Abstract

Intercalation of a kaolinite-containing halloysite from Biela Hora (Slovakia) with urea was investigated by simultaneous TG–DTA, XRD, FTIR (DRIFT), and Raman spectroscopy. The process of intercalation and thermal deintercalation was followed for the as-prepared and the washed (with isopropanol) samples. The proposed structural model was supported by molecular mechanical calculations. Incorporation of the intercalate (in 5 wt%) in molten polypropylene at 200 °C resulted in the complete delamination of the mineral. It is supposed that gas formation as a result of urea decomposition between the layers prevents reorientation and restructuring of the layers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Kaolinite and its polytype, halloysite, are among the most abundant clay minerals worldwide [1]. In addition to their common use as additives or fillers, these minerals can be considered as possible precursors of obtaining polymer nanocomposites with potential industrial application due to their better thermal, physical, and mechanical properties [2, 3]. The uniform dispersion of the inorganic nanoparticles (e.g., delaminated kaolinite or halloysite nanotubes) in the polymer matrix is a critical factor of ensuring the desired properties of the composites. Another problem is the use of suitable compatibilizing agents to provide interfacial bonding between the additive and the matrix. This is especially difficult with polymers of low polarity, such as polypropylene (PP) [4].

Halloysite (and kaolinite) is a 1:1 layered aluminosilicate consisting of double layers joined together through apical oxygen atoms. One side of the double layer is gibbsite-like with aluminum atoms octahedrally coordinated with four oxygen atoms and two hydroxyl groups. The other side is a two-dimensional silicate layer structure, where silicon atoms are tetrahedrally coordinated with four oxygen atoms. The double layers are connected as sheets to other double layers via hydrogen bonds. Halloysite occurs in two main polymorphs: the hydrated form (with basal distance of about 10 Å) and the dehydrated form (with basal distance of about 7 Å), being identical to kaolinite. The hydrated form converts irreversibly into the dehydrated form upon mild heating [5]. During intercalation, reactive guest molecules enter the interlamellar space and break up the hydrogen bonds resulting in a nanolayered mineral [6].

Although halloysite can be intercalated almost completely with dimethyl sulphoxide or hydrazine, in the light of potential industrial applications these hazardous compounds should be avoided. Expansion of the layers with urea—a more friendly reagent—can be made either in solution [7, 8] or via mechanochemical means [9–11].

In this study, a kaolinite-containing halloysite from Biela Hora (Slovakia) was intercalated in solution with urea. The structure of the nanocomplex formed was investigated with simultaneous TG–DTA, FTIR (DRIFT) spectroscopy, Raman microscopy, and X-ray diffraction (XRD). The complex was incorporated in PP matrix to produce an organoclay–polymer composite.

Experimental

Sample preparation

The chemical composition of the halloysite used in wt.% is: SiO2, 45.48; Al2O3, 33.74; Fe2O3, 1.27; CaO, 0.39; MgO, 0.1; K2O, 0.02; Na2O, 0.02; TiO2, 0.05; loss on ignition, 17.36. The clay contains about 96 wt.% halloysite/kaolinite and about 7 wt.% quartz.

Intercalation was carried out by mixing 2 g of the clay with 100 cm3 10 M urea (Merck p.a.) solution in a closed vessel at room temperature for 80 h. The excess solution was removed by centrifugation, and the complex was kept in a desiccator before analysis.

A 1 g portion of the complex was washed five times with isopropyl alcohol (using 10 cm3 alcohol each time) in a vacuum filter and kept also in the desiccator.

The organoclay–polymer composite was made by mixing the complex (at a ratio of 5 wt.%) into PP in a Brabender W50E chamber with cam blades at 200 °C and at a rotor speed of 100 r.p.m.

