Abstract

The thermal behavior of the anticancer drug-irinotecan was measured by Thermogravimetry–Differential thermal analysis (TG–DTA) to explore the application of TG–DTA in nanomedicine firstly. The TG–DTA result showed that the irinotecan was oxidized completely before 700 °C. When irinotecan was loaded onto nanosized mesoporous silica spheres, the loading capacity for irinotecan measured by TG–DTA was about 9.11% in the irinotecan/mesoporous SiO2 composite, similar to the typical UV–Vis spectra results (10.5%), which showed that TG–DTA characterization provided an alternative method to determine the drug loading amount on inorganic carriers. Secondly, Thermogravimetry–Differential scanning calorimetry–Mass Spectrometry coupling techniques (TG–DSC–MS) were used to characterize the hydrogen adsorption temperature and capacity of TiCr1.2 (V-Fe)0.6 alloy. The MS result showed that the released region of hydrogen was 250–500 °C, which was consistent with the TG–DSC results. Lastly, TA–MS combined with pulse thermal analysis (PulseTA) were used for a simultaneous characterizing study in the changes of mass, determination and quantitative calibration of the evolved nitrogen formed during the thermal decomposition of the InN powder. The results showed that relative error of this method between measured value and theoretical value was 2.67% for the quantitative calibration of evolved N2. It shows that TA–MS combined with PulseTA techniques offer a good tool for the quantification of the evolved nitrogen in the InN powder.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thermal analysis (TA) is a technology with a history of more than 100 years. It has been used to measure the physical and chemical transformation of samples as a function of temperature in the scanning mode or as a function of time in the isothermal mode [1–4]. TG–DTA/DSC is the quick and convenient techniques and has been widely used to characterize the changes of mass and enthalpy of materials during the thermal decomposition process. These techniques played an important role on the preparation of materials and the later treatment. However, with the appearance in the new and complex organic–inorganic materials, the single TA technique cannot fulfill their characterization. It is necessary to study the thermal behavior of materials by various simultaneous methods, such as TA–MS coupling techniques [5–13], and to provide more scientific information for the preparation of materials.

In this article, firstly TG–DTA was used to determine the thermal behaviors for the irinotecan and the irinotecan/SiO2 composite. Nanomedical research shows great potential in the therapy of serious disease such as cancer, in which drug delivery systems (DDSs) have been explored widely. Mesoporous silica spheres have been adopted as DDSs because of their high surface area, high pore volume, ordered pore structures, and the excellent biocompatibility [14–18]. The typical characterization method of drug loading amount in mesoporous silica spheres is the spectra characterization. The inevitable error has been introduced because of the multistep operation. It is urgent to develop other methods to substitute spectra characterization. Thermal analysis provides an alternative method to decide the exact drug loading amount in DDSs, especially in inorganic nanocarriers, because most drugs are organic molecules, which could be burned out under the elevated temperature. Herein, the authors chose a typical anticancer drug-irinotecan as the model drug, and nanosized mesoporous silica spheres as the drug carrier to demonstrate the applications of TG–DTA in nanomedicine, and compared the thermal data with spectra data to determine the accuracy of thermal characterization. It is the first report, as far as the authors know, to carry out the research in possible applications of thermal characterization in nanomedicine. Secondly, TG–DSC–MS coupling techniques were used to examine the hydrogen adsorption temperature and capacity of TiCr1.2 (V-Fe)0.6 alloy. Lastly, pulse thermal analysis (PulseTA) combined with TA–MS were used for a simultaneous characterizing study in the changes of mass, determination, and quantitative calibration of the evolved gases formed during the thermal decomposition of InN powder.

Experimental

TG–DTA/DSC–MS measurements

The Netzsch STA 449C TG–DTA/DSC thermoanalyzer coupled with Balzers Thermostar Quadrupole Mass Spectrometer was used in the experiments. The quartz capillary was used as the interface between thermoanalyzer and the quadrupole MS. The vacuum in the quadrupole MS was 10−4 Pa. The multiple ion detector (MID) mode was used for the MS measurements.

PulseTA measurements

PulseTA device was produced by the Netzsch Company in Germany. The PulseTA enables the quantification of the mass spectrometric signals of the evolved gases in the TA–MS system [19–22]. Introducing into the TA–MS system a known amount of the calibration gas and determining the relationship between the amount of the injected gas and the observed integral signal, it is possible later to quantify the MS signals resulting from evolution of the unknown amount of evolved gases during the decomposition. Specified amounts of calibration gas can be introduced into the mass spectrometer by two principal methods:

(i) by decomposing solids via a well known, stoichiometric reaction

(ii) by injection of known amounts of calibration gas into the carrier gas stream flowing with constant rate through the system

Method (ii) was used to the experiments of this article.

