Abstract

The current study was performed to investigate possible interactions between triazole antifungal drug itraconazole (ITR) with selected excipients commonly used for development of solid lipid nanoparticles. The excipients included common lipids (glyceryl behenate (Compritol 888 ATO™), glyceryl monostearate, stearic acid, and cetyl palmitate), charge inducers (dicetyl phosphate and stearlyamine), and surfactants (sodium cholate and sodium deoxycholate). Differential scanning calorimetry, isothermal stress testing, Fourier transform infrared spectral analysis, optical microcopy, and X-ray powder diffraction analysis were performed for assessing the compatibility between the drug and the excipients. Results of the study suggest that the stearic acid exhibited drug–excipient interactions, whereas all other excipients used in the study were found to be compatible with ITR.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The incompatibility between drugs and excipients can alter the physicochemical properties of drugs, and hence, can have an effect on its efficacy and many times safety profile [1]. Therefore, drug–excipient interaction study at the initial stage of a formulation development should be treated as an imperative exercise to ensure correct selection of excipients, hereby, increasing the possibility of developing a successful dosage form. In particular, the cost and time constraints associated with the process of pharmaceutical product development have made this type of predictability techniques even more desirable.

Regardless of the significance of drug–excipient compatibility testing, no globally accepted protocol is now available for evaluating compatibility/incompatibility between drugs and excipients [2, 3]. Some of the reported methods have poor predictive values, while others are tedious and time consuming. Differential scanning calorimetry (DSC) has been used as an important tool for evaluating drug–excipient interactions [4–6]. Despite its advantages like small sample requirements and rapid results, DSC is often associated with drawbacks like requirement of anhydrous operating conditions, and impractical exposure of the samples to high temperatures (e.g., up to or exceeding 300 °C), which in real situations is not usually experienced by the dosage form to be developed. Therefore, DSC used in isolation usually result in misleading or incomplete interpretations.

Isothermal stress testing (IST) involves storage of drug–excipient blends with or without moisture at high temperatures for a specific period of time (usually 3–4 weeks). This allows the acceleration of drug and its possible interaction with excipients. After that the samples are visually examined and drug content is determined.

Ideally, DSC and IST should be used in conjunction during drug–excipient interaction studies for the selection of appropriate excipients. Also, the use of physicochemical techniques has been emphasized in recent reports to provide conclusive information about possible drug–excipient interactions [7–9].

Itraconazole (ITR) is a triazole antifungal agent used in the treatment of infections caused by a variety of pathogenic fungi [10]. Being a BCS Class II drug, (with aqueous solubility of 1 × 10−9 g mL−1 at neutral pH), based on administration of the commercial capsules, absorption of ITR from gastrointestinal tract is highly variable, dose dependent, and incomplete [11–14]. This prompted us to devise our mainstream project involving development of novel solid lipid nanoparticles (SLNs)-based carrier system of ITR, which is expected to improve the bioavailability of ITR in comparison to the conventional dosage forms.

As a part of our ongoing project, the present study explains the findings of ITR-excipient compatibility studies carried out using SLN components, i.e., common lipids, surfactants, and surface charge inducers. Besides DSC and IST, in current study, Fourier transform infrared (FTIR) spectroscopy, powder X-ray diffraction (PXRD), and optical microscopy of ITR-excipient mixtures have been utilized as complementary methods to evaluate possible ITR-excipients interactions.

Materials and methods

Chemicals and reagents

Itraconazole was provided as gift sample by Nosch Labs Pvt. Ltd. (Hyderabad), India. Glyceryl behenate (marketed as Compritol 888 ATO™) was a generous gift from Colorcon Asia Pvt. Ltd. (Goa), India. Dicetyl phosphate, sodium cholate, sodium deoxycholate, and stearylamine were procured from Sigma-Aldrich Corporation (Bangalore), India. Glyceryl monostearate and stearic acid were procured by Loba Chemie Pvt. Ltd., (Mumbai) India, whereas cetyl palmitate was procured from Merck Chemicals (Goa), India.

Preparation of ITR-excipient binary mixtures

The binary mixtures were prepared by taking equal masses of drug and excipients and screening them through 60-mesh sieve repetitively until homogenous mixtures were formed, which were subsequently used for FTIR spectroscopy, PXRD analysis, and optical microscopy. For IST studies, nominal maximum expected ratio of excipient to ITR was used while preparing the binary physical mixtures.

