Abstract

Three transition metal perchlorate complexes of general formula [M(dah)2)](ClO4)2 (where M = Zn, Cu, and Ni; dah = 1,6-diaminohexane) have been prepared, and characterized by elemental analysis, infrared spectroscopy (IR), and gravimetric method. The thermal decomposition has been studied by thermogravimetry (TG), differential thermal analysis (DTA), and differential scanning calorimetry (DSC). Kinetics parameters of their thermolysis were evaluated by model-fitting and isoconversional methods using isothermal TG data. Model-fitting method has given the single value of activation energy (E) whereas; isoconversional method yields a series of E values which vary with the extent of conversion. Further ignition delay of these complexes was measured to see the response toward rapid heating with varying amounts. The thermal stability of the complexes decreases in the order as: [Zn(dah)2)](ClO4)2 > [Cu(dah)2)](ClO4)2 > [Ni(dah)2)](ClO4)2

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Metal nitrate and perchlorate complexes fall in the category of energetic metal complexes because of the presence of reducing and oxidizing group in the same molecule. Now a day, keen interest has been increased to the thermolytic studies of energetic metal amine complexes [1–4]. Explosivity of such energetic compounds lies between those of primary and secondary explosives [4]. These complexes may find applications in pyrotechnics, explosives, and propellants compositions. Nickel hydrazine nitrate has been prepared and found insensitive to impact, friction, or electrostatic charge, but more sensitive to flame [5]. Transition metal complexes are also used to obtain nano size metal oxides, which can have interesting electrical, magnetic, and catalytic properties [6]. Recently, Singh et al. [7–11] reported the use of energetic metal complexes and metal salts as ballistic modifiers for ammonium perchlorate-based composite solid propellants. Thermal characterization of these complexes helps in knowing the thermal stability, safety in handling, and storage. Kinetics of thermolysis provides a good approach for the mechanism of thermal decomposition of new high energetic compounds. Recently, we have undertaken studies on thermolysis and kinetics of some hexaammine metal perchlorates [10, 12], metal nitrates of bis(propylenediamine) [10], bis(diethylenetriamine) [13], perchlorates of bis(propylenediamine) [14], bis(1,4-diaminobutane) [15] and polymeric bis(4,4′-bipyridine) metal nitrates [16], hydrogen-bonded hexamethylenetetramine nitrates [17] and perchlorates [18], piperidine metal nitrates [19], and 2,2′-bipyridyl perchlorates [20]. Thus, in the continuation of our earlier study, we report here, the preparation, characterization, and thermolysis of transition metal perchlorate complexes with 1,6-diaminohexane ligand. Kinetics of thermolysis has been evaluated using isothermal TG by model-fitting and isoconversional methods. These were found to ignite when subjected to higher temperatures. The decomposition pathways of the complexes have also been proposed.

Experimental

Materials

Following AR grade commercially available Cupric carbonate (BDH), nickel carbonate, zinc carbonate (Thomas Baker), perchloric acid, ethanol (Hayman), methanol (Ranbaxy), and 1,6-diaminohexane and petroleum ether (Merck) were used as received.

Preparation and characterization of the complexes

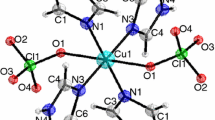

Various DAHP (diaminohexane perchlorate) complexes were prepared following a two step procedure as reported earlier [14]. Precipitated complexes were washed with methanol and petroleum ether and dried. The complexes were characterized by gravimetric estimation [21], infrared [22, 23] (JASCO FT/IR-5300, KBr pellet), and elemental analysis (C, H, N-Heraeus Carlo Erba 1108 instrument), and data are presented in Table 1.

Thermal decomposition studies

TG in air

Non-isothermal TG (Fig. 1) was undertaken using an indigenously fabricated TG apparatus [24] in static air atmosphere (sample mass 33 mg, heating rate 278 K min−1).

Simultaneous TG–DTG–DTA

Simultaneous TG–DTG–DTA curves of the complexes were obtained on Pyris Diamond Star system in flowing nitrogen atmosphere (flow rate 50 mL min−1, heating rate 283 K min−1, sample mass ~4 mg) in open crucible (Fig. 2).

