Abstract

The purpose of this study is to determine the pyrolysis characteristics and gas product properties of printed circuit board (PCB) waste. For this purpose, a combination of Thermogravimetry-Fourier Transform Infrared Spectrum (TG-FTIR) and pyrolysis-gas chromatography/mass spectrometry (Py-GC/MS) techniques is employed. In the TG-FTIR experiment, a heating rate of 10 °C min−1 and a terminal pyrolysis temperature of 600 °C are applied. The thermal decomposition temperature, weight losses, and the temperature trend of evolving gaseous products of PCB waste are investigated. Py-GC/MS is used for the qualitative and semi-quantitative analysis of the higher-molecular-weight volatile decomposition products. Associated with the analysis results of TG-FTIR and Py-GC/MS for the volatile products, PCB waste degradation could be subdivided into three stages. The main products in the first stage (<293 °C) are H2O, CH4, HBr, CO2 and CH3COCH3. High-molecular-weight organic species, including bromophenols, bisphenol A, p-isopropenyl phenol, phenol, etc., mainly evolve in the second stage. In the last stage, at temperature above 400 °C, carbonization and char formation occur. This fundamental study provides a basic insight of PCB waste pyrolysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Printed circuit board (PCB) waste, which contains various valuable substances together with hazardous materials, is thus considered both as an attractive secondary resource and an environmental contaminant. Various recycling technologies with a view to recovering resources and at the same time preventing environmental contamination, i.e. hydrometallurgical technology, mechanical methods, pyrolytic methods and so on, have been adopted by the previous researchers to treat PCB waste [1–3]. Among these methods, pyrolysis has been recognized as a promising resource recovery alternative, because in pyrolysis process (heating without oxygen), the organic phase in PCB is decomposed to gases and liquids, which can be used as fuels or chemical feedstock, while the inorganic components (metals, glass fibres, etc.) remain almost unaltered during the process. Furthermore, the baseplate of PCB after pyrolysis is very friable, prone to delamination and could be easily liberated for glass fibre and metallic fractions. The metal could be sent to the smelting plant and the glass fibre can be recycled into other composites or any other plastic materials [4]. It can be seen that recycling of PCB waste by pyrolysis is of importance because of energy and material recovery considerations. In this aspect, a detailed knowledge of thermal degradation characteristics of PCB waste, which is very significant for both the design and the operation of PCB waste thermal treatment facilities, is of great importance.

Thermogravimetric (TG) analysis has been widely used to study the thermal decomposition of solid materials [5–8]. However, it is still unable to provide enough information on the thermal degradation mechanism because of the insufficient capability of the evolved gas mixture analysis. In thermoanalytical investigations, the determination of the composition of the evolved gases is very important, especially when investigating decomposition processes or gas–solid reaction occurring in multi-components systems. Thus, the direct analysis of gas composition, by continuous monitoring with a hyphenated technique, has attracted more attention in the identification of gaseous products to study the characteristics and products of pyrolysis. Thermogravimetric analyser coupled with Fourier transform infrared spectrometer (TG-FTIR) is a useful tool in dynamic analysis as it monitors continuously both the weight of the non-volatile materials (residue) and the time-dependent evolution of the volatile products generated during the thermal degradation. Considering the advantage of simultaneous online gas analysis, the technology of TG-FTIR has been adopted widely to study pyrolysis volatile products of poly [9], diazoaminoderivatives [10], agricultural residues [11], etc. Furthermore, with the development of instrumental analyzing methods, another hyphenated technique, pyrolysis-gas chromatography/mass spectrometry (Py-GC/MS), has been widely used to evaluate the thermal decomposition behaviour and pyrolysis products of polymers in detail [12, 13] due to its rapidity, high sensitivity, and effective separation of complex mixture compounds containing some pyrolysates of similar compositions. However, few articles present the product-evolution process and degradation characteristics of PCB waste conducting on TG-FTIR and Py-GC/MS [14, 15].

Therefore, in the present study, the combined TG-FTIR and Py-GC/MS techniques are employed to study the pyrolysis process and products of PCB waste. The weight loss of PCB waste is measured in a TG, and the gases evolved during TG run are detected online by FTIR. In addition, Py-GC/MS experiment is performed to separate and identify the major volatile components produced by pyrolysis of PCB waste. The information thus obtained is used to interpret possible thermal decomposition mechanism of PCB waste.

