Abstract

Comparative studies on the Hailar lignite pyrolysis/gasification characteristics at N2/CO2 atmosphere and the influence of inherent mineral matters, external ash and pyrolysis temperature on its reactivity during gasification at CO2 atmosphere were conducted by non-isothermal thermogravimetric analysis, FTIR, and X-ray diffraction (XRD) analysis. Thermogravimetric test results show that the atmosphere of N2 or CO2 almost has no effects on the pyrolysis behavior, and the gasification reaction under CO2 atmosphere occurs over 943 K at the heating rate of 40 K min−1. The external ash prepared at 1173 and 1223 K shows a certain catalytic effect on promoting the gasification reaction, although the inherent mineral matters of Hailar lignite are found in stronger catalytic effects on gasification than the external ash. The lignite gasification reactivity decreases with increasing pyrolytic temperature between 1073 and 1273 K.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Coal occupies about 70% of the total primary energy consumption in China and it is estimated that it will be kept around 50% in 2050 [1, 2]. The amount of lignite resource is over 1,290 million tons and counts for 12.7% of the total coal reserves, and gasification can be regarded as a feasible thermochemical conversion technology to utilize lignite due to its high chemical activity and volatile matter. The gasification of lignite can be influenced by many factors, such as inherent mineral matters, particle size, heating rate, temperature, pressure, gasifying agents [3, 4]. Among the many gasification processes, the dual-bed gasification technology has been widely regarded as an advanced technology and was received considerable attentions. In the dual-bed gasification process, the circulating ash works as the solid heat carrier to supply part of the energy required for gasification reactions, and it is important that whether the ash influences the gasification behavior of the lignite.

Presently, the research on the effects of external ash on coal gasification is very few, and the discussions are mainly on the effects of inherent mineral materials. Skodras and Sakellaropoulos [5] and Samaras et al. [6] investigated the influence of mineral matters on the Greek lignite gasification by thermogravimetric analysis (TG) and fixed-bed reactor. They found that Ca, Na, K, and Mg elements have distinct catalytic effects on promoting gasification rate in CO2 atmospheres. Köpsel and Zabawski [7, 8] found that the inherent mineral matters had some catalytic effects on the demineralized coal gasification. Otto et al. [9] found that ash from reactive coals can significantly enhance the gasification rates of chars derived from less reactive coals, while the effects of ashes on raw coal gasification and especially the effects of ash-producing temperature on that were not discussed.

Thermogravimetric analysis is one of the most commonly used thermal analysis techniques to study the thermal chemical behavior of carbonaceous materials. There are two modes of TG for estimating the reactivity of coal: isothermal [10–15] and non-isothermal [16–21]. In this work, the Hailar lignite from Inner Mongolia of China is taken as the initial raw material, and its gasification characteristics is investigated by non-isothermal TG, FTIR, and X-ray diffraction (XRD) methods. The main objective of the study is to investigate the catalytic effects of inherent mineral matters and external ash of different ash-producing temperatures on the gasification of lignite in CO2 atmosphere, and the influences of pyrolysis temperature are also discussed.

Experimental

Preparation of coal samples

All the Hailar lignite samples were ground to less than 75 μm. The proximate and ultimate analysis and the ash constituent of the raw coal were listed in Table 1 and Table 2. The demineralized coal sample preparation procedures are like this: First, the raw coal samples were treated by mixed solution (the distilled water: 37%HCl : 40% HF = 50: 30: 20) at 333 K for 4 h to remove the inherent mineral matters; then the demineralized samples were washed with distilled water until no precipitation was detected by AgNO3 solution, and the PH value of the washed water approaches 7. Finally, the demineralized samples are dried at 378 K and then preserve in sampling bag.

Preparation of ash samples

Ash samples were prepared according to the GB/T 212-2008. Briefly, when the temperature of muffle furnace raised to 1123 K, the coal samples were put inside, then calcined at 1088 K for 40 min and the residues were denoted as Ash-1088. Then the Ash-1088 was recalcined in muffle furnace at 1173, 1223, and 1273 K for 50 min denoted as Ash-1173, Ash-1223 and Ash-1273, respectively.

Pure SiO2 particles were used here as a reference to determinate whether the Ash-1173, Ash-1223, and Ash-1273 samples showed the catalytic effects on Hailar lignite gasification reaction because it had been proved to be inert during gasification. The Hailar lignite was mixed with SiO2, Ash-1173, Ash-1223 and Ash-1273 samples at a mass ratio of 1:2 and the mixed samples were denoted as HS, HA-1173, HA-1223, and HA-1273.

