Abstract

A new class of thermoset polymers was synthesized based on agrochemical renewable cardanol—a by-product of cashew nut industry. A solventless synthesis of bisbenzoxazine monomers based on bisphenol-A (b) and aniline (abbreviated as Bzb-A) and cardanol (c) with diamines namely bis-(4-(4-aminophenoxy)phenyl)ether (HP), bis-(3-(4-aminophenoxy)phenyl)ether (HM), 4,4′-diaminodiphenylsulphone (DDS) and 2,2-bis(4-(4-aminophenoxy)phenyl)propane (BA) was carried out. The benzoxazine monomers (Bzc-HP, Bzc-HM, Bzc-DDS and Bzc-BA) were characterized by 1H-NMR and FTIR spectroscopy. The curing exotherm depended on the structure of the monomers. The onset curing temperature (T o) was lowest for Bzb-A (460 K) and highest in Bzc-HM (518 K). The decomposition temperature for 5% mass loss (T 5%) of resins followed the order PBzb-A < PBzc-DDS < PBzc-BA < PBzc-HM ≈ PBzc-HP. The materials showed their potential as adhesives. Lap shear strength on steel plates followed the trend PBzc-DDS < PBzc-HM < PBzc-BA < PBzc-HP.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polybenzoxazines (PBzs), a new class of thermosetting resins, first reported in 1994 [1] are gaining attention due to better performance than the state-of-the-art phenolic resins. The advantages [2–4] of PBzs include nearly zero shrinkage upon curing, low water absorption, usually T g much higher than the cure temperature, no strong acid catalysts required for curing, ideally very long shelf life, and no release of by-products during curing thereby leading to crack-free mouldings. Besides these properties they have good thermal stability and chemical resistance.

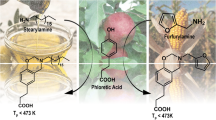

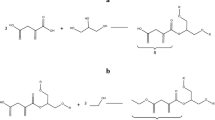

Benzoxazines (Bzs) monomers are cyclic heterocycles generated by the Mannich-like condensation of a phenol, formaldehyde and an amine [5] either by employing solution or solventless methods. We have earlier reported [6] synthesis and characterization of cardanol-based monofunctional benzoxazine (Bzc-A) of low viscosity, according to Scheme 1.

Synthesis of cardanol-based benzoxazine monomer (Bzc-A) [6]

This monobenzoxazine are cured by ring-opening polymerization (ROP) to yield a linear polymer. In order to prepare cross-linked polymer it is desirable to have bifunctional monomer, i.e. bisbenzoxazine. This can be achieved by using either a difunctional phenol such as bisphenol-A or a diamine. The synthetic strategy utilized over past mainly include reaction of difunctional aromatic phenols bisphenol-A [1, 7, 8] and their derivatives such as 2,2-bis(4-hydroxyphenol)hexafluoropropane [9], 2,2′-diallyl bisphenol-A [10], dihydroxynapthalene [11], etc. Very few studies have been reported on preparation of bisbenzoxazines based on aromatic/aliphatic diamines. The amines that have been used are 4,4′-diaminodiphenyl methane [12, 13], 4,4′-diaminodiphenylsulphone [12, 14], fluorinated aliphatic diamines [15], poly(propyleneoxide) di-/tri-amines [16], ethylene diamine [17], etc. Polyfunctional oxazine derivatives [18] such as trisbenzoxazines were reported by Jones et al.

Lin et al. [12] have recently reported synthesis of bifunctional benzoxazines from monofunctional phenol and aromatic diamines using solvent by a three-step process involving (a) formation of Schiff’s base followed by (b) reduction of imine linkage to secondary amine structure and finally (c) its condensation with formaldehyde to form bisbenzoxazine derivative.

We now report, the solventless condensation reaction of cardanol with aromatic diamines having different structure, i.e. bis-(4-(4-aminophenoxy)phenyl)ether (HP) and bis-(3-(4-aminophenoxy)phenyl)ether (HM), 4,4′-diaminodiphenylsulphone (DDS) and 2,2-bis(4-(4-aminophenoxy)phenyl)propane (BA) was carried out according to Scheme 2. The monomers were characterized by 1H-NMR and FTIR spectroscopy. The thermal stability and curing behaviour was compared with the bisphenol-A (Bzb-A) bisbenzoxazine deivative (Scheme 2).

