Abstract

A eutectic is formed from a mixture of two or more solids and has a melting point lower than that of each of its constituents. It is generally represented by a phase diagram where the liquid and solid phases impact upon each other with a value known as the eutectic point. In pharmaceuticals, poor water solubility is a major obstacle for releasing new dosage forms into the market. Eutectic formation overcomes these problems. Preparation of a phase diagram by Differential Scanning Calorimetry can determine eutectic properties, but it is tedious. A modified Van’t Hoff (VH) equation was used in this study. Devalina Law developed a dimensionless index for the VH equation. The difference in melting points of an excipient polymer and drug are divided by the slope of the VH equation. In previous studies, five excipient–drug compositions were evaluated. The final index relationship was in good agreement except for the salt, quinine sulfate. In order to test the validity of the VH index, further studies of PEG with acetylsalicylic acid, acetaminophen, diflunisal, dimenhydrinate, ketoconazole, and mefenamic acid were performed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Poor water solubility and slow dissolution into the gastrointestinal tract (GIT) are the two major obstacles impeding the pharmaceutical industry in releasing new dosage forms into the market. These issues have been responsible for the rejection of 70% of the potentially active drugs. Eutectic mixtures have played a key role in improving the absorption of many compounds by increasing their solubility and dissolution properties [1].

A eutectic is a mixture of two or more compounds having a melting point lower that of each constituent, in this case a poorly water soluble drug and a highly water soluble carrier molecule [2]. This combination in general is immiscible in the solid state and miscible in the liquid state. Upon crystallization of a liquid mixture, a reduction in particle size is obtained resulting in a final product where the drug is incorporated into the interstitial spaces of the carrier molecule. Formation of this mixture causes faster release of the drug present in the carrier [3].

The general method of preparing the samples, running through the Differential Scanning Calorimetry (DSC), and interpreting the results to obtain the eutectic point is labor-intensive and time consuming. A short and sweet preformulation predictive method has been proposed by Van’t Hoff, which involves the use of a modified Van’t Hoff equation. The equation is as follows [4]:

where \( T_{\text{d}}^{\text{f}} \) melting point of the major component, w p weight fraction of the minor component, R universal gas constant, \( \Updelta H_{\text{d}}^{\text{f}} \) molar heat of fusion of the major component and T mix is the temperature along the liquidus line as a function of w p.

On the basis of the above equation, Law et al. [5] proposed an index, (I c ), which is useful in the calculation of the eutectic point by using the melting points of the drug and PEG carrier [5]. The equation is as follows:

where I c is the dimensionless index, \( T_{\text{d}}^{\text{f}} \) is the melting point of the drug, \( T_{\text{p}}^{\text{f}} \) is the melting point of PEG 8000, R is the universal gas constant, \( \Updelta H_{\text{d}}^{\text{f}} \) is the molar heat of fusion of the drug molecule.

The I c value obtained from the calculations can be used to determine the eutectic point (as shown in Table 1).

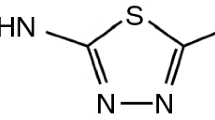

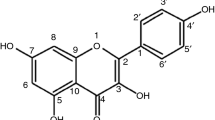

In previous studies, five PEG–drug systems, whose composition consisted of hydrochlorothiazide, menadione, propylthiouracil, quinine sulfate, and sulfamerazine, were evaluated by this equation [4]. The formula was found to be in agreement in all of the cases, except for quinine sulfate, which is a salt form of the drug, whereas the remaining drugs were either weak acids, weak bases or neutral compounds. In order to test the success of the formula, further work has been performed on samples of PEG with acetylsalicylic acid, acetaminophen, diflunisal, dimenhydrinate, ketoconazole, and mefenamic acid.

Experimental

Chemicals

Acetyl salicylic acid, acetaminophen, diflunisal, dimenhydrinate, ketoconazole, and mefenamic acid were obtained from Spectrum chemicals. Solvents such as acetonitrile, methylene chloride were used for the eutectic formation by the solvent method and were obtained from Fischer Scientific. Ethanol, which is also used as a solvent, was obtained from Pharmaco products Inc.

Equipment

Mettler Toledo DSC 822e fitted with a TSO801RO sample robot and a TSO800GCI Gas controller using Star (e) software V8.10 was used to obtain the scans. Samples in the range of 9–10 mg were weighed in 40 or 100 μL aluminum pans using the Mettler MT 5 microbalance. The measured pans are hermetically sealed and placed in the DSC. A heating rate of 5 °C min−1 was applied to all the mixtures. A purge gas of nitrogen gas flowed at the rate of 50 mL min−1. Any presence of crystallization in the drug–PEG mixture may be identified by using the X-Ray Diffractometer—PANalytical X-Pert Pro v. 1.6 with X-Pert Data Collector v. 2.1 with an angular range of 5–35° for aspirin and 5–55° for the remaining compounds. Scanning was done at a rate of 1 °C min−1 on passing the sample through a 100 mesh size. Visual observation of the melting point may be done with a hot-stage microscopy. A Bausch & Lomb microscope was equipped with a hot stage (Powerstat® variable autotransformer 3PN116B, The Superior Electric Co.) was used. A heating rate of 10 °C min−1 was maintained [5].

