinity) material. When 20T10P compound was injection-molded into 90 °C steel or 23 °C PolyJet mold, the hybrid effect of the crystalline ratio with talc and PEG was less dominant due to the embrittlement effect of high talc content demonstrated previously, but nevertheless impact strength was still much higher compared to the same material injection-molded into 23 °C steel mold.

Finally, WAXD was used to analyze the possible change in crystallite size caused by the different cooling rates caused by the different thermal conductivity of the steel and PolyJet mold materials (Figs. 15, 16). On the WAXD spectra, the peak related to 9.4°, 18.9° and 28.6° can be attributed to the presence of talc, while the peak at 16.6° can be directed to the crystalline structure of PLA. This peak was used to determine crystallite size from the possibly line-broadening by using the Scherrer method. Generally, during slow cooling of a polymer melt, larger crystallites develop, which represent lower impact strength, compared to smaller crystallites, which in contrary typically develop during higher cooling rate. In this case, PolyJet mold obviously represents slow cooling, and thus, the parts made by using PolyJet mold would have lower impact strength compared to the high cooling rate of steel mold. The results showed that the PLA-based compounds injection-molded into 23 °C steel mold had a crystallite size of 3–4 nm (Fig. 15), while the compounds injection-molded into either PolyJet or 90 °C steel mold had a much larger crystallite size of 45–50 nm (Fig. 16), meaning that 90 °C steel mold also represented significantly slower cooling compared to 23 °C steel mold. Although higher crystallite size generally represents lower impact strength, but in this case the higher crystallite size of the 10T10P compound injection-molded into 90 °C steel mold or 23 °C PolyJet mold compared to the 23 °C steel mold does not explain the significantly higher impact strength. This phenomenon is still most probably related to the much more significant effect of crystalline ratio and also to the hybrid effect of crystalline ratio with talc and PEG content.

Conclusions

In our research, it was first demonstrated in the literature that it is possible to use epoxy-based mold made by PolyJet Rapid Prototyping (Additive Manufacturing) technology for conventional injection molding to produce small series of products from poly(lactic acid) (PLA), a renewable-resource-based and inherently biodegradable polymer. Pure PLA and nucleated PLA [with talc and poly(ethylene glycol) (PEG)] representing various crystallization abilities were injected into epoxy-based Rapid Prototyped PolyJet mold as well as conventional steel mold (P20), and the effect of the difference in thermal conductivity of the two mold materials was investigated on the mechanical, thermal and thermomechanical properties of the final PLA product.

Due to the low thermal conductivity of the PolyJet mold (0.28 W (mK)−1), the PLA-based compounds had significantly higher crystallinity caused by the slow cooling rate (~32–36 %) compared to 23 °C cold steel mold with high thermal conductivity (20–25 W (mK)−1) representing high cooling rate (~14–15 %). In case of pure PLA despite the slow cooling rate caused by the low thermal conductivity of the PolyJet mold, it was still not enough to develop significant and also much higher crystallinity (~2 %) compared to the case of 23 °C steel mold (practically amorphous). At the same time, in its curve, an enthalpy relaxation was observed above glass transition temperature indicating aged material, which could be directly connected to the thermal history, since in case of PolyJet mold PLA took significantly more time during cooling between glass transition temperature and room temperature compared to 23 °C steel mold. The difference in crystallinity caused by the different thermal conductivity of the PolyJet and steel mold also had significant effect on the thermomechanical properties. In case of nucleated PLA compounds, Vicat softening temperature highly enhanced from 60–65 to 118–124 °C when they were not injection-molded into 23 °C steel, but PolyJet mold, respectively, as the effect of high crystallinity. High Vicat softening temperature of 120–121 °C also developed when the nucleated PLA was injection-molded into 90 °C steel mold, which is typically used in case of industrial injection molding production of PLA parts to develop high crystallinity and thus high softening temperature. This also means that it is possible to mimic the crystallization of nucleated PLA injection-molded into and annealed in hot steel mold by using an epoxy-based PolyJet mold due to the slow-cooling-rate-induced crystallization caused by the low thermal conductivity of this polymeric mold. Moreover, in this case, not only crystallinity but crystallite size was also practically the same as determined by WAXD.