Preparation of char samples

Char samples were prepared by the steps below: the coal samples of 6.0 g in the crucible with a cap were sent to muffle furnace for 50 min at 1073, 1173, and 1273 K, respectively. Then the char samples were taken out from the muffle furnace and cooled down to room temperature. The char samples were denoted as Char-1073, Char-1173, and Char-1273.

Thermogravimetric analysis

The non-isothermal thermogravimetric analyses were carried out with a Netzsch STA-449C thermogravimetric analyzer: a sample of about 5 mg was weighted and put into an open alumina crucible for each run. The samples were heated from ambient temperature to an end temperature of 1473 K at a fixed heating rate of 40 K min−1 at CO2 atmosphere for gasification and N2 atmosphere for pyrolysis. The flow rates of N2 and CO2 were set at 50 mL min−1.

FTIR characterization

Infrared spectra of both Hailar lignite and the demineralized Hailar lignite were obtained by FTIR spectrometer (Bruker EQUINOX 55). The coal samples and the dried KBr were ground at a ratio about 1:100. The spectra were obtained with 32 scans at a resolution of 4 cm−1.

XRD characterization

Ash-1173, Ash-1223 and Ash-1273 samples were characterized by XRD (X’ Pert MPD Pro, made by PANalytical B.V. Almelo, the Netherlands) using monochromatic Cu Ka radiation at 40 kV and 30 mA (λ = 1.5406 Å) to identify and quantify the phases insides the ashes. Scans were conducted at a scanning range from 5° to 60° 2θ with a scanning rate of 2°/min and a step size of 0.033°.

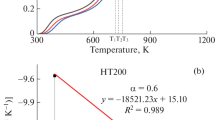

Thermogravimetry data processing

The thermogravimetry (TG, %) and differential thermogravimetry (DTG, %/min) data were obtained by the following Eqs. 1 and 2, respectively.

The conversion fraction (X) and reactivity (\( \frac{{{\text{d}}X}}{{{\text{d}}t}} \)) were defined by Eqs. 3 and 4:

where m t is the instantaneous sample weight at the time t, m 0 is the initial sample weight, m f is the weight of remaining ash after complete reaction.

Results and discussions

TG and DTG results of pyrolysis and gasification of Hailar lignite

TG and DTG results of pyrolysis and gasification of Hailar lignite are shown in Fig. 1. It can be seen that the gasification process in CO2 atmosphere can be separated into three stages. The first stage is the drying stage (<513 K) and the TG curve shows a slightly downward trend, and there is a small peak in the DTG curve. The basic decomposition products are water and the adsorbed gases, such as CO, CO2, and CH4. The second stage is the pyrolysis stage (513~943 K). The DTG curve has a peak value at 733 K, and the corresponding weight loss is about 31.58%. The decomposition products in this stage are complex, mainly consists of the gaseous hydrocarbon and tar, besides the CO, CO2 and CH4. The third stage (943~1473 K) is mainly the char gasification step, and the main products are CO and CO2. The total weight loss of coal samples in CO2 atmosphere is 87.35% at the end temperature of 1473 K, higher than 38.85% in N2 atmosphere, due to the gasification of char in CO2. The TG as well as the DTG curve almost has the same tendency in the weight loss both in N2 atmosphere and in CO2 atmosphere from the initial temperature to 943 K, and the weight losses are quite similar (31.73% and 31.85, respectively). Thus, the experimental results indicate that atmosphere has little effects on the pyrolytic behaviors of Hailar lignite. The major differences between the two DTG curves are marked as 1 and 2 in Fig. 1. There is a weak peak of DTG curve in N2 atmosphere at about 1033 K, while the major peak in CO2 atmosphere appears at about 1163 K. The peak 1 may be attributed to the decomposition of the mineral matters of calcite as mentioned in reference [22, 23] that calcite will decompose and release CO2 at about 1033 K. The peak at 1163 K in DTG curve for CO2 atmosphere can be attributed to the gasification of the nascent char. The decomposition of calcite may also be partly attributed to this peak, since the decomposition temperature of calcium carbonate in pure CO2 is about 1173 K.

