Abstract

In this study, two Turkish crude oils from southeastern part of Turkey and their saturate, aromatic, resin fractions were analyzed by differential scanning calorimetry (DSC). The experiments were performed at three different heating rates (5, 10, 15 °C min−1) under air atmosphere. Two different reaction regions were observed from DSC curves due to the oxidative degradation of crude oil components. In the first reaction region, it was deduced that the free moisture, volatile hydrocarbons were evaporated from the crude oils, light hydrocarbons were burned, and fuel was formed. The second reaction region was the main combustion region where the fuel was burned. From DSC curves, it was observed that as the sample got heavier, the heat of the reaction increased. Saturates gave minimum heat of reaction. As the heating rate increased, shift of peak temperatures to high values and extended reaction region intervals were observed. The kinetic analysis of the crude oils and their fractions were also performed using ASTM E-698 and Borchardt and Daniels methods, respectively. Activation energy values of the crude oil samples and the fractions’ high-temperature oxidation region were close to each other and varied between 67 and 133 kJ mol−1 in ASTM and 35 and 154 kJ mol−1 in Borchardt and Daniels methods, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thermal analysis techniques constitute an important part in crude oil characterization. Numerous researchers used thermogravimetry (TG/DTG), differential thermal analysis, and differential scanning calorimeter (DSC) techniques to determine the composition and kinetics of crude oils [1, 2].

Vossoughi and Willhite [3] described kinetic model of the in situ combustion process for the data obtained from DSC and TG. In TG, four different reaction regions were observed, known as distillation, low-temperature oxidation (LTO), first and second combustion/cracking reactions. From the DSC, the heat availability and the fuel heating value were calculated. Kok and Iscan [4, 5] applied DSC to the combustion of crude oils in the presence and absence of metal oxides. Three different reaction regions were observed: LTO, fuel deposition (FD), and high-temperature oxidation (HTO). The kinetic data indicated that the crude oils with catalyst had lower activation energy. This is attributed to the fact that catalysts lowered the energy need for commencing the reactions and provided additional pathways for the reactions. Castro and Vazquez [6] analyzed the four different Mexican crude oils and their SARA fractions using TG and DSC techniques. TG technique was used to characterize the volatilization and decomposition temperature of crude oils and observed that the decomposition temperature was increased with the increasing average molecular mass of crude oil. DSC experiments showed the transition regions of SARA fractions. Ranjbar and Pusch [7] characterized the oil on the basis of light hydrocarbon, resin, and asphaltene content and studied the effects of oil composition on the pyrolysis kinetics of oil and combustion kinetics of fuel under the idealized reservoir conditions. The results revealed that the colloidal composition of oil as well as transferability and the heat transfer of the medium where pyrolysis reactions are taking place have an influence on the fuel formation and composition. Karacan and Kok [8, 9] investigated the pyrolysis behavior of crude oils and their fractions using DSC and TG. The DSC curves showed endothermic effect at the end of mass loss completion. Mass loss properties of SARA fractions showed that each fraction in the crude oil follows its own reaction path. Ambalae et al. [10] studied the pyrolysis and combustion behavior of crude oil and its asphaltenes each mixed with the reservoir sand using TG. Arrhenius method was applied for the determination of kinetic parameters. The activation energy calculated for the whole oil and the asphaltene were in close agreement. Al-Saffar et al. [11] investigated the oxidation behavior of North Sea light crude oil and its SARA fractions in consolidated cores. The results demonstrated that the light crude oils were highly reactive at low temperatures since they were highly composed of saturates fraction and saturates mainly contribute to the FD and oxygen consumption at low temperatures. Mendez Kuppe et al. [12] studied the heat of combustion of three different crude oils and their respective SARA fractions. They concluded that saturates and aromatics heating values were higher than the resins and asphaltenes. Moreover, saturates and aromatics heating values were close to each other also for resins and asphaltenes. Heat of combustion values were not independent of the presence of the other fractions. Freitag and Verkoczy [13] studied the low-temperature oxidation reactions of the SARA fractions of crude oils. The results indicated that the observed reaction kinetics could not be modeled with the usual approach for modeling LTO where reaction products were measured and relatively stable residues with high oxygen contents were obtained. Alvarez et al. [14] carried out thermal analysis experiments for the tendency of coke formation of atmospheric residue from heavy crude oil and its SARA fractions. Pyrolysis kinetics of residue and its fractions were also done by isoconversional analysis assuming first order kinetics. The highest amount of coke and also the activation energy was obtained from asphaltene fraction.