DSC

DSC curves were obtained on Mettler Tolledo Star system in flowing nitrogen atmosphere (flow rate 50 mL min−1, sample mass ~4 mg) in a crimped crucible with a small hole at a heating rate of 283 K min−1. DSC curves are shown in Fig. 3. The thermoanalytical data on complexes are presented in Table 2.

Isothermal TG

The isothermal TG on DAHP complexes (sample mass 33 mg, 100–200 mesh) was carried out in static air using the same TG apparatus [24] as mentioned earlier at appropriate temperature for early thermolysis (~30% mass loss). The sample was diluted with alumina (1:1 by wt). The isothermal TG curves are given in Fig. 4.

Kinetic analysis of isothermal TG data

Kinetics of thermolysis is evaluated from isothermal TG data using model-fitting as well as model-free isoconversional method [25]. The following equation was found to be hold under isothermal condition:

where, α is the extent of conversion, E is the activation energy at a particular α, R the gas constant, and T i the absolute temperature. E is evaluated from the slope of the plot of −lnt α,i against 1/T i . Thus, E was evaluated at various extent of conversion α. The linear dependencies of E on the extent of conversion are shown in Fig. 5.

Ignition delay measurements

Ignition delay (D i) at various temperatures was undertaken with the tube furnace [26]. The sample (mass 20 and 7 mg, 100–200 mesh) was taken in an ignition tube (length ~5 cm and diameter ~0.4 cm) clamped with a bent wire and inserted manually into the tube furnace (TF). The time interval between the insertion and the moment of audible ignition gave the value of ignition delay in seconds (s). The accuracy of temperature was ±274 K. Each run was repeated four times, and mean D i values are reported in Table 3.

The kinetics of fast decomposition [27, 28] is evaluated from ignition delay data, D i. The D i data were found to fit in equation

where E* is the activation energy for ignition, and T is the absolute temperature. The value of E* was obtained from the slope of lnD i versus 1/T.

Results and discussion

The analytical data presented in Table 1, clearly show that there is a good agreement between observed and calculated percentage of C, H, N, and metal which confirms the proposed molecular formula of the complexes. The IR spectral data (Table 1) also signalize the proposed molecular/empirical formula. M–N stretching at 418–457 cm−1, which confirms the metal to ligand bond formation.

TG curves, taken in static air show that all the three complexes decompose in one step of which initial mass loss is slow and later is rapid (Fig. 1). After a little weight loss, the residue ignited giving a sharp weight loss. Initial decomposition temperature is almost same for all the three complexes, but the temperature of rapid thermolysis is the highest for zinc complex and is the lowest for copper complex. This shows the lower thermal stability of copper complex than nickel and zinc complexes. Finally, the corresponding metal oxide residue is left.

In flowing nitrogen atmosphere, the complex decomposes in two steps (Fig. 2). First step is rapid, and second stage is gradual. In first step, 48.2, 40.0, and 43.6% mass losses has been observed for zinc, copper, and nickel complexes, respectively (Table 2). Corresponding to this first step mass loss, DTG peaks are obtained. Although the thermolysis is done up to the temperature of 893 K, the residue left is more than the corresponding metal oxide, indicates the incomplete decomposition. In second stage of decomposition, the residue left after first step, ignites slowly giving a gradual mass loss curve and have no clear DTG peaks. Figure 2 clearly shows that the first step of mass loss is exothermic as indicated by the exothermic peak in DTA and DSC curves (Fig. 3). Second step decomposition is also exothermic, but instead of exothermic peak an exothermic hump is obtained in DTA. This may be due to the slow thermolysis in which exothermic and endothermic processes may occur simultaneously. However, in DSC curve (Fig. 3) only one exothermic peak is obtained at 605, 512, and 500 K for zinc, copper, and nickel complexes, respectively. In DTA, corresponding peak occurs at 600, 521, and 515 K. In DSC, the second exothermic hump is absent because DSC is run up to 823 K, whereas it is present since DTA was run up to ~873 K. Although the peak temperature of copper complex is higher to that of nickel, the starting decomposition temperature is lower. Comparison of inflection temperature (T i) of DTA peak and starting temperature of mass loss (Table 2) reveals that it is higher for Zn and lower for Cu complexes. Temperatures of rapid decomposition in air atmosphere follow the same trend as in case of inert atmosphere. Thus, the complexes may be arranged in the order of decreasing thermal stability as [Zn(dah)2](ClO4)2 > [Ni(dah)2](ClO4)2 > [Cu(dah)2](ClO4)2.

