Abstract

Municipal sewage sludge can be chosen as an inhibitor to solve the problems related to alkali metal during biomass combustion. Emission of NO x and N2O is an important factor for the co-combustion of biomass with municipal sewage sludge. Thermogravimetry–mass spectrometry was adopted to study nitrogen transformation during the co-combustion of the blends. In this paper, the release characteristics of nitrogen-containing species of the blends during heating process are mainly studied. The yields of main nitrogenous gases (HCN, NH3, NO and HNCO) decrease by mixing biomass with municipal sewage sludge during the heating process. The decrease rate is significant when municipal sewage sludge share changes from 0 to 30 %. The co-combustion of corn straw and cotton stalk mixed with sludge releases less nitrogenous gases than that of wheat straw mixed with sludge.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The circulating fluidized bed boilers have been widely used in the world due to the advantages of the compact furnace structure, effective combustion of various fuels, relatively uniform temperature and the ability to reduce emission of NO x and SO2 [1]. Biomass fuels, such as agricultural straw, containing large amounts of alkali metal, have shown a great possibility to cause corrosion and agglomeration during circulating fluidized bed combustion [2–4].

In recent study, it has been found that some elements in coals, such as aluminum and sulfur, can form compounds of high melting point with alkali metal in biomass fuels [5, 6]. Municipal sewage sludge, a kind of new fuels, can improve corrosion and agglomeration during the co-combustion with biomass fuels [7–9]. Åmand et al. [7] indicated the importance of aluminum silicate reaction in alkali capture during the co-combustion of municipal sewage sludge with wood. Elled et al. [9] found that the addition of sewage sludge was beneficial due to the existence of aluminum, phosphorus, iron, sulfur, etc., all of which were involved in potassium capture.

On the other hand, the nitrogen content in municipal sewage sludge is rather high, which is able to be converted into nitrogenous gases leading to the air pollution during combustion [10, 11] as well as co-combustion of biomass with municipal sewage sludge. Åmand and Leckner et al. [12, 13] have studied the emission of nitrogenous gases from co-combustion of sewage sludge with wood in a fluidized bed. It is concluded that the addition of raw sludge can lead to the decrease in NO x , but the result of adding dried sludge was opposite due to different moisture contents.

At present, nitrogen conversion mechanism during co-combustion of biomass, especially agricultural straw, with municipal sewage sludge is not clear. In order to solve corrosion and agglomeration of biomass fuels and to prevent air pollution from nitrogenous gases, it is important to explore release characteristics of nitrogenous gases during co-combustion of biomass with municipal sewage sludge.

Thermogravimetry–mass spectrometry (TG–MS) provides data of both thermal gravimetric analysis (TG) and mass spectroscopy (MS). In this study, TG–MS results were utilized to determine the nitrogen transformation during the co-combustion of biomass with municipal sewage sludge. Different from the normal way calculating the mass change in each batch, in this study, the analysis of nitrogenous product signals is undertaken, despite the lack of completely quantitative analysis. By means of nitrogenous product signals obtained from TG–MS, a semiquantitative analysis is applied to illustrate the product change. This study aims to conclude the regularity of nitrogen transformation by discussing the changes in nitrogenous product with different influencing factors during the co-combustion of biomass with municipal sewage sludge.

Materials and methods

Materials

Three kinds of biomass fuels, wheat straw, corn straw and cotton stalk, and a kind of municipal sewage sludge were selected in this study. Municipal sewage sludge was from Wuxi sewage treatment plant in Wuxi, Jiangsu Province. Before TG–MS tests, all the samples were dried in Muffle furnace at 105 °C for 2 h, then milled and sieved (0.15–0.2 mm) to powder. Proximate and ultimate analyses of the feedstock are listed in Table 1. Main inorganic elements in feedstock are given in Table 2. Municipal sewage sludge has much higher ash, lower volatiles and fixed carbon content than biomass, as well as higher nitrogen, calcium and iron contents.