Experimental

Materials

The PCB waste used in the study is a kind of woven glass fabric PCBs without electronic elements, so the metallic portion only consists of Cu. The metallic layers are removed by treatment with a dilute aqueous solution of hydrochloric acid and hydrogen peroxide, followed by washing with distilled water. After being dried in an oven at 100 °C, the metal-free materials are crushed to fine dust for subsequent TG-FTIR and Py-GC/MS analyses. Table 1 presents the results of ultimate and proximate analysis of this glass–nonmetal sample. An Elementar-VarioEL III analyser is used for chemical composition analysis, such as carbon, hydrogen, and nitrogen. A SDTGA5000 automatic proximate analyser is used for proximate analysis.

TG-FTIR analysis

The TG-FTIR simultaneous measurement for the online analysis of volatile compounds formed during TG runs consists of a thermogravimetric analyser (TG209F1, Netzsch) coupled with a FTIR spectrophotometer (Vertex70, Bruker). In this study, approximately 10 mg of sample is heated in N2 at 10 °C min−1, first from ambient temperature to 120 °C to dry the sample for 10 min, and then to 600 °C for pyrolysis. The flow rate of carrier gas (N2) was set at 30 ml min−1. The gas products released from the pyrolysis in TG were swept immediately to a cold gas cell, followed by analysis using FTIR. The transfer line and gas cell were heated to 190 °C to prevent condensation of the produced gases. Resolution in FTIR was set at 4 cm−1, spectrum scan frequency at eight times per minute, and the spectral region at 600–4,000 cm−1. The distribution of gaseous products from pyrolysis was analysed, with respect to the changing of reaction temperatures, from 120 to 600 °C.

Py-GC/MS analysis

Pyrolysis-gas chromatography/mass spectrometry (Py-GC/MS) system was employed to separate and identify the pyrolysis volatiles. For this purpose, a Frontier PY-2020iD-type pyrolyser was directly attached to a gas chromatography/mass spectrometry (5890GC/5972MSD, Agilent). In the characterization process, the pyrolysis temperature of 600 °C was used. The chromatographic separation of the volatile products was performed using a Varian CP-Sil 24CB capillary quartz column (30 m × 0.25 mm, 0.25 μm). Before the chromatograph separation, the temperature of the chromatographic column was progressively increased as follows: (i) 35 °C for 3 min; (ii) from 35 to 260 °C at a rate of 4 °C min−1; (iii) the capillary column was maintained at 260 °C for about 40 min. Helium was used as carrier gas at a constant flow of 1.0 mL min−1. The mass range used for the mass selective detector was 40–550 m/z. The decomposition products were identified by means of the comparison between the experimental mass spectrum and the mass spectrum library attached to the Py-GC/MS instrument. The identification of each volatile products can be confirmed if the qualification percentage reaches 85% and even higher.

Results and discussion

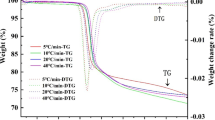

Thermogravimetric analysis

The thermogravimetric curve (TG, %) and differential thermogravimetric curve (DTG, % min−1) of PCB waste at the heating rate of 10 °C min−1 are presented in Fig. 1. The pyrolysis of PCB waste only includes one stage of loss weight. The main weight loss occurred between 274 and 402 °C. The temperature where the rate of weight loss is at a maximum, T max, and maximum degradation rate, r max, in pyrolysis were found to be about 320 °C and −13.07% min−1, respectively. At the end of the run, PCB sample gave a solid residue equal to ~64.02% of its original mass.

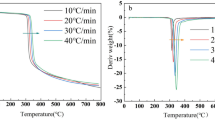

3D FTIR spectra analysis

FTIR has been widely used to identify various inorganic and organic compounds of pyrolysis. The 3D infrared spectrum of evolved gas includes information on infrared absorbance, wave number and temperature. After evolved gas from TG was swept into the gas cell, absorbance information at various wave numbers and temperatures could be obtained by FTIR. A typical spectral output from TG-FTIR of PCB pyrolysis is shown in Fig. 2. In accordance with the TG data in Fig. 1, the formation of volatile products mainly takes place between 270 and 400 °C.

When the temperature is fixed, absorbance information at different wave number can be obtained to study the volatile components released at this moment. Figure 3 shows typical FTIR spectra of the gaseous products in different pyrolysis temperatures for PCB waste. At low temperature (as indicated in Fig. 3a, b), a few of the small molecular gaseous products are released, such as H2O, CH4, HBr, CO2 and CH3COCH3. These compounds were easily identified by their characteristic absorbance: the band at 3,274 cm−1 cooresponds to the stretching of O–H bonds, related to H2O release. The band at 2,987 cm−1 in the spectrum indicates the existence of methane. The peak at 1,716 cm−1 could be the result of a carbonyl group (C=O), indicating the presence of acetone. And other substances, such as HBr at 2,400–2,800 cm−1, CO2 at 2,197–2,405 cm−1, etc. are also detected. However, some gases like H2, N2 and O2 have weak or no IR absorption and so are undetectable by FTIR [16].

