Abstract

Bulk single crystals of hydrazonium l-tartrate (HLT) an organic nonlinear optical material have been grown by isothermal solvent evaporation method using water:methanol (5:1) as solvent. The title compound crystallizes in orthorhombic system with noncentrosymmetric space group P212121. The thermal stability, thermal decomposition, and specific heat capacity of HLT have been explored by thermogravimetric/differential thermal analysis, differential scanning calorimetric analysis and modulated differential scanning calorimetric analysis. Improved photopyroelectric technique was adapted to analyze the most important thermophysical parameters in heat transfer calculations such as thermal effusivity, thermal diffusivity, thermal conductivity and heat capacity of HLT single crystal. The measured specific heat of HLT obtained from single crystal sample at 300 K is found to be about 3875 J kg−1 K−1 suggesting that the HLT could possesses high optical damage value and will be useful for the fabrication of optical devices. The anisotropic mechanical behaviors of HLT have been tested on crystallographic planes (100), (010), and (001) using Vickers microhardness tester at room temperature and the results were analyzed through classical Mayer’s law. Room temperature Vickers microhardness test reveals that hardness number of HLT are significantly different in measured orientations and interestingly (100), (001) orientations of HLT belong to soft material category, while the (010) belongs to hard material category because of Van der Waals forces. All these studies have been performed for the first time and aimed to explore the useful and safe regions of thermal and mechanical properties to enhance its usefulness for device fabrications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The invention of high-intensity laser beam paved the way to investigate the versatile and highly efficient nonlinear optical materials to realize their potential applications in terahertz wave generation and detection, nonlinear optics (NLO), and electro-optics. Organic nonlinear optical crystals have been investigated because of their large nonlinearity, moderate chemical and mechanical stabilities, low dielectric constant, and high resistance to laser damage threshold as compared to their inorganic counterparts [1–4]. Molecular spices of the nonlinear optical chromophores are the origin of optical nonlinearity of the bulk NLO media. These chromophores are arranged in the bulk in a net acentric and polar fashion to exhibit second order nonlinearity [5]. Identification of thermal stability of such chromophores is principally important consideration for NLO applications dictated by demands for long-term device performance and reliability [6–8]. Furthermore, the analyses of properties such as thermal, optical, electric, and mechanical through various techniques are essential for materials characterization [9–15]. As the tartaric acid possesses the chiral structure it has the ability to coordinate with certain organic bases and some of the combinations have indeed crystallized with noncentrosymmetric structure, a prerequisite to be an NLO material [16, 17]. The hydrazonium l-tartrate (HLT) is one such crystal which belongs to tartrate family of NLO materials that crystallizes in orthorhombic system with noncentrosymmetric space group P212121. The HLT single crystals have already been grown using water as solvent under argon atmosphere to avoid coloration of HLT solutions, and some of their physical properties have also been reported [18, 19]. Moreover, the structure of HLT was solved again using crystals grown from aqueous methanol solution by Fun et al. [20]. The information on HLT is very limited because of coloration problem and consequently the unavailability of high-quality single crystals. Recently, we have reported the influences of coloration on HLT solution during the growth of high-quality single crystals in aqueous methanol solutions under normal ambient atmosphere [21]. The powder second harmonic generation (SHG) efficiency of HLT was found to be nearly 1.5 times greater than that of standard potassium dihydrogen phosphate (KDP). The improved SHG efficiency, phasematchability, lower cut-off wavelength (239 nm), improved optical transparency (80 %), wide band gap (5.12 eV), and nonhygroscopicity of HLT motivated us to continue our investigations on thermal and mechanical properties. In this article, we report the results of thermogravimetric/differential thermogravimetric analysis (TG–DTA), differential scanning calorimetric (DSC) analysis, modulated differential scanning calorimetric (MDSC) analysis, thermophysical properties by photopyroelectric (PPE) technique, and Vickers hardness studies of HLT.