Experimental

Materials

Cardanol was procured from Satya Cashew Chemicals Pvt. Ltd. (India), paraformaldehyde and chloroform from Rankem, 4,4′-diaminodiphenylsulphone (DDS) (Aldrich), 2,2-bis(4-(4-aminophenoxy)phenyl)propane (BA) (ABR organic) and sodium sulphate from CDH. The diamine bis-(4-(4-aminophenoxy)phenyl)ether (HP) and bis-(3-(4-aminophenoxy)phenyl)ether (HM) were synthesized in the laboratories according to literature [19]. All the reagents were used as received.

Synthesis

The synthesis of diamine HP and HM was carried out by partial modification of the process reported earlier by Solanki et al. [19] via nucleophilic substitution reaction of 1-chloro-4-nitrobenzene with hydroquinone or resorcinol followed by catalytic reduction in the laboratory according to Scheme 3.

Benzoxazine monomer

The monomers were synthesized by using a single step condensation reaction of aromatic diamine, cardanol and paraformaldehyde. A typical preparation of Bzc-HM is described in the following text.

A mixture of cardanol (10.4 g, 34.2 mmol), paraformaldehyde (2.0 g, 68.5 mmol), bis-(3-(4-aminophenoxy)phenyl)ether (HM) (5.0 g, 17.1 mmol) was gradually heated from room temperature to 393 K over a period of an hour, then stirred at 393–413 K for 8 h. The reaction starts at 343 K as indicated by evolution of water and change in colour of solution from red to reddish brown. On cooling, chloroform (100 mL) was added and organic layer was washed with water (3 × 100 mL), aqueous sodium hydroxide (2 N, 2 × 50 mL) followed by washing with aq. HCl (0.5 N, 3 × 20 mL). The pH was neutralized with aq. ammonia (34%) followed by washing with water (50 mL). The organic layers were combined, dried over sodium sulphate and filtered to give red oil. The solvent was removed under reduced pressure and the residue was dried at 353 K under vacuum to give benzoxazine (Bz-HM) in quantitative yield as yellow solid.

Characterization techniques

A Nicolet 200, FTIR spectrometer was used for recording the IR spectra as thin films on a KBr disc. A Bruker AC 300 MHz FT-NMR spectrometer was used to record the 1H-NMR of the samples in CDCl3 using tetramethyl silane as an internal standard.

Thin layer chromatography was performed on Merck aluminium plates coated with silica gel F254 using chloroform as eluent.

The curing behaviour of monomers was evaluated by using TA 2100 thermal analyzer having 910 DSC module. A heating rate of 10 K min−1 in static air atmosphere and a sample mass of 2–3 mg in aluminium pans was used. The benzoxazine monomers were dried under vacuum at 323 K for 1 h before DSC analysis.

Isothermal curing of bisbenzoxazines was done by heating at 393 K (1 h), 423 K (1 h), 473 K (1 h), and 503 K (1 h) for Bzc-HP and Bzc-BA while curing of Bzc-HM and Bzc-DDS was accomplished by heating the sample further at 523 K instead for 503 K for 1 h in an air oven.

A Perkin Elmer Diamond SDTA thermal analyzer was used for thermal characterization of isothermally cured polybenzoxazine resins in nitrogen atmosphere (flow rate 60 mL min−1). A sample mass of 5–6 mg was used and the rate of heating was 10 K min−1.

Lap shear strength (LSS) of bonded joints on steel plates of roughness (R a 0.9–1.1 μm) was measured in accordance with ASTM standard D1002. INSTRON 5582 100KN tensile testing machine equipped with a PC to acquire test data on Merlin software and a crosshead speed of 1.3 mm min−1 was used. LSS samples were prepared by coating adhesive (0.12 ± 0.02 g resin) on a 15 × 15 mm2 area. The assembly was clamped with paper clips (15 mm) and cured at 453 K for 90 min and 513 K for 1 h in an air oven.

Results and discussion

The colour of the monomers depended on the backbone structure and ranged from yellow solid (Bzc-HM), reddish brown solid (Bzc-HP), orange viscous oil (Bzc-DDS) and reddish brown viscous oil (Bzc-BA).