Change of atmosphere may change the thermolysis pattern of compounds. A perusal of decomposition shows that the rate of thermolysis is high in air relative to inert atmosphere. Also, in air, final decomposition residue corresponds to the metal oxides (~12%) at 873 K, whereas under inert atmosphere up to 893 K the amount of residue left is more than metal oxides formed at 873 K which could be due to incomplete decomposition. This difference in thermolysis pattern is due to the oxidative nature of air atmosphere. A survey of literature shows that the metal perchlorate with diamine ligand such as ethylenediamine [25], propylenediamine [14], and 1,4-diaminobutane [15] decomposes in single step in nitrogen atmosphere. The change of one step decomposition to two steps may be explained on the basis of oxidizing (ClO4 −) and reducing (–CH2–) group ratio and oxygen balance of the complexes. In the complexes with 1,6-diaminohexane ligand, the reducing group (–CH2–)6 is large in comparison to (–CH2–)2, (–CH2–)3, and (–CH2–)4 of ethylenediamine, propylenediamine, and 1,4-diaminobutane, respectively, whereas the oxidizing group is same. The oxygen balance for metal perchlorate complexes with 1,6-diaminohexane, 1,4-diaminobutane, propylenediamine, and ethylenediamine ligands are approximately −106, −76, −58, and −39, respectively. Thus, an increase of reducing group increases the oxygen deficiency of the molecule. The fast decomposition is attributed to a chain type explosive reaction due to simultaneous presence of reducing and oxidizing group in the same molecule. It seems that an intramolecular solid phase redox reaction occurring between reducing and oxidizing group is responsible for rapid decomposition. However, when reducing group becomes larger (oxygen deficiency increases), the self-oxidizing nature, and so decomposition becomes slow. Since, available oxygen in the molecule is not sufficient to oxidize the reducing group, hence left residue after first rapid step, decomposes slowly at elevated temperatures in non-oxidative nitrogen atmosphere. However, in air atmosphere, oxygen supply to the thermolysis may change two steps decomposition into single rapid step and final residue obtained may correspond to metal oxide.

Though the mode of decomposition of these compounds is a complex process, it may be speculated that first step of decomposition process may be partial dissociation of the compounds into ligand and metal perchlorate, M(ClO4)2. However, such a dissociation occurring in these perchlorates is difficult to detect by TG and DTA at atmospheric pressure. The reason for this being the unstable nature of the metal perchlorates at higher temperatures which may decompose instantaneously by exothermic reactions. The expected endotherm corresponding to partial dissociation of ligands may thus be overshadowed by exothermic process resulting in an overall exothermic effect. Thus, the speculated mechanism of thermolysis may be given as

The kinetic analysis of early decomposition (α = 0.30) of the complexes has been evaluated using isothermal TG data taken in air atmosphere by applying model-fitting as well as model-free isoconversional method [25]. Each model results in approximately the same activation energy (E) irrespective of the model used. The activation energy for zinc, copper, and nickel complexes are 73.0, 35.0, and 45.8 kJ mol−1, respectively. It is impossible to assign a single value of E to a particular process in such a complex solid state decomposition. Isoconversional method allows the estimation of apparent activation energy independent of the model. This approach indicates that the decomposition of these complexes is not as simple as indicated by model-fitting method. As Fig. 5 shows that the E value changes with extent of conversion, α. E is the highest for zinc complex whereas it is the lowest for copper complex in all the α range. A single value of activation energy derived from model-fitting method is the highest and the lowest for Zn and Cu complexes, respectively. Thus, on the basis of E value, the thermal stability of complexes decreases in the order [Zn(dah)2](ClO4)2 > [Ni(dah)2](ClO4)2 > [Cu(dah)2](ClO4)2.

