Abstract

Thermal analysis is an essential, analytic tool used in preliminary studies and preparation of new pharmaceutical formulations. This study was performed to investigate the possible interactions between trandolapril and three commonly used natural excipients, namely α-lactose monohydrate, microcrystalline cellulose, and pregelatinized starch. The compatibility studies were carried out using thermoanalytic along with other complementary techniques. Differential scanning calorimetry and thermogravimetric analysis have proved that trandolapril is fully compatible with all the studied excipients until 100 °C. The complementary techniques used in this study were X-ray powder diffraction, Fourier transform-infrared spectroscopy, and scanning electron microscopy which confirmed the findings of thermal analysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Angiotensin-converting-enzyme (ACE) inhibitors are used for controlling blood pressure, treating heart failure, preventing strokes, and preventing kidney damage in people with hypertension or diabetes. They also improve survival after heart attacks. Because of their performance, ACE inhibitors are one of the most important groups of drugs.

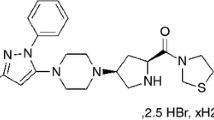

Trandolapril is the ethyl ester prodrug of a non-sulfhydryl ACE inhibitor, trandolaprilat. Trandolapril is chemically described as (2S, 3aR, 7aS)-1-[(S)-N-[(S)-1-carboxy-3-phenylpropyl]alanyl] hexahydro-2-indolinecarboxylic acid, 1-ethyl ester [1] with empirical formula C24H34N2O5. Its melting point according to the literature is 126 °C [2, 3], and its molecular weight is 430.54 amu.

This active pharmaceutical ingredient (API) is mixed with selected excipients to prepare solid formulations for the treatment of hypertension. The successful formulation of a stable and effective solid dosage form depends on the careful selection of the excipients used to make administration easier or more suitable, improve patient compliance, promote release, and bioavailability of the drug and protect it from degradation [4, 5]. Therefore, in the design of dosage forms, it is considered crucial to examine potential physical and chemical interactions between drugs and excipients which might affect the chemical nature, stability, solubility, in vivo absorption and consequently the therapeutic efficacy and safety of drugs [6, 7].

There are many factors affecting formulation stability, which can be divided into three major categories: drug and excipient, which includes chemical structure, physical form, moisture content, particle size, surface area and morphology; formulation which includes drug–excipient ratio, processing method, mixing and powder packing, and environment which includes temperature, humidity, packaging, light, and oxygen [8]. The solid-state stability includes physical and chemical stabilities. Many factors may affect the final product, such as residual moisture or solvent from wet granulation, moisture sorbed in excipients or in the capsule shell, melting of the drug itself or an ingredient in the formulation, which has a low melting point, a solvate of hydrate, which loses its lattice solvent with time, and temperature fluctuation. Physical degradation routes include polymorphic transitions, hydrate or solvate formations, crystallization of amorphous materials, vaporization, sorption, and particle sedimentation.

Although excipients have traditionally been thought of as being inert, experience has shown that they may interact with a drug to affect its absorption and bioavailability. In fact, rather frequently, excipients are added to a formulation to take advantage of the results of specific interactions between them. However, there are many cases in which an interaction might not be expected and might adversely affect the bioavailability of a drug [5]. Hence, the previous knowledge of the drug-excipient behavior is considered crucial and must be examined before the formulation [8, 9]. In this sense, employing a fast screening method is considered essential by the pharmaceutical industry.

There are numerous ways to conduct excipient compatibility screening, and they all involve mixing two or more materials together and monitoring possible interactions. One rather time-consuming type of study involves stored drug–excipient mixtures being examined with TLC, HPLC, or spectrophotometry [10–13], but for such a study, the reactions must be monitored for several weeks and with great precision. On the other hand, thermal analysis techniques such as differential scanning calorimetry (DSC) and thermogravimetric (TG) have been used to detect drug–excipient incompatibilities for over 30 years [14]. Their advantages include minimal compound requirements, rapid measurements, and relative experimental simplicity. In particular, DSC has been proposed as a rapid evaluation method of physicochemical interactions between components of the formulation and therefore, selection of suitable excipients [15–20].