Experimental details

Material synthesis and crystal growth

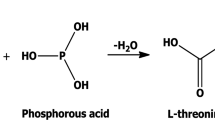

HLT, N2H4·C4H6O6, was synthesized under normal ambient atmosphere by adding hydrazine hydrate (99–100 % Merck) to the aqueous methanol solution of l-tartaric acid (99 % Merck), taking in the stoichiometric ratio 1:1 [21]. Bulk growth of HLT was achieved by employing a water bath equipped with a programmable Eurotherm temperature controller (3216) having an accuracy of ±0.01 °C. The spontaneously grown HLT single crystal of typical dimensions 13 × 6 × 3 mm3 is shown in Fig. 1. The unit cell parameters of HLT single crystal were obtained using an Enraf–Nonius CAD-4 Diffractometer with Mo Kα (0.71073 Å) radiation at room temperature. Cell parameters were obtained from least-squares refinement of the setting angles of 25°. The HLT crystallizes in orthorhombic crystal system with noncentrosymmetric space group P212121. The obtained unit cell dimensions are a = 7.033 (2) Å, b = 7.639 (2) Å, c = 13.449 (2) Å, V = 722.7 (3) Å3, and Z = 4 all of which agreed well with the reported data [20].

Characterization techniques

TG–DTA analyses were carried out using a Simultaneous Thermal Analyzer SDT Q600 V8.3 Build 101 in Nitrogen atmosphere with a heating rate of 20 °C min−1 in the temperature range of 40–400 °C by taking Alumina as crucible and reference material. The balance sensitivity, calorimetric accuracy, and temperature sensitivity of the analyzer were 0.1 μg, ±2 % and 0.001 °C respectively. The melting point of HLT crystal was determined directly by using a melting point apparatus (INLAB Equipments (Madras) Pvt. Ltd). The DSC curve was obtained in the range between 40 and 500 °C using TA-Q20 DSC Differential Scanning Calorimeter. The specific heat of HLT was determined for its powder sample using MDSC technique with a cooling rate of 2 °C min−1 by Mettler-Toledo DSC1 thermal analyzer. An improved PPE technique [22] has been used for the measurement of the thermophysical properties such as thermal diffusivity (α), thermal effusivity (e), thermal conductivity (K), and heat capacity (C p) of HLT single crystal. A carefully polished HLT crystal initially with aqueous methanol solvent and finally with alumina powder was used as sample. The prepared samples had a thickness of 0.7 mm. In order to enhance optical absorption in the crystal, a very thin layer of carbon black from a benzene flame was carefully coated onto the surface (001) of the prepared sample. In this measurement, a thermally thick, polyvinylidene difluoride film of thickness 28 μm, coated with Ni–Cr film on both side, with pyroelectric coefficient P = 0.25 × 10−8 V cm−1 K−1 was used as the pyroelectric detector. The pyroelectric detector film was attached to one side of the sample by means of a thermally thin layer of a compound whose contribution to the attenuation of the generated thermal wave signal is negligible and the combination was mounted on a thermally thick backing medium made up of copper. The other side of the sample was illuminated by an intensity-modulated beam of light, which gives rise to periodic temperature variations by optical absorption. A 120-mW He–Cd laser of a wavelength 442 nm, intensity modulated by a mechanical chopper, has been used as the optical heating source. The thermal waves so generated propagate through the sample and were detected by the pyroelectric detector. The sample-detector-packing assembly was enclosed in a chamber maintained at room temperature. The signal output was measured with a lock-in amplifier (SR830 DSP) having 10 MΩ input impedance and 50 pF input capacitance. The frequency of modulation of the laser light was kept in the range of above 30 Hz to ensure that the detector, the sample, and the packing medium were thermally thick during the measurements.

