Abstract

Thermal behavior and decomposition kinetics of Formex-bonded PBXs based on some attractive cyclic nitramines, such as 1,3,5-trinitro-1,3,5-triazinane (RDX) and 1,3,5,7-tetranitro-1,3,5,7-tetrazocane (HMX). Actually, cis-1,3,4,6-tetranitrooctahy droimidazo-[4,5-d]imidazole (BCHMX) and 2,4,6,8,10,12-hexanitro-2,4,6,8,10, 12-hexaazaisowurtzitane (CL-20), was investigated by means of nonisothermal thermogravimetry (TG) and differential scanning calorimetry (DSC). It was found that the mass loss rate of PBXs involved in this research depends greatly on heating rate and the residue of the decomposition of these PBXs decreases with the heating rate. The onset of the exotherms was noticed at 215.4, 278.7, 231.2 and 233.7 °C with the peak maximum at 235.1, 279.0, 231.2 and 233.7 °C for RDX-Formex, HMX-Formex, CL-20-Formex, and BCHMX-Formex, respectively. Their corresponding exothermic changes were 1788, 1237, 691, and 1583 J g−1. It was also observed that the dependence on the heating rate for onset temperatures of HMX- and BCHMX-based PBXs was almost the same due to their similar molecular structure. In addition, based on nonisothermal TG data, the kinetic parameters for thermal decomposition of these PBXs were calculated by isoconversional methods. It was shown that the Formex base has great effects on the activation energy distribution of nitramines. It was further found that the kinetic compensation effects occurred during the thermal decomposition of nitramine-based PBXs, and they almost have the same compensation effects due to similar decomposition mechanism.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A polymer-bonded explosive or PBX is an explosive material in which explosive powder is bonded together in a matrices using typically 5–10 % by weight of a synthetic polymer [1]. In fact, PBXs are widely used in many military and civilian applications because of their high safety, processing ease, and superior strength [2]. The next generation of PBX materials will be improved in terms of insensitivity and high energetic density properties combined with an enhanced mechanical integrity [3]. Development of energetic materials with improved detonation properties and low sensitivity is underway to meet superior performance requirements of PBXs, and they appear to be the future candidates to compete with the currently used high performance high-energy materials such as RDX and HMX. Actually, BCHMX and CL-20 are energetic compounds of this kind [4–6].

There are always several aspects to investigate the performance and properties of such new PBXs, including their formulations and processability, initiation and sensitivity, thermal decomposition and stability, mechanical properties as well as detonation performance. Thermal degradation of polymers plays an important role in the thermal responses of many solid propellants and plastic-bonded explosives [7, 8]. Sell et al. [9] had applied isoconversional analysis to study thermal degradation of several propellants that include ammonium perchlorate as an oxidizer and polybutadiene-acrylic acid acrylonitrile terpolymer, hydroxy terminated polybutadiene, or bisazidomethyloxetane/azidomethyl-methylazidocopolymer as polymer binders. They demonstrate that comparison of the E a dependencies for degradation of a neat polymer and of a propellant based on this polymer allows one to elucidate the role of the latter. Felix et al. [10] have studied an effect of addition of polymers, Kel F and Viton A, on the kinetics of the thermal degradation of a plastic-bonded explosive. It is noteworthy that the standard model-fitting approach has not detected any effect, whereas isoconversional analysis revealed clearly that the addition of these polymers lowers the E a values from 250 to 180 kJ mol−1 for the early stages of degradation. The result has inspired further mechanistic studies. In fact, there are many more papers than I could summarize herein published related to thermal kinetic analysis of polymer-based explosives. However, as one of prominent energetic candidates for RDX, CL-20, and BCHMX have been used in many polymer-based explosives [11–13], while no data is available with regard to their thermal decomposition kinetics. In particular, therefore, this paper will discuss some new findings in the effect of polymer matrices (Formex P1) on thermal decomposition of PBXs containing BCHMX, HMX, RDX, and CL-20 (BCHMX-Formex, HMX-Formex, RDX-Formex, and CL-20-Formex, are defined in ‘Experimental’ section).

Experimental

Materials

BCHMX, which is a new polycyclic nitramine, was prepared by a two step continuous laboratory synthesis in our workgroup [6]. About 87 % of BCHMX, HMX (β-type, imported from Russia and particle size close to Class 3), RDX (a product of Dyno Nobel, mixture of Class 2 and 5), and CL-20 (ε-type, a product of Explosia pilot plant in Czech Republic) by weight was bonded by 13 % Formex matrices containing 25 % styrene–butadiene rubber (SBR) plasticized by 75 % oily material to form four new PBXs named BCHMX-Formex, HMX-Formex, RDX-Formex, and CL-20-Formex. The molecular structures of these cyclic nitramines are shown as scheme 1.

