Abstract

To accomplish an effective analysis of adsorption, the strong acid dye from aqueous solution of sodium alginate (SA) and multi-walled carbon nanotubes (MWCNTs) composite gel beads were used as important parameters. Differential scanning calorimetry (DSC) was used to measure the heat of breakdown reaction. The experimental conditions were set at 0.5, 1, 2, 4, and 8 °C min−1, and the temperature range was 30–300 °C. The heating rates and the temperature range were set as follows: Four kinds of proportion in this experiment contained 2 SA % w/v (SA), 0.03, 0.09, 0.18, 0.36 % w/v (MWCNTs), and 10 % w/v calcium chloride, respectively. Four samples, 5, 6, 7, 8, and 9 mg, were used to detect the experimental data. It contributed to understanding the reaction for the distinctive MWCNTs. With the thermokinetic data by isoconversional approach obtained from advanced kinetics and technology solutions (AKTS), the related thermal safety information can be obtained from the thermal reaction of MWCNTs. Valuable parameters, such as activation energy (E a) and heat of decomposition, can be applied in operation, including adsorption and desorption processes. After DSC tests, and under the four compositions of SA/MWCNTs, at different heating rates of 0.5, 1, 2, 4, and 8 °C min−1, primarily we found that when the heating rate was increased, exothermic onset temperature would increase gradually. After analyzing E a value by isoconversional kinetics, we learned that in four different adsorption compositions, SA/MWCNTs0.03 (161.20 kJ mol−1) was the minimum. Among them, the highest value was SA/MWCNTs0.18 (220.48 kJ mol−1). However, in this study, for SA/MWCNTs compositions we found that E a value will drop in the final material SA/MWCNTs0.36. Accordingly, if the ratio of SA and calcium chloride was fixed, then different compositions of the MWCNTs would affect adsorption efficiency of SA/MWCNTs and E a variation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

From the time of Ijima’s discovery of carbon nanotubes (CNTs) in 1991 [1], they have become one of the more popular academic research topics globally [2]. CNTs are the thinnest tubes that can be made so far. With their light mass, they have high strength, high toughness, flexibility, high surface area, high thermal conductivity, sound electric conductivity, and chemical stability. To fully exploit the superior mechanical, electrical, and optical properties of multi-walled carbon nanotubes (MWCNTs), the dispersion and adhesion to a polymeric matrix are two key issues [3]. Both dispensability and matrix adhesion of MWCNTs can be improved either by covalent or non-covalent functionalization. Alginate is a collective term for a family as well as impeccable product mainly from brown seaweeds that has been widely used in food, biomedical, pharmaceutical, and sewage-treating industries. In molecular terms, alginate consists of unbanked binary copolymers of α-l-guluronic acid (G) and (1,4)-linked β-d-mannuronic acid (M) residues as monomers, constituting M-, G-, and MG sequential block structures [4].

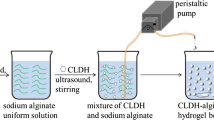

Most applications of alginate are based upon its gel-forming ability by means of cation binding: the shift from water-soluble sodium alginate (SA) to water insoluble calcium alginate, for example. Divalent cations preferentially bind toward the G-block instead of the M-block [5, 6]. The composition of monomers and their sequential character (i.e., blackness) do influence the gelatin behavior of alginate. In the presence of Ca2+, G-rich samples normally form hard, brittle gels, when M-rich samples produce soft and elastic gels [4], and the “egg-box” has been recognized as a general model to explain the gel formation [7, 8]. In practice, calcium chloride is a polymer flocculant that has been used to assist the description check used in wastewater treatment.

We used 0.5, 1, 2, 4, and 8 °C min−1 of heating rates at differential scanning calorimetry (DSC), and respectively used 2/0.03, 2/0.09, 2/0.18, 2/0.36 g, 10 % (w/v) in Table 1 of SA/MWCNTs and calcium chloride by the different ratios in this experimental test. The sample masses of 5, 6, 7, 8, and 9 mg were used to detect the experimental data by materials. Isoconversional kinetics analysis was used for SA and calcium chloride for the same mass, and adsorption on different compositions of MWCNTs, and understanding for adsorption efficiency.

Experimental procedures

Materials and methods

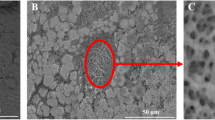

The MWCNTs were prepared by sulfuric and nitric mixed acid under ultrasonic vibration. The proper amount of MWCNTs was added to mix acid; the volume ratio of H2SO4 to HNO3 in terms of concentration was 3:1. Ultrasonic vibration was employed based upon reaction time. Filtration was conducted with a sand core filter and micropore filter. Pure DI water was applied to rinse the filtrate until the aqueous solution was finally neutral. As planned, the compositions of the SA, MWCNTs, and SA/MWCNTs series specimens were prepared in this study. Ten mL of an SA/MWCNTs aqueous solution was added dropwise to 50 mL of calcium chloride (10 %, w/v) aqueous solution for 20 min, followed by the sampling of supernatant at the pre-set time intervals. To determine the expression characteristics, the gel particles were pre-consolidated under a pressure of 8–30 kPa in a consolidation cell with an inner diameter of 2.0–3.0 mm to generate a packed gel bed and schematic evolution of the SA and MWCNTs of microsphere as a function of the calcium chloride. In addition, extra supplementary agents were of analytical grades (purity > 99.8 mass%) and all solutions were treated with double distilled water.