Procedure

Drug and PEG 8000 are placed in a beaker and mixed with a suitable solvent. Ethanol is used as a solvent for all the mixtures except ketoconazole, where methylene chloride was used. The mixture is then heated on low flame on a plate and is vacuum dried for 2 h. It is then placed overnight in a desiccator for the complete removal of the solvent. It is then stored at −20 °C for 4 days to ensure crystallization. The presence of crystallization may be verified by X-ray diffractometer. Samples are then ground in a mortar with a pestle and are passed through a US standard sieve. Size-reduced samples are then accurately weighed on the microbalance and placed into aluminum pans, hermetically sealed, and are scanned from 25 °C to temperatures above the melting point of the drug. Samples were purged at 50 °C min−1 in a stream of nitrogen gas at a heating rate of 10 °C min−1.

Results and discussion

DSC scans

The mixtures of drugs and PEG 8000 were analyzed on the DSC and the following scans (Figs. 1, 2, 3, 4, 5, 6) were obtained and interpreted for the point at which the mixture exists in its homogeneous form.

Calculations

All the mixtures of drug and PEG, thus formed, were found to show eutectic type behavior, and their eutectic point was determined from the DSC scans. These points were compared with the ones calculated by the use of the Van’t Hoff equation. Table 2 shows the comparison.

The table shows a good correlation of the measured points with that of the calculated ones by using the “Higher heating rate index” (I c ). Three of the six results were in excellent agreement, while the other three differed by 5%.

However, finally, upon characterization of these mixtures by various other analytical techniques like Wide Angle X-Ray Diffraction and Scanning Electron Microscopy, it was found that only acetyl salicylic acid showed eutectic type behavior, while the rest of the drugs only showed this behavior in their preliminary stages. Thus, the equation once again proved its validity as a preformulation tool in predicting the eutectic compositions of various drugs and excipients at their preliminary stages of formulation.

Conclusions

From the results, provided in the tables, it is clear that a good correlation exists between the values calculated by the higher heating rate index (I c ) and those obtained from the phase diagrams of the DSC. Three of the six calculations were in excellent agreement, while the other three differed by a deviation of 5%. Hence, the equation was found to show satisfactory results in calculating the expected eutectic points (% drug w/w) of these samples without actually constructing the phase diagrams. In summary, it can be concluded that the index has been successful in predicting the eutectic point compositions of most of the mixtures and hence can be used as a preformulation tool to give an approximate idea of the composition at which a eutectic might be formed.

Recently, several quality articles on eutectics have elucidated the structure property relationship (see S. O. Firstov et al.) [6]. Their observations can be applied to other eutectics composed of drugs and excipients. Sathyapal Hegde, K. Narayan Prabhu [7] and S. M. Lakiza [8] investigated and studied the structure and physical mechanical properties of various eutectic metal alloys. Sathyapal and Narayan reported that “The mechanical properties of Al–Si alloys are strongly related to the size, shape and distribution of eutectic silicon present in the microstructure.” Lakiza studied directionally solidified eutectics in Al2O3–ZrO2–Ln(Y)2O3 systems and emphasized their use as structural materials at high temperatures [8].

References

Stott PW, Williams AC, Barry BW. Characterization of complex coacervates of some tricyclic antidepressants and evaluation of their potential for enhancing transdermal flux. J Control Release 1998;50:298–307.

Chiou WL, Riegelman S. Pharmaceutical applications of solid dispersions systems. J Pharm Sci. 1971;60:1281–302.

Sekiguchi K, Obi N. Studies on absorption of eutectic mixtures. I. A comparison of the behavior of eutectic mixture of sulfathiazole and that of ordinary sulfathiazole in man. Chem Pharm Bull. 1961;9:866.

Oberoi LM, Alexander KS, Riga AT. Differential scanning calorimetry as a preformulation tool for studying eutectics relevant in pharmaceuticals. Am Pharm Rev. 2004;78:83–9.

Law D, Wang W, Schmitt EA, Long MA. Prediction of poly(ethylene) glycol-drug eutectic compositions using an index based on the van’t Hoff equation. Pharm Res. 2002;19:315–21.

Firstov SO, Horna ID, Horpenko KO, Beha MD, Koval OY, Kotko AV. Structure and physicomechanical properties of eutectic Ti-Si-X alloys. J Mater Sci. 2008;43:342–51.

Sathyapal H, Narayan Prabhu K. Modification of eutectic silicon in Al-Si alloys. J Mater Sci. 2008;43:3009–27.

Lakiza SM. Directionally solidified eutectics in the Al2O3-ZrO2-Ln(Y)2O3 systems. Powder Metall Met Ceram. 2009;48:42–59.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article can be found at http://dx.doi.org/10.1007/s10973-010-1212-z

Rights and permissions

About this article

Cite this article

Avula, S.G., Alexander, K. & Riga, A. Predicting eutectic behavior of drugs and excipients by unique calculations. J Therm Anal Calorim 99, 655–658 (2010). https://doi.org/10.1007/s10973-009-0595-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0595-1