FTIR spectroscopy

Fourier transform infrared absorption spectra were recorded using KBr disk method (Perkin-Elmer Co., England). Scanning was performed over a range of 500–4,000 cm−1 with a resolution of 4 cm−1.

PXRD analysis

The PXRD patterns were recorded on an X-ray diffractometer (X’Pert-PRO, PANalytical, Netherlands) with Cu as tube anode. The diffractograms were recorded under the following conditions: voltage: 40 kV, current: 35 mA, slit: 0.1 mm, and scanning speed: 2θ° min−1.

Optical microscopy

Optical micrographs of ITR and ITR-excipient binary mixtures were recorded at 100× magnification (oil immersion objective) by optical microscope fitted with built-in camera (Eclipse 80i, Nikon Instruments Inc., Tokyo, Japan).

DSC analysis

The calorimeter (DSC, Q20, TA Instruments-Waters LLC, USA) was calibrated for temperature and heat flow accuracy using the melting of pure indium. Each sample (5 × 10−3 g) was taken in aluminum pan, covered with lid and sealed. DSC curves were obtained under a nitrogen purge of 50 cm3 min−1 at a heating rate (V h) of 10 °C min−1 over the temperature range of 25–350 °C.

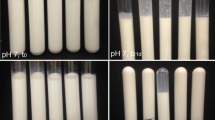

IST study

Isothermal stress studies were performed using the method suggested by Singh and Nath with slight modification [15]. The samples (ITR and different excipients in maximum expected w/w ratios) were weighed directly in 5 mL glass vials (n = 2), and preliminarily mixed using vortex mixer, and water-dimethylsulfoxide mixture (1:1, v/v) equal to the mass of ITR-excipient blend was added to the vials. The drug–excipient blends were then stirred using glass capillary (both end of which were heat sealed). To avoid any loss of sample, the capillary was broken and left within each vial. Each vial was screw capped tightly and kept at 50 °C in hot air oven, (Narang Scientific works, India). The samples were periodically examined for any change in color. Following storage of 4 weeks in the above conditions, the samples were quantitatively examined using HPLC.

For the analysis of active-excipient mixtures, an HPLC system equipped with binary pumps (model 515), dual wavelength detector (model 2487) and Rheodyne manual injector (Waters, MA, USA) was used. The data was acquired and processed in Empower 2 software (Waters, MA, USA). Chromatographic separation was achieved using Hibar® 250 × 4.6 mm2 HPLC column Purospher STAR RP-18 endcapped (5 μm particle size; Merck KGaA, Germany). The wavelength of detection was 254 nm. The mobile phase consisted of a mixture of acetonitrile and ammonium formate buffer (20 mM, pH 7.0) in 70:30 ratio (v/v). The flow rate of mobile phase was kept at 1.0 mL min−1. The injection volume employed for analysis was 20 × 10−3 mL. A concentrated stock solution of ITR (1 × 10−3 g mL−1) was prepared in dimethylsulfoxide. The calibration curve standards were prepared by serial dilution of the stock solution in mobile phase to achieve solutions containing ITR ranging between 0.02 and 2.0 × 10−6 g mL−1. All the samples were filtered through 0.45 μm nylon membrane filter (Sartorius AG, Germany) before analysis. Validation of the method was performed as per ICH and USFDA validation guidelines.

Results and discussion

The PXRD patterns of ITR and ITR-excipient binary mixtures have been represented in Fig. 1. As described in our previous reports [16, 17], the PXRD patterns for ITR, exhibited sharp characteristic peaks which can be used as a fingerprint. The peak corresponding to 100 % relative intensity was observed at 2θ° value of 20.384. Also, other important peaks corresponding to 61.04, 57.22, and 58.22 % relative intensity were observed at 2θ° values of 14.471, 17.971, and 23.518, respectively. The above mentioned four peaks were taken as reference for comparison with the diffractograms of ITR-excipient binary mixtures.