Differential scanning calorimetry (DSC)

DSC has been employed broadly for evaluating thermal hazards and investigating decomposition mechanisms of reactive chemicals in various industries and academic institutions. It is easy to operate, renders quantitative results, and provides information on thermal sensitivity (exothermic onset temperature, T 0), and severity (heat of decomposition, ΔH d) at the different heating rates. DSC was applied to measure and derive the fundamental exothermic features of 2/0.03, 2/0.09, 2/0.18, 2/0.36 g, and 10 % (w/v) SA/MWCNTs with calcium chloride. In this research, calorimetric technique was used to measure with Mettler Toledo DSC 821e with the application of thermal analysis STARe software, as through specimen temperature scanning. In practice, DSC is used to measure the relationship of heat accumulation and temperature change.

DSC is a useful tool for evaluating thermal hazards and investigating decomposition mechanisms of reactive chemicals if the experiments are carried out carefully. The experimental conditions were set as follows: The heating rates were at 0.5, 1, 2, 4, and 8 °C min−1 with a range of 30–300 °C. About 5, 6, 7, 8, and 9 mg of the sample were used to detect the experimental data.

Advanced kinetics and technology solutions (AKTS)

Through isoconversional kinetics model, the intent of advanced kinetics and technology solutions (AKTS) was to assist the study of raw materials and products within the scope of any type of kinetic analysis of thermoanalytical data. AKTS can be used during non-isothermal experiments for the heating rates of 0.5, 1, 2, 4, and 8 °C min−1 as a benchmark. AKTS thermodynamic package consists of a complete solid-state kinetic analysis of at least three major steps:

Results and discussion

We used DSC 821e of DSC for analyzing adsorption experiments in MWCNTs. By investigating experimental results, we learned the thermal stability and the material exothermic phenomenon decomposition reaction of MWCNTs. Tables 2, 3, 4, and 5 show that the heating rates were producing exothermic phenomena as temperature rose from 0.5 to 8 °C min−1. Through DSC experimental results, when the heating rate was increased, the measured exothermic wave of MWCNTs would rise to the highest temperature.

Different compositions of SA and calcium chloride were, in turn, employed as a bridge, making MWCNTs adsorption as an implementation to DSC preliminary analysis. Tables 2, 3, 4, and 5 also demonstrate that when SA and calcium chloride concentration was fixed, exothermic onset temperature T o also gradually increased. Table 6 shows that, by AKTS, the E a was 161.20, 196.26, 220.48, and 171.44 kJ mol−1 for the four compositions.

Hazard analysis by AKTS

The E a data for MWCNTs at various heating rates by DSC are presented in Tables 2, 3, 4, and 5. In each experimental point, α = 0.5, the corresponding conversion rate and temperature measurements. From a small experiment, but with a variety of equipment, it was easy to set up the conversion rate of reaction and temperature relationship. These parameters can be applied to derive and evaluate the activation energy E a and the modified pre-exponential factor A′(α) without explicitly guessing a particular form of the reaction model f(α). The results of differential conversion rate for MWCNTs accurately simulate the reaction rate dα/dt and reaction progress α as illustrated in Figs. 1 and 2 using the expressions of Eqs. (1) and (2):

Conversion rate with respect to temperature can be used to evaluate f(α) model of the special form of reaction activation energy E a(α). This is the most common differential conversion method proposed by Friedman. The conversion rate dα/dt as a function of the reciprocal temperature at any conversion α is expressed in Eq. (3):

where f(α) is a constant in the last term at any fixed value of α and the dependence of the logarithm of the conversion rate dα/dt on 1/T demonstrates a straight line with the slope m = −E a /R and intercept equals ln(A(α) f(α)) as presented in Figs. 3 and 4.