The yield of all the bisbenzoxazine monomers was in the range of 70–80% except Bzc-DDS (~20%). The lower yield of the Bz-DDS could be attributed to the low reactivity of amino groups in DDS due to the presence of electron-withdrawing sulphone group at p-position of amino group. Instead of using a solventless synthesis, a reaction in less polar solvent, dioxane [20] was also tried for the synthesis of Bz-DDS. However, this approach also was not successful in enhancing the yield. The condensation reaction of diamines with cardanol and paraformaldehyde at 413 K resulted in the formation of corresponding cardanol-based bisbenzoxazine monomers.

In order to check the purity of bisbenzoxazine monomers, thin layer chromatography was performed. The absence of unreacted cardanol and diamine was indicated by such studies.

The structure of the monomers was confirmed by FTIR and 1H-NMR spectroscopy. A typical FTIR spectrum of Bzc-HM is shown in Fig. 1.

The typical absorption frequencies due to benzoxazine structure Bzc-HM were observed at 3009 (C–H aromatic stretching vibrations), 2956, 2853 (C–H aliphatic stretch), 1619, 1510 (1,2,3-trisubstituted benzene), 1390 (C–N stretch), 1229 (Ar–O–C antisymmetric stretch), 1036 (Ar–O–C symmetric stretch), 972 cm−1 (N–C–O stretch). In Bzc-HP monomer, characteristic IR vibrations observed at 1622, 1504 (1,2,3-trisubstituted benzene), 1365 (C–N stretch), 1224 (Ar–O–C antisymmetric stretch), 1055 (Ar–O–C symmetric stretch), 972 cm−1 (N–C–O stretch). Similar absorptions were observed in Bzc-DDS except some additional absorption bands due to sulphone group at 1379 (>SO2 asymmetric stretch), and 1144 cm−1 (>SO2 symmetric stretch) were absorbed.

In 1H-NMR spectrum of Bzc-HM multiplet due to methyl protons resonance were observed at 0.86–0.93 ppm (m, CH3). Other signals were at 1.21–1.72 (m, aliphatic CH2 protons), 1.92–2.14 (m, CH2CH=), 2.52 (t, CH2Ar), 2.75–2.90 (m, CH2(CH=)2), 4.57 (s, ArCH2N–), 5.30 (s, –OCH2N–), 4.92–5.14, 5.31–5.48, 5.72–5.93 (m, CH=, CH2=CH–, HC=CH2), 6.53–6.82 (m, ArH), 6.91–7.05, 7.09–7.30 (m, ArH). 1H-NMR spectra of Bzc-HP, Bzc-DDS and Bzc-BA, aliphatic protons signals were observed at similar ppm as Bzc-HM. Besides aliphatic protons, other characteristic signals are listed for these monomers. 1H-NMR spectrum of Bzc-HP showed 4.55 ppm (s, ArCH2N–), 5.30 (s, –OCH2N–), 6.63 (s, ArH), 6.70–6.79 (m, ArH), 6.81–7.17 (m, ArH) and 7.30 (s, ArH). In Bzc-DDS the characteristic absorption due to various protons were at 3.88 (s, br, –NCH2Ar), 4.61 (s, ArCH2N–), 4.85–5.10, 5.20–5.90 (m, CH=, CH2=CH–, –OCH2N–, HC=CH2), 6.60–7.30 (m, ArH), 7.80–7.85 ppm (m, ArH). In Bzc-BA proton resonance signals were at 1.2–1.8 (m, aliphatic CH2, >C(CH3)2), 4.55 (s, ArCH2N–), 5.28 (s, –OCH2N–),6.53–6.65 (s, ArH), 6.70–6.78 (d, ArH), 6.78–6.95, 7.05–7.22 (m, ArH).

The ring closure reaction of amino group with aldehyde group and phenolic –OH resulted in oxazine ring formation. The success of the reaction and formation of Bzc-diamines was supported by the appearance of absorption bands due to Ar–O–C oxazine asymmetric and symmetric stretch at ~1230 and ~1035 cm−1, respectively. The monomers also showed the presence of C–N and N–C–O stretch at ~1365 and ~972 cm−1, respectively. In addition, the other absorption bands observed are aromatic, vinylic, aliphatic C–H (3008, 2926, 2854 cm−1) and aromatic, aliphatic C=C (1580–1623 cm−1) supporting the aromatic ring and aliphatic side chains in the structure of Bz monomers. Bzc-DDS showed the appearance of asymmetric and symmetric stretches due to >SO2 moiety [21] at 1378 and 1140 cm−1, respectively.