Experimental techniques

There are four kinds of samples involved in this experiments which are BCHMX-Formex, HMX-Formex, RDX-Formex, and CL-20-Formex. They are studied with regard to the kinetics of thermal decomposition, using thermogravimetry (TG, Netzsch 209F3 instrument, Al2O3 crucible) at heating rates of 2.5, 5, 7.5 (with data collecting rate of 40 points per Kelvin) and 10 °C min−1 (with data collecting rate of 60 points per Kelvin). The test temperature range for TG was 30–400 °C with the sample mass of about 1.35–1.45 mg under 30 mL min−1 dynamic nitrogen atmosphere. Their heat flow properties were also evaluated by the technique of differential scanning calorimetry (DSC, Netzsch 200F3 instrument, Aluminum pan with a pin hole cover, heat flow was calibrated by sapphire material), which was performed in the dynamic nitrogen atmosphere with a pressure of 0.1 MPa. The sample mass for DSC was about 0.9 mg with a heating rate of 5 °C min−1 and temperature range of 30–350 °C.

Nonisothermal kinetic parameters calculation

Solid-state reactions of composite energetic material PBX are in many cases complex and may involve several overlapping processes. The kinetic analysis of such solid-state reactions is challenging, as far as the kinetic parameters, including activation energy (E a), preexponential factor (A) and kinetic model (f(α)) of each individual process, should be determined for a complete kinetic description of the overall reaction. Thus, while a large number of analytical methods are available for evaluation of the kinetic parameters of discrete solid-state reactions, the number of procedures for the analysis of complex processes is much more limited. Methods for the analysis of discrete processes include isoconversional or model-free methods, model-fitting procedures [14], master plots [15], nonparametric analysis [16], and combined kinetic analysis [17]. With regarding to a one-step process, we can use model-free methods, which state that at a constant extent of conversion the reaction rate is only a function of the temperature. In fact, the slight pressure dependence could be ignored in most of kinetic computational methods used in the area of thermal analysis. First of all, one can simply obtain the value of two kinetic parameters E a and A of the major exothermic decomposition reaction of PBXs by using Kissinger’s method [18] [see Eq. 1]

where β is the heating rate, and T p the peak temperature of DTG or DSC curve at that rate. When ln(β/T 2p ) is plotted against 1/T p, a straight line is obtained, and the activation energy is calculated from the slope −E a/R.

However, the abovementioned Kissinger method has a number of important limitations that should be understood, which arise from the underlying assumptions of the method. In addition, the original Kissinger method does not provide any information about a possible dependence of the activation energy on the degree of conversion α. For this reason, a number of so-called isoconversional methods were developed, one of the most popular being the Kissinger–Akahira–Sunose (KAS) equation [19]

This method offers high accuracy of the E a values determination; however, as shown by Starink [20], somewhat more accurate estimates of E a are accomplished by the following equation

Nevertheless, even the isoconversional methods have limitations that need to be understood. Due to the large influence of experimental conditions on the data quality of the process “tails”, it is a common practice to consider only values of E A obtained for the interval α = 0.3–0.7 when calculating average value. During the initial and final stages of the process the errors arising from inaccurate baseline subtraction or thermal gradients involvement increase exponentially as the ratio between the measured signal and its background decreases. In addition, in case of rapid processes even for the above suggested interval of α complications associated with high thermal gradients and resulting lags, significantly deforming measured signal may occur. In this regard, also the isoconversional methods should not be overrated. One should always bear in mind that if applied blindly, the isoconversional methods may in certain cases provide biased and unrealistic results due to the natural dependence of these methods on evaluation of α based solely on mathematical computation (artificial α evaluation). Unlike the Kissinger method, where the determination of E A is given by the actual physical essence of the decomposition process (maximum of the heat release rate is driven entirely by the fundamental decomposition mechanism), which in addition is almost independent of the experimental conditions, the evaluation according to the KAS method is heavily dependent on the actual shape of the peak and the baseline approximation method (due to the purely mathematical calculation of α). Therefore, correspondingly, the results of this method may be largely influenced by every possible change in experimental conditions that can occur either with the change of heating rate, increase in the process rapidity or simply with the long-term duration of the experiments sequence.