The FTIR spectrum of ITR exhibited the characteristic bands including 1,699 cm−1 (C=O stretch), 1,454 cm−1, and 1,512 cm−1 (aromatic C=C stretch), 1,045 cm−1 (aryl-Cl), 1,224 cm−1, and 1,046 cm−1 (C–O stretch), and 1,383 cm−1 (C–N stretch). Also, peaks attributable to sp3 alkyl C–H and sp2 alkyl C–H stretch vibrations were encountered at 2,823–2,965 and 3,068–3,129 cm−1, respectively. The FTIR spectra of various excipients and ITR-lipid binary mixtures have been depicted in Figs. 2 and 3, respectively. The excipients showed markedly different FTIR spectra in comparison with the drug (Figs. 2a1–a4, 3c1–c4). The binary mixtures of ITR with various excipients were examined for the presence of C=O, C–O, C=C, aryl-Cl, and C–N stretch bands to affirm unchanged chemical structure of the drug and the absence of chemical interaction between ITR and each excipient be assumed at least at ambient temperature.

The optical microscopic images of ITR and ITR-excipient binary mixtures are depicted in Fig. 4. As previously described [18], the microscopic image of ITR reveals that the drug possess acicular crystal habit. The long crystals show great variations in their length. Optical micrographs of ITR-excipient binary mixtures were studied to ensure the retention of the ITR crystal habitat and also, absence of any adhesive interfaces.

In accordance with literature reports [19, 20], the DSC curve of ITR exhibits a sharp endotherm ranging between 166 and 169 °C (Fig. 5), which represents the melting point of ITR. The DSC curve of ITR, excipients, and ITR-excipient binary mixtures have been depicted in Figs. 5, 6, 7, 8, 9, 10, 11, and 12.

The individual comparison of PXRD patterns, FTIR spectra, optical photomicrographs, and DSC curves of ITR and each ITR-excipient binary mixture is discussed in this article.

ITR-glyceryl behenate

The DSC curve of glyceryl behenate showed sharp melting endotherm at 79.72 °C, whereas the ITR-glyceryl behenate binary mixture displayed individual peaks of both components, showing their compatibility (Fig. 5). The PXRD pattern of the binary mixture (Fig. 1a) revealed characteristic ITR diffraction peaks and FTIR studies (Fig. 2b1) of the same, consisted of characteristic stretch bands arising from functional groups present in ITR molecule. The optical micrograph of ITR-glyceryl behenate (Fig. 4a) showed needle shaped ITR crystals and no adhesive interface was seen.

ITR-cetyl palmitate

A broad melting endotherm at 51.96 °C was observed in the DSC curve of cetyl palmitate, and the scan of binary mixture also consisted of the individual ITR and cetyl palmitate peaks (Fig. 6). This was hence concluded that ITR is compatible with cetyl palmitate. In addition, PXRD (Fig. 1b), FTIR spectroscopy (Fig. 2b2) and microscopy (Fig. 4b) results confirmed the same.

ITR-glyceryl monostearate

The DSC curve of glyceryl monostearate exhibited broad melting endotherm at 69.45 °C (Fig. 7). However, the binary mixture of ITR and glyceryl monostearate showed endothermic peaks at 60.22 and 151.83 °C. The FTIR spectrum of ITR-glyceryl monostearate mixture has not shown any changes in the ITR characteristic peaks (Fig. 2b3). This shift in peaks could be a result of some chemical incompatibility between ITR and glyceryl monostearate in presence of heat, because in addition to FTIR spectroscopy, PXRD (Fig. 1c), and microscopy (Fig. 4c) ruled out any physical interaction while studying ITR-glyceryl monostearate mixture at ambient temperature.

ITR-stearic acid

While studying the DSC curve of ITR-stearic acid binary mixture (Fig. 8), it was noted that ITR endotherm was completely missing in, and this strongly suggests that presence of chemical incompatibility between ITR and stearic acid, in presence of heat. The PXRD patterns of the binary mixture also showed suppressed ITR diffraction peaks (Fig. 1d). However, FTIR of ITR-stearic acid mixture showed no new peaks (Fig. 2b4). The microscopic study also showed partial loss of crystal habit (Fig. 4d). In totality, these results reflect the occurrence of chemical interaction between ITR and stearic acid.

ITR-stearylamine

The DSC curve of stearylamine showed melting endotherm at 60.86 °C, and the excipient and drug peaks were well retained in the case of binary mixture (Fig. 9). The PXRD (Fig. 1e), FTIR spectra (Fig. 3d1), and optical microscopy (Fig. 4e) also confirmed the absence of ITR interaction with stearylamine.