X-ray diffraction

The X-ray diffraction analyses were carried out on a Philips PW 3710 type diffractometer equipped with a PW 3020 vertical goniometer and curved graphite diffracted beam monochromator. The radiation applied was CuKα from a broad-focus Cu tube, operating at 50 kV and 40 mA. The samples were measured in continuous scan mode with 0.02° s−1 scanning speed. Data collection and evaluation were performed with PC-APD 3.6 software. The back-packed mounts of finely powdered samples were used to eliminate preferential orientation.

Thermal analysis

Thermal analyses were carried out in a Derivatograph PC type equipment (Hungarian Optical Works) in static air atmosphere at a heating rate of 5 °C min−1. Samples were heated in a ceramic crucible up to 1000 °C.

FTIR analyses

Fourier transform infrared spectroscopic investigations were carried out in a Bruker Equinox 55 type FTIR spectrometer using a Harrick diffuse reflectance (DRIFT) cell (2 mg sample was mixed with 100 mg KBr in an agate mortar and placed into the sample holder). 512 spectra were recorded (and averaged) at a resolution of 2 cm−1 using a room temperature DTGS detector.

Raman microscopy

Raman spectra were recorded at a resolution of 3 cm−1 in a Bruker Senterra spectrometer using a He–Ne laser (633 nm, 20 mW) and a liquid nitrogen-cooled CCD detector. 64 spectra (obtained from an area of 3 μm in diameter) were averaged to improve the signal to noise ratio. Band fitting was done using the Jandel Scientific Peakfit version 4.0 (AISN Inc.) program. The Lorentz–Gauss ratio was greater than 0.7, and fitting was undertaken until reproducible results were obtained with correlations for R 2 greater than 0.998.

Molecular mechanical modeling

Geometric optimization of urea in the complex was made by molecular mechanical means using the Spartan’02 Windows (Wavefunction Inc, USA) program.

Results and discussion

The XRD patterns of the original and the urea-treated halloysite are shown in Fig. 1. The original clay displays a 001 reflection at 7.2 Å (curve a). In the complex, a new diffraction peak appears at 10.8 Å, indicating 93% expansion/intercalation (curve b). Washing the complex with isopropanol, a significant reduction of the urea band can be seen (curve c) with practically the same intercalation ratio (92%). This means that removal of excess urea from the particle surfaces has no effect on the rate of layer expansion.

The TG–DTG–DTA curves of the halloysite studied can be seen in Fig. 2. Adsorbed water (10.30%) is lost up to 220 °C. Dehydroxylation takes place between 400 and 700 °C with maximum rate at 524 °C. The amount of dehydroxylation water is 15.07% (on a dry basis).

The thermal behavior of the complex can be seen in Fig. 3. The adsorbed water (6.91%) is lost up to 127 °C. Decomposition of urea takes place in four steps up to 408 °C. The endothermic peak in the DTA curve at 135 °C belongs to the melting of surface-adsorbed reagent. The total amount of urea on a dry basis is 52.33%. Dehydroxylation of the clay takes place after the complete removal of urea (following the collapse of the expanded layers to the original d value of 7.2 Å). The amount of dehydroxylation water is 14.51%, which is very close to that of the pure mineral (15.07%). This means that intercalation and thermal deintercalation of urea has no effect on the reversible expansion of halloysite, although the regained structure is more disordered as shown by XRD.

The thermal behavior of the washed complex can be studied in Fig. 4. The water content (lost up to 128 °C) is reduced from 6.91 to 4.54%. The disappearance of the endothermic peak in the DTA curve at 135 °C indicates the efficiency of removing adsorbed urea by washing with isopropanol. The amount of urea on a dry basis is only 26.72%, which indicates that almost half (48.90%) of the reagent was removed by washing. It means that not only the adsorbed, but also part of the complexed reagent was removed, as well. The removal of urea from the washed complex upon heating is significantly different showing two decomposition stages at 206 and 276 °C, only. The disappearance of the mass loss step at 321 and 370 °C is surprising, since in principle the loosely bonded (adsorbed) urea should be more easily removed than the intercalated (hydrogen bonded) portion. This anomaly may be due to the complicated process of urea decomposition (through the formation of biuret). In addition, the decomposition of isolated molecules in the complex may follow a different pattern. As to the removal of hydroxyl groups, no significant difference can be observed in the washed complex (the amount of dehydroxylated water is 13.82%, which is close to that of the pure mineral).