Commercial diglycidyl ether of bisphenol A DGEBA (I) and diglycidyl ether of tetrabromobisphenol A DGETBBA (II) were used as received as epoxy monomers in PCB, which have the chemical structure as shown in Fig. 4. They were epoxylated bisphenol A solid resins [17]. The presence of low-molecular-weight compounds, such as water, carbon dioxide, methane, hydrogen bromide and acetone, indicated that the cleavages of the C(phenyl)–Br, C(phenyl)–C, C–C and O–CH2 bonds take place.

With the elevation of the pyrolysis temperatures, especially above 309 °C, low-molecular-weight gaseous products mentioned above continue to increase, but some new volatiles are also emitted. Release rate of evolving gases reaches its maximum at about 320 °C, and then with pyrolysis progression, the content of gaseous products decreased (see Fig. 3e). The spectra of gaseous products at the maximum mass rate are presented in Fig. 3d. The spectra fits well to the previously reported FTIR features of gas products [17]. Besides low-molecular-weight compounds, the FTIR data in Fig. 3d also evidence the formation of higher-molecular-weight organic species with the well-distinguished absorption bands of bromophenols (at 3,646 cm−1), phenol (at 3,567 cm−1) ketones and aldehydes (at 1,733 cm−1). In addition, the absorption band at 3,283 cm−1 is associated with the O–H stretches in phenols or H2O. The peak at 3,052 cm−1 is the result of unsaturated carbon–hydrogen bond in aromatics group or alkene. The absorption band at 2,965 cm−1 is attributed to the asymmetric C–H stretching of –CH3– containing systems. The band at 2,088 cm−1 in the spectrum indicates the formation of carbon monoxide. Two wave bands at 1,600 and 1,498 cm−1 denoted framework vibration of benzene functional group caused by the stretching of carbon–carbon bonds of benzene rings. The bands at 1,342 cm−1 and 1,259 cm−1 might be associated with C–O–C stretching vibrations in ethers, and the absorption peak at 1,184 cm−1 might result from the stretching of the carbon–oxygen bond of a phenol structure. Furthermore, mono and polycyclic and substituted aromatic groups are indicated by the adsorption peaks between 607 and 900 cm−1. However, the simultaneous evolution of several volatile compounds having similar chemical structure did not allow the identification of the single species by the analysis of the FTIR spectra. Detailed information about the organic compounds formed during PCB waste pyrolysis was thus obtained from GC–MS analysis of the degradation products fraction conducted on a Py-GC/MS setup, and will be discussed in the following section.

When the temperature reaches about 464 °C, since a large amount of the organic material is completely decomposed into gas and liquid, a few products are released, which is consistent with the analysis results of TG curve. No new volatiles were detected again in this temperature interval. However, the concentration of CO2 and CO continues to increased. Carbon dioxide could have been formed by the decomposition of calcium carbonate fillers in the polymer [18]. In fact, the brominated systems (using brominated bisphenols A) in epoxylated resins formed phenoxy radicals after the elimination of bromine. These phenoxyl radicals are the precursors for char and dioxin formation. At higher temperature, the unimolecular decomposition of the phenoxy radical becomes relevant, and an increase in the quantity of CO could be observed [19].

In view of the above FTIR spectra analysis, PCB waste pyrolysis process was subdivided in three steps. (1) In step one (<293 °C), some low-molecular-weight compounds, such as H2O, CH4, HBr, CO2 and CH3COCH3 are detected. (2) In step two, between 293 and 400 °C, higher-molecular-weight organic species, including bromophenols, phenols, ethers, ketones and aldehydes, are evolved. (3) In step three, at temperature above 400 °C, carbonization and char formation occur.