Results and discussion

Application of TG–DTA for characterization of anticancer drug

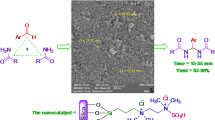

The TEM results of mesoporous silica spheres

Nanosized mesoporous silica spheres (mSiO2) were prepared using cetyltrimethylammonium bromide (C16TAB) as surfactant and tetraethoxysilane (TEOS) as the silica source according to previous report [23]. The highly dispersed mSiO2 with ordered pore structures were firstly prepared as DDSs to encapsulate and delivery anticancer drugs (irinotecan), using C16TAB as structural directing agent. After the irinotecan was encapsulated, the drug loading amount was determined by TG–DTA characterization and UV–Vis characterization, respectively. The morphology and dispersity of mSiO2 could be clearly observed in TEM images (Fig. 1). The mSiO2 exhibits a near-spherical morphology and the pore structures show ordered 2D hexagonal array. The sizes of mSiO2 are between 60 and 120 nm, which is suitable for intravenous injection.

The TG–DTA results of irinotecan

Before studying the loading amount of the irinotecan in the irinotecan/mSiO2 composite, the authors investigated the thermal behavior of pure irinotecan. The results are depicted in Fig. 2. The TG results showed that the mass change was −99.97% at 50–700 °C. There was no mass losses appeared above 700 °C. The DTA curve showed an endothermic peak at 92.1 °C, three exothermic peaks at 279, 351, and 529.7 °C, respectively. It showed that the irinotecan was oxidized completely before 700 °C.

The TG–DTA results of mSiO2 and irinotecan/mSiO2 composite

Figure 3 was TG–DTA curves of mSiO2 and irinotecan/mSiO2 composite. The results showed that the TG curve of mSiO2 had two mass losses: 17.73% (30–200 °C), 4.54% (200–1000 °C). The TG curve of irinotecan/mSiO2 had two mass losses: 14.57% (30–200 °C), 13.65% (200–1000 °C). It can be inferred that the mass losses at 30–200 °C was the vaporization and adsorbed water on the surface of the mSiO2 and irinotecan/mSiO2. Through the comparison, the loading capacity for the irinotecan in the composite was about 9.11% at 200–1000 °C. Both the mSiO2 and irinotecan/mSiO2, the DSC curves appeared an endothermic peak at 92.1 °C. It was worth to point out that the DSC curve of the mSiO2 tends to level and there was no obvious enthalpy at about 200–1000 °C, but the DSC curve of the irinotecan/mSiO2 had two exothermic peaks at 291.2 and 366 °C. It can be concluded that the irinotecan in the irinotecan/mSiO2 was oxidized at 200–1000 °C.

Figure 4 showed the UV–Vis spectra of irinotecan before and after interaction with mesoporous silica spheres. According to the UV–Vis calculation similar to the previous report [24], the irinotecan loading amount was about 10.5%, close to the TG results. It is known the spectra usually exists the error because of the multistep operation, while TG results directly show the exact drug loading amount on the support. Based on above analysis, it was believe that TG–DTA provides an alternative method to achieve the exact drug loading mount on nanocarriers, which is of great significance for further clinical usage of nanocarriers.

Application of TG–DSC–MS for characterization of the TiCr1.2 (V-Fe)0.6 Alloy

In order to determine the condition under which hydrogen could be fully released, TG–DSC–MS coupling techniques were used for characterization the hydrogen adsorption temperature and capacity of TiCr1.2 (V-Fe)0.6 alloy in this experiment. The mass of TiCr1.2 (V-Fe)0.6 was 19.7 mg. The Argon with a flow speed of 20 mL/min was used as the carrying gas. The temperature region of TG–DSC was from room temperature to 500 °C. The heating rate was 10 K/min.

Figure 5a was the TG–DSC curves of TiCr1.2 (V-Fe)0.6 alloy. The TG results showed that the mass loss was 0.32 mg (about 1.62%) at 30–500 °C. The DSC curve showed two endothermic peaks at 302.8 and 397.7 °C. Moreover, the mass spectra of the evolved H2 were studied by the TA–MS coupling techniques. Figure 5b was the MS spectra of the TiCr1.2 (V-Fe)0.6 alloy. The MS signal appeared the positive ion mass spectra peaks of H2 + (m/z = 2) in the range of 250–500 °C (peak at 303.1 and 398.3 °C). It can be concluded that the released region of hydrogen was 250–500 °C, which was consistent with the TG–DSC results.