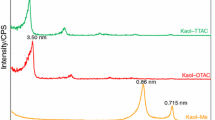

The infrared and Raman spectra of the samples in the OH stretching range are given in Figs. 5 and 6. Band assignment was made based on the characteristic group frequencies available in the literature [12]. In the infrared, the three inner surface OH bands (ν1–ν3) are found at 3696, 3670, and 3649 cm−1 in the resolved spectrum, while the band belonging to the inner OH groups (ν5) appears at 3621 cm−1. The ν2 and ν3 bands cannot be resolved in the Raman spectrum, which is typical of halloysite minerals. In addition, the ν4 band at 3685 cm−1 is also missing. Interestingly, the inner OH band is very broad (and can be resolved into two bands at 3629 and 3624 cm−1 in the Raman spectrum) indicating a disturbance of the inner OH groups. As a result of intercalation, the intensity of the inner surface OH bands decrease significantly, indicating the connection of urea molecules to the layers. The relative increase of the ν1–ν3 bands after washing the complex with urea is a proof that not only the adsorbed urea, but also a certain part of intercalated urea is removed, as well. The OH bands at 3592 cm−1 indicate the presence of water molecules in the complex (Table 1).

As to the OH deformation range, the inner OH groups show a broad band at 910–915 cm−1 in the DRIFT spectrum (Fig. 7). The position of the inner surface OH bands at 938 cm−1 is not changed in the complex, but a new band appears at 900 cm−1. After washing, the intensity of this band increases at the expense of the inner OH band. The appearance of the 900 cm−1 band is an indication of hydrogen-bond formation between the inner surface OH groups and urea. The increase in intensity of this band as a result of washing is surprising and is the subject of further studies.

As to the structure of the intercalation complex, the urea bands in the DRIFT spectrum are of utmost importance (Fig. 8). The shift of the amide I band (at 1628 cm−1 in pure urea) to 1615 cm−1 is an indication that the –NH2 groups form hydrogen bonds with the inner surface OH groups. Since the conjugation between the C=O and the –NH2 groups no longer exists, the C=O group also interacts with the layers (the C=O stretching band shifts from 1684 to 1673 cm−1). This is in harmony with the model proposed for kaolinite–urea complexes [10].

The orientation of urea in the interlayer space was investigated by molecular mechanical calculations based on the commonly used TO layer model available in the literature [11]. The optimal geometry for a single urea molecule in the interlayer space is shown in Fig. 9a with the indication of the atomic distances. This model is in harmony with the supposition that the conjugation of the amide groups ceases and both –NH2 groups are connected to the layers. Surprisingly, the model shows that the –NH2 groups are oriented to the octahedral, while the C=O groups to the tetrahedral sheets. However, urea molecules in the interlayer space are connected to each other as well, which can significantly modify the geometry proposed by the model for isolated reagent molecules. If a group of five urea molecules are taken into account in the model, then hydrogen-bond formation is possible between the reagent molecules and the layers and between adjacent reagent molecules, as well (Fig. 9b). While the atomic distances are in the order of 2.8 Å, the lengths of the hydrogen bonds are in the 1.8–3.0 Å range. The –NH2 groups can basically connect to the C=O group of an adjacent urea molecule, to the oxygen sheet of the siloxane layer, and to the octahedral oxygen atoms (as confirmed by the bands at 1615 and 1592 cm−1 in the DRIFT spectrum). When the C=O group is connected either to the octahedral sheet or to an adjacent urea molecule, its stretching band appears at 1674 cm−1. If the C=O group is oriented toward the siloxane layer, its stretching band shifts to 1684 cm−1 as a result of disconjugation. Considering the distance between the carbonyl oxygen and the hydrogen atom of the inner OH group (O3–H7), it is likely that the carbonyl group has an orientation/polarization effect on the inner OH group. This could explain the broadening of the inner OH bands in both the DRIFT and the Raman spectra. The O2–H3 and the O2–H6 distances support the existence of intermolecular interactions, while the O1–H2 distances support the connection of the C=O groups to the octahedral layer.

