Abstract

The catalytic effect of NiO on thermal decomposition of nitrocellulose (NC) has been investigated via thermogravimetry–mass spectrometry (TG–MS) coupling technique, and the residue of NC with 20% NiO reacted in tubular furnace was analyzed by X-ray diffraction (XRD). TG–MS analysis showed that adding 2% NiO to NC accelerated the thermal decomposition process and promoted the generation of gaseous products. The catalytic mechanism was based on the accelerated generation of NO2, which further reacted with the radical to produce other gaseous products. XRD analysis of catalyst residue showed that Ni was formed during the catalytic reaction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrocellulose (NC) is widely used as chief ingredient in the production of smokeless powders, blasting gelatin, dynamites, single-base, and double-base gun and rocket propellants [1]. The thermal characteristics of NC have been widely studied. Bingke et al. [2] have studied the melting process of NC. Shehata et al. [3] have studied the effect of two novel polymeric compounds and their synergistic activity on the stability of NC. The effects of nitrate content and particle size on the thermal decomposition of NC were also individually studied [4, 5].

The thermal decomposition can be investigated by many thermoanalytical methods such as thermogravimetry (TG), differential thermal analysis (DTA), and differential scanning calorimetry (DSC). Compared to TG analysis alone, which is only able to measure the total volatile as a single group, thermogravimetry–mass spectrometry (TG–MS) coupling technique is highly preferred [6], because TG–MS is suitable for studying the mass change during the thermal decomposition. TG–MS coupling technique has been used in a wide variety of studies of the thermal decomposition of energetic materials [7–10].

Nickel oxide (NiO) has received lots of attention for the electronic, magnetic especially catalytic properties [10–16]. In this work, TG–MS analysis was applied to investigate the catalytic effect of NiO on the thermal decomposition of NC, and the catalyst residue was analyzed via X-ray diffraction (XRD) method.

Experimental

Preparations

Preparation of NiO

All the reagents were analytical grade, and NiO was prepared by the precipitation method. First, according to the molar ratio of nickel nitrate hexahydrate (Ni(NO3)2·6H2O) to oxalic acid dihydrate (H2C2O4·2H2O) at 1:1, a stoichiometric amount of Ni(NO3)2·6H2O and H2C2O4·2H2O were accurately weighed and dissolved in deionized water, respectively. Then, the two solutions were mixed and stirred with a magnetic stirrer at 60 °C. After the reaction was complete, the precipitated powder was filtered off, washed with deionized water, and dried in an oven at 80 °C. Then, the powder was sintered at 400 °C for 2 h to yield NiO.

Preparation of sample for TG–MS analysis

Nitrocellulose, which contained 12% of nitrogen, was from Xi’an Modern Chemistry Research Institute. In order to investigate the catalysis of NiO on the thermal decomposition process of NC, the catalyst and NC were mixed with the mass ratio of 1:49.

Preparation of sample for XRD analysis

As known, while using a thermal-analyzer, the sample amount is limited. In order to investigate the composition of catalyst residue, NC and NiO were mixed with the mass ratio of 4:1, and the mixture was heated in a tubular furnace from room-temperature till the reaction was finished in nitrogen (and this temperature was around 210 °C). Then, the catalyst residue was taken out immediately and analyzed via XRD method.

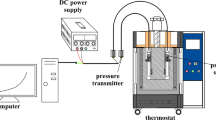

Instrumentation

A simultaneous thermal-analyzer (Mettler Toledo, model TGA/SDTA 851e) coupled on line with a quadrupole mass spectrometry (Pfeiffer Vacuum, model Thermostar GSD301T3) was applied for the TG–MS analysis on the thermal decomposition process of NC. The mass spectrometer was operated with an electron impact ionizer with energy 70 eV, and the mass scan speed is 1 a.m.u/s. The connection between the TGA–SDTA apparatus and the mass spectrometer was done by means of a quartz capillary of 0.15 mm internal diameter, maintained at 150 °C.

The catalytic reaction was studied in the flowing argon gas atmosphere (purity, 99.99%; flowing rate, 30 mL min−1; atmospheric pressure) at the heating rate of 20 °C min−1 when the sample quantum was about 1.00 mg with Al2O3 crucible as reference, and the sample was placed in alumina crucible.