As the most important type of thermal analysis, the kinetic studies can be of either practical or theoretical purpose. A major practical purpose is the reliable prediction of process rates and material lifetimes when sound kinetic analysis methods are used. The theoretical purpose of kinetic analysis is interpretation of experimentally determined kinetic triplets. Each of the components of a kinetic triplet is associated with some fundamental theoretical concept. E a is associated with the energy barrier, A with the frequency of vibrations of the activated complex [21], and f(α) or g(α) with the reaction mechanism [22]. In order to evaluate how the Formex matrices affect the decomposition process of cyclic nitramines, the Kissinger and modified Kissinger–Akahira–Sunose approach (Eqs. 1, 3) were used herein to calculate their thermolysis kinetic parameters. As a matter of fact, the isoconversional analysis provides a fortunate compromise between the simple and widely used single-step Arrhenius kinetic treatment and the prevalent occurrence of processes whose kinetics are multi-step and/or nonArrhenian [7]. Although the resulting activation energies tend to be effective or composite values and vary with the extent of conversion and temperature, they can be employed to make reliable kinetic predictions, to get information about complex mechanisms, and, ultimately, to access intrinsic kinetic parameters.

Results and discussions

TG/DTG studies

TG curves of BCHMX-Formex, HMX-Formex, RDX-Formex, and CL-20-Formex were recorded (see Fig. 1) under different conditions. It was shown that the decomposition processes of RDX-Formex and BCHMX-Formex are slower that that of HMX-Formex and CL-20-Formex, which indicate that the energy release rate of the former two is relatively slow.

Interestingly, the TG curve of HMX-Formex is quite strongly dependent on the heating rate. It was found that the decomposition curve basically obey the sigmoidal trend under the heating rate of 2.5 °C min−1 which was reproduced several times without any change. However, when the heating rate exceeds 5 °C min−1, the results are totally different. It could be observed in Fig. 1 that a fast decomposition process occurred after its onset temperature, which overlaps at the end of the decomposition with the curve obtained at the heating rate of 2.5 °C min−1. This extremely rapid mass loss is probably caused by the explosion or combustion of the sample. In fact, energy will be accumulated too rapidly inside the sample under fast heating, so that it cannot be released during kinetically controlled decomposition and will results in explosion or combustion. For this reason, the interval of applicable heating rates for high-energetic materials is largely limited. In addition, such fast explosion/combustion may cause a large error in calculation of kinetic parameters, which will be discussed in the following sections. Besides, as the most powerful energetic compound, CL-20 plays a dominant role in the thermal decomposition of its PBX. It can be seen that the decomposition rates are very fast even under a lower heating rate. After its onset temperature, the curves are nearly vertical and parallel, which again reveals the occurrence of fast combustion reaction or explosion reaction. To avoid the explosion, the maximum applied heating rate was in case of BCHMX-Formex lowered from 10 to 7.5 °C min−1.

The DTG curves of all samples under the heating rates of 2.5, 5, 7.5, and 10 °C min−1 are shown in Fig. 2. It was observed that their mass loss rates differ greatly in dependence on the actual involved processes. In case of RDX-Formex and BCHMX-Formex, the proceeding processes are simple kinetically controlled decompositions; the shape of their DTG peaks then very well corresponds to the first order kinetics, which is in fact very common for decomposition processes. In case of the HMX-Formex it can be seen that for the 2.5 °C min−1 heating rate the process is fully under kinetic control, for the 5 °C min−1 the initial part of the peak shows signs of the kinetically controlled process, which however changes afterward into the mechanically controlled process (explosion or combustion), for the 10 °C min−1 heating rate almost the whole process proceeds as a rapid explosion. In case of the CL-20-Formex the reaction for all three heating rates proceeds as an explosion as was already stated earlier—the DTG peaks correspond to this finding too. From what was stated in this paragraph, it is apparent that the peak height (mass loss rate) increases not only with the heating rate but also with energy content of the sample. The “qualitative” kinetic analysis in case of the introduced materials is further complicated by the fact that RDX is usually considered to decompose at liquid state [23], while HMX, BCHMX, and CL-20 decompose at solid state [12, 24, 25].