ITR-dicetyl phosphate

Similarly, the DSC curve of dicetyl phosphate showed sharp endothermic peak at 75.54 °C, which was well preserved along with the drug peak in the DSC curve of ITR-dicetyl phosphate (Fig. 10). In addition, the acicular needles in optical micrograph (Fig. 4f), the stretch vibration bands of FTIR spectra (Fig. 3d2) and X-ray diffraction pattern in accordance with ITR (Fig. 1f) for the ITR-dicetyl phosphate reconfirmed the absence of any incompatibility.

ITR-sodium cholate

The presence of distinct ITR melting endotherm, in DSC curves of ITR-sodium cholate (Fig. 11), binary mixture was observed. Also, no solid state interaction was evident in the results of PXRD (Fig. 1g), FTIR spectra (Fig. 3d3), and microscopic analysis (Fig. 4g). Therefore, it could be assumed that the ITR and sodium cholate are compatible.

ITR-sodium deoxycholate

Similarly, the DSC curve of ITR-sodium deoxycholate also consisted of sharp endothermic peak of ITR melting, ruling out drug–excipient interaction (Fig. 12). In addition, the results of PXRD (Fig. 1h), FTIR spectroscopic analysis (Fig. 3d4), and optical microscopy affirmed the absence of solid state interaction of ITR and sodium deoxycholate.

IST studies

The results of IST have been depicted in Table 1. It was observed that <2 % loss of drug content of in the stressed drug–excipient blends with respect to control samples was observed for ITR-glyceryl behenate, ITR-cetyl phosphate, ITR-stearylamine, ITR-sodium cholate, and ITR-sodium deoxycholate blends. On the other hand, ITR showed noticeable chemical interaction with stearic acid, and only 12.78 % of ITR was present in ITR-stearic acid stressed sample. The drug contents of ITR-glyceryl monostearate and ITR-dicetyl phosphate were found to be lower than control samples by 3.9 and 3.3 %, respectively.

The ITR-stearic acid blend showed brown color after stress studies (originally white). However, the other drug–excipient blends did not show any change in physical appearance.

Therefore, the IST studies showed that only stearic acid showed major chemical interaction with ITR, whereas the drug loss from remaining drug–excipient blends was very less, proving that all the selected excipients except stearic acid were found to be compatible with ITR.

Conclusions

Drug–excipient compatibility study has become an indispensible part of preformulation step of formulation development of new as well as established drugs. The results suggest that in combination to DSC, PXRD, FTIR, and microscopy could be used as efficient tools to evaluate compatibility between ITR and excipients. In addition to these techniques, IST should also be adopted in conjunction with the above mentioned studies to make definite conclusions. In this study, the DSC studies showed strong incompatibility between ITR and stearic acid especially in the presence of heat. As the production of SLNs involves exposure to heat during melting of lipid to solubilize the hydrophobic drug, stearic acid is not a good lipid for preparing ITR SLNs. In addition, other techniques for solid state compatibility testing also showed signs of possible incompatibility. But, the definitive conclusion was drawn only after IST study was performed. No evidences of interaction between ITR and rest of the excipients were observed. Therefore, based on the results of present study, it should be concluded that the SLNs of ITR could be developed using all the studied excipients except stearic acid.

References

Verma RK, Garg S. Selection of excipients for extended release formulations of glipizide through drug–excipient compatibility testing. J Pharm Biomed Anal. 2005;38:633–44.

Verma RK, Garg S. Compatibility studies between isosorbide mononitrate and selected excipients used in the development of extended release formulations. J Pharm Biomed Anal. 2004;35:449–58.

Pani NR, Nath LK, Acharya S. Compatibility studies of nateglinide with excipients in immediate release tablets. Acta Pharm. 2011;61:237–47.

Abbas D, Kaloustian J, Orneto C, Piccerelle P, Portugal H, Nicolay A. DSC and physico-chemical properties of a substituted pyridoquinoline and its interaction study with excipients. J Therm Anal Calorim. 2008;93(2):353–60. doi:10.1007/s10973-008-9062-7.