Microhardness study was performed using a Shimadzu microhardness tester (HMV-2) containing a diamond pyramidal indenter with a face angle of 136°. The resolution of the tester was 0.01 μm. For this purpose, carefully selected inclusion-free HLT single crystal was cut normal to their principal crystallographic X, Y, and Z axes. The sample was then polished using a soft tissue paper with fine grade alumina powder (1 μm) dispersed in a mixture of dimethylformamide and methanol in the volume ratio 4:1. Typical sample dimensions were 10 × 5 × 2.5 mm (l × b × h). Sample with parallel surfaces was obtained along (100), (010), and (001) planes. To evaluate the Vickers hardness number, static indentations were performed at room temperature on these orientations of HLT crystal. The applied load was varied from 25 to 200 g for a constant indentation period of 15 s for all indentations. The indented impressions were approximately square when viewed under optical microscope. In order to avoid the mutual influence of any previous indentation, the distance between any two indentations was maintained to be greater than five times that of the diagonal length of the indented square.

Results and discussion

TG–DTA studies

Thermogravimetric and differential thermal analyses (TG–DTA) generally give the information regarding phase transition and different stages of decomposition in the crystal system. The simultaneous TG–DTA was performed on 7.724 mg of HLT powder sample and the results are shown in Fig. 2. From the DTA curve it could be observed that the title compound undergoes an irreversible endothermic transition at 171.8 °C, where the melting begins. The first endothermic peak at 181 °C corresponds to the end of melting of the grown crystal. The absence of characteristic endothermic or exothermic peaks before this melting point indicates the absence of isomorphic transition. Good degree of crystallinityof HLT is evidenced by the sharpness of the endothermic peak. TG curve shape after the melting point represents the thermal decomposition of HLT with formation of volatile reactive products [23]. The decomposition of HLT occurs at several stages, the first mass loss starts at 171.8 °C indicates the simultaneous melting and decomposition point. This mass loss continues up to 190 °C about 20 % could be attributed to dehydrazination. The next two mass losses that occur between 270 and 600 °C indicate the complete decompositions of HLT [24]. From the TG curve, it is clearly seen that the title compound could be thermally stable up to 171.8 °C. Further, it is important to note that the title compound has no phase transition till the material reaches its melting point. The melting point of HLT obtained by melting point apparatus is found to be 171 °C. The temperature at the intercept of the leading edge of the mass loss that can involve sublimation and/or decomposition by the base line of the TG scans is estimated as decomposition temperature [25]. All these results suggest that HLT could be useful for fabricating NLO devices below its melting point [4].

DSC analysis

The DSC curve recorded with a heating rate of 10 °C min−1 for HLT powder sample is shown in Fig. 3. From the curve, it is seen that a sharp endothermic peak is occurred with an onset, peak maximum, and offset at 171.82, 177.42, and 183.91 °C respectively. Since the material absorbs energy in order to melt, this endothermic peak is assigned to the sample’s melting process. In view of the fact that the melting point for crystalline sample is reflected by the onset temperature at which melting begins, and not the peak maximum value, and for HLT, the melting point is recognized as 171.82 °C [26]. Since poor thermal contact will result in a broader peak with lower peak height, the values of peak maximum and peak height will be influenced by sample mass and possibly by encapsulation procedure [26, 27]. The purity of any sample can be determined by analyzing the shape of the melting curve obtained by DSC plot. The higher the concentration of an impurity present in a given sample the lower the melting point and the broader the melting range. The sharpness of DSC melting peak with the higher melting point suggests that HLT has higher crystallinity and purity.