Although DSC cannot replace chemical methods for quantitative determination of drug concentration in long-term stability tests, it gives fast and adequate data to select appropriate excipients for a stable formulation [21]. However, interpretation of DSC results is not always simple, and thorough evaluation is necessary to avoid misinterpretation and unreliable conclusions [4, 11]. Therefore, other analytic techniques often have to be used to adequately interpret DSC findings [22–24].

Trandolapril usually comes with excipients, such as α-lactose monohydrate, microcrystalline cellulose (mcc), pregelatinized starch, Mg stearate, dimethicone, and aerosil [25]. In these formulations, α-lactose monohydrate, mcc and pregelatinized starch correspond to 95.5 % wt of the total formulation [25] and for this reason we have selected these three excipients in the present study. The TG/DTG and DSC curves of the API and of each of the investigated excipients were compared with those obtained from their 1:1 w/w physical mixtures. The 1:1 w/w ratio was selected to maximize the probability of observing any interaction and is the commonly preferred ratio for this type of studies [16, 17, 26, 28]. Besides thermal analysis techniques, FTIR spectroscopy and X-ray powder diffraction have been used as complementary methods for the evaluation of possible interactions between the components.

Experimental

Trandolapril was gifted by Chunghwa Chemical Synthesis & Biotech Co., LTD (New Taipei City, Taiwan). The excipients were α-lactose monohydrate (Aldrich), microcrystalline cellulose (Avicel PH 101) (mcc), and pregelatinized starch (Carlo Erba, Milano, Italy) (starch). Physical mixtures of trandolapril and each selected excipient were prepared in the 1:1 w/w ratio by blending in a mortar with a spatula at room temperature.

Thermogravimetric (TG) analysis was carried out with a Setaram Setsys TG–DTA 16/18. Samples (6.0 ± 0.2 mg) were placed in alumina crucibles. An empty alumina crucible was used as reference. The samples were heated from ambient temperature to 730 °C in a 50 mL min−1 flow of N2, with a heating rate of 5 °C min−1. Continuous recordings of sample temperature, sample weight, and heat flow were performed. DSC curves were obtained using a Setaram DSC 141. 6.0 ± 0.2 mg of each sample was placed in aluminum crucibles, while an empty one was used as reference. Samples were heated from ambient temperature to 500 °C in a 50 mL min−1 flow of N2 with a heating rate of 5 °C min−1. Fourier transform infrared spectroscopy (FTIR) in transmittance mode was used. KBr pellets with 1 % wt of the powdered material were produced. The spectra were obtained using a Spectrum 1000 PERKIN-ELMER spectrometer in the spectral area 4,000–400 cm−1, with a resolution 2 cm−1 and 32 scans. X-ray powder diffraction patterns (XRPD) were recorded by a water-cooled Rigaku Ultima+ diffractometer using CuKa radiation, a step size of 0.02°, and a step time of 3 s, operating at 40 kV and 30 mA. The morphology of the prepared samples was examined in a scanning electron microscopy (SEM) system (JEOL JSM 840A-Oxford ISIS 300 microscope). The samples were carbon coated to provide good conductivity of the electron beam. Operating conditions were accelerating voltage 20 kV, probe current 45 nA, and counting time 60 s.

Results and discussion

Thermal behavior of trandolapril

In Fig. 1a, the TG/DTG curves of trandolapril are presented, and it is clear that the API remains stable up to 110 °C, presenting no mass loss. A small mass reduction, about 4.25 %, is observed between 110 and 175 °C, and it is followed by a second, significant mass loss step that results in zero residual, starting approximately at 215 °C. These steps can clearly be seen from the DTG curve, presented in the same figure.

In Fig. 1b, the DSC curve of trandolapril is presented revealing important information. As seen from DTG curve, the first mass loss step occurs between 110 and 175 °C; in this area, two endothermic peaks can be observed from the heat flow curve. The sharp peak 1 that corresponds to the melting of trandolapril has an onset at 110 °C and peak temperature at 128.6 °C. The shoulder (overlapped peak 2) is due to evaporation of a water molecule. From our preliminary studies, it was found that trandolapril is stable until the onset of its melting when a cyclization phenomenon occurs, resulting in a small mass reduction [27]. This process was confirmed by FTIR spectroscopy findings. The complete differentiation of trandolapril after that step was also confirmed by XRPD patterns [27]. The main degradation step, which occurs between 215 and 400 °C, is also confirmed by the recorded endothermic peak 3 of DSC curve. No residual was detected above 510 °C.