TG–MS test

TG–MS tests were performed by a simultaneous thermal analyzer (NETZSCH STA-449F3) coupled with a quadrupole mass spectrometer (QMS403C Aeolos). According to an early study [14], some typical nitrogen oxides and their precursors were selected to study. The ion current intensity signals of mass/charge ratio of 30(NO+), 17(NH3 +), 27(HCN+) and 43(HNCO+) atomic mass unit, which are assigned to represent NO, NH3, HCN and HNCO, respectively, were focused. The carrier gas was O2/Ar (O2/Ar = 1/4, volume) with a constant flow rate of 100 mL min−1. A sample of 10 ± 0.1 mg was put into an Al2O3 crucible for each test and heated in the TG–MS apparatus from room temperature to about 900 °C at a heating rate of 10 °C min−1. Before the TG–MS test, Ar was used to normalize the MS signals. Data and curves of ion current intensity–time/temperature were received from TG–MS after test. Relative yields of nitrogenous gases can be determined by the following steps: firstly, integrate the original curves to achieve values of ion current intensities with time; secondly, non-dimensionalize values by a selected fiducial value [15].

Results and discussion

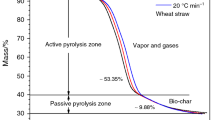

The release of nitrogenous gases of the individual sample

The curves of different nitrogenous gases released from an individual sample are presented in Fig. 1. There are two reaction stages in each curve, corresponding to the volatile burning phase and the fixed carbon burning phase. The temperatures of release peaks in the first release stage from corn straw and cotton stalk are a little higher than those from wheat straw and municipal sewage sludge. Considering the temperatures of the second peak, that of cotton stalk is the lowest, and the highest belongs to corn straw. According to Fig. 1, nitrogenous gases from four kinds of fuels are released mainly in the low-temperature section (200–400 °C). In the mid-temperature section (400–600 °C), the release peaks of nitrogenous gases are weaker than those in the low-temperature section (200–400 °C). In the high-temperature section (600–900 °C), there are no evident nitrogen-containing species except a little HCN. The release curves indicate that the main nitrogen form in biomass and municipal sewage sludge is volatile nitrogen.

The relative yields of different nitrogenous gases released from each individual sample are presented in Fig. 2. Among three kinds of biomass fuels, NH3 yield is the highest in wheat straw, the lowest in cotton stalk and the middle in corn straw; the yields of HCN and NO are the highest in cotton stalk, the lowest in wheat straw and the middle in corn straw; and the HNCO yield is the highest in wheat straw, the lowest in the corn straw and the middle in cotton stalk. Compared with biomass fuels, municipal sewage sludge releases less nitrogenous gases mentioned above.

Nitrogen is mainly from proteins, amino acids, nitrogenous bases (DNA and RNA), alkaloids and chlorophyll in biomass [16], while that in municipal sewage sludge is mainly in the form of proteins, amino acids, lower amines and a lot of complex nitrogen-containing heterocyclic compounds [17, 18]. Therefore, the majority of organic nitrogen in biomass is in the form of amino acid and protein, namely amine-N and protein-N; only a small amount exists in the five-membered ring (pyrrole) and six-membered ring (pyridine), namely pyrrole-N and pyridine-N. However, for municipal sewage sludge, besides amino-N and protein-N, the content of pyrrole-N and pyridine-N is also considerable [16, 17]. The difference in the nitrogen functionalities in biomass and municipal sewage sludge may contribute to distinctive nitrogen transformation during the co-combustion of biomass and municipal sewage sludge. Whether interaction of nitrogen behavior between the fuels exists is interesting and studied in this paper. During the heating process, amino-N is released in the form of NH3 with the produce of another N-containing compounds (e.g., diketopiperazine, DKP, nitrile-N), while pyrrolic-N will convert to heterocyclic-N with HCN release when temperatures are higher than 300 °C [18–21]. Protein-N is converted into amine-N first and then is transferred to heterocyclic compounds (e.g., DKP, nitrile-N) with the release of NH3 [18]. When the temperature continues to rise, pyridine-N and the residual pyrrole-N are decomposed to HCN and further oxidized to NO; nitrile-N, which is produced by amino-N and protein-N, is converted into HNCO or HCN [18–21]. Above all, nitrogen in biomass and municipal sewage sludge is converted to HCN, NH3 and other intermediates rapidly for the subsequent reactions in the low-temperature region [22, 23]. From Table 2 and Fig. 2, it seems that municipal sewage sludge releases the fewest nitrogenous gases despite containing the highest nitrogen content. It can be inferred that some factors influence the release of nitrogenous gases, which will be discussed in detail in the next part.