The 1H-NMR spectra of Bz monomers showed the characteristic resonances at ~5.3 ppm (s, ArOCH2N), ~4.6 ppm (s, ArCH2N) suggesting the reaction of hydroxyl functional group of cardanol in the formation of oxazine structure and hence successful formation of cardanol-based bisbenzoxazine monomers. A typical 1H-NMR spectra of Bzc-HM is shown in Fig. 2. In case of Bzc-BA, isopropylidine methyl groups overlapped with aliphatic methylene protons of alkylene side chain. The resonances between 6.5 and 7.9 ppm are assigned to the aromatic protons. The high temperature required during the solventless synthesis of benzoxazine monomers usually resulted in thermally assisted ring-opening oligomerization. The formation of oligomers occurs due to opening of Mannich bridge and signal corresponding to N–CH2–Ph appear around 3.8–4 ppm [1]. The absence of such signal in all monomers except Bzc-DDS suggests no oligomer impurity. Oligomerization in Bz-DDS could be attributed to assistance provided by the electron-withdrawing sulphone group for ROP to some extent.

The curing characteristics of various resins were studied by DSC. The exothermic transition was characterized by determining melting temperature (T m), onset curing temperature (T o), temperature of exothermic peak (T p) and heat of curing reaction (ΔH) from the area under the curve. DSC scans of monomers namely Bzc-HP, Bzc-HM, Bzc-DDS, Bzc-BA and Bzb-A are shown in Fig. 3. The curing characteristics (T m, T o, T p and ΔH) of bisbenzoxazine monomers are summarized in Table 1. Bzc-HM and Bzc-HP showed a melting endotherm at 343 and 387 K, respectively. The higher melting peak temperature of the latter monomer is due to its symmetric structure allowing better packing. The processing of Bzc-HM monomer is comparatively more economical than Bzc-HP as it has a lower melting temperature and a wider processing window, i.e. difference in temperature between melting of monomer and onset of curing of monomer. Higher the difference better is the ease in fabrication and processing of thermoset composite. No melting endotherm, due to melting of diamine impurity, was present in DSC scans of monomers indicating absence of such impurities. However, in some of the cardanol-based bezoxazines, no melting peak was observed (e.g. Bzc-DDS and Bzc-BA), Bzc-HP showed a lower T m by 50 K. The lower values in melting point were attributed to the presence of longer alkyl chain length in Bzc monomers which slowed down and prevent crystallization and resulted in amorphous domains. The T o values follows the order Bzc-HP < Bzc-DDS < Bzc-BA < Bzc-HM. A lower T o value for Bzc-DDS as compared to other bisbenzoxazines may be due to formation of oligomers during synthesis (as supported by 1H-NMR) process which initiate autocatalytic ROP. Bzc-DDS showed a lower T o, T p and ΔH as compared to the Bzc-HM. The polymerization enthalpy of difunctional Bz monomers is nearly same except Bzc-HM as shown in Table 1.

The architecture of backbone of polybenzoxazine is formed by thermally activated ring-opening of the oxazines of the monomers. Thermal stability of isothermally cured benzoxazines was studied by TG. The TG traces of PBzc-HP, PBzc-HM, PBzc-DDS, PBzc-BA and PBzb-A is shown in Fig. 4. The relative thermal stability of these samples was estimated by comparing temperatures for initial 5 and 10% mass loss (T 5% and T 10%, respectively), temperature of maximum rate of mass loss (T max, from DTG trace), and char yield at 1073 K. TG traces of PBzc-HP, PBzc-HM, PBzc-DDS, PBzc-BA and PBzb-A is shown in Fig. 4. The inset in Fig. 4 showed a magnified picture of initial mass percent (0–20%) variation with temperature of the cured resins. The TG results are summarized in Table 2. Cardanol-based PBzs showed a lower thermal stability (70–90 K) than the phenol-based polymer.