Py-GC/MS analysis

To get some insights on the formation of higher-molecular-weight decomposition products, thermal degradation run is performed on Py-GC/MS setup. Figure 5 shows the pyrogram of volatile products from the pyrolysis of PCB waste, most of which have been identified, and their corresponding % areas are reported in Table 2. The Py-GC/MS analyses revealed the formation of a large number of products: phenol (11.22%), p-isopropenyl phenol (12.59%) and bisphenol A (35.69%) are the most prominent products. The pyrolysis products also contained many other phenolic derivatives, e.g. cresol, xylenol, allylphenol and ethylphenol. Besides, it contained a particularly large number of diphenyl-containing compounds (products 19, 21, 22 and 26 in Table 2). Only two halogenated compounds, 2-bromophenol (product 4 in Table 2) and 2-bromo-p-cymene (product 15 in Table 2), could be identified in the pyrolysis products. These products may well originate from the bisphenol A-based epoxy resin. The source of brominated compounds should be the brominated bisphenol A component of the resin (TBBA) [20].

Py-GC/MS detection of gaseous products evolved from pyrolysis of PCB waste. Peak numbers correspond to compounds on Table 2

Thermal decomposition of polymer in PCB sample is a complex process, including several competing reactions. It is generally accepted that [17, 21] degradation of epoxies resins start by dehydration of secondary alcoholic groups followed by homolytic scission of the formed allylic bonds. The brominated systems (using brominated bisphenols A) are, however, thermally less stable than the non-brominated ones. The degradation initiation reaction in such systems is associated with the formation of HBr which could further destabilize the epoxy network and catalyse the decomposition reaction. The homolytic scission of the aromatic bromine, and its condensation with phenolic hydroxyl are the main processes. During the debromination phase, successive C–Br bond fission and hydrogen abstraction form HBr and phenols with minor bromine content. Figure 6 describes possible pathways via which bisphenol A, p-isopropenyl phenol, phenol and 4-(1-methylethyl)-phenol were produced from debromination phase. Bisphenol A was formed due to the cleavage of O–CH2 bond on both sides of the same monomeric structure. The breakdown of the bonds connecting the phenyl ring to an isopropylidene group would result in the formation of isopropenyl or isopropyl phenol and phenol, and phenol could also be produced by the decomposition of various intermediate products. Relatively high yield of bisphenol A detected in decomposition products indicate that the thermal cracking of the O–CH2 bonds is a prevailing scission reaction. It was noticeable that the quantities of p-isopropenyl phenol was higher than that of 4-(1-methylethyl)-phenol in pyrolyzate, indicating the breakdown of the isopropyl–phenyl bond (Ar–C(CH3)2–) of the bisphenol A structure preferred to formation of isopropylidene double bonds. It might be seen that the decomposition pathways proposed in Fig. 6 well represent the reaction network involved in the formation of the main decomposition products detected in PCB waste thermal decomposition process.

Conclusions

Using TG-FTIR and Py-GC/MS analyses, the thermal behaviors of PCB waste are investigated. The knowledge of this process could be of relevance in a pyrolytic approach to the recycling of PCB waste. The conclusions that could be reached are as follows:

-

(1)

TG analysis showed that thermal degradation of PCB waste commences at around 274 °C and showed a maximum reaction rate at 320 °C. The generated solid residue was 64.02% at 600 °C. Its pyrolysis process only included one stage of loss weight. Gaseous products from PCB waste pyrolysis in TG, as detected online using FTIR, mainly evolved at 270–400 °C, which is consistent with the observation obtained from the thermoanalysis.

-

(2)

The pyrograms obtained from Py-GC/MS of PCB waste included a range of interesting compounds. The Py-GC/MS analysis indicates that phenol, p-isopropenyl phenol and bisphenol A were the most prominent higher-molecular-weight decomposition products. The high amounts of bisphenol A detected in decomposition products indicated that the cleavage of the O-CH2 bonds is a prevailing scission reaction of PCB waste decomposition.

-

(3)

Associated with the analysis results of TG-FTIR and Py-GC/MS for the volatile products, the mechanism of PCB waste pyrolysis includes three steps. The products released during the first stage were mainly low-molecular-weight compounds, including H2O, CH4, HBr, CO2 and CH3COCH3. High-molecular-weight organic species including bromophenols, bisphenol A, p-isopropenyl phenol, phenol, etc., mainly evolve in the second stage. In the last stage, at temperature above 400 °C, carbonization and char formation occur.

References

Xiang Y, Wu P, Zhu N, Zhang T, Liu W, Wu J, Li P. Bioleaching of copper from waste printed circuit boards by bacterial consortium enriched from acid mine drainage. J Hazard Mater. 2010;184:812–8.

Murugan RV, Bharat S, Deshpande AP, Varughese S, Haridoss P. Milling and separation of the multi-component printed circuit board materials and the analysis of elutriation based on a single particle model. Powder Technol. 2008;183:169–76.