Finally, the effect of the thermal conductivity of PolyJet and steel mold was analyzed on the mechanical properties of the final products. In the tensile and flexural mechanical properties, mainly the stiffness and strength-increasing effect of talc and crystalline ratio as well as the stiffness and strength-decreasing effect of PEG were observable. According to impact tests, both talc and PEG content increased impact strength, and it was found that the mold material had again very significant influence, since the impact strength of 10 m% talc and 10 m% PEG content PLA-based compound injection-molded into 23 °C steel mold was 30.9 kJ m−2, while when the same material was injection-molded into PolyJet or 90 °C steel mold, impact strength reached 65.3 and 71.4 kJ m−2, respectively. Since the only difference in these materials is the crystalline ratio, thus this phenomenon could be explained by the crystalline ratio, as well as its hybrid effect with talc and PEG content.

References

Wholers T. Wholers report 2012. Colorado: Wohlers Associates; 2012.

Gebhardt A. Understanding additive manufacturing. Munich: Carl Hanser Verlag; 2011.

Hopkinson N, Dickens P. A comparison between stereolithography and aluminium injection moulding tooling. Rapid Prototyping J. 2000;6:253–8.

Colton JS, Lebaut Y. Thermal effects on stereolithography injection mold inserts. Polym Eng Sci. 2000;40:1360–8.

Flieger M, Kantorová M, Prell A, Rezanka T, Votruba J. Biodegradable plastics from renewable resources. Folia Microbiol. 2003;48:27–44.

Imre B, Renner K, Pukánszky B. Interactions, structure and properties in poly(lactic acid)/thermoplastic polymer blends. Express Polym Lett. 2014;8:2–14.

Kovács JG, Nagy P, Oroszlány Á, Pavlik A, Hidas P. Testing of prototype interference screw for ACL reconstruction in porcine femurs. Biomech Hung. 2012;4:7–15.

Oroszlány Á, Kovács JG. Gate type influence on thermal characteristics of injection molded biodegradable interference screws for ACL reconstruction. Int Commun Heat Mass. 2010;37:766–9.

Karger-Kocsis J, Kéki S. Biodegradable polyester-based shape memory polymers: concepts of (supra)molecular architecturing. Express Polym Lett. 2014;8:397–412.

Kimble LD, Bhattacharrya D, Fakirov S. Biodegradable microfibrillar polymer-polymer composites from poly(L-lactic acid)/poly(glycolic acid). Express Polym Lett. 2015;9:300–7.

Auras R, Lim LT, Selke SEM, Tsuji H. Poly(lactic acid) synthesis, structures, properties, processing and applications. 1st ed. Hoboken: Wiley; 2010.

Lim LT, Auras R, Rubino M. Processing technologies for poly(lactic acid). Prog Polym Sci. 2008;33:820–52.

Tábi T, Sajó IE, Szabó F, Luyt AS, Kovács JG. Crystalline structure of annealed polylactic acid and its relation to processing. Express Polym Lett. 2010;4:659–68.

Barrau S, Vanmansart C, Moreau M, Addad A, Stoclet G, Lefebre JM, Seguela R. Crystallization behavior or carbon nanotube-Polylactide nanocomposites. Macromolecules. 2011;44:6496–502.

Pengju P, Zhichao L, Amin C, Yoshio I. Layered metal phosphonate reinforced poly(L-lactide) composites with a highly enhanced crystallization rate. Appl Mater Interfaces. 2009;1:402–11.

Shusheng W, Changyu H, Junjia B, Lijing H, Xuemei W, Lisong D. Morphology, crystallisation and enzymatic degradation of poly(L-lactide) nucleated using layered metal phosphonates. Polym Int. 2011;60:284–95.

Ping S, Guangyi C, Zhiyong W, Ying C, Wanxi Z, Jicai L. Rapid crystallization of poly(L-lactic acid) induced by a nanoscaled zinc citrate complex as nucleating agent. Polymer. 2012;53:4300–9.

Harris AM, Lee EC. Improving mechanical performance of injection molded PLA by controlling crystallinity. J Appl Polym Sci. 2008;107:2246–55.

Battegazzore D, Bocchini S, Frache A. Crystallisation kinetics of poly(lactic acid)-talc composites. Express Polym Lett. 2011;5:849–58.