All PBzs based on diamines were found to be stable up to 600 K except PBzc-DDS and PBzc-BA. Both PBz-HM and PBz-HP showed a similar mass loss pattern with a shoulder at 683 K and maximum mass loss at 713 K. This may be due to formation of similar three-dimensional network in both the polymer—irrespective of variation in monomer structure. The initial decomposition temperature variation in TGA of PBzs follows the order PBzc-DDS < PBzc-BA < PBzc-HM ≈ PBzc-HP. Earlier studies on polybenzoxazines [12] also showed a comparable trend, DDS-based PBz has lower thermal stability than HP-based PBz. Among studied mono-amine PBzs, PBzb-A showed the lowest thermal stability, while PBzc-A the highest one. Bifunctional Bz monomers yields cross-linked network of lower thermal stability compared to monofunctional monomer (PBzc-A).

On comparison with PBzc-A, DTG traces of bifunctional Bz did not show a two step (bimodal) weight loss except PBzc-BA with maximum weight loss centered at 694 K (T 1) and 703 K (T 2). All the polymers based on diamine had 10–30 K and 40–30 K lower value of T 1 and T 2, respectively, than mono-amine (aniline)-based monomer. However, T 1 values were nearly 100 K higher than bifunctional Bz monomer based on bisphenol-A (PBzb-A).

Adhesive properties of phenolic resin either neat [2] or blends with cardanol formaldehyde resins [22–24] have been studied. We have investigated the applications of benzoxazine polymers derived from cardanol as adhesive for steel plates and results are tabulated in Table 3. Higher the LSS better is the adhesive. The presence of non-polar isopropylidene group (PBzc-BA), polar linkages such as ether linkage (PBzc-HP and PBzc-HM), sulphone (PBzc-DDS) and polar groups introduced during ROP of the monomers would expected to show an effect on the adhesive properties of the systems. It was found LSS values follows the order PBzc-DDS < PBzc-HM < PBzc-BA < PBzc-HP. Adhesive strength was found to be higher for the polymers containing flexibilizing group (–O–) between the benzene ring than the rigid group (–SO2–). The higher adhesion of HP over HM polymer isomer could be accounted due the difference in position of –O– linkage which probably accounts for better wettability of the adhering surfaces. Even though, DDS unit-based PBz resin has polar group but it showed poor adhesion which might be outweighed by the structural rigidity.

Summary and conclusions

A solventless synthesis of cardanol-based difunctional benzoxazine monomer derived from aromatic diamines was carried out successfully. The synthetic procedure reported recently [12] for phenol and aromatic diamines based Bz monomers either involved several synthetic steps and tedious purification methods or involve the use of solvents. We successfully reported the use of renewable source cardanol could effectively use both as solvent and reactant to carry out such reactions. The low viscosity of cardanol could successfully assist the ease in replacement of non-renewable petroproducts such as phenol, bisphenol-A, etc., and act simultaneously as solvent for benzoxazine monomers by this synthetic procedure. The curing characteristics of Bzc monomers are similar to petro-based Bz monomers as demonstrated by DSC analysis. Benzoxazine moieties were shown to readily undergo thermally activated ring-opening reaction to form cross-linked polymer networks. The thermosets polymers showed enhanced thermal stability and this was attributed to the presence of cardanol units in the polymer network. Cured monomers showed potential for high temperature adhesive applications.

References

Ning X, Ishida H. Phenolic materials via ring-opening polymerization: synthesis and characterisation of bisphenol-A based benzoxazines and their polymers. J Polym Sci, Part A: Polym Chem. 1994;32:1121–9.

Nair CPR. Advances in addition-cure phenolic resins. Prog Polym Sci. 2004;29:401–98.

Yagci Y, Kiskan B, Ghosh NN. Recent advancement on polybenzoxazine—a newly developed high performance thermoset. J Polym Sci, Part A: Polym Chem. 2009;47:5565–75.

Liu J, Ishida H. A new class of phenolic resins with ring opening polymerization. In: Salamon JC, editor. The polymeric materials encyclopedia. Boca Raton, FL: CRC press; 1996. p. 484–94.

Burke WJ, Bishop JL, Glennie ELM, Bauer WN. A new aminoalkylation reaction. Condensation of phenols with dihydro-1,3-aroxazines. J Org Chem. 1965;30:3423–7.