In order to ensure there was no air in the instrument and to calibrate the analyzer, the apparatus was operated in argon before the thermal decomposition process was performed.

X-ray diffraction measurements were performed on a Bruker D8 Advance X-ray diffraction using CuKα radiation to study the composition of catalyst residue, and the diffraction angle (2θ) from 10° to 80° was scanned.

Results and discussion

TG–MS analysis on thermal decomposition of NC with and without NiO

Figure 1 shows TG curves for NC with and without NiO.

It can be found that NiO is an effective catalyst for the thermal decomposition of NC. With the catalysis of NiO, the thermal decomposition of NC is accelerated and this process becomes more acute.

In order to investigate the detailed changes of gaseous products during the thermal decomposition process, the mass spectrometer was applied.

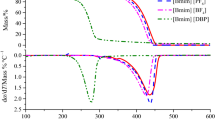

The evolution curves of major gaseous products evolved during thermal decomposition of NC with and without NiO are exhibited in Fig. 2.

The MS curves are clearly associated to the TG curve and the detection of H2O, HCN, CO, N2, HCHO, NO, CO2, NO2, and HCOOH is observed.

According to the profile of MS curves, it can be seen that with the catalysis of NiO, the ion currents of evolved products attain the maximum intensity at lower temperatures, and the MS curves becomes narrower and sharper.

There are two peaks on the MS curves for m/z = 46. It is known that NO is the most intense fragment of NO2 according to the reference mass spectra in NIST database [17], and HCOOH is the secondary product of gaseous products [18, 19]. Therefore, the first peak on the MS curves for m/z = 46 is attributed to the evolution of NO2 while the second is caused by the evolution of HCOOH gas, which was detected later than other gaseous products.

The thermal decomposition mechanism of NC has been widely studied [18–21]. It is known that during the thermal decomposition of NC, fission of oxygen–nitrogen bond is the first and rate-determining step [3], and this step leads to the generation of NO2.

Then, NO2 reacts with the radical to produce other gaseous products.

According to Fig. 2, it can be found that the generation of NO2 is accelerated, while NC is catalyzed with 2% NiO, and the maximum ion intensity of evolved NO2 is obviously increased in lower temperature, revealing that more NO2 is withdrawn from catalyzed NC. It means that the reaction, which is rate determining is promoted, and then the generated NO2 further reacts with the radical. Therefore, the decomposition of NC is accelerated with the catalysis of NiO.

XRD analysis of the catalyst residue

X-ray diffraction was used to study the composition of catalyst residue and the curves are shown in Fig. 3.

From Fig. 3, it can be found that Ni was formed during the catalysis process. It means that the composition of the catalyst is changed, and it is indicated that NiO is not only a catalyst in the catalytic reaction, but also takes part in the reaction.

Conclusions

Via TG–MS method, it is found that with the catalysis of NiO, the thermal decomposition of NC was accelerated and the process became more acute. MS analysis showed that after adding 2% NiO, the ion currents of gaseous products attained maximum intensities at lower temperatures and MS curves became narrower and sharper.

With the catalysis of NiO, the evolution of NO2 was promoted and its maximum ion intensity was obviously increased in lower temperature. It means that adding NiO to NC accelerates the fission of oxygen–nitrogen bond, which is the first and rate-determining step, and then the generated NO2 reacts with radical to produce other gaseous products. Therefore, the thermal decomposition of NC is accelerated.

X-ray diffraction analysis of the catalyst residue showed that Ni was formed, which indicates that NiO is not only a catalyst in the catalytic reaction but also takes part in the catalysis reaction.

References

Mahajan RR, Makashir PS, Agrawal JP. Combustion behaviour of nitrocellulose and its complexes with copper oxide. J Therm Anal Calorim. 2001;65:935–42.

Bingke N, Rong L, Xianqi C, Yuan W, Rongzu H, Qingsen Y. Study on the melting process of nitrocellulose by thermal analysis method. J Therm Anal Calorim. 1999;58:249–56.

Shehata AB, Hassan MA, Nour MA. Effect of new poly 2-acryloyl-N, N′-bis (4-nitrophenyl) propandiamide and poly 2-acryloyl-N, N′-bis (4-methylphenyl) propandiamide and their synergistic action on the stability of nitrocellulose. J Hazard Mater. 2003;102:121–36.