In order to make a quantitative comparison, the characteristic parameters of TG and DTG curves of all the samples are summarized in Table 1. It was shown that for all Formex-bonded explosives, the onset temperature of thermal decomposition and initial mass loss temperature increase with the heating rates. The initial mass loss temperature of CL-20-Formex is most dependent on the heating rate that changed from 86.7 °C at 2.5 °C min−1 to 123.3 °C at 10 °C min−1, which is of course consequence of the explosion controlled reaction. For all samples, the residue of the decomposition decreases with the heating rate, but the experimental residue mass of sample CL-20-Formex may be less than the actual values due to some loss from explosion blow away, which could be proved by the fact that only 4.53 % of residue was obtained under the heating rate of 5 °C min−1 while 8.53 % residue was obtained under 10 °C min−1. For RDX-Formex and BCHMX-Formex samples, their residue mass is more close to real value without considering the error of the base line. In addition, the maximum decomposition velocity of CL-20-Formex was over 100 times faster than that of BCHMX-Formex and RDX-Formex due to ultra high-energy release rate during explosion or combustion.

From the DTG parameters in Table 1, it was found that the onset temperatures for all the samples increase with the heating rate. In order to make a comparison for the dependencies of onset temperatures on heating rate, the correlations of onset temperatures with the heating rate for different samples are made and the corresponding parameters are summarized in Table 2. In fact, this dependence (slope k i) with a unit of min could be defined as time constant of initiation herein. It was indicated from k i that the dependence for HMX- and BCHMX-based PBXs are almost the same due to their similar structure. The onset temperature dependence of RDX-Formex is relatively lower while that of CL-20-Formex is more dependent on the heating rate. However, the correlation error is large for HMX-Formex, which may affect the accuracy of further decomposition kinetic parameters. Interestingly, after comparing the time constant of initiation (k i) with the volume heat of detonation (Q det) obtained from our previously published paper [26], as shown in Fig. 3, a good linear correlation has been found. It was indicated that the logarithm of volume heat of detonation for Formex-based explosives is linearly dependent on the time constant of initiation. In fact, the low-temperature characteristics of PBXs (including onset temperature or initiation temperature, kinetic parameters of low-temperature decomposition) could be used to extrapolate their detonation properties in which the effect of autocatalysis is excluded [27].

DSC studies

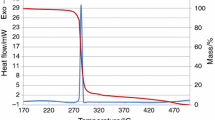

TG/DTG data were supplemented by DSC studies performed at a heating rate of 5 °C min−1. The samples were encapsulated in an aluminum pan with a pin hole (i.e., the measurements were realized at atmospheric pressure). Measurements were performed under similar conditions for both, pure energetic materials and their Formex mixtures. The obtained curves are shown in Fig. 4 and the characteristic parameters are summarized in Table 3.

Looking first at the pure energetic materials, it can be seen that their exothermic peaks are well formed, showing signs of kinetically controlled decomposition processes. On the other hand, if we look at the Formex-based mixtures of these compounds, similar characteristics at this heating rate exhibits only the RDX-Formex material. All the other Formex mixtures then show very sharp peaks corresponding to rapid heat evolution associated either with extremely fast decomposition kinetics, combustion or explosion. In addition, it can be seen that for all studied materials the peak for the mixture with Formex is shifted to lower temperatures. Also, if we compare the decomposition enthalpies, those for the Formex mixtures are significantly lower than those for pure energetic materials—and not only for the 13 % of the inert material (Formex). This may be probably explained by the involved explosion, where the heat release is so rapid that it cannot be properly recorded by the DSC sensor. Another effect that can be observed in the obtained data is the small endothermic peak corresponding to melting of the Formex matrices. Peak temperatures for this effect differ considerably (from 156.7 to 190.9 °C), therefore, it is obvious that the energetic material does not act as simple filling agent but affects properties of the mixture significantly. Enthalpies of fusion associated with this effect differ again significantly; however, extremely low value was obtained for the RDX-Formex material. This is in fact very interesting and can be explained as followings: the enthalpy of RDX dissolution was determined experimentally from the solubility data, and the heat of its dissolution in all solvents studied was exothermic [28]. It could be estimated, therefore, that RDX dissolved in Formex when it was melting, and the positive heat of dissolution compensated the heat absorption effect of Formex melting. In addition, in case of RDX-Formex mixture a second endothermic effect can be observed at 204.4 °C, which corresponds to the melting of RDX (similar effect can be found also for the pure RDX nitramine, which confirms that both RDX and RDX-based PBX decompose at liquid state). It is possible, that the two compounds form a eutectic at the temperature of 204.4 °C, which would however need extra experimental data to prove [29]. Last “anomaly” in the measured data was identified in case of CL-20-Formex, where a shoulder peak was found at temperature slightly higher than that of the fast exothermic reaction. It might be caused by a secondary chemical reaction due to uncontrolled high temperature. In fact, the temperature increase of DSC is always controlled by computer program set. However, the temperature could not be controlled due to ultra fast heat release of CL-20, which would result in a sudden temperature elevation. It was also proved that the volatile products of primary pyrolysis could undergo secondary reactions with the liquid intermediate products at higher temperatures [30].