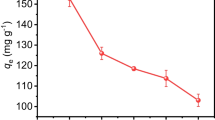

Adsorption analysis with different compositions of MWCNTs on MB

Finally, E a with the different compositions of MWCNTs is given in Fig. 5. As shown in Figs. 6, 7, 8, and 9, the adsorption of methylene blue (MB) increased with time. The absorbance of sample 3 (SA/MWCNTs0.18) can reach 2.225 absorbance after 72 h, which characterizes that SA itself has the ability to absorb the MB. Then there is the decolorization of SA/MWCNTs0.03, SA/MWCNTs0.09, and SA/MWCNTs0.36, with 2.042, 2.245, and 2.478 absorbance under the same conditions, respectively, when the content of MWCNTs was increased. In Fig. 10, the pH values were wholly raised in samples 1 and 4, which was an upward trend in 48 h. It is attributed to the fact that the surface of MWCNTs has plenty of carbonyl that reacted with MB. Another reason may be that the MWCNTs have huge specific surface area, giving them great adsorption ability. Furthermore, MWCNTs have void defects, which also show in favor of the adsorption of MB.

Conclusions

After analyzing E a value by AKTS, we found that under four different compositions the minimum E a as SA/MWCNTs0.03 was 161.20 kJ mol−1 and the highest value of SA/MWCNTs0.18 was 220.48 kJ mol−1. However, for various SA/MWCNTs compositions found in this experiment, E a value will drop in the final material SA/MWCNTs0.36. In the experiment, it can be seen from Fig. 1 that, at (a), (b), (d) of the three samples, the exothermic onset temperature was about 155–165 °C, and the sample (c) was at 180 °C in exothermic onset temperature. As the ratio of SA and calcium chloride was fixed, the results showed a great impact on the adsorption efficiency at different compositions for MWCNTs.

Finally, by means of isoconversional kinetics analysis with AKTS software, along with the study of the adsorption of the gel beads prepared by sol–gel with SA and MWCNTs, we explored the forming conditions of the gel beads and discussed the ability of adsorption to the gel beads, showing the stability and reusability of SA/MWCNTs. The results can be used for the adsorption of impurities in domestic or industrial wastewater.

Abbreviations

- E a :

-

Activation energy (kJ mol−1)

- ΔH d :

-

Heat of decomposition (J g−1)

- t :

-

Time (min)

- T :

-

Temperature (°C)

- T f :

-

Final temperature (°C)

- T p :

-

Peak temperature (°C)

- T 0 :

-

Exothermic onset temperature (°C)

- R :

-

Gas constant (8.31415 J K−1 mol−1)

- α :

-

Reaction progress

- β :

-

Imposed heating rate dT/dt (°C min−1)

- A′:

-

Modified pre-exponential factor A′(α) = A(α) f(α) (m3 mol−1 s−1)

- A :

-

Pre-exponential factor (m3 mol−1 s−1)

References

Olson TM. Oxidation kinetics of natural organic matter by sonolysis and ozone. Water Res. 1994;6:1383–91.

Hsieh SH, Horng JJ. Adsorption behavior of heavy metal ions by carbon nanotubes grown on microsized Al2O3 particles. J Univ Sci Technol. 2007;1:1–8.

Iijima S. Helical microtubules of graphitic carbon. Nature. 1991;354:56–8.

Chen C, Liang B, Ogino A, Wang X, Nagatsu MJ. Oxygen functionalization of multiwall carbon nanotubes by microwave-excited surface-wave plasma treatment. J Phys Chem C. 2009;113:7659–65.

Moe ST, Draget KI, Skjak-Brae G, Smidsrod O. Alginates. In: Stevens AM, editor. Food polysaccharides and their applications. New York: Marcel Dekker; 1995. p. 245–86.

Braccini I, Grasso RP, Perez S. Conformational and configurational features of acidic polysaccharides and their interactions with calcium ions: a molecular modeling investigation. Carbohydr Res. 1999;317:119–30.

Braccini I, Perez S. Molecular basis of Ca2+-induced gelation in alginates and pectins: the egg-box model revisited. Biomacromolecules. 2001;2:1089–96.

Morris ER, Rees DA, Thom D, Boyd J. Chiroptical and stoichiometric evidence of a specific, primary dimerisation process in alginate gelation. Carbohydr Res. 1978;66:145–54.

AKTS AG. AKTS-thermokinetics software and AKTS-thermal safety software. http://www.akts.com.

Maciejewski M. Computational aspects of kinetic analysis. Part B. The ICTAC kinetics project—the decomposition kinetics of calcium carbonate revisited, or some tips on survival in the kinetic minefield. Thermochim Acta. 2000;355:145–54.

Burnham A. Computational aspects of kinetic analysis. Part D. The ICTAC kinetics Project-Multi-thermal-history model-fitting methods and their relation to isoconversional methods. Thermochim Acta. 2000;355:165–70.

Roduit B. Computational aspects of kinetic analysis. Part E. The ICTAC kinetics project-numerical techniques and kinetics of solid state processes. Thermochim Acta. 2000;355:171–80.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Weng, SY., Liu, SH., Tsai, LC. et al. Thermokinetics simulation for multi-walled carbon nanotubes with sodium alginate by advanced kinetics and technology solutions. J Therm Anal Calorim 113, 1603–1610 (2013). https://doi.org/10.1007/s10973-013-3092-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3092-5