Quan C, Li A, Gao N, dan Z. Characterization of products recycling from PCB waste pyrolysis. J Anal Appl Pyrol. 2010;89:102–6.

Cunliffe AM, Williams PT. Characterisation of products from the recycling of glass fibre reinforced polyester waste by pyrolysis. Fuel. 2003;82:2223–30.

Açıkalın K. Thermogravimetric analysis of walnut shell as pyrolysis feedstock. J Therm Anal Calorim. 2011;105:145–50.

Aboulkas A, Harfi KE, Bouadili AE, Nadifiyine M. Study on the pyrolysis of Moroccan oil shale with poly (ethylene terephthalate). J Therm Anal Calorim. 2010;100:323–30.

Quan C, Li A, Gao N. Thermogravimetric analysis and kinetic study on large particles of printed circuit board wastes. Waste Manage. 2009;29:2353–60.

Sarwar A, Khan MN, Azhar KF (2011) Kinetic studies of pyrolysis and combustion of Thar coal by thermogravimetry and chemometric data analysis. J Therm Anal Calorim. doi:10.1007/s10973-011-1725-0.

Loría-Bastarrachea MI, Herrera-Kao W, Cauich-Rodríguez JV, Cervantes-Uc JM, Vázquez-Torres H, Ávila-Ortega A. A TG/FTIR study on the thermal degradation of poly(vinyl pyrrolidone). J Therm Anal Calorim. 2011;104:737–42.

Mocanu AM, Odochian L, Apostolescu N, Moldoveanu C. TG-FTIR study on thermal degradation in air of some new diazoaminoderivatives. J Therm Anal Calorim. 2010;100:615–22.

Souza BS, Moreira APD, Teixeira AMRF. TG-FTIR coupling to monitor the pyrolysis products from agricultural residues. J Therm Anal Calorim. 2009;97:637–42.

Arshad M, Masud K, Arif M, Rehman S, Arif M, Zaidi JH, Chohan ZH, Saeed A, Qureshi AH. The effect of AlBr3 additive on the thermal degradation of PMMA. A study using TG-DTA-DTG, IR and PY-GC-MS techniques. J Therm Anal Calorim. 2009;96:873–81.

Cai GM, Yu WD. Study on the thermal degradation of high performance fibers by TG/FTIR and Py-GC/MS. J Therm Anal Calorim. 2011;104:757–63.

Webb M, Last PM, Breen C. Synergic chemical analysis-the coupling of TG with FTIR, MS and GC-MS 1. The determination of the gases released during the thermal oxidation of a printed circuit board. Thermochim Acta. 1999;326:151–8.

Blazsó M, Czégény Z, Csoma C. Pyrolysis and debromination of flame retarded polymers of electronic scrap studied by analytical pyrolysis. J Anal Appl Pyrol. 2002;64:249–61.

Bassilakis R, Carangelo RM, Wójtowicz MA. TG-FTIR analysis of biomass pyrolysis. Fuel. 2001;80:1765–86.

Balabanovich A, Hornung A, Merz D, Seifert H. The effect of a curing agent on the thermal degradation of fire retardant brominated epoxy resins. Polym Degrad Stab. 2004;85:713–23.

Biswas B, Kandola BK, Horrocks AR, Price D. A quantitative study of carbon monoxide and carbon dioxide evolution during thermal degradation of flame retarded epoxy resins. Polym Degrad Stab. 2007;92:765–76.

Marongiu A, Bozzano G, Dente M, Ranzi E, Faravelli T. Detailed kinetic modeling of pyrolysis of tetrabromobisphenol A. J Anal Appl Pyrol. 2007;80:325–45.

Barontini F, Marsanich K, Petarca L, Cozzani V. Thermal degradation and decomposition products of electronic boards containing BFRs. Ind Eng Chem Res. 2005;44:4186–99.

Luda MP, Balabanovich AI, Camino G. Thermal decomposition of fire retardant brominated epoxy resins. J Anal Appl Pyrol. 2002;65:25–40.

Acknowledgements

The above study was supported by the Geping GreenAid Project—Environmental Scientific Research “123 Project” of Liaoning, China and the National Natural Science Foundation of China (No. 51006018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Quan, C., Li, A. & Gao, N. Research on pyrolysis of PCB waste with TG-FTIR and Py-GC/MS. J Therm Anal Calorim 110, 1463–1470 (2012). https://doi.org/10.1007/s10973-011-2048-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-2048-x