The effects of inherent mineral matters on lignite gasification

Figure 2 shows the differences of the FTIR spectra between the Hailar raw coal and the demineralized coal samples. In Fig. 2a, the absorption bands near 1450–1410, 880–860, and 720–680 cm−1 in the spectra of the raw coal can be identified as carbonates [24–26]. Considering the metal elements of ash sample in Table 2, the alkaline, alkaline-earth compounds and transition-metal compounds, such as Na2CO3, CaCO3, FeCO3 may exist in the Hailar lignite because of the high concentration of carbonates. The absorption bands of silicate minerals near 1100–800 and 600–400 cm−1 and those of kaolinite near 3700–3600 cm−1 [27–29] can also be identified in the spectra of raw coal. On the contrary, the absorption bands of silicates, kaolinite and carbonate have almost disappeared at all after the demineralization as shown in Fig. 2b. To be mentioned, the peak around 2358 cm−1 is the adsorbed CO2 in raw coal, and the adsorbed CO2 is removed after the demineralization.

The conversion fraction (X) as well as reactivity (\( \frac{{{\text{d}}X}}{{{\text{d}}t}} \)) of the Hailar lignite and the demineralized samples are shown in Fig. 3. The results show that the reactivity (\( \frac{{{\text{d}}X}}{{{\text{d}}t}} \)) of the demineralized sample is similar to that of the lignite less than 973 K. For the case higher than 973 K, the gasification of the raw coal sample terminated at about 1263 K, 60 K prior to that of the demineralized sample, and the temperature corresponding to the maximum conversion fraction (X) temperature of the raw coal sample is 1163 K, lower than that of the demineralized one (1281 K). This indicates that the raw sample perform a higher reactivity (\( \frac{{{\text{d}}X}}{{{\text{d}}t}} \)) than that of the demineralized sample. It also indicates that the inherent mineral matters of Hailar lignite have strong catalytic effects on gasification process.

The effects of external ash on lignite gasification

Figure 4 shows the effects of Ash-1173, Ash-1223, and Ash-1273 samples on the gasification of Hailar lignite and the effects of SiO2 as inert matter is also illustrated for comparison. It can be seen that the maximum value of \( \frac{{{\text{d}}X}}{{{\text{d}}t}} \) is −16.19%/min for HS sample appeared at 1137 K, and the maximum value for HA-1173, HA-1223 and HA-1273 samples are −18.44, −19.68, and −18.37%/min at the temperatures of 1122, 1125, and 1137 K, respectively. The temperature corresponding to the maximum conversion rate of HA-1173 and HA-1223 samples is obviously lower than that of HS sample ranged from 1073 K to the end temperature, while the sample of HA-1273 almost has no difference to that of HS. The result indicates that Ash-1173 and Ash-1223 can promote the gasification conversion of raw coal, while Ash-1273 almost has no catalytic effect on lignite gasification.

To explain the different catalytic effects among the different external ash samples, FTIR analysis was conducted as shown in Fig. 5. It can be seen that the peak of 520 cm−1 [30], representation of Fe–O vibration in the sample is distinctly weaker for Ash-1273 than the peaks for the other two samples treated under lower temperatures of 1173 and 1223 K. The Fe–O vibration belongs to Fe2O3, which has been confirmed by XRD analysis. As proved by other researches that Fe2O3 has certain catalytic effects by oxygen transfer mechanism on coal gasification reaction [31–35], and thus the decrease of the content of Fe2O3 in the sample of Ash-1273 makes the catalytic effect on gasification decrease.

To further explain the catalytic effects of the ashes, XRD analysis was conducted as shown in Fig. 6. It shows that the element Ca in the ash sample of Ash-1273 has been partly transformed to calcium sulfate and silicates and thus lost much catalytic activity. Additionally, the figure shows that the minerals such as augite, aluminian and akermanite–gehlenite with lower catalytic activity on gasification exist by the peak around 2θ = 30° in the XRD patterns of these ash samples. The peak intensity around 2θ = 30° for Ash-1273 becomes stronger than those for Ash-1173 and Ash-1223, which indicates that more Fe2O3 is transformed into the minerals above at higher temperature. So the Ash-1173 and Ash-1223 show more catalytic effects on the gasification than Ash-1273.