The aim of this research is to investigate the combustion behavior and kinetics of different-origin crude oil and their SARA fractions. At the same time, the aim was to assess the variations in the combustion behavior of crude oil and SARA fraction combustion as the heating rate was changed.

Materials and methods

In this study, TA Instruments DSC Q-200 was used to perform the experiments. All the DSC experiments were run with copper pans. For all the experiments sample mass of approximately 2 mg was used (as it is proposed for thermal measurements) with constant heating rates of 5, 10, and 15 °C min−1 in a temperature range 25–600 °C. The DSC T-zero calibration is done by sapphire disks and temperature calibration is done by heating indium through its melting transition.

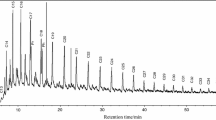

Each of the crude oils from southeastern part of Turkey was tested using the full ASTM-recommended procedure using n-hexane to separate the asphaltenes. The ASTM procedure is a chromatographic separation of the non-asphaltic oil components through two columns: an attapulgite clay-packed column adsorbs the resins and a second column packed with activated silica gel separates aromatics from the saturate fraction. A 50:50 mixture of toluene and acetone is used to recover the resin fraction from the clay packing. The aromatics can be recovered by Soxhlet extraction of the silica gel in hot toluene. Volatile components lost during the process are calculated by mass difference [8]. The properties of the crude oils and the SARA fractions are given in Tables 1 and 2, respectively.

Results and discussion

Although crude oils are complex mixtures with widely varying physical properties, in an oxidizing environment, the system undergoes exothermic reactions and as a result exothermic peaks occur in DSC curves with the exception of distillation process which is an endothermic process.

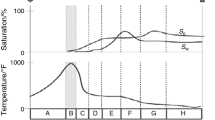

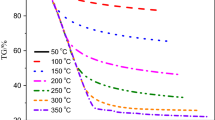

In air atmosphere two distinct reaction zones were identified for both crude oils and their fractions known as LTO and HTO. It is a known fact that the crude oils formed from four main fractions which are the saturates, aromatics, resins, and asphaltenes. Among them, saturates are the lightest part and react with oxygen at relatively low temperatures. Therefore, they are highly reactive at LTO reactions. LTO reactions are the heterogeneous reactions between liquids and gases. In LTO reaction regions, volatile hydrocarbons are vaporized and the light hydrocarbons are oxidized. During this reaction, the crude oil is coked and deposited in the solid matrix as fuel for the continuity of in situ combustion process. Therefore, saturates are responsible for triggering of the oil combustion and formation of the coke for the continuity of the combustion. On the other hand, asphaltenes are the heaviest part of the crude oils and were affected from the oxygen at relatively high temperatures. HTO reaction regions are heterogeneous reactions between liquid and gas and produce carbon oxides and water. Aromatics and resins are between these two ends. These two reaction regions involve quite different chemical reactions at different heating rates, but occur across overlapping temperature ranges (Figs. 1, 2, 3, 4, 5, 6). It is the known fact that the heavier oils release high amount of heat in HTO reaction region. This high heat release in HTO is attributed to the asphaltene content of the crude oil. Hence, the role of asphaltene in the combustion process is sustaining the combustion. In other words, asphaltene is needed for the continuity of the combustion.