Compatibility with excipients studied with thermal analysis

On the TG/DTG curves of α-lactose monohydrate, presented in Fig. 2 (curve 2), four regions of mass loss can be observed. The first mass loss step occurs between 94 and 185 °C and corresponds to 5 % mass reduction, which is due to loss of crystalline water and is in good agreement with the literature [18]. The next degradation steps are consecutive and result in overlapping peaks of the DSC curve. An important observation is that at 730 °C, the residual is 4.1 %.

From the heat flow curves of Fig. 3 (curve 1), three endothermic peaks can be observed. The first endothermic peak, around 140 °C, corresponds to water evaporation that was already identified from the TG curve. The melting of α and β-lactose occurs between 210 and 215 °C [29], while a small endothermic peak is also observed at 230 °C which corresponds to a mass loss step, as seen from the TG curves for that temperature region. A small exothermic peak is clearly seen from the DSC curve at 310 °C. This peak is the sum of the degradation exotherm and the mass loss endotherm, which occur in the same temperature region for α-lactose monohydrate.

From the TG curves of the 1:1 blend of trandolapril and α-lactose monohydrate (Fig. 2, curve 3), three degradation steps can be distinguished. The first occurs between 95 and 180 °C. The second step is ranging between 180 and 340 °C and covers at least three overlapping mass loss steps, as can be seen from the DTG curve which is not shown here, resulting in a total of 70 % mass loss. The third step is a monotonous mass reduction which results in a residual of 1.6 % at 730 °C. The residual seems to match the theoretical value of the residual of α-lactose monohydrate. The careful study of the DSC curves of both substances and their blend reveals that the melting of the API remains practically unchanged in the 1:1 blend, indicating the compatibility of the two substances at least until 180 °C. Above 200 °C, the interactions between the substances are evident; for instance, the α-lactose monohydrate melting peak is shifted from 216 to 209 °C in the studied blend.

From Fig. 2, curve 4, the first mass loss step of mcc appears to begin at ambient temperature and ends at 125 °C and corresponds to water evaporation of about 5 %, with a DSC endothermic peak around 50 °C, which is in agreement with the literature [18]. The second mass loss step is ranging between 202 and 400 °C, which leads to a 75 % mass reduction. Above 400 °C, the excipient monotonously decreases its mass, which ultimately results in a residual of 6.4 % at 730 °C.

TG curves of the 1:1 blend of trandolapril and mcc are also presented in Fig. 3 (curve 5), and three steps of mass loss can be seen from them. The first one starts almost when the heating begins and ends at 100 °C, resulting in a mass reduction of no less than 2 %. This corresponds to water evaporation that was recorded from mcc TG curves. The second step is ranging between 113 and 180 °C and follows the trend of trandolapril at that temperature range, which loses about 4.2 % of its mass as previously mentioned. The main degradation of the blend occurs between 200 and 400 °C, and the final residual at 730 °C is 3 %.

The results from DSC curves (Fig. 3, curves 3–4) of pure components and their blend indicate the compatibility of trandolapril and mcc at least below 250 °C. The melting of trandolapril remains unchanged in the binary blend revealing that, at least up to that point, the components have not interacted. Above 250 °C, the main mass loss step occurs and results in a broad endothermic peak in the DSC curve, corresponding to the sum of the degradation exothermic and the mass loss endothermic peaks.

As in the case of mcc, starch begins to lose the absorbed water as soon as heating starts (Fig. 2, curve 6). This step is completed at 164 °C and leads to an 8 % mass reduction. It is followed by the main decomposition step which is ranging between 212 and 412 °C and results in a total mass loss of 66 %. Initially, the DSC curve (Fig. 3, curve 5) exhibits a wide endothermic peak corresponding to dehydration. The residual at 730 °C is 2.8 %.