Regarding the mutual comparisons of particular energetic materials, there are big differences between the peak temperatures of cyclic nitramines with their PBXs. Just as stated in ‘TG/DTG studies’ section, there should be also some relationship between the shifts of the peak temperatures [26] with the detonation properties. The correlation of the heat of detonation with the peak temperature shift has been made in Fig. 5. It was found that except for RDX-Formex, the shift of peak temperature is linearly dependent on the heat of detonation. This fact could be interpreted by their different decomposition states, only RDX-Formex decomposed in a complete liquid state, while the others decomposed in solid state (BCHMX-Formex and CL-20-Formex) or partially liquid state (HMX-Formex). The peak temperature of RDX-Formex is greatly affected by heat absorption of its melting process.

If we compare the two employed experimental techniques (DTG and DSC) it can be clearly seen that for the rapid decomposition processes it is the DTG, which provides results more suitable for kinetic analysis—kinetically controlled behavior persists until higher heating rates.

Thermal decomposition kinetics

Kinetic parameters obtained by Kissinger method

The kinetics of the thermal decomposition of Formex-bonded PBXs at different temperatures ranges were studied by nonisothermal TG (the mass loss was recorded with respect to temperature). The kinetic parameters are firstly calculated according to the original Kissinger method, which is based on the shift of the peak temperatures with heating rate. The calculation results are summarized in Table 4.

It was found that the activation energy obtained by this method is extremely high for HMX-Formex. Such big error is caused by huge variation of decomposition mechanism under different heating rate, as stated in ‘TG/DTG studies’ section—the kinetically controlled decomposition process occurring at low heating rates changes to a rapid mass release associated with explosion or combustion kinetics at higher heating rates. As this happens within the applied interval of heating rates, it is obvious that the kinetic results for this material cannot be considered to have a physically meaningful interpretation. In addition, as will be shown later, the activation energy obtained by the original Kissinger method is almost equal to the activation energy at half conversion obtained by isoconversional method. In fact, they are result from the advanced kinetic analysis, where the proper kinetic model would be associated with the experimental data.

Dependence of kinetic parameters on extent of conversion

As stated in ‘Nonisothermal kinetic parameters calculation’ section, to obtain dependence of activation energy on the degree of conversion the modified Kissinger–Akahira–Sunose (KAS) isoconversional method was used for all samples. For this study, the activation energies at the conversion rates from 5 up to 85 % were determined; however, the mean values were calculated only for the 0.3–0.7 α interval as it is commonly suggested due to the increased inaccuracy in case of the DTG peak tails. The linear fitting curves at selected conversion rates (0.2, 0.3, 0.4 … 0.8) are presented in Fig. 6. It can be seen that the fitting lines are nearly parallel for all Formex mixtures except for the one with HMX nitramine. In case of the HMX-Formex material the slope of determined dependencies largely changes with the degree of conversion due to the fact that the mechanism controlling the proceeding reaction was not similar for all applied heating rates (kinetically controlled decomposition at low heating rates, fast explosive reaction at high heating rates). Interestingly, parallel lines were obtained also for the CL-20-Formex for which the “explosion or combustion kinetics” controlled the reaction mechanism for all heating rates (the curves are very close to each other, which indicate very sharp DTG peaks).

If we compare the results for the original Kissinger method (Table 4) and those obtained from the calculations according to the modified KAS equation (Table 5), it can be seen that almost perfect agreement was obtained for the BCHMX-Formex and CL-20-Formex materials. Slightly higher activation energy (in comparison with modified KAS) was obtained from the Kissinger method for the RDX-Formex material. In case of the HMX-Formex mixture there is of course a huge difference in the results obtained by the two employed methods; however, none of them are physically meaningful as the change of the reaction mechanism happens with applied heating rate and not with the actual reached degree of conversion.