Specific heat capacity analysis

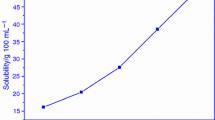

The intensity of incident laser power influences the conversion efficiency of a NLO crystal for harmonic generation. As a result, the utility of such material for suitable devices largely depends on its ability to withstand high-power laser in addition to its linear and nonlinear optical properties [28]. The laser damage threshold and thermal conductivity of a crystal strongly depend on its specific heat capacity (C P). In most cases, the Debye theory describes the specific heat data of solids in terms of harmonic frequency spectrum for each crystalline lattice. Since HLT is an organic material, it is very complicated to determine the specific heat of the bulk material with the prediction of a lattice theory like Debye’s due to its complexity [29]. Hence, the specific heat of HLT was determined for its powder sample using MDSC technique with a cooling rate of 2 °C min−1 using Mettler-Toledo DSC1 thermal analyzer. The advantages of MDSC over conventional methods have been discussed by Verdonck et al. [30] in the year 1999. The result of temperature dependence of specific heat of HLT is shown in Fig. 4. From the figure, it is clear that HLT exhibits a constant specific heat (2.01 J g−1 K−1) from 300 to 406 K, thereafter C P increases rapidly up to the onset of the melting point to attain its maximum. From the figure, it can be observed that the specific heat of HLT increases linearly from 2.01 to 4.74 J g−1 K−1 between the temperature range 300 and 435 K. The anomalous variation in specific heat capacity after melting point could be attributed to softening of phonon modes and the corresponding enhanced contribution of phonon modes to the specific heat capacity [31]. The measured specific heat of HLT obtained from powder samples at 300 K is found to be about 2010 J kg−1 K−1. The specific heats of few known NLO crystals are depicted in the Table 1 for comparison. From the Table, it is observed that C P of HLT is greater than that of organic materials such as N-methyllutidone trihydrate (NM), 2,6-diaminopyridinium 4-nitrophenolate 4-nitrophenol (DAPNP), 1-ethyl-2,6-dimethyl-4(1H)-pyridinone trihydrate (EDMP·3H2O), l-histidinium-4-nitrophenolate 4-nitrophenol (LHPP), bis-2,7-diethylaminohepta-2,5-dien-4-one (BEDO), semiorganic materials such as l-arginine phosphate monohydrate (LAP), sodium p-nitrophenolate dihydrate (NPNa·2H2O), and 4-dimethylaminopyridinium dihydrogen phosphate (DMAPDP); and inorganic materials, such as KDP, potassium titanyl phosphate (KTP), lithium borate (LBO), ammonium dihydrogen phosphate (ADP), and lithium niobate (LN) [32–36] at the same temperature. Since a crystal with high specific heat will have smaller temperature gradient than a crystal with a low specific heat when absorbing the same quantity of heat, an NLO crystal with higher specific heat could be expected to have more resistance to laser damage. It is also observed that NLO crystals with higher specific heat exhibit high laser damage thresholds of KDP: 5 GW cm−2 (1 ns); KTP, 9–20 GW cm−2 (1 ns); LAP, 13 GW cm−2 (25 ns); LN, 0.3 GW cm−2 (10 ns); and NPNa·2H2O, 11.16 GW cm−2 (8 ns). In this direction, it could be expected that HLT would also possess higher damage threshold [36, 37]. Since prolonged heating by laser radiation of a hydrated crystalline material may promote the liberation of water vapor and hence degrade the structure of the material, the anhydrous nature of HLT (Fig. 2) is favorably viewed in terms of its thermal stability.

PPE effect study

The diffusivity is a measure of how quickly a body can change its temperature. It increases with the ability of a body to conduct heat and decreases with the amount of heat required to change the temperature of a body (C P). The thermal diffusivity is of direct importance in heat flow studies as it determines the rate of periodic heating or transient heat propagation through the medium with pulsed or chopped laser radiation. Actually, the inverse of thermal diffusivity is a measure of the time required to establish thermal equilibrium in a system for which a transient temperature change has occurred. The thermal effusivity is a unique thermal property of a material which essentially measures the ability of the sample to exchange heat with the environment (thermal impedance). The main difference between these two terms is that effusivity is relatively a surface property whereas diffusivity is a bulk property of the material. The thermal thickness of the HLT at room temperature was evaluated by plotting the PPE amplitude and phase for different frequencies as shown in Figs. 5 and 6 respectively. The measurement of the PPE signal phase and amplitude enabled us to determine thermal diffusivity (α), and thermal effusivity (e) or heat penetration coefficient of the sample. The thermal effusivity of HLT measured at room temperature was found to be 0.3158 ± 0.0037 × 104 J m−2 K−1 s−1/2 which is relatively higher than all other organic NLO crystals listed in Table 1 except 2A5NPT (0.3216 × 104 J m−2 K−1 s−1/2). From the measured values of α and e, the thermal conductivity (K) and heat capacity (C P) of HLT were calculated using the following relations:

where ρ s is the density of the sample. From the repeated tests on several samples of known thermal properties, the degrees of uncertainty in the measured values of K and C P were found to be less than 2 %. The temperature of the sample was maintained as constant by allowing sufficient time to reach its thermal equilibrium. Table 1 also provides the thermal parameters of other known organic and inorganic crystals for comparison. From Table 1, it can be seen that the thermal conductivity of HLT is relatively larger than the organic, semiorganic, and inorganic crystals such as N-methyllutidone trihydrate (NM), 1-ethyl-2,6-dimethyl-4(1H)-pyridinone trihydrate (EDMP·3H2O), bis-2,7-diethylaminohepta-2,5-dien-4-one (BEDO), l-arginine phosphate monohydrate (LAP), 4-dimethylaminopyridinium dihydrogen phosphate (DMAPDP), KTP, KDP, ADP, and lithium iodate [34–45]. The higher thermal conductivity could be expected to facilitate the dissipation of heat energy that is created when the laser beam passes through it.

Microhardness

Mechanical behavior of a crystalline material generally depends on its chemical structure and composition. Microhardness testing is one of the best techniques of understanding the mechanical properties such as fracture behavior, brittleness index, yield strength and temperature of cracking of materials [46]. Hardness of a material is a measure of the resistance it offers to local deformation, and it plays a key role in device fabrication. The Vickers Hardness Number (VHN) of HLT was estimated using the relation:

where H v is the Vickers hardness number in kg mm−2, p is the applied load in kg, and d is the average diagonal length of the indentation in mm. The calculated values of H v for various loads corresponding to each orientation are shown in Fig. 7. Each data point represents an average value obtained from several indentations. From the results, it could be observed that H v are significantly different in (100), (010), and (001) orientations and reveal the anisotropic nature of HLT single crystal. It could also be observed that at lower loads, there is an increase in hardness up to 200 g for (100) and (001) orientations, which can be attributed to the work hardening of the surface layers [17]. The strain energy is sufficient to nucleate the cracks at lower loads. A load of about 200 g was sufficient to induce cracking in the title crystal and beyond this load, and the plastic flow of the material may be larger. Beyond 200 g, the microhardness number ceases to depend on loads when the impression reaches a depth at which undistorted materials exist [17, 47]. This suggests that (100) and (001) orientations of HLT crystal exhibit reverse indentation size effect (ISE) where the apparent microhardness increases with increasing applied test load in contrast to normal ISE [48]. In contrast, for (010) orientation of HLT, the apparent H v decreases with increasing load obeying normal ISE. The plots obtained between “log (p)” and “log (d)” were more or less a straight line for all the three orientations measured. From Meyer’s law, the relation between the applied load (p) and diagonal length (d) of the indenter is given by p = a d n. Here, “n” is Meyer’s index or work hardening coefficient that has been determined from the slope of straight line using least square fitting procedure. The calculated n values of HLT single crystal along various orientations are depicted in Table 2. From the Table, it could be seen that n > 2 for (100), (001) orientations and n < 2 for (010) orientation of HLT single crystal. The calculated n value along (001) orientation is found to be 2.7882, while its parent compound L-tartrate n value was reported as 1.58 [49]. According to Onitsch [50], if n > 2, the material is considered as softer material; and if n < 2, the material is harder. It is also stated that there is increase in H v with the increasing load for n > 2 (reverse ISE) and decrease in H v with the increasing load for n < 2 (normal ISE). From the Fig. 7, it is obvious that (100) and (001) orientations of HLT crystal belong to the soft material category following reverse ISE, while the (010) orientation of HLT crystal belongs to hard material category following normal ISE. From Wooster’s formula C 11 = (H v)7/4 [51], the elastic stiffness constants of HLT were calculated for different orientations and are listed in Table 3. The elastic stiffness coefficient C 11 gives the measure of resistance to deformation by a load applied on flat crystal surface. The two important factors in measuring the C 11 values are the tightness of the bonding between the neighboring atoms and rate of variation with position of the atoms of forces of attraction and repulsion between them [52]. From the calculated stiffness constants (Table 3), it is obvious that the binding forces between the atoms along (010) orientation of HLT are quite strong than that of other orientations (100), (001). The reason for this high stiffness constant along (010) could be attributed to the weak Van der Waals forces [18]. This result is also corroborated with the other mechanical behaviors such as work hardening coefficients and ISEs of HLT single crystal (Table 2). These results suggest that (010) orientation of HLT single crystal exhibits significant behaviors when compared to other orientations studied.