Figure 10 shows the optical microscopic image of the original mineral and that of the urea-intercalated halloysite embedded in PP matrix at a solid loading of 5 wt.%. The untreated mineral shows uneven distribution and large-size agglomerates in the polymer. When the intercalate is mixed in the molten polymer at 200 °C, a drastic reduction in the particle size can be observed. It means that halloysite is present in delaminated form in the polymer. It can be supposed that gas formation as a result of decomposition of urea between the layers prevents the rearrangement of the expanded layers. The appearance of gas bubbles in the composite can also support this supposition.

Conclusions

The combination of thermal analysis and advanced spectroscopic techniques is essential to follow the complicated process of clay mineral intercalation and delamination. Structure elucidation can be supported by molecular mechanical modeling thereby increasing the reliability of the model proposed by vibrational spectroscopic analyses. The use of urea—a convenient delamination agent—is very promising in the light of producing organoclay–polymer nanocomposites of improved chemical and mechanical properties.

References

Churchman GJ. The alteration and formation of soil minerals by weathering. In: Sumner ME, editor. Handbook of soil minerals. Boca Raton: CRC Press; 2000.

Pinnavaia TG, Beall GW, editors. Polymer-clay nanocomposites. New York: Wiley; 2000.

Elbokl TA, Detellier C. Aluminosilicate nanohybrid materials. Intercalation of polystyrene in kaolinite. J Phys Chem Solids. 2006;67:950–5.

Liu M, Guo B, Lei Y, Du M, Jia D. Benzothiazole sulfide compatibilized polypropylene/halloysite nanotubes composites. Appl Surf Sci. 2009;255:4961–9.

Joussein E, Petit S, Churchman J, Theng B, Righi D, Delvaux B. Halloysite clay minerals—a review. Clay Miner. 2005;40:383–426.

Lagaly G. Clay organic interactions. Phil Trans R Soc London. 1984;A311:315–32.

Weiss A, Thielepape, W, Orth H. Intercalation into kaolinite minerals. In: Proceedings of the international clay conference. Jerusalem: Israel University Press; 1966. p. 277.

Kristóf J, Frost RL, Horváth E, Kocsis L, Inczédy J. Thermoanalytical investigations on intercalated kaolinites. J Therm Anal Calorim. 1998;53:467–75.

Gardolinski JE, Wypych F, Cantao MP. Exfoliation and hydration of kaolinite after intercalation with urea. Quim Nova. 2001;24:761–7.

Makó É, Kristóf J, Horváth E, Vágvölgyi V. Kaolinite–urea complexes obtained by mechanochemical and aqueous suspension techniques—a comparative study. J Colloid Interface Sci. 2009;330:367–73.

Nicolini KP, Fukamachi CRB, Wypych F, Mangrich AS. Dehydrated halloysite intercalated mechanochemically with urea: thermal behavior and structural aspects. J Colloid Interface Sci. 2009;338:474–9.

Socrates G. Infrared and Raman characteristic group frequencies, tables and charts. 3rd ed. Chichester: Wiley; 2001.

Acknowledgements

This study was supported by the Hungarian Ministry of Culture and Education under Grant No. TÁMOP-4.2.2-08/1/2008-0018. The financial and infrastructural support of the State of Hungary and the European Union in the frame of the TÁMOP-4.2.1/B-09/1/KONV-2010-0003 project is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horváth, E., Kristóf, J., Kurdi, R. et al. Study of urea intercalation into halloysite by thermoanalytical and spectroscopic techniques. J Therm Anal Calorim 105, 53–59 (2011). https://doi.org/10.1007/s10973-011-1522-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1522-9