From the TG curves of the binary 1:1 blend of trandolapril and starch (Fig. 2, curve 7), three degradation steps can be observed. The first and the second step occur below 204 °C, corresponding to the sum of mass loss curves of the individual components. The monotonous mass decrease below 120 °C is exclusively due to the water evaporation of the excipient. The mass loss below 100 °C is not less than 4–5 % for the binary blend. The main degradation ends at 435 °C, and the residual at 730 °C is 3.7 %.

The heat flow curve of the binary 1:1 blend of trandolapril and pregelatinized starch (Fig. 3, curve 6) reveals that the components are fully compatible at least below 300 °C, as the characteristic peaks of the pure components remain unchanged in the curve of the blend. In detail, the first broad endotherm that corresponds to water evaporation of pregelatinized starch as well as the melting endotherm of trandolapril remain unchanged in the heat flow curve of the blend at the same temperatures. Above 200 °C, the recorded heat flow curve of the blend corresponds to the sum of exothermic degradation and endothermic mass loss peaks as the blend undergoes its major degradation steps.

Compatibility with excipients studied with FTIR, XRPD, and SEM

FTIR spectroscopy and X-ray powder diffraction have been used as complementary techniques to investigate possible chemical interactions and changes in crystallinity between APIs and excipients, respectively. They are used rather frequently in such cases because they provide high quality results and both are non-destructive methods. Such changes would indicate possible interactions between the two substances [9, 30, 31]. Also, SEM microphotographs of trandolapril, excipients and their mixtures can provide visual support for the results of the other techniques.

SEM micrograph of trandolapril (Fig. 4) reveals that trandolapril crystals are of columnar crystal habit, long and slender with a great variation in their length. This is also in accordance with the literature where it has been reported that crystals of trandolapril are needle-like and have columnar shape [3]. The detailed FTIR and XRPD studies of trandolapril are described in our previous study [27] and therefore, here they are going to be only briefly discussed. The XRPD pattern of trandolapril is presented in Fig. 5 (pattern 1), revealing its high crystallinity. The peaks with higher intensity are observed at 16.95°, 18.63°, 21.47°, 7.25°, 14.53°, 22.07°, and 21° and correspond to the W crystalline form of trandolapril, as described in the literature [2].The complex FTIR spectrum of trandolapril is presented in Fig. 6 (spectrum 1). The peak at the area 1,600–1,800 cm−1 can be assigned to the carbonyl group which appears in carboxylic acid, ester, and tertiary amide groups of trandolapril [32]. The characteristic peak due to C–N vibrations of the tertiary amide is at around 1,500 cm−1, while, the C–N stretch, N–H wag, and N–H stretching vibrations of the amine groups can be seen at 1,103–1,180 cm−1, 700–750 cm−1, and 3,280 cm−1, respectively. Benzene ring vibrations give rise to some small peaks that appear in the spectral regions of 3,000–3,100 cm−1, 1,400–1,620 cm−1, and 700–1,100 cm−1.

The α-lactose monohydrate powder consists of granules with irregular shape and size [33], while the shapes of the XRPD patterns reveal its highly crystalline nature. It is known from the literature that even 100 % crystalline lacrosse contains both α and β forms [18]. From both the XRPD patterns and the FTIR spectra (Figs. 5, 6) recorded from trandolapril:α-lactose monohydrate 1:1 blend, it is clear that the curves of the blend are the result of the sum of the characteristic peaks of individual components, which is in agreement with the thermal analysis finding that no physical or chemical interactions take place between trandolapril and a-lactose monohydrate in room temperature. Also, from the SEM microphotograph of the mixture (Fig. 4b), no adhesive interfaces were detected, and the two components can clearly be distinguished, suggesting that no interactions take place between the two components at room temperature.

The XRPD patterns of mcc along with the FTIR spectrum (data not shown here) confirm that mcc is amorphous, as known from the literature [4, 19]. Three broad diffraction peaks were recorded at 15°, 22°, and 34°, while the same finding can also be supported by the FTIR spectrum of mcc which consists of broad and overlapped absorption peaks (data not shown here). The FTIR and XRPD curves of the 1:1 blend correspond to the sum of the spectra and patterns of the pure components. This is also in agreement with the observed sample from SEM (Fig. 4c), from which it can clearly be seen that the mixture consists of the two individual components which have no obvious interactions. Hence, trandolapril is fully compatible with mcc in room temperature, as no interactions between them could be observed by FTIR and XRPD.