In summary, the product of volatile nitrogen from biomass and municipal sewage sludge includes NO, NH3, HCN and HNCO. The release temperature is relatively low, and the NO x precursors formed from volatile nitrogen remain in the original form of HCN and NH3, which can be detected. In the low-temperature section, NO, HCN and HNCO are formed from volatiles directly instead of the oxidation of NO x precursor [14, 24, 25]. The release temperature of char-N from unburned char mixed with ash is relatively high, and NO x precursors can be oxidized to HNCO, further to NO.

The release of nitrogenous gases from different mixing ratios of biomass and municipal sewage sludge

The curves of nitrogenous gases released from the samples of biomass with different percents of municipal sewage sludge during the heating process are presented in Figs. 3–7. It can be concluded that the yields of four nitrogenous gases are less than the individual biomass during the co-combustion of biomass fuels mixed with municipal sewage sludge. The addition of municipal sewage sludge can greatly reduce the formation of nitrogenous gases both in the low-temperature section (200–400 °C) and in the mid-temperature section (400–600 °C). The decrease rate is significant when the share of municipal sewage sludge changes from 0 to 30 %, but not significant when the share changes from 30 to 100 %. The addition of municipal sewage sludge also raises the temperature of second release peaks, which shows that char-N from unburned char mixed with ash in municipal sewage sludge is more difficult to release than that in biomass. For all mixtures, with the increase of municipal sewage sludge in mixtures, the release of nitrogenous gases decreases for wheat straw/sludge, while for corn straw/sludge and cotton stalk/sludge, the release of nitrogenous gases firstly deceases and then increases. The results indicate that 70 % municipal sewage sludge in corn straw/sludge and cotton stalk/sludge is the best mixing ratio.

From Figs. 3–7, the release of the four nitrogenous gases (NO, NH3, HCN and HNCO) in the biomass samples decreases by mixing municipal sewage sludge during the heating process compared with biomass. From Table 1, the nitrogen content in municipal sewage sludge is higher than biomass, almost four times as high as that in wheat straw, which is counter to the test results of the release of nitrogenous gases. TG–MS results do not include the analysis of a common nitrogenous gas: N2. The TG–MS experiments are carried out under the fuel–lean condition; thus, precursors (e.g., HCN) are able to become NO quickly through intermediate product N2O. The N2O-intermediate mechanism becomes rather important [26–28]. The reaction Eqs. (1–5) are as follows:

When the temperature reaches 400–600 °C, the following reaction Eqs. (6–9) become important [23, 26]:

After the above analysis, the missing part of nitrogen should convert into N2.

In addition, biomass, especially agricultural straw, is rich in alkali metal (K and Na) and Cl, while from Table 2, municipal sewage sludge is rich in Fe and Ca. It is indicated that Fe and Ca during the heating process can promote the conversion of both fuel-N → N2 and NO → N2 [29–32]. From the mentioned results, it can be inferred that Cl and alkali metal from biomass and Fe from municipal sewage sludge jointly promote the conversion of NO to N2. However, the specific mechanism is not determined by the experiments conducted in this study; thus, further research is needed. As a result, it is considered that when municipal sewage sludge is added to mixtures, the fuel-N has a large trend to convert to N2 instead of nitrogenous gases focused in TG–MS test.

The release of nitrogenous gases from different kinds of biomass

Figure 8 shows the curves of nitrogenous gases released from the samples of municipal sewage sludge with different biomass fuels during the heating process. The mixtures of wheat straw/sludge release significantly more nitrogenous than the other two kinds of mixtures do. The release curves of corn straw/sludge and cotton stalk/sludge almost coincide. The release of nitrogenous gases in low-temperature region (200–400 °C) is affected by the kinds of biomass fuels, especially between wheat straw/sludge and the other two kinds of mixtures. The temperatures of the first and second release peaks from corn straw/sludge and cotton stalk/sludge are higher than those from wheat straw/sludge, respectively. This indicates that nitrogen from corn straw and cotton stalk is more difficult to release than that from wheat straw.