The effects of pyrolysis temperature on lignite gasification

A gasification process involves an initial pyrolysis stage and a subsequent char gasification stage. The conditions in the pyrolysis stage can influence the char yield and the char gasification reactivity. The curves of conversion fraction (X) and reactivity (\( \frac{{{\text{d}}X}}{{{\text{d}}t}} \)) versus temperature for Char-1073, Char-1173, and Char-1273 are shown in Fig. 7. Herein, the two values of \( T_{X = 0.5} \) and \( T_{{\left( {\frac{{{\text{d}}X}}{{{\text{d}}t}}} \right)_{\max } }} \) representing the temperature when the mass loss is 50% and the temperature when the mass loss rate reaches the maximum value, are used as indicative temperatures to estimate the reactivity of char [36, 37]. As shown in Table 3, the both values of \( T_{X = 0.5} \) and \( T_{{\left( \frac{dX}{dt} \right)_{\max } }} \) increase with the increasing pyrolysis temperature in the coal pyrolysis process for char-producing. Figure 7 shows that the char-producing temperature in the range from 1073 to 1173 K has slightly influence on the char gasification reactivity, while the char-1000 sample obtained under 1273 K shows a rather low gasification reactivity compared to the other two char samples.

Conclusions

-

(1)

The Hailar lignite gasification process in CO2 atmosphere by the TG analysis can be divided into three stages: drying, pyrolysis and char gasification. The gasification reaction starts at the temperature higher than 943 K at the test conditions.

-

(2)

The external ash prepared at 1173 and 1223 K shows a certain catalytic effect on promoting the gasification reaction, although the inherent mineral matters of Hailar lignite are found in stronger catalytic effects on gasification than the external ash. The external ash obtained at 1273 K almost has no catalytic effects on lignite gasification.

-

(3)

The char obtained under different pyrolysis temperature has different indicative temperatures during gasification. The char prepared in lower temperature from 1073 to 1173 K has a higher gasification reactivity than that in higher temperature of 1273 K.

References

Chen WY, Xu RN. Clean coal technology development in China. Energy Policy. 2008;38:2123–30.

Zhou P. Chinese coal properties, classification and utilization. 1st ed. Beijing: Chemical Industry Press; 2001.

Kabe T, Ishihara A, Qian EW, Sutrisna IP, Kabe Y. Coal and coal-related compounds: structures, reactivity and catalytic reactions. Amsterdam: Elsevier Besloten Vennootschap; 2004.

Ling DQ, Xie KC. Kinetics of coal gasification and role of minerals. 1st ed. Taiyuan: Shanxi Education Science Press; 1990.

Skodras G, Sakellaropoulos GP. Mineral matter effects in lignite gasification. Fuel Process Technol. 2002;77–78:151–8.

Samaras P, Diamadopoulos E, Sakellaropoulos GP. The effect of mineral matter and pyrolysis conditions on the gasification of Greek lignite by carbon dioxide. Fuel. 1996;75:1108–14.

Köpsel R, Zabawski H. Catalytic effects of ash components in low rank coal gasification: 1. Gasification with carbon dioxide. Fuel. 1990;69:275–81.

Köpsel R, Zabawski H. Catalytic effects of ash components in low rank coal gasification: 2. Gasification with steam. Fuel. 1990;69:282–8.

Otto K, Bartosiewicz L, Shelef M. Catalysis of carbon-steam gasification by ash components from two lignites. Fuel. 1979;58:85–91.

Yücel H, Çakal GÖ, Gürüz AG. Physical and chemical properties of selected Turkish lignites and their pyrolysis and gasification rates determined by thermogravimetric analysis. J Anal Appl Pyrol. 2007;80:262–8.

Zhang LX, Huang JJ, Fang YT, Wang Y. Gasification reactivity and kinetics of typical Chinese anthracite chars with steam and CO2. Energy Fuel. 2006;20:1201–9.

Ochoa J, Cassanello MC, Bonelli PR, Cukierman AL. CO2 gasification of Argentinean coal chars: a kinetic characterization. Fuel Process Technol. 2001;74:161–76.

Sun QL, Li W, Chen HK, Li BQ. The CO2-gasification and kinetics of Shenmu maceral chars with and without catalyst. Fuel. 2004;83:1787–93.

Jenkins RG, Nandi SP, Walker PL. Reactivity of heat-treated coals in air at 500°C. Fuel. 1973;52:288–93.

Cai HY, Guell AJ, Chatzakis IN. Combustion reactivity and morphological change in coal chars: effect of pyrolysis temperature, heating rate and pressure. Fuel. 1996;75:15–24.

Brown RC, Liu Q, Norton G. Catalytic effects observed during the co-gasification of coal and switchgrass. Biomass Bioenerg. 2000;18:499–506.

Gong XZ, Guo ZC, Wang Z. Reactivity of pulverized coals during combustion catalyzed by CeO2 and Fe2O3. Combust Flame. 2009;157:351–6.