In order to make a comprehensive comparison for the activation energies of pure nitramines with their PBXs, the dependence of activation energies for these materials on degree of conversion are plotted in Fig. 7. The isoconversional activation energies for pure HMX [31, 32], RDX [33], and CL-20 [34] were obtained from the literature. The mean activation energy of pure BCHMX (210.2 kJ.mol−1) was obtained by manometric method [34], which gives slightly higher value than our calculated results. The results presented in Fig. 7 for pure BCHMX was also obtained in our laboratory by nonisothermal TG experiments, which will be published in another separate paper in detail due to the length limit of this paper. According to some previous results from thermal decomposition kinetics investigations on RDX- and HMX-based PBXs [31–34], the activation energy of PBXs with nonenergetic matrices is normally lower than that of pure energetic fillers such as RDX, HMX, and CL-20. For BCHMX, whose energy is higher than RDX but slightly lower than HMX [13]; however, the activation energy of its PBXs based on this inert fomex is higher (based on our unpublished results shown in Fig. 7). On the other hand, the results provided by the manometric method [35] would confirm the formerly suggested relationship (E being higher for the pure nitramine) this question therefore, still needs further investigation. In addition, as was already mentioned earlier, our present results for HMX-Formex are not physically meaningful and therefore, no comparison with the value for pure HMX can be made.

As can be seen, the Formex base has significant effect on the activation energy distribution of cyclic nitramines. Relatively similar tendency was obtained for RDX and BCHMX and their respective Formex-bonded explosives. In fact, for energetic fillers with lower content of energy, such as PETN, TNT or RDX, the decomposition process will be only slightly affected, due to relatively slow decomposition velocity and corresponding low heat release rate (i.e., lower auto-heating effect). On the other hand, as was found within the framework of this research, the Formex matrice greatly affected the decomposition mechanisms of high-energy fillers such as CL-20. In case of CL-20-Formex, the effect of Formex makes the activation energy independent with the conversion.

Kinetic compensation effect

The “kinetic compensation effect” arises from deficiencies in the Arrhenius equation. Determination of the pre-exponential factor generally comprises only the reconciliation of the expression of the temperature dependence of the rate (the exponential term) with the observed rate [35]. The kinetic compensation effect states that there is a linear relationship between Arrhenius parameters ln A and E for a family of related processes. It is a widely observed phenomenon in many areas of science, notably heterogeneous catalysis [36]. The applicability of the Arrhenius equation to a particular reaction could be tested by finding constancy or a predictable variation in the “frequency factor” with changes in experimental conditions or sample treatment or history. It is demonstrated, both theoretically and by numerical simulations, that random errors in kinetic data generate an apparent compensation effect (sometimes termed the statistical compensation effect) when the true Arrhenius parameters are constant. Expressions for the gradient of data points on a plot of ln A against E are derived when experimental kinetic data are analyzed by linear regression.

where a and b are the coefficients of linear regression, which depend on the type of sample and their structures. With a set of variant kinetic parameters, the kinetic compensation effect plots could be established for different materials. Based on this theory, different plots for PBXs are obtained herein and the corresponding parameters are summarized in Fig. 8.

According to Fig. 8, it was shown that all of the points (E a and ln A pairs) are in good correlation, which indicates the kinetic compensation effects happened during the decomposition of PBXs [35]. In fact, the compensation effect does have an underlying physical significance. One physical explanation for the kinetic compensation effect is that it results from a correlation between the enthalpy change and the entropy change on going from the reagents to the transition state of the reaction. It is known from transition state theory that E corresponds to enthalpy change while ln A is related to entropy change. A wide variety of other physical reasons for the kinetic compensation effect have been proposed in the literature for particular situations [34]. Interestingly, the kinetic points of all nitramine-based PBXs fall almost on the same compensation line with a correlation coefficient of greater than 0.99. It might reveal that they have the same compensation effects due to similar decomposition mechanism. Besides, by using such compensation effects, one can get a credible pre-exponential factor (A 0), which could be used in Eq. 5 to judge the reaction model when a isoconversional method has been used to calculate the kinetic parameters.

where E 0 is the mean activation energy that almost independent on the extent of conversion. In order to get a proper reaction model, one should carry out at least an isothermal TG experiment for comparison [18]. Due to the limited length of this paper, the reaction models for thermal decomposition of these PBXs are not included, which will be presented in some other papers by combining more complete experimental results.

Conclusions

The thermal behavior and decomposition kinetics of Formex-bonded PBXs based on some attractive cyclic nitramines were investigated by nonisothermal TG and DSC techniques. The following conclusions could be made:

-

(1)

The mass loss rate of PBXs involved in this research depends greatly on heating rate and the residue of the decomposition of these PBXs decreases with the heating rate. Regarding the qualitative kinetic description—the kinetically and explosion controlled processes were for each of the materials distinguished in dependence on heating rate. It was also indicated that the dependence of onset temperature on the heating rate for HMX- and BCHMX-based PBXs are almost the same due to their similar molecular structure.