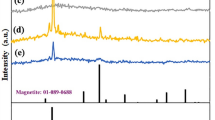

Application of TG–MS–PulseTA for characterization of the InN powder

Indium nitrate (99.5% In(NO3)3·4.5H2O) was used as the main raw material. Firstly, the desired amount of indium nitrate was dissolved in distilled water and the concentration of indium nitrate solution adjusted to 0.3 mol/L. This aqueous solution was then neutralized to pH 8 with 1.0 mol/L ammonia solution at room temperature. Secondly, the precipitate was separated from the solution by filtration, and repeatedly washed with distilled water. Then, the white cake was dried at 110 °C for 24 h and calcinations at 450 °C for 2 h. The crystalline In2O3 nanoparticles were obtained. Lastly, the InN powder was prepared by the nitridation of In2O3 with NH3 gas at 600 °C for 8 h [25]. The whole reaction can be expressed as

Figure 6a was the TG–DTG curve of the InN powder. The argon with a flow speed of 20 mL/min was used as the carrying gas. The temperature region of TG–DSC was from room temperature to 1000 °C. The heating rate was 10 K/min. The results showed that the TG curve had one mass loss from 550–750 °C (about 10.36%). Corresponding to the TG curve, the DTG curve appeared maximum decomposition temperature of the InN powder at 678.4 °C. Figure 6b was the MS spectra of the InN powder. There was the positive ion mass spectra peak of the N2 + (m/z = 28) at 679.5 °C. The peak area of N2 was 55.6E-07A*s. Nitrogen (99.999%) was used as the known amounts of calibration gas. The injection volume of nitrogen was 0.5 mL at a time. The density of N2 was 1.25 g/L. Injection temperature is at 20 °C. Nitrogen pulse peak was injected for three times in an experiment. The peak area of N2 was 9.214E-07A*s, 8.795E-07A*s, and 8.645E-07A*s, respectively. The average of the three peak areas was 8.885E-07A*s. The measured value of the evolved nitrogen was 3.64 mg. The mass of the InN powder for the experiment was 34.38 mg. The theoretical value of the evolved nitrogen was 3.74 mg. The relative error of this method between measured value and theoretical value was 2.67% for the quantitative calibration of evolved N2. It showed that TA–MS combined with PulseTA techniques offer a good tool for the quantification of the evolved nitrogen in the InN powder.

Conclusions

According to the results measured by the TG–DTA, TG–DSC–MS, TG–MS–PulseTA coupling techniques, the conclusions are the follows:

-

(1)

The irinotecan was oxidized before 700 °C completely. When irinotecan was loaded onto nanosized mesoporous silica spheres, the loading capacity for irinotecan measured by TG–DTA in the composite was about 9.11%, similar to the typical UV–Vis results, which showed that TG–DTA characterization provided an alternative method to determine the drug loading amount on inorganic carriers, showing their promise applications in nanomedicine.

-

(2)

The hydrogen adsorption capacity and temperature of TiCr1.2 (V-Fe)0.6 alloy were obtained at 250–500 °C by TG–DSC–MS coupling techniques. The thermal decomposition of the InN powder had one step mass loss from 550–750 °C. The relative error of this method between measured value and theoretical value was 2.67% for the quantitative calibration of evolved N2. The presented results indicate that TA–MS combined with PulseTA techniques offer a very good tool for the quantification of the InN powders. Moreover, this method is being extended to investigate the thermal behavior of other nitride and carbon nanostructured materials.

References

Ozawa T. Thermal analysis-review and prospect. Thermochim Acta. 2000;355:35–42.

Dakka SM. TG/DTA/MS of poly (methyl methacrylate) the effect of particle size. J Therm Anal Calorim. 2003;74:729–34.

Vyazovkin S. Thermal Analysis. Anal Chem. 2004;76:3299–312.

Utschick H, Ritz M, Mallon HJ, Arnold M, Ludwing W, Kettrup A, Mattuschek G, Cyrys J. Investigations on the thermal degradation of post-chlorinated polyvinyl chloride. Thermochim Acta. 1994;234:139–51.

Lu CW, Wang Q, Chen YX, Shi JL. Simultaneous characterizing study of the metallic iron—organic coordination compounds by TG–DSC–MS coupling techniques. Thermochim Acta. 2003;404:63–70.

Jacab E, Till FST, Kozhabekov SS, Zhubanov BA. Thermal decomposition of aryl—alicyclic polyimides studied by thermogravimetry/mass spectrometry and pyrolysis—gas chromatography/mass spectrometry. J Anal Appl Pyrolysis. 1992;23:229–43.