Cai JM, Bi LS. Kinetic analysis of wheat straw pyrolysis using isoconversional methods. J Therm Anal Calorim. 2009;98:325–30.

Dumanli AU, Taş S, Yürüm Y. Co-firing of biomass with coals. Part 1. Thermogravimetric kinetic analysis of combustion of fir (Abies bornmulleriana) wood. J Therm Anal Calorim. 2011;103:925–33.

Aboulkas A, El Harfi K, El Bouadili A, Nadifiyine M. Study on the pyrolysis of Moroccan oil shale with poly (ethylene terephthalate). J Therm Anal Calorim. 2010;100:323–30.

Niu SL, Lu CM, Han KH, Zhao JL. Thermogravimetric analysis of combustion characteristics and kinetic parameters of pulverized coals in oxy-fuel atmosphere. J Therm Anal Calorim. 2009;98:267–74.

Charland JP, MacPhee JA, Giroux L, Price JT, Khan MA. Application of TG-FTIR to the determination of oxygen content of coals. Fuel Process Technol. 2003;81:211–21.

Hughes RW, Lu D, Anthony EJ, Wu Y. Improved long-term conversion of limestone-derived sorbents for in situ capture of CO2 in a fluidized bed combustor. Ind Eng Chem Res. 2004;43:5529–39.

Öztaş NA, Yürüm Y. Pyrolysis of Turkish Zonguldak bituminous coal. Part 1. Effect of mineral matter. Fuel. 2000;79:1221–7.

Bellamy LJ. The infrared spectra of complex molecules. 2nd ed. London: Chapman and Hall; 1975.

Painter PC, Rimmer SM, Snyder RW, Davis A. A Fourier transform infrared study of mineral matter in coal: the application of a least squares curve-fitting program. Appl Spectrosc. 1981;35:102–6.

Nyquist RA, Kagel RO. Infrared spectra of inorganic compounds. New York: Academic Press; 1971.

Painter PC, Snyder RW, Youtcheff J, Given PH, Gong H, Suhr N. Analysis of kaolinite in coal by infrared spectroscopy. Fuel. 1980;59:364–6.

Finkelman RB, Fiene FL, Painter PC. Determination of kaolinite in coal by infrared spectroscopy-a comment. Fuel. 1981;69:643–4.

Bai J, Li W, Li CZ, Bai ZQ, Li BQ. Influences of minerals transformation on the reactivity of high temperature char gasification. Fuel Process Technol. 2010;91:404–9.

Zhu XY, Song B, Kim D, Kang SK, Lee S, Jeon S, Choi Y, Byoun Y, Moon W, Lee J, Kim H, Lee H, Shim J. Kinetic study on catalytic gasification of a modified sludge fuel. Particuology. 2008;6:258–64.

Asami K, Sears P, Furimsky E, Ohtsuka Y. Gasification of brown coal and char with carbon dioxide in the presence of finely dispersed iron catalysts. Fuel Process Technol. 1996;47:139–51.

Ohme H, Suzuki T. Mechanisms of CO2 gasification of carbon catalyzed with Group VIII metals. 1. Iron-catalyzed CO2 gasification. Energy Fuel. 1996;10:980–7.

Suzuki T, Inoue K, Watanabe Y. Temperature-programmed desorption and carbon dioxide-pulsed gasification of sodium- or iron-loaded Yallourn coal char. Energy Fuel. 1988;5:653–79.

Furimsky E, Sears P. Iron-catalyzed gasification of char in CO2. Energy Fuel. 1988;2:634–9.

Huang YQ, Yin XL, Wu CZ, Wang CW, Xie JJ, Zhou ZQ, Ma LL, Li HB. Effects of metal catalysts on CO2 gasification reactivity of biomass char. Biotechnol Adv. 2009;27:568–72.

Zhou JH, Kuang JP, Zhou ZJ, Lin M, Liu JZ. Research on alkali-catalysed CO2-gasification of coal black liquor slurry char and coal water slurry char. Proceedings of the CSEE. 2006;26:149–55.

Acknowledgements

Financial support from the Project of Knowledge Innovation Program of the Chinese Academy of Sciences (Grant No. KGCX2-YW-396) and National Natural Science Foundation of China (Grant No. 20221603).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou, A., Wang, Z., Song, W. et al. Thermogravimetric analysis on gasification reactivity of Hailar lignite. J Therm Anal Calorim 109, 337–343 (2012). https://doi.org/10.1007/s10973-011-1712-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1712-5