-

(2)

The onset of the exotherms were noticed at 215.4, 278.7, 231.2, and 233.7 °C with the peak maximum at 235.1, 279.0, 231.2, and 233.7 °C for RDX-Formex, HMX-Formex, CL-20-Formex, and BCHMX-Formex, respectively. Their corresponding exothermic releases were covered by energy changes of 1788, 1237, 691, and 1583 J g−1, which are lower than that of their pure cyclic nitramines.

-

(3)

The Formex base has significant effect on the activation energy distribution of nitramines. In case of low-energetic compounds this effect is relatively small, on the other hand in case of high-energy compound the Formex base significantly influences distribution of activation energy and hence, the overall kinetics of the decomposition process.

-

(4)

All the kinetic points are in good correlation, which indicates the kinetic compensation effects happened during the thermal decomposition of nitramine-based PBXs. The kinetic points of all nitramine-based PBXs fall on almost the same compensation line, which reveals that they have identical compensation effects due to similar molecular structure.

References

Clements BE, Mas EM. A theory for plastic-bonded materials with a bimodal size distribution of filler particles. Modell Simul Mater Sci Eng. 2004;12(3):407–21.

Nouguez B, Mahé B, Vignaud PO. Cast PBX related technologies for IM shells and warheads. Sci Technol Energ Mater. 2009;70(5–6):135–9.

Chapman RD, Wilson WS, Fronabarger JW, Merwin LH, Ostrom GS. Prospects of fused polycyclic nitroazines as thermally insensitive energetic materials. Thermochim Acta. 2002;384(1–2):229–43.

Elbeih A, Pachman J, Zeman S, Akštein Z. Replacement of PETN by Bicyclo-HMX Semtex 10. In: 8th international armament conference on scientific aspects of armament and safety technology, Pułtusk; 2010. p. 7–16.

Elbeih A, Pachman J, Zeman S, Trzciński W, Akštein Z. Advanced plastic explosive based on BCHMX compared with composition C4 and Semtex 10. In: new trends in research of energetic materials, Czech Republic; 2011. p. 119–126.

Klasovitý D, Zeman S. Preparation of cis-1,3,4,6-tetranitrooctahydroimidzo-[4,5-d]imidazole (bicycle-HMX, BCHMX) by two step synthesis. Czech Appl. Pat. PV-2009-503, Int. Cl.: C07D 487/04, University of Pardubice, 28 July 2009.

Vyazovkin S, Sbirrazzuoli N. Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol Rapid Commun. 2006;27:1515–32.

Yi C. The correctional kinetic equation for the peak temperature in the differential thermal analysis. J Therm Anal Calorim. 2008;93(1):111–3.

Sell T, Vyazovkin S, Wight CA. Thermal decomposition kinetics of PBAN—binder and composite solid rocket propellants, combust. Flame. 1999;119:174.

Felix SP, Singh G, Sikder AK, Aggrawal JP. Studies on energetic compounds—part 33: thermolysis of keto-RDX and its plastic bonded explosives containing thermally stable polymers. Thermochim Acta. 2005;426:53–60.

Gilardi RF, Anderson JL, Evans R. Cis-2,4,6,8-tetranitro-1H,5H-2,4,6,8-tetraazabicyclo [3.3.0] octane, the energetic compound (bicyclo-HMX). Acta Crystallogr. 2002; 58:0972.

Klasovity D, Zeman S, Ruzicka A, Jungova M, Rohac M. cis-1,3,4,6-Tetranitrooctahydroimidazo-[4,5-d]imidazole (BCHMX), its properties and initiation reactivity. J Hazard Mater. 2009;164(2–3):954–61.

Elbeih A, Pachman J, Trzcinski WA, Zeman S, Akstein Z, Šelesovsky J. Study of plastic explosives based on attractive cyclic nitramines Part I. Detonation characteristics of explosives with PIB binder. Propellants Explos Pyrotech. 2011;36(5):433–8.

Burnham AK. A Comparison of isoconversional and model-fitting approaches to kinetic parameter estimation and application predictions. In: NATAS 34th annual conference, Bowling Green, 6–9 Aug 2006 UCRL-CONF-221685.