Kawamoto N, Sakai A, Horikoshi T, Urushihara T, Tobita E. Physical and mechanical properties of Poly(L-lactic acid) nucleated by dibenzoylhydrazide compound. J Appl Polym Sci. 2007;103:244–50.

Kawamoto N, Sakai A, Horikoshi T, Urushihara T, Tobita E. Nucleating agent for Poly(L-lactic acid)—an optimization of chemical structure of hydrazide compound for advanced nucleation ability. J Appl Polym Sci. 2007;103:198–203.

Zhaobin Q, Zhisheng L. Effect of orotic acid on the crystallisation kinetics and morphology of biodegradable poly(L-lactide) as an efficient nucleating agent. Ind Eng Chem Res. 2011;50:12299–303.

Nam JY, Okamoto M, Okamoto H, Nakano M, Usuki A, Matsuda M. Morphology and crystallization kinetics in a mixture of low-molecular weight aliphatic amide and polylactide. Polymer. 2006;47:1340–7.

Wen L, Xin Z. Effect of a novel nucleating agent on isothermal crystallisation of poly(L-lactic acid). Chin J Chem Eng. 2010;18:899–904.

Kulinski Z, Piorkowska E. Crystallisation, structure and properties of plasticized poly(L-lactide). Polymer. 2005;46:10290–300.

Saeidlou S, Huneault MA, Li H, Park CB. Poly(lactic acid) crystallisation. Prog Polym Sci. 2012;37:1657–77.

Li H, Huneault MA. Effect of nucleation and plasticization on the crystallisation of poly(lactic acid). Polymer. 2007;48:6855–66.

Tábi T, Suplicz A, Czigány T, Kovács JG. Thermal and mechanical analysis of injection moulded poly(lactic acid) filled with poly(ethylene glycol) and talc. J Therm Anal Calorim. 2014;118:1419–30.

Tsuji H, Takai H, Saha SK. Isothermal and non-isothermal crystallisation behaviour of poly(L-lactic acid): effects of stereocomplex as nucleating agent. Polymer. 2006;47:3826–37.

Rahman N, Kawai T, Matsuba G, Nishida K, Kanaya T, Watanabe H, Okamoto H, Kato M, Usuki A, Matsuda M, Nakajima K, Honma N. Effect of Polylactide stereocomplex on the crystallization behavior of Poly(L-lactic acid). Macromolecules. 2009;42:4739–45.

Ozcelik B, Ozbay A, Demibras E. Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int Commun Heat Mass. 2014;37:1359–65.

Kovács JG, Bercsey T. Influence of mold properties on the quality of injection molded parts. Period Polytech Mech. 2005;49:115–22.

Kovács JG, Suplicz A. Thermally conductive polymer compounds for injection moulding: the synergetic effect of hexagonal boron-nitride and talc. J Reinf Plast Comp. 2013;32:1234–40.

Cai H, Dave V, Gross RA, McCarthy SP. Effects of physical aging, crystallinity, and orientation on the enzymatic degradation of poly(lactic acid). J Polym Sci Pol Phys. 1998;34:2701–8.

Acknowledgements

This paper was supported by the János Bolyai Research Scholarship of the Hungarian Academy of Sciences. This publication was supported by the Italian–Hungarian and the Mexican–Hungarian bilateral agreement of the Hungarian Academy of Sciences. This work was supported by the Hungarian Scientific Research Fund (OTKA K105257, OTKA PD105995). This work is connected to the scientific program of the “Development of quality-oriented and harmonized R + D + I strategy and functional model at BME” project. This project is supported by the New Széchenyi Plan (Project ID: TÁMOP-4.2.1/B-09/1/KMR-2010-0002). The work reported in this paper has been developed in the framework of the project “Talent care and cultivation in the scientific workshops of BME” project. This project is supported by the Grant TÁMOP—4.2.2.B-10/1-2010-0009. The authors thank Arburg Hungária Kft. for the Arburg Allrounder 370S 700-290 injection molding machine, Lenzkes GmbH for the clamping tool system and Piovan Hungary Kft. for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tábi, T., Kovács, N.K., Sajó, I.E. et al. Comparison of thermal, mechanical and thermomechanical properties of poly(lactic acid) injection-molded into epoxy-based Rapid Prototyped (PolyJet) and conventional steel mold. J Therm Anal Calorim 123, 349–361 (2016). https://doi.org/10.1007/s10973-015-4997-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4997-y