Conclusions

Single crystals of optically transparent HLT were grown from water:methanol (5:1) solvent by isothermal solvent evaporation technique. The HLT crystallized in orthorhombic system with noncentrosymmetric space group P212121. The TG–DTA studies elucidated the decomposition and confirmed the thermal stability of HLT and suggest that it could be used in optical applications below its melting point. The DSC curve corroborated the purity and crystallinity through its sharp endothermic melting peak, whereas the MDSC study describes the temperature dependence specific heat of HLT. Thermal effusivity, thermal diffusivity, thermal conductivity and heat capacity of HLT single crystal were measured by PPE technique. These results suggest that the HLT possesses high optical damage value and will be useful for the fabrication of optical devices. Vickers microhardness test reveals that H v of HLT are significantly different in (100), (010), and (001) orientations which confirm the anisotropic nature of HLT single crystal. Interestingly (100), (001) orientations of HLT belong to soft material category, while the (010) belongs to hard material category because of Van der Waals forces. The thermophysical and mechanical behaviors of HLT suggest that it could be a suitable material for the NLO applications below its melting point and yield strength.

References

Shanmugam G, Brahadeeswaran S. Spectroscopic, thermal and mechanical studies on 4-methylanilinium p-toluenesulfonate—a new organic NLO single crystal. Spectrochim Acta Part A. 2012;95:177–83.

Brahadeeswaran S, Bhat HL, Kini NS, Umarji AM, Balaya P, Goyal PS. Dielectric, thermal, and mechanical properties of the semiorganic nonlinear optical crystal sodium p-nitrophenolate dehydrate. J Appl Phys. 2000;88:5935–40.

Brahadeeswaran S, Venkataramanan V, Bhat HL. Nonlinear optical activity of anhydrous and hydrated sodium p-nitrophenolate. J Cryst Growth. 1999;205:548–53.

Brahadeeswaran S, Venkataramanan V, Sherwood JN, Bhat HL. Crystal growth and characterization of semiorganic nonlinear optical material: sodium p-nitrophenolate dehydrate. J Mater Chem. 1998;8:613–8.

Zyss J. Molecular nonlinear optics: materials, physics, devices. San Diego: Academic Press; 1994.

Burland D, Miller RD, Walsh C. Second-order nonlinearity in poled-polymer systems. Chem Rev. 1994;94:31.

Lytel R, Lipscomb GF, Binkley ES, Kenny JT, Ticknor AJ. Electro-optic polymers for optical interconnects. Proc SPIE. 1990;1215:252.

Prime RB, Chiou GY, Twieg RJ. Evaluation of the thermal stability of some nonlinear optical chromophores. J Therm Anal Calorim. 1996;46:1133–50.

Ramamurthi K, Madhurambal G, Ravindran B, Mariappan M, Mojumdar SC. The growth and characterization of a metal organic crystal, potassium thiourea thiocyanide. J Therm Anal Calorim. 2011;104:943–7.

Mojumdar SC, Raki L. Preparation, thermal, spectral and microscopic studies of calcium silicate hydrate-poly(acrylic acid) nanocomposite materials. J Therm Anal Calorim. 2006;85:99–105.

Varshney G, Agrawal A, Mojumdar SC. Pyridine based cerium(IV) phosphate hybrid fibrous ion exchanger: synthesis, characterization and thermal behaviour. J Therm Anal Calorim. 2007;90:731–4.

Mojumdar SC, Šimon P, Krutošíková A. [1]Benzofuro[3,2-c]pyridine synthesis and coordination reactions. J Therm Anal Calorim. 2009;96:103–9.