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Criado JM. Generalized kinetic master plots for the thermal degradation of polymers following a random scission mechanism. J Phys Chem A. 2010;114(30):7868–76.

Sanchez-Jimenez PE, Criado JM, Perez-Maqueda LA. Kissinger kinetic analysis of data obtained under different heating schedules. J Therm Anal Calorim. 2008;94:427.

Perez-Maqueda LA, Sanchez-Jimenez PE, Criado JM. Kinetic analysis of solid-state reactions: precision of the activation energy calculated by integral methods. Int J Chem Kinet. 2005;37:658.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404(1–2):163–76.

Starink MJ. Activation energy determination for linear heating experiments: deviations due to neglecting the low temperature end of the temperature integral. J Mater Sci. 2007;424(2):83–489.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Atkins P, de Paula J. Physical chemistry (discussion of negative activation energies is also found in earlier editions, see subject index under “activation energy, negative”). 9th ed. New York: W.H. Freeman; 2010.

Brown ME. Introduction to thermal analysis. 2nd ed. Dodrecht: Kluwer; 2001.

Dong X-F, Yan Q-L, Zhang X-H. Effect of potassium chlorate on thermal decomposition of cyclotrimethylenetrinitramine (RDX). J Anal Appl Pyrol. 2012;93:160–4.

Liao L-Q, Yan Q-L, Zheng Y. Thermal decomposition mechanism of particulate core-shell KClO3-HMX composite energetic material. Indian J Eng Mater Sci. 2011;18(5):393–8.

Yan Q-L, Song Z-W, Shi X-B, Yang Z-Y, Zhang X-H. Combustion mechanism of double-base propellant containing nitrogen heterocyclic nitroamines (II): the temperature distribution of the flame and its chemical structure. Acta Astronaut. 2009;64(5–6):602–14.

Elbeih A, Zeman S, Jungová M, Akštein Z, Vávra P. Detonation characteristics and penetration performance of plastic explosives. In: Li S, Niu P, editors. Theory and practice of energetic materials, vol. IX. Beijing: Science Press; 2011. p. 508–13.

Zeman S. Sensitivities of high energy compounds. In: Klapoetke T, editor. High energy density materials, series: structure and bonding, 125. New York: Springer; 2007. p. 195–271.

Kim D-Y, Kim K-J. Solubility of cyclotrimethylenetrinitramine (RDX) in binary solvent mixtures. J Chem Eng Data. 2007;52(5):1946–9.

Shao Y-H, Ren X-N, Liu Z-R. An investigation on eutectic binary phase diagram of volatilizable energetic materials by high pressure DSC. J Therm Anal Calorim. 2011;101(3):1135–41.

Colomba DB. Analysis of convection and secondary reaction effects within porous solid fuels undergoing pyrolysis. Combust Sci Technol. 1993;90(5–6):315–40.

Tarver CM, Tran TD. Thermal decomposition models for HMX-based plastic bonded explosives. Combust Flame. 2004;137(1–2):50–62.

Singh G, Felix SP, Soni P. Studies on energetic compounds part 28: thermolysis of HMX and its plastic bonded explosives containing Estane. Thermochim Acta. 2003;399(1–2):153–65.

Singh G, Felix SP, Soni P. Studies on energetic compounds part 31: thermolysis and kinetics of RDX and some of its plastic bonded explosives. Thermochim Acta. 2005;426:131–9.

Lee J, Jaw K-S. Thermal decomposition properties and compatibility of CL-20, NTO with silicone rubber. J Therm Anal Calorim. 2006;85(2):463–7.

Ninan KN, Catherine KB, Krishnan K. Effect of molecular weight on non-isothermal decomposition kinetics of hydroxyl terminated polybutadiene. J Therm Anal Calorim. 1990;36(3):855–67.

Barrie PJ. The mathematical origins of the kinetic compensation effect: 1. the effect of random experimental errors. Phys Chem Chem Phys. 2012;14:318–26.

Acknowledgements

The work in this paper was mainly carried out as a part of the Ministry of Interior of the Czech Republic Project No. VG20102014032. The work was also partially supported by the research project (No. MSM 00221627501) provided by the Ministry of Education, Youth & Sports of the Czech Republic.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, QL., Zeman, S., Šelešovský, J. et al. Thermal behavior and decomposition kinetics of Formex-bonded explosives containing different cyclic nitramines. J Therm Anal Calorim 111, 1419–1430 (2013). https://doi.org/10.1007/s10973-012-2492-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2492-2