The XRPD pattern of starch (data not shown here) shows several overlapped and broad peaks which reveal the high degree of amorphization of the material which is in agreement with the literature [20]. This is also concluded by the very broad FTIR absorption bands (data not shown here). The XRPD pattern (Fig. 5, pattern 4) and FTIR spectrum (Fig. 6, spectrum 4) of the 1:1 blend of trandolapril and starch reveal that no interactions take place between the two substances, as the studied curves are the sum of the corresponding ones of the pure components. This is also in agreement with the SEM observation (Fig. 4d), from which it can clearly be seen that the mixture consists of the two individual components which have no obvious interactions.

Conclusions

The results demonstrated the applicability of thermal analysis techniques, especially DSC, as fast screening methods for drug–excipient interactions at early stages of preformulation process. The thermal stability of trandolapril and its compatibility with various excipients were studied in this study using DSC and TG, as well as XRPD, FTIR, and SEM. In practice, in every studied case, the thermal profiles of the binary blends can be considered as a superimposition of the curves of trandolapril and the corresponding excipient. No interactions were recorded between trandolapril and each studied excipient below 100 °C, which suggests that the drug is fully compatible with these commonly used excipients at least below its melting point.

Furthermore, it was found that the binary blends of the API and each excipient result in solid residuals less than 3.7 % in every case at much lower temperatures than their components.

References

Guay DRP. Trandolapril: a newer angiotensin-converting enzyme inhibitor. Clin Ther. 2003;25:713–75.

Jaweed M., Merwade A., Ansari S., Saiyad A. Novel crystalline polymorph of trandolapril and a process for preparation thereof. Patent. WO/2007/026372. 2007.

Makai Z, Bajdik J, Eros I, Pintyehodi K. Evaluation of the effects of lactose on the surface properties of alginate coated trandolapril particles prepared by a spray-drying method. Carbohydr Polym. 2008;74:712–6.

Tiţa B, Fuliaş A, Bandur G, Marian E, Tiţa D. Compatibility study between ketoprofen and pharmaceutical excipients used in solid dosage forms. J Pharm Biomed Anal. 2011;56:221–7.

Jackson K. Drug–excipient interactions and their affect on absorption. Pharm Sci Technol Today. 2000;3:336–45.

Moura EA, Correia LP, Pinto MF, Procópio JVV, Souza FS, Macedo RO. Thermal characterization of the solid state and raw material fluconazole by thermal analysis and pyrolysis coupled to GC/MS. J Therm Anal Calorim. 2009;100:289–93.

Picciochi R, Diogo HP, Minas da Piedade ME. Thermochemistry of paracetamol. J Therm Anal Calorim. 2010;100:391–401.

Huang L-F, Tong W-Q. Impact of solid state properties on developability assessment of drug candidates. Adv Drug Delivery Rev. 2004;56:321–34.

Bruni G, Amici L, Berbenni V, Marini A, Orlandi A. Drug-excipient compatibility studies. Search of interaction indicators. J Therm Anal. 2002;68:561–73.

Schmitt E. Rapid, practical and predictive excipient compatibility screening using isothermal microcalorimetry. Thermochim Acta. 2001;380:175–84.

Van Dooren AA. Design for drug-excipient interaction studies. Drug Dev Ind Pharm. 1983;9:43–55.

Waltersson JO. Factorial designs in pharmaceutical preformulation studies. I. Evaluation of the application of factorial designs to a stability study of drugs in suspension form. Acta Pharm Suec. 1986;23:129–38.

Dürig T, Fassihi AR. Identification of stabilizing and destabilizing effects of excipient-drug interactions in solid dosage form design. Int J Pharm. 2003;97:161–70.

Jacobson H, Reier G. Application of differential thermal analysis to compatibility and stability problems in penicillin-stearic acid mixtures. J Pharm Sci. 1969;58:631–3.

Cunha-Filho MSS, Martínez-Pacheco R, Landín M. Compatibility of the antitumoral beta-lapachone with different solid dosage forms excipients. J Pharm Biomed Anal. 2007;45:590–8.