Similar analyses to mixing ratio of biomass and municipal sewage sludge have been done. From Table 2, wheat straw has the lowest Ca and Fe contents among three biomass fuels, and thus, the conversion of both fuel-N → N2 and NO → N2 is not obvious [29–32], so wheat straw/sludge releases more nitrogenous gases than the other two mixtures. On the whole, it is indicated that considering the release of nitrogenous gases from three kinds of biomass fuels with municipal sewage sludge during the co-combustion process, cotton stalk/sludge and corn straw/sludge are better than wheat straw/sludge.

Conclusions

The release characteristics of nitrogenous gases from heating biomass fuels with municipal sewage sludge were investigated. Some preliminary conclusions on nitrogen transformation during co-combustion of biomass mixed with municipal sewage sludge are reached.

Municipal sewage sludge releases less nitrogenous gases than biomass fuels do. The addition of municipal sewage sludge in the mixture can reduce the formation of nitrogenous gases, especially in the low-temperature section (200–400 °C).

The decrease rate is more significant when municipal sewage sludge share changes from 0 to 30 %. Seventy percent municipal sewage sludge in corn straw/sludge and cotton stalk/sludge is the best mixing ratio to reduce the release amount of NO and NO x precursors.

The main form of nitrogen in biomass and municipal sewage sludge is volatile nitrogen. NO x precursors released by volatile nitrogen in biomass fuels and municipal sewage sludge maintain the original form. Cotton stalk/sludge and corn straw/sludge are better than wheat straw/sludge, considering the release of nitrogenous gases.

References

Ghani WAWAK, Alias AB, Savory RM, Cliffe KR. Co-combustion of agricultural residues with coal in a fluidized bed combustor. Waste Manag. 2009;29(2):767–73.

Jensen PA, Frandsen FJ, Hansen J, Dam-Johansen K, Henriksen N, Horlyck S. SEM investigation of superheater deposits from biomass-fired boilers. Energy Fuels. 2004;18(2):378–84.

Werther J, Saenger M, Hartge EU, Ogada T, Siagi Z. Combustion of agricultural residues. Prog Energy Combust Sci. 2000;26(1):1–27.

Masiá TAA, Buhre BJP, Gupta RP, Wall TF. Characterising ash of biomass and waste. Fuel Process Technol. 2007;88(11–12):1071–81.

Zeuthen JH, Jensen PA, Jensen JP, Livbjerg H. Aerosol formation during the combustion of straw with addition of sorbents. Energy Fuels. 2007;21(2):699–709.

Lindström E, Sandström M, Boström D, Ohman M. Slagging characteristics during combustion of cereal grains rich in phosphorus. Energy Fuels. 2007;21(2):710–7.

Åmand LE, Leckner B, Eskilsson D, Tullin C. Deposits on heat transfer tubes during co-combustion of biofuels and sewage sludge. Fuel. 2006;85(10–11):1313–22.

Davidsson KO, Åmand LE, Elled AL, Leckner B. Effect of cofiring coal and biofuel with sewage sludge on alkali problems in a circulating fluidized bed boiler. Energy Fuels. 2007;21(6):3180–8.

Elled AL, Davidsson KO, Åmand LE. Sewage sludge as a deposit inhibitor when co-fired with high potassium fuels. Biomass Bioenergy. 2010;34(11):1546–54.

Werther J, Ogada T, Philippek C. N2O emissions from the fluidised-bed combustion of sewage sludges. J Inst Energy. 1995;68:93–101.

Shimizu T, Toyono M. Emissions of NO x and N2O during co-combustion of dried sewage sludge with coal in a circulating fluidized bed combustor. Fuel. 2007;86(15):2308–15.

Åmand LE, Miettinen-Westberg H, Karlsson M, Leckner B, Lücke K, Budinger S, Hartge EU, Werther J. Co-combustion of sewage sludge with wood/coal in a circulating fluidised bed boiler-a study of NO and N2O emissions. In: Proceedings of the 3rd international symposium on incineration and flue gas treatment technologies, Institution of Chemical Engineers England, The University of Sheffield England, Vrije Universiteit Brussels Belgium, 2–4 July, Brussels, Belgium, 2001.