Di was measured to examine the response of the complexes subjected to sudden high temperature. Table 3 shows that zinc complex does not ignite at 698 K (up to ~7 min) although their partial decomposition has been observed. Copper and nickel complex ignite at lower temperatures (after partial decomposition). At a particular temperature, for the sample mass 20 or 7 mg, the time of ignition for Ni is more than Cu complex. This shows the greater thermal stability of Ni over Cu complex. Also, the activation energy for ignition (E*) follows the decreasing order as [Zn(dah)2](ClO4)2 > [Ni(dah)2](ClO4)2 > [Cu(dah)2](ClO4)2. Thus, the thermal stability decreases in the same order. Similar thermal stability order has also been observed during TG, DTA, and DSC analysis as reported earlier. The higher stability of Zn complex may be attributed to the filled d10 electronic configuration of Zn++ ion and higher ionization potential (9.39 eV). Comparison of Di values for 20 or 7 mg indicates that it is lower for 7 mg for all the three complexes. This suggests that self-propagative heating effect of sample particles is less than the contact heating with the wall of ignition tube. Although the Di is different for different sample masses, activation energy for ignition is nearly same.

Conclusions

All these compounds gave a common exothermic peak in DTA and DSC which may be due to ignition, giving a sudden weight loss in TG. The rate of thermolysis is high in air as compared to inert nitrogen atmosphere. A conventional model-fitting approach fails to describe any change in the mechanism of isothermal decomposition of these complexes. The isoconversional method emphasizes that mechanism of thermolysis changes as the reaction proceeds. Ignition delay measurement indicates the same mechanism for thermal ignition of all the three complexes. Thermal stability of the complexes decreases in the order [Zn(dah)2](ClO4)2 > [Ni(dah)2](ClO4)2 > [Cu(dah)2](ClO4)2.

References

Singh G, Kapoor IPS, Pandey DK. Hexammine metal perchlorate complexes as energetic burning rate modifiers. J Energ Mater. 2002;20:223–44.

Allan JR, Beaumont PC, Milburn GHW, Wood I. Structural and thermal studies of the chloro complexes of cobalt, nickel and copper with 1,6-hexanediamine. Thermochim Acta. 1993;219:159–65.

Mathew S, Nair CGR, Ninan KN. Quantitative correlations of activation parameters and procedural factors-dependence on reaction type. Thermochim Acta. 1991;184:269–94.

Patil KC, Verneker VRP, Jain SR. Metal perchlorate ammines: thermal and infrared studies. Thermochim Acta. 1976;15:257–60.

Hariharanath B, Rajendran AG, Chandrabhanu SK, Ravindran M, Kartha CB. In: Proceedings of 3rd international high energetic materials conference and exhibit (HEMCE); 2000. p. 469.

Sawant SY, Kannan KR, Verneker VMS. Thirteenth national symposium on thermal analysis BARC. Mumbai; 2002.

Singh G, Felix SP. Studies of energetic compounds Part 29: effect of NTO and its salts on the combustion and condensed phase thermolysis of composite solid propellants HTPB-AP. Combust Flame. 2003;132:422–32.

Singh G, Kapoor IPS, Tiwari SK, Felix SP, Varghese TL, Ninan KN. Studies on energetic compounds, Part 15: transition metal salts of NTO as potential energetic ballistic modifiers for composite solid propellants. J Energ Mater. 2002;20:309–27.

Singh G, Pandey DK. Studies on energetic compounds, Part 27: kinetics and mechanism of thermolysis of bis(ethylendiamine)metal nitrates and their role in the burning rate of solid propellants. Propellant Explos Pyrotech. 2003;28:231–9.

Singh G, Pandey DK. Studies on energetic compounds, Part 35: kinetics of thermal decomposition of nitrate complexes of some transition metals with propylenediamine. Combust Flame. 2003;135:135–43.