DSC reaction intervals, peak temperatures, heat of reactions, and heat flow rates of the crude oils and their fractions at three different heating rates are given in Table 3. From this table, it can be deduced that reaction temperatures of saturates (both LTO and HTO) were lower than other fractions, since they are the lightest part in crude oils. On the other hand, reaction temperatures of resins (both LTO and HTO) were highest.

Under non-isothermal conditions, DSC curves giving heat flow rates as the crude oils and their fractions reacted with the flowing gas indicated that crude oils and their fractions were generating almost similar heat flow rates in different heating rates. From the viewpoint of heat of reactions it was observed that saturates gives the lowest amount of heat and resins give the highest; since saturates were the lightest part of the crude oil. It was observed that the peak temperatures for all fractions were shifted to the high temperatures with increasing heating rates. The peak temperatures for saturates were lower whereas higher in resins. Moreover, the reaction temperature intervals for all samples were increased with an increase in heating rate (Table 3).

Kinetic analysis

Modeling of the reactions taking place during in situ combustion is a complex process which involves the simultaneous heat and mass transfer in multi-phase environment. Separating the oil into its SARA fractions which is more representative and less complex than whole oil offers more meaningful kinetic study of oxidation reactions. In this study, ASTM E-698 [15] and Borchardt and Daniels [16] kinetic methods were applied.

ASTM E-698 covers the determination of the overall kinetic parameters for exothermic reactions and is applicable to reactions whose behavior can be described by the Arrhenius equation and the general rate law. Determination of kinetic parameters by the peak temperatures requires very precise measurement of reaction peak temperatures as a function of linear programmed heating rates. In this method, the sample temperature is increased in linear heating rates and any exothermic peaks are recorded. Trial and error procedure is used and the activation energy is calculated from the slope as follows:

where T is the peak temperature, β is the heating rate, and E is the activation energy.

The Borchardt and Daniels kinetics analysis calculates kinetics parameters, such as reaction order, heat of reaction and activation energy, and the Arrhenius frequency factor from data obtained during a single linear heating rate scan. The Borchardt and Daniels kinetics analysis uses twenty segments of the curve, evenly spaced by temperature, the first segment starts at 10 % of maximum peak height and the last segment ends at 50 % of peak area. The values for parameters reaction order, activation energy, and Arrhenius constant are obtained by a multiple regression analysis of this data. This model, based on a single-heating rate run to analyze the curing reaction assuming nth order kinetics, is expressed by the following equation.

where α is the amount of sample undergoing the reaction, n is the reaction order, and E is the activation energy.

Activation energy values of crude oil samples and fraction at different heating rates for high-temperature oxidation reactions were calculated using the above-mentioned kinetic models. In ASTM method, activation energy values were in the range of 67–133 kJ mol−1 for crude oil-1 and fractions and 77–99 kJ mol−1 for crude oil-2 and the fractions, respectively (Table 4). Aromatics and resins behaved in a same manner; that is, the activation energies of aromatic were lower than resins. Although saturates’ activation energy values were not lower than the aromatics and resins, which could be attributed to the close peak temperatures of saturates at each heating rate. In Borchardt and Daniels kinetics analysis, activation energy and Arrhenius constant values are determined in high-temperature oxidation region at three different heating rates separately. The activation energy values were in the range of 35–154 kJ mol−1 for crude oil-1 and fractions and 50–122 kJ mol−1 for crude oil-2 and the fractions, respectively (Table 5). In Borchardt and Daniels kinetics analysis, it was observed that the activation energy and the pre-exponential factor values were increased with increased heating rate. The activation energies and the pre-exponential factors were highest for resin fractions. The activation energy values of the crude oil were again higher than the saturate. Saturates’ low activation energy values indicates that they require low energy for the combustion. Therefore, they activate the combustion at very low temperatures.

In general the activation energy values were not close to each other in two different kinetic models studied. Differences between the activation energy values can be explained with the different equation parameters and assumptions that those models are based on.

Conclusions

In this research, thermal behavior and kinetics of crude oils and SARA fractions were studied by differential scanning calorimeter. The following conclusions were derived from the research conducted.