Leckner B, Åmand LE, Lücke K, Werther J. Gaseous emissions from co-combustion of sewage sludge and coal/wood in a fluidized bed. Fuel. 2004;83(4–5):477–86.

Ledesma EB, Li CZ, Nelson PF, Mackie JC. Release of HCN, NH3, and HNCO from the thermal gas-phase cracking of coal pyrolysis tars. Energy Fuels. 1998;12(3):536–41.

Arenillas A, Rubiera F, Pis JJ. Simultaneous thermogravimetric-massspectrometric study on the pyrolysis behavior of different rank coals. J Anal Appl Pyrol. 1999;50:31–46.

Ye CX, Zhu ND, Liao WB, Liu WQ. Botany. China: Higher Education Press; 2007.

Werther J, Ogada T. Sewage sludge combustion. Prog Energy Combust Sci. 1999;25(1):55–116.

Tian K, Liu WJ, Qian TT, Jiang H, Yu HQ. Investigation on the evolution of N-containing organic compounds during pyrolysis of sewage sludge. Environ Sci Technol. 2014;48(18):10888–96.

Ren QQ, Zhao CS. NO x and N2O precursors from biomass pyrolysis: nitrogen transformation from amino acid. Environ Sci Technol. 2012;46:4236–40.

Kambara S, Takarada T, Toyoshima M, Kato K. Relation between functional forms of coal nitrogen and NO x emission from pulverized coal combustion. Fuel. 1995;74(9):1247–53.

Kambara S, Takarada T, Yamamoto Y, Kato K. Relation between functional forms of coal nitrogen and formation of NO x precursors during rapid pyrolysis. Energy Fuels. 1993;7(6):1013–20.

Miller JA, Bowman CT. Mechanism and modeling of nitrogen chemistry in combustion. Prog Energy Combust Sci. 1989;15(4):287–338.

Bowman CT. Control of combustion-generated nitrogen oxide emissions: technology driven by regulations. In: Twenty-fourth symposium (international) on combustion, The Combustion Institute, Pittsburgh, PA, 859–878, 1992.

Ashman PJ, Haynes BS, Buckley AN, Nelson PF. The fate of char-nitrogen in low-temperature oxidation. In: The 27th international symposium on combustion. 1998.

Wargadalam VJ, Löffler G, Winter F, Hofbauer H. Homogeneous formation of NO and N2O from oxidation of HCN and NH3 at 600–1000 °C. Combust Flame. 2000;120(4):465–78.

Stephen R. Turns. An introduction to combustion: concepts and applications (2nd edition), 1999.

Kilpinen P, Hupa M. Homogeneous N2O Chemistry at fluidized bed combustion conditions: a kinetic modeling study. Combust Flame. 1991;85(1/2):94–104.

Åmand LE, Leckner B, Andersson S. Formation of N2O in circulating fluidized bed boiler. Energy Fuels. 1991;5(6):815–23.

Hayhurst AN, Ninomiya Y. Kinetics of the conversion of NO to N2 during the oxidation of iron particles by NO in a hot fluidized bed. Chem Eng Sci. 1998;53(8):1481–9.

Zhao Z, Li W, Qiu J, Li BQ. Catalytic effect of Na–Fe on NO–char reaction and NO emission during coal char combustion. Fuel. 2002;81(18):2343–8.

Che DF. Thermal coal-N transformation and nitrogen oxide generation, 205–206. Xi’an Jiaotong University Press, 2013.

Illan-Gomez MJ, Linares-Solano A, Delecea CS, Calo JM. Nitrogen oxide (NO) reduction by activated carbons. 1. The role of carbon porosity and surface area. Energy Fuels. 1993;7(1):146–54.

Acknowledgements

This work is funded by National Natural Science Foundation of China (No. 51476169) and the External Cooperation Program of BIC, Chinese Academy of Sciences (Grant No. GJHZ201301).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Ren, Q., Li, L. et al. TG–MS analysis of nitrogen transformation during combustion of biomass with municipal sewage sludge. J Therm Anal Calorim 123, 2061–2068 (2016). https://doi.org/10.1007/s10973-015-4712-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4712-z