Singh G, Pandey DK. Studies of energetic compounds, Part 43: effect of some BEMP complexes on the combustion and condensed phase thermolysis of HTPB-AP composite solid propellants. Ind J Chem Technol. 2005;12:175–80.

Singh G, Pandey DK. Kinetics and mechanism of thermolysis of hexammine metal perchlorates. J Energ Mater. 2002;20:135–52.

Singh G, Pandey DK. Thermal studies on energetic compounds Part 30: kinetics and mechanism of bis(diethyltriamine) metal nitrate complexes. J Therm Anal Calorim. 2004;76:507–19.

Singh G, Pandey DK. Studies on energetic compounds, Part 40: kinetics of thermal decomposition of bis(propylenediamine)metal perchlorate complexes. J Therm Anal Calorim. 2005;82:253–60.

Singh G, Mannan SM. Kinetics of thermolysis of some transition metal perchlorate complexes with 1,4-diaminobutane ligand. Thermochim Acta. 2005;437:21–5.

Singh G, Singh CP, Mannan SM. Preparation, characterization and thermolysis of metal nitrate complexes with 4,4′-bipyridine. J Therm Anal Calorim. 2006;85:425–31.

Singh G, Baranwal BP, Kapoor IPS, Kumar D, Singh CP, Frohlich R. Preparation, X-ray crystallography and thermal decomposition of some transition metal nitrate complexes with hexamethyleneteramine. J Therm Anal Calorim. 2008;91:971–6.

Singh G, Baranwal BP, Kapoor IPS, Kumar D, Frohlich R. Preparation, X-ray crystallography and thermal decomposition of some transition metal perchlorate complexes of hexamethyleneteramine. J Phys Chem A. 2007;111:12972–6.

Singh G, Kapoor IPS, Kumar D. Preparation, characterization and kinetics of thermal decomposition of some transition metal nitrate complexes of piperidine. In: Proceedings of IASPEP; 2007. pp. 120–26.

Singh G, Kapoor IPS, Kumar D, Nidhi Goel, Singh UP. Preparation, X-ray crystallography and thermal decomposition of transition metal perchlorate complexes with perchlorate and 2,2′-bipyridyl ligands. Inorg Chim Acta. 2009;362:4091–8.

Vogel AI, Basset J, editors. Vogel′s text book of quantitative inorganic analysis. 4th ed. London: Longman; 1995.

Nakamoto K. Infrared and Raman spectra of inorganic and coordination compounds. New York: Wiley and Sons; 1978. p. 206–8.

Robert CW. Handbook of physics and chemistry. 66th ed. Florida: CRC Press; 1996. p. 197–8.

Singh G, Singh RR. Indigenously fabricated apparatus for thermogravimetric analysis. Res Ind. 1978;23:92–3.

Singh G, Felix SP, Pandey DK. Studies on energetic compounds Part 37: kinetics of thermal decomposition of perchlorate complexes of some transition metal metals with ethylenediamine. Thermochim Acta. 2004;411:61–71.

Singh G, Kapoor IPS, Vasudeva SK. Thermolysis of AP-PS additive mixtures. Ind J Technol. 1991;29:589–94.

Semenov N. Chemical kinetics and chain reactions. Oxford: Clarendon Press; 1935. Chapter 18.

Freeman ES, Gorden S. The application of the absolute rate theory of the ignition of propagatively reacting systems: thermal ignition of the system, lithium nitrate–magnesium, sodium nitrate–magnesium. J Phys Chem. 1956;60:867–71.

Acknowledgements

Thanks are due to Head, Chemistry Department DDU Gorakhpur University, Gorakhpur for lab facilities, Department Testing Station Gondkhiry, Nagpur for the TG, DTA, and DSC studies. Council of Scientific and Industrial Research (CSIR) is also thanked for providing Emeritus Scientist to Dr. G. Singh and SRF to Dinesh Kumar.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, G., Shrimal, A.K., Kapoor, I.P.S. et al. Kinetics of thermolysis of some transition metal perchlorate complexes with 1,6-diaminohexane ligand. J Therm Anal Calorim 103, 149–155 (2011). https://doi.org/10.1007/s10973-010-0968-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-0968-5