Jona E, Rudinska E, Sapietova M, Pajtasova M, Ondrusova D, Jorik V, et al. Interaction of pyridine derivatives into the interlayer spaces of Cu(II)-montmorillonites. Res J Chem Environ. 2005;9:41–3.

Mojumdar SC, Miklovic J, Krutosikova A, Valigura D, Stewart JM. Furopyridines and furopyridine–Ni(II) complexes—synthesis, thermal and spectral characterization. J Therm Anal Calorim. 2005;81:211–5.

Rajasekaran M, Anbusrinivasan P, Mojumdar SC. Growth, spectral and thermal characterization of 8-hydroxyquinoline. J Therm Anal Calorim. 2010;100:827–30.

Ivanova BB. Spiteller M, Organic mandelates as promising materials with non-linear optical application. Struct Chem. 2010;21:989–93.

Nagalakshmi R, Krishnakumar V, Sudharsana N, Wojciechowski A, Piasecki M, Kityk IV, Belsley M, Isakov D. Studies on physico-chemical properties of hydroxyethylammonium (l) tartrate monohydrate single crystals. Physica. 2011;B406:4019–26.

Delfino M, Loiacono GN, Osborne WN, Kostecky G. Solution growth of l(+) hydrazonium tartrate. J Cryst Growth. 1979;46:241–4.

Delfino M, Jacco JC, Gentile PS, Bray DD. Solid-state study of hydrazonium tartrate and deuterated hydrazonium tartrate enantiomers. J Solid State Chem. 1977;2:243.

Fun HK, Sivakumar K, Jiang YZ, Sun J, Zhou ZY. Hydrazinium l-tartrate. Acta Cryst. 1995;C51:2085–7.

Kannan V, Brahadeeswaran S. Investigations on influence of coloration on growth of high quality Hydrazonium l-tartrate single crystal. J Cryst Growth. 2013;374:71–8.

Menon CP, Philip J. Simultaneous determination of thermal conductivity and heat capacity near solid state phase transitions by a photopyroelectric technique. Meas Sci Technol. 2000;11:1744–9.

Bottom R. Thermogravimetric analysis. In: Gabbot P, editor. Principles and applications of thermal analysis. London: Blackwell; 2008. p. 88–118.

Yasodhai S, Govindarajan S. Preparation and thermal behaviour of some hydrazinium dicarboxylates. Thermochim Acta. 1999;338:113–23.

Kwon OP, Kwon SJ, Jazbinsek M, Choubey A, Gramlich V, Gunter P. New organic nonlinear optical polyene crystals and their unusual phase transitions. Adv Funct Mater. 2007;17:1750–6.

Hatakeyama T, Liu Z. Handbook of thermal analysis. Chichester: Wiley; 1998.

Gabbot P. A practical introduction to differential scanning calorimetry. In: Gabbot P, editor. Principles and applications of thermal analysis. London: Blackwell; 2008. p. 1–50.

Glass AJ, Guenther AH. Laser induced damage of optical elements—a status report. Appl Opt. 1973;12:637–49.

Sun ZH, Xu D, Wang XQ, Zhang GH, Yu G, Zhu LY, Fan HL. Growth and characterization of the nonlinear optical single crystal: l-lysinium trifluoroacetate. Mater Res Bull. 2009;44:925–30.

Verdonck E, Schaap K, Thomas LC. A discussion of the principles and applications of modulated temperature DSC (MTDSC). Int J Pharm. 1999;192:3–20.

Philip J, Manjusha MV. Thermal transport across incommensurate phases in potassium selenate: photopyroelectric and calorimetric measurements. J Phys Condens Matter. 2009;21:45901–7.

Chen T, Sun Z, Li L, Wang S, Wang Y, Luo J, Hong M. Growth and characterization of a nonlinear optical crystal. 2,6-Diaminopyridinium-4-nitrophenolate 4-nitrophenol (DAPNP). J Cryst Growth. 2012;338:157–61.

Dhanaraj G, Srinivasan MR, Bhat HL, Jayanna HS, Subramanyam SV. Thermal and electrical properties of the novel organic nonlinear crystal l-arginine phosphate monohydrate. J Appl Phys. 1992;72:3464–7.