Małecka B, Łacz A. Thermal decomposition of cadmium formate in inert and oxidative atmosphere. Thermochim Acta. 2008;479:12–6.

Liu YH, Zhao JZ, Zhang H, Zhu YC, Wang ZC. Thermal decomposition of basic zinc carbonate in nitrogen atmosphere. Thermochim Acta. 2004;414:121–3.

Madarasz J, Kaneko S, Okuya M, Pokol G. Comparative evolved gas analyses of crystalline and amorphous titanium(IV)oxo-hydroxo-acetylacetonates by TG–FTIR and TG/DTA–MS. Thermochim Acta. 2009;489:37–44.

Kooli F. Thermal stability investigation of organo-acid-activated clays by TG–MS and in situ XRD techniques. Thermochim Acta. 2009;486:71–6.

Lu CW, Xi TG. “Thermal Analysis-Mass Spectrometry”. China: Shanghai Science and Technology Reference Publishing House; 2002.

Zayed MA, Nour FA, Dien EL, Hawash MF, Fahmey MA. Mass spectra of gliclazide drug at various ion sources temperature its thermal behavior and molecular orbital calculations. J Therm Anal Calorim. 2010;101:1161–5.

Alcolea A, Ibarra I, Caparros A, Rodrıguez R. Study of the MS response by TG–MS in an acid mine drainage efflorescence. J Therm Anal Calorim. 2010;102:305–12.

Chen Y, Chen HR, Guo LM, He QJ, Chen F, Zhou J, Feng JW, Shi JW. Hollow/Rattle-type mesoporous nanostructures by a structural difference-based selective etching strategy. ACS Nano. 2010;4(1):529–39.

Zhu YF, Shi JL, Shen WH, Dong XP, Feng JW, Ruan ML, Li YS. Novel stimuli-responsive controlled drug release from a hollow mesoporous silica sphere/polyelectrolyte multilayers core-shell structure. Angew Chem Int Ed. 2005;44:5083–7.

Hsiao JK, Tsai CP, Chung TH, Hung Y, Yao M, Liu HM, Mou CY, Yang CS, Chen YC, Huang DM. Mesoporous silica nanoparticles as a delivery system of gadolinium for effective human stem cell tracking. Small. 2008;4(9):1445–52.

Lee CH, Cheng SH, Wang YJ, Chen YC, Chen NT, Souris J, Chen CT, Mou CY, Yang CS, Lo LW. Near-infrared mesoporous silica nanoparticles for optical imaging: characterization and in vivo biodistribution. Adv Funct Mater. 2009;19:215–22.

Zhao WR, Chen HR, Li YS, Li L, Lang MD, Shi JL. Uniform rattle-type hollow magnetic mesoporous spheres as drug delivery carriers and their sustained-release property. Adv Funct Mater. 2008;18:2780–8.

Maciejewski M, Emmerich WD, Baiker A. Pulse thermal analysis–a new range of opportunities. J Therm Anal Calorim. 1999;56:627–37.

Maciejewski M, Baiker A. Quantitative calibration of mass spectrometric signals measured in coupled TA–MS system. Thermochim Acta. 1997;295:95–105.

Maciejewski M, Muller CA, Tschan R, Emmerich WD, Baiker A. Novel pulse thermal analysis method and its potential for investigating gas-solid reactions. Thermochim Acta. 1997;295:167–82.

Eigenmann F, Maciejewski M, Baiker A. Gas adsorption studied by pulse thermal analysis. Thermochim Acta. 2000;359:131–41.

Li X, Zhang LX, Dong XP, Liang J, Shi JL. Preparation of mesoporous calcium doped silica spheres with narrow size dispersion and their drug loading and degradation behavior. Microporous Mesoporous Mater. 2007;102:151–8.

Zhu YF, Shi JL, Li YS, Chen HR, Shen WH, Dong XP. Storage and release of ibuprofen drug molecules in hollow mesoporous silica spheres with modified pore surface. Microporous Mesoporous Mater. 2005;85(1–2):75–81.

Gao L, Zhang QH, Li JG. Preparation of ultrafine InN powder by the nitradation of In2O3 or In(OH)3 and its thermal stability. J Mater Chem. 2003;13:154–8.

Acknowledgements

The authors greatly acknowledge the financial supports from National Nature Science Foundation of China (no. 21005083) and National Key Technology R & D Program (no. 2006BAA04B02-01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huimei, Y., Lingjun, Q., Qinghong, Z. et al. Application of TA–MS combined with PulseTA for characterization of materials. J Therm Anal Calorim 106, 47–52 (2011). https://doi.org/10.1007/s10973-010-1280-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-1280-0