Lochab B, Varma IK, Bijwe J. Thermal behaviour of cardanol-based benzoxazines: monomers and polymers. J Therm Anal Calorim. 2010;102:769–74.

Agag T, Takeichi T. Synthesis and characterisation of novel benzoxazine monomers containing allyl groups and their high performance thermosets. Macromolecules. 2003;36:6010–7.

Kimura H, Matsumoto A, Hasegawa K, Fukuda A. New thermosetting resin from bisphenol A-based benzoxazine and bisoxazoline. J Appl Polym Sci. 1999;72:1551–8.

Lin CH, Chang SL, Lee HH, Chang HC, Hwang KY, Tu AP, Lu WC. Fluorinated benzoxazines and the structure-property relationship of resulting polybenzoxazines. J Polym Sci Part A: Polym Chem. 2008;46:4970–83.

Kumar KSS, Nair CPR, Radhakrishnan TS, Ninan KN. Bis allyl benzoxazine: synthesis, polymerization and polymer properties. Eur Polym J. 2007;43:2504–14.

Shen SB, Ishida H. Synthesis and characterisation of polyfunctional napthoxazines and related polymers. J Appl Polym Sci. 1996;61:1595–605.

Lin CH, Chang SL, Hsieh CW, Lee HH. Aromatic diamine-based benzoxazines and their high performance thermosets. Polymer. 2008;49:1220–9.

Men W, Lu Z. Synthesis and characterisation of 4,4′-diaminodiphenyl methane-based benzoxazines and their polymers. J Appl Polym Sci. 2007;106:2769–74.

Agag T, Jin L, Ishida H. A new synthetic approach for difficult benzoxazines: preparation and polymerisation of 4,4′-diaminodiphenyl sulphone-based benzoxazine monomer. Polymer. 2009;50:5940–4.

Valez-Herrera P, Doyama K, Abe H, Ishida H. Synthesis and characterisation of highly fluorinated polymer with the benzoxazine moiety in the main chain. Macromolecules. 2008;46:9704–14.

Yildirim A, Kiskan B, Demirel AL, Yagci Y. Synthesis, characterisation and properties of napthoxazine-functional poly(propyleneoxide)s. Eur Polym J. 2006;42:3006–14.

Takeichi T, Kano T, Agag T. Synthesis and thermal cure of high molecular weight polybenzoxazine precursors and the properties of the thermosets. Polymer. 2005;46:12172–80.

Subrayan RP, Jones FN. Condensation of substituted phenols with hexakis(methoxymethyl)melamine: synthesis, characterisation, and properties of substituted 2,4,6-tris[3,4-dihydro-1,3-(2H)-benzoxazin-3-yl]-s-triazine derivatives. Chem Mater. 1998;10:3506–12.

Solanki A, Choudhary V, Varma IK. Synthesis and characterisation of bisitaconimdes. I. J Appl Polym Sci. 2002;84:2277–82.

Ishida H, Low HY. Synthesis of benzoxazine functional silane and adhesion properties of glass-fiber-reinforced polybenzoxazine composites. J Appl Polym Sci. 1998;69:2559–67.

Williams DH, Fleming I. Spectroscopic methods in organic chemistry. 4th ed. New Delhi: Tata McGraw-Hill; 1994. p. 29–62.

Varghese LA, Thachil ET. Adhesive properties of blends of phenol/cardanol-formaldehyde copolymer resin with polychloroprene rubber. J Adhes Sci Technol. 2004;18:1217–24.

Varghese LA, Thachil ET. Studies on the adhesive properties of neoprene-phenolic blends. J Adhes Sci Technol. 2004;18:181–93.

Lubi MC, Thachil ET. Cashew nut shell liquid—a versatile monomer for polymer synthesis. Des Monomers Polym. 2000;3:123–53.

Acknowledgements

One of the authors, Dr. Bimlesh Lochab, is grateful to Department of Science & Technology, Delhi, India for the Young Scientist award and providing funds to carry out the project. We are thankful to Mr. Satya Priye, Satya Cashew Chemicals Pvt. Ltd. (SCCPL®) for providing cardanol for research purposes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lochab, B., Varma, I.K. & Bijwe, J. Cardanol-based bisbenzoxazines. J Therm Anal Calorim 107, 661–668 (2012). https://doi.org/10.1007/s10973-011-1854-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1854-5