Pourmortazavi SM, Hosseini SG, Rahimi-Nasrabadi M, Hajimirsadeghi SS, Momenian H. Effect of nitrate content on thermal decomposition of nitrocellulose. J Hazard Mater. 2009;162:1141–4.

Sovizi MR, Hajimirsadeghi SS, Naderizadeh B. Effect of particle size on thermal decomposition of nitrocellulose. J Hazard Mater. 2009;168:1134–9.

Wu QL, Pan N, Deng KM, Pan D. Thermogravimetry-mass spectrometry on the pyrolysis process of Lyocell fibers with and without catalyst. Carbohydr Polym. 2008;72:222–8.

Jones DEG, Lightfoot PD, Fouchard RC, Kwok Q, Turcotte AM, Ridley W. Hazard characterization of KDNBF using a variety of different techniques. Thermochim Acta. 2002;384:57–69.

Yu ZX, Sun YX, Wei WX, Lu LD, Wang X. Preparation of NdCrO3 nanoparticles and their catalytic activity in the thermal decomposition of ammonium perchlorate by DSC/TG-MS. J Therm Anal Calorim. 2009;97:903–9.

Yu ZX, Chen LF, Lu LD, Yang XJ, Wang X. DSC/TG-MS study on in situ catalytic thermal decomposition of ammonium perchlorate over CoC2O4. Chin J Catal. 2009;30(1):19–23.

Wei WX, Jiang XH, Lu LD, Yang XJ, Wang X. Study on the catalytic effect of NiO nanoparticles on the thermal decomposition of TEGDN/NC propellant. J Hazard Mater. 2009;168:838–42.

Biju V, Abdul Khadar M. Analysis of AC electrical properties of nanocrystalline nickel oxide. Mater Sci Eng A. 2001;304–306:814–7.

Ichiyanagi Y, Wakabayashi N, Yamazaki J, Yamada S, Kimishima Y, Komatsu E, et al. Magnetic properties of NiO nanoparticles. Physica B. 2003;329–333:862–3.

Carnes CL, Klabunde KJ. The catalytic methanol synthesis over nanoparticle metal oxide catalysts. J Mol Catal A Chem. 2003;194:227–36.

Li JF, Xiao B, Du LJ, Yan R, Liang TD. Preparation of nano-NiO particles and evaluation of their catalytic activity in pyrolyzing cellulose. J Fuel Chem Technol. 2008;36(1):42–7.

Chen LJ, Li GS, Qi P, Li LP. Thermal decomposition of ammonium perchlorate activated via addition of NiO nanocrystals. J Therm Anal Calorim. 2008;92:765–9.

Wang YP, Zhu JW, Yang XJ, Lu LD, Wang X. Preparation of NiO nanoparticles and their catalytic activity in the thermal decomposition of ammonium perchlorate. Thermochim Acta. 2005;437:106–9.

NIST Chemistry Webbook Standard Reference Database, No. 69. 2008. http://www.webbook.nist.gov/chemistry. September 2008 Release.

Wang Y, Liu R, Ning BK, Pan Q, Hu RZ. A study of the thermal decomposition mechanism of nitrocellulose. Energy Mater. 1998;6:157–68. (in Chinese).

Liu ZR. Thermal analyses for energetic materials. Beijing: Defense Industry Press; 2008. p. 63 (in Chinese).

Konkin AL, Ershov BG, Kargin YM, Chichirov AA, Agafonov MN. Study of the radical products of the thermal decomposition of nitrocellulose. Russ Chem Bull. 1989;38:2426–8.

Makashir PS, Mahajan RR, Agrawal JP. Studies on kinetics and mechanism of initial thermal decomposition of nitrocellulose. J Therm Anal. 1995;45:501–9.

Acknowledgements

We gratefully acknowledge the National Natural Science Foundation of China (No. 50972059) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wei, W., Cui, B., Jiang, X. et al. The catalytic effect of NiO on thermal decomposition of nitrocellulose. J Therm Anal Calorim 102, 863–866 (2010). https://doi.org/10.1007/s10973-010-0695-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-0695-y