Mura P, Faucci MT, Manderioli A, Bramanti G, Ceccarelli L. Compatibility study between ibuproxam and pharmaceutical excipients using differential scanning calorimetry, hot-stage microscopy and scanning electron microscopy. J Pharm Biomed Anal. 1998;18:151–63.

Barboza F, Vecchia DD, Tagliari MP, Silva MAS, Stulzer HK. Differential scanning calorimetry as a screening technique in compatibility studies of acyclovir extended release formulations. Pharm Chem J. 2009;43:363–8.

Tiţa B, Fuliaş A, Szabadai Z, Rusu G, Bandur G, Tiţa D. Compatibility study between ibuprofen and excipients in their physical mixtures. J Therm Anal Calorim. 2010;105:517–27.

Kiss D, Zelkó R, Novák C, Éhen Z. Application of DSC and NIRS to study the compatibility of metronidazole with different pharmaceutical excipients. J Therm Anal Calorim. 2006;84:447–51.

Bernardi L, Oliveira P, Murakami F, Silva M, Borgmann S, Cardoso S. Characterization of venlafaxine hydrochloride and compatibility studies with pharmaceutical excipients. J Therm Anal Calorim. 2009;97:729–33.

Botha SA, Lötter AP. Compatibility study between naproxen and tablet excipients using differential scanning calorimetry. Drug Dev Ind Pharm. 1990;16:673–83.

Byrn S, Pfeiffer R, Ganey M, Hoiberg C, Poochikian G. Pharmaceutical solids: a strategic approach to regulatory considerations. Pharm Res. 1995;12:945–54.

Bettinetti G, Mura P. Dissolution properties of naproxen in combinations with polyvinylpyrrolidone. Drug Dev Ind Pharm. 1994;20:1353–66.

Bettinetti GP, Mura P, Liguori A, Bramanti G, Giordano F. Solubilization and interaction of naproxen with polyvinylpyrrolidone in aqueous solution and in the solid state. Farmaco Ed Prat. 1988;43:331–43.

Karavas E., Koutris E., Kotzagiorgis E., Bikiaris D., Improved pharmaceutical composition containing ace inhibitor and method for the preparation thereof, Patent. WO/2000/044353A. 2008.

Corvi Mora P, Cirri M, Mura P. Differential scanning calorimetry as a screening technique in compatibility studies of DHEA extended release formulations. J Pharm Biomed Anal. 2006;42:3–10.

Roumeli E, Tsiapranta A, Kachrimanis K, Bikiaris D, Chrissafis K. Physicochemical characterization and decomposition kinetics of trandolapril. Thermochimica Acta. 2012;. doi:10.1016/j.tca.2012.04.009.

Giron D. Applications of thermal analysis in the pharmaceutical industry. J Pharm Biomed Anal. 1986;4:755–70.

Gombás A, Antal I, Szabó-Révész P, Marton S, Erõs I. Quantitative determination of crystallinity of alpha-lactose monohydrate by near infrared spectroscopy (NIRS). Int J Pharm. 2003;256:25–32.

Verma RK, Garg S. Compatibility studies between isosorbide mononitrate and selected excipients used in the development of extended release formulations. J Pharm Biomed Anal. 2004;35:449–58.

Peres-Filho MJ, Gaeti MPN, Oliveira SR, Marreto RN, Lima EM. Thermoanalytical investigation of olanzapine compatibility with excipients used in solid oral dosage forms. J Therm Anal Calorim. 2010;104:255–60.

Smith BC. Infrared spectral interpretation: a systematic approach. 1st ed. Boca Raton: CRC Press; 1998.

Bruni G, Berbenni V, Milanese C, Girella A, Marini A. Drug-excipient compatibility studies in binary and ternary mixtures by physico-chemical techniques. J Therm Anal Calorim. 2009;102:193–201.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Roumeli, E., Tsiapranta, A., Pavlidou, E. et al. Compatibility study between trandolapril and natural excipients used in solid dosage forms. J Therm Anal Calorim 111, 2109–2115 (2013). https://doi.org/10.1007/s10973-012-2476-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2476-2