Vanishri S, Babureddy JN, Bhat HL, Ghosh S. Laser damage studies in nonlinear optical crystal sodium p-nitrophenolate dehydrate. Appl Phys B Laser Opt. 2007;88:457–61.

Dhanuskodi S, Manivannan S, Kirschbaum K, Philip J, Selladurai S. Structural, thermal and dielectric studies on a new solution grown 4-dimethylaminopyridinium dihydrogen phosphate crystal. J Cryst Growth. 2006;290:548–53.

Chen T, Sun Z, Song C, Ge Y, Luo J, Lin W, Hong M. Bulk crystal growth and optical and thermal properties of the nonlinear optical crystal l-histidinium-4-nitrophenolate 4- nitrophenol (LHPP). Cryst Growth Des. 2012;12:2673–8.

Dhanuskodi S, Manivannan S, Philip J. Growth, structural, thermal and optical properties of organic NLO crystal: N-methyllutidone trihydrate. J Cryst Growth. 2004;265:284–9.

Beasley JD. Thermal conductivities of some novel nonlinear optical materials. Appl Opt. 1994;33:1000–3.

Dmitriev VG, Gurzadyan GG, Nikogosyan DN. Handbook of nonlinear optical crystals. 3rd ed. Berlin: Springer; 1999.

Eimerl D. Electro-optic, linear and nonlinear optical properties of KDP and its isomorphs. Ferroelectrics. 1987;72:95–139.

Hager GD, Hanes SA, Dreger MA. Continuous wave frequency doubling of a high energy 1315 nm laser. IEEE J Quantum Electron. 1992;28:2573–6.

Bierlein JD, Vanherzeele H. Potassium titanyl phosphate: properties and new applications. J Opt Soc Am B. 1989;6:622–33.

Minemoto H, Ozaki Y, Sonoda N, Sasaki T. Intracavity second-harmonic generation using a deuterated organic ionic crystal. Appl Phys Lett. 1993;63:3565–8.

Nikogosyan DN. Nonlinear optical crystals: a complete survey. New York: Springer; 2005.

Manivannan S, Dhanuskodi S, Tiwari SK, Philip J. Laser induced surface damage, thermal transport and microhardness studies on certain organic and semiorganic nonlinear optical crystals. Appl Phys. 2008;B90:489–96.

Lawn BR, Fuller ER. Equilibrium penny-like cracks in indentation fracture. J Mater Sci. 1975;10:2016–24.

Sangwal K. Microhardness of as-grown and annealed lead sulphide crystals. J Mater Sci. 1989;24:1128–32.

Gong J, Miao H, Peng Z, Qi L. Effect of peak load on the determination of hardness and Young’s modulus of hot-pressed Si3N4 by nanoindentation. Mater Sci Eng. 2003;A354:140–5.

Mary Linet J, Jerome Das S. Optical, mechanical and transport properties of unidirectional grown l-tartaric acid bulk single crystal for non-linear optical application. Mater Chem Phys. 2011;126:886–90.

Onitsch EM. Over the microhardness of the metals. Mikroskopie. 1947;2:131–51.

Wooster WA. Physical properties and atomic arrangements in crystals. Rep Prog Phys. 1953;16:62–82.

Sudharsana N, Keerthana B, Nagalakshmi R, Krishnakumar V, Guru Prasad L. Growth and characterization of hydroxyethylammonium picrate single crystals for third-order nonlinear optical applications. Mater Chem Phys. 2012;134:736–46.

Acknowledgements

The authors (VK and SB) are grateful to the Department of Science and Technology (DST), New Delhi, India, for their financial support through the Grant No, SR/S2/CMP-0028/2011, Dt.1-12-2011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kannan, V., Rakhikrishna, R., Philip, J. et al. Studies on thermophysical and mechanical properties of hydrazonium l-tartrate. J Therm Anal Calorim 116, 339–347 (2014). https://doi.org/10.1007/s10973-013-3444-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3444-1