Drebushchak VA, Shakhtshneider TP, Apenina SA, Medvedeva AS, Safronova LP, Boldyrev VV. Thermoanalytical investigation of drug–excipient interaction. J Therm Anal Calorim. 2006;86(2):303–9. doi:10.1007/s10973-005-7440-y.

Pani N, Nath L, Acharya S, Bhuniya B. Application of DSC, IST, and FTIR study in the compatibility testing of nateglinide with different pharmaceutical excipients. J Therm Anal Calorim. 2012;108(1):219–26. doi:10.1007/s10973-011-1299-x.

Bruni G, Berbenni V, Milanese C, Girella A, Marini A. Drug–excipient compatibility studies in binary and ternary mixtures by physico-chemical techniques. J Therm Anal Calorim. 2010;102(1):193–201. doi:10.1007/s10973-009-0382-z.

Marini A, Berbenni V, Pegoretti M, Bruni G, Cofrancesco P, Sinistri C, et al. Drug–excipient compatibility studies by physico-chemical techniques: the case of atenolol. J Therm Anal Calorim. 2003;73(2):547–61. doi:10.1023/a:1025478129417.

Tita D, Jurca T, Fulias A, Marian E, Tita B. Compatibility study of the acetylsalicylic acid with different solid dosage forms excipients. J Therm Anal Calorim. 2013;112(1):407–19. doi:10.1007/s10973-013-2937-2.

De Beule K, Van Gestel J. Pharmacology of itraconazole. Drugs. 2001;61(S1):27–37.

Dobaria N, Badhan A, Mashru R. A novel itraconazole bioadhesive film for vaginal delivery: design, optimization, and physicodynamic characterization. AAPS PharmSciTech. 2009;10(3):951–9. doi:10.1208/s12249-009-9288-0.

Heykants J, Van Peer A, Van de Velde V, Van Rooy P, Meuldermans W, Lavrijsen K, et al. The clinical pharmacokinetics of itraconazole: an overview. Mycoses. 1989;32:67–87. doi:10.1111/j.1439-0507.1989.tb02296.x.

Buchanan CM, Buchanan NL, Edgar KJ, Klein S, Little JL, Ramsey MG, et al. Pharmacokinetics of itraconazole after intravenous and oral dosing of itraconazole-cyclodextrin formulations. J Pharm Sci. 2007;96(11):3100–16. doi:10.1002/jps.20878.

Barone JA, Moskovitz BL, Guarnieri J, Hassell AE, Colaizzi JL, Bierman RH, et al. Food interaction and steady-state pharmacokinetics of itraconazole oral solution in healthy volunteers. Pharmacotherapy. 1998;18(2):295–301.

Singh AK, Nath LK. Evaluation of compatibility of tablet excipients and novel synthesized polymer with lamivudine. J Therm Anal Calorim. 2012;108:263–7.

Kumar N, Shishu, Bansal G, Kumar S, Jana AK. Preparation and cyclodextrin assisted dissolution rate enhancement of itraconazolium dinitrate salt. Drug Dev Ind Pharm. 2012;. doi:10.3109/03639045.2012.681382.

Kumar N, Shishu, Bansal G, Kumar S, Jana AK. Ditosylate salt of itraconazole and dissolution enhancement using cyclodextrins. AAPS PharmSciTechnol. 2012;. doi:10.1208/s12249-012-9804-5.

Kumar N, Shishu, Kapoor VR. Facile syntheses of novel salts of a triazole antifungal agent with enhanced solubility. J Heterocycl Chem. 2012;. doi:10.1002/jhet.1120.

DiNunzio JC, Brough C, Miller DA, Williams RO, McGinity JW. Fusion processing of itraconazole solid dispersions by kinetisol® dispersing: a comparative study to hot melt extrusion. J Pharm Sci. 2010;99(3):1239–53. doi:10.1002/jps.21893.

Six K, Daems T, de Hoon J, Van Hecken A, Depre M, Bouche M-P, et al. Clinical study of solid dispersions of itraconazole prepared by hot-stage extrusion. Eur J Pharm Sci. 2005;24(2–3):179–86.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, N., Goindi, S., Saini, B. et al. Thermal characterization and compatibility studies of itraconazole and excipients for development of solid lipid nanoparticles. J Therm Anal Calorim 115, 2375–2383 (2014). https://doi.org/10.1007/s10973-013-3237-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3237-6