-

In combustion with air, two main transitional stages are detected at each heating rate known as low- and high-temperature oxidation reactions.

-

As the heating rates increased, the peak temperatures were shifted to high temperatures. The heat flow from the samples was increased for all samples and the temperature at which the reactions completed was increased. The resins, heavier part of the crude oils, released more heat during combustion. Their temperature extents were larger and reaction completing temperatures were higher.

-

Activation energy values of the crude oil samples and the fractions’ high-temperature oxidation region were close to each other and varied between 67 and 133 kJ mol−1 in ASTM and 35 and 154 kJ mol−1 in Borchardt and Daniels methods, respectively.

References

Tovar LP, Maciel MRW, Araujo AS, Maciel R, Batistella CB, Medina LC. Kinetic study on catalytic cracking of Brazilian high-boiling-point petroleum fractions. J Therm Anal Calorim. 2012;110:1267–81.

Silva EFB, Ribeiro MP, Coriolano ACF, Melo ACR, Santos AGD, Fernandes VJ, Araujo AS. Kinetic study of degradation of heavy oil over MCM-41. J Therm Anal Calorim. 2011;106:793–7.

Vossoughi S, Willhite GP. Development of a kinetic model for in-situ combustion and prediction of the process variables using TGA/DSC techniques. Soc Petrol Eng (SPE) 1982;4:1–12.

Kok MV, Iscan AG. Catalytic effects of metallic additives on the combustion properties of crude oils by thermal analysis techniques. J Therm Anal Calorim. 2011;64:1311–8.

Kok MV. Characterization of medium and heavy crude oils using thermal analysis techniques. Fuel Process Technol. 2011;92:1026–2031.

Castro LV, Vazquez F. Fraction and characterization of Mexican crude oils. Energy Fuels. 2009;23:1603–9.

Ranjbar M, Pusch G. Pyrolysis and combustion kinetics of crude oils, asphaltenes and resins in relation to thermal recovery processes. In: Proceedings of the 9th international conference on fundamental aspect. Analytical Techniques, Processes and Applications of Pyrolysis. 1991.

Karacan O, Kok MV. Pyrolysis analysis and kinetics of crude oils. J Therm Anal. 1998;52:781–8.

Kok MV, Karacan CO. Behavior and effect of SARA fractions of oils during combustion. Soc Petrol Eng J. 2000;3:380–5.

Ambalea A, Mahinpey N, Freitag N. Thermogravimetric studies on pyrolysis and combustion behavior of a heavy oil and its asphaltenes. Energy Fuels. 2006;20:560–5.

Al-Saffar HB, Hasanin H, Price D, Hughes R. Oxidation reactions of a light crude oil and its SARA fractions in consolidated cores. Energy Fuels. 2001;15:182–8.

Mendez Kuppe GJ, Mehta SA, Moore RG, Ursenbach MG, Zalewski E. Heats of Combustion of Selected Crude Oils and Their SARA Fractions. J Can Petrol Technol. 2008;47:38–42.

Freitag NP, Verkoczy B. Low temperature oxidation of oils in terms of SARA fractions: why simple reaction models don’t work. J Can Petrol Technol. 2005;44:54–61.

Alvarez E, Marroquin G, Trejo F, Centeno G, Ancheyta J, Diaz J. Pyrolysis kinetics of atmospheric residue and its SARA fractions. Fuel. 2011;90:3602–7.

ASTM E-698. Standard Test method for arrhenius kinetic constants for thermally unstable materials using differential scanning calorimetry and Flynn/Wall/Ozawa method.

Borchardt H, Daniels F. The application of differential thermal analysis to the study of reaction kinetics. J Am Chem Soc. 1957;79–80:41–46.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kök, M.V., Gul, K.G. Combustion characteristics and kinetic analysis of Turkish crude oils and their SARA fractions by DSC. J Therm Anal Calorim 114, 269–275 (2013). https://doi.org/10.1007/s10973-013-3256-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3256-3