Abstract

The aim of this work was to compare the influence of organocations with different length of alkylammonium chain on the structural stability of clays towards mechanochemical treatment. An industrial product JP A030 (Envigeo, Inc., Slovakia) based on Jelšový Potok bentonite (Slovakia) and three organoclays prepared from this material via ion exchange with tetramethylammonium, octyltrimethylammonium and octadecyltrimethylammonium cations (TMA-JP A030, OTMA-JP A030 and ODTMA-JP A030, respectively) were ground for 1–20 min in a high-energy planetary mill. The products were investigated by X-ray diffraction analysis, thermal analysis, scanning electron microscopy and energy dispersive X-ray analysis. The long-chain organic cations apparently enhance the structural stability of bentonite during high-energy grinding.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Grinding and milling of raw materials and their products correspond to the oldest industrial treatment processes and are still frequently used in material processing. Fine grinding is an intermediate case between coarse grinding and mechanical activation and is gaining much importance as the demand for fine particles from various industries increases [1]. Mechanochemical activation is such a method leading to physical disintegration along with the formation of active surfaces as well as changes in the physicochemical behaviour of materials. Generally, this kind of process as applied to crystalline solid produces loss of crystallinity (amorphization) along with the increase in surface energy and surface reactivity of the material and consequently in chemical activity [2]. The powder mixtures can be mechanically activated to induce chemical reactions, i.e. mechanochemical reactions at room temperature or at least at much lower temperatures than normally required to produce variety of commercially useful materials [3]. Nowadays, the mechanochemical methods are in the wide use in preparation of nanocrystalline ceramics [4] and nanopowders [5], in catalysis [6], metallurgy [7], etc. The purpose of high-energy mills is to transfer the maximum amount of energy from the working medium to the treated solid during the mechanical activation in relatively short time. This can lead to prominent problem of possible contamination of the compound subjected to the mechanical activation with the materials composing the working medium and the reactor body [8].

The mechanochemical treatment of clays and clay minerals is used to increase their catalytic activities, acid dissolution, adsorption of organic molecules from different solvents, water purification from radionuclides and more other properties [9–12]. The intercalation of surfactant ions converts the initially hydrophilic clay particles into hydrophobic organoclays. Because of their ability to swell and disperse in organic solvents, organoclays have traditionally been used as thickening and gelling agents of organic systems, such as paints, lubricants, cosmetics and many environmental applications [13–15]. The incorporation of organoclays into polymers in order to make nanocomposites exhibits a remarkable improvement in properties when compared with conventional composites (micro/macro-composites) or matrix alone [16]. Lots of polymer nanocomposites are synthesised by blending the organically modified clays into the polymer melt. Thermal stability of organoclays and knowledge of decomposition processes of the organic compounds are crucial for making polymer/clay nanocomposites in this way and their applications and other possible uses of organoclays [17–19]. Therefore, it is widely studied and described in various papers [20–24].

All applications of clays and organoclays strongly depend on their structure and properties. The structural changes of bentonite modified with quaternary ammonium surfactants with different length of alkylammonium chains caused by grinding in high-energy planetary ball mill were studied in detail by different physical and chemical techniques. Thermal degradation of organically modified bentonite and its ground products was investigated by thermal analysis and compared with natural bentonite.

Experimental

Materials

Detailed description of used materials and preparation of organoclays is described in [16]. The clay used in this study was Jelšový Potok A030 (JP A030), a bentonitic industrial non-activated product (Envigeo Inc., Slovakia). Its chemical composition given in mass percent is 65.29% SiO2, 17.84% Al2O3, 2.25% Fe2O3, 3.44% MgO, 1.58% CaO, 1.45% K2O and 0.82% Na2O, loss in ignition is 6.58%. The cation exchange capacity (CEC) is 69 meq/100 g. The main mineral is montmorillonite (>55%), quartz dominates among the accessory minerals. Three readily available quaternary ammonium surfactants with different length of alkylammonium chains, tetramethylammonium (TMA) chloride (≥98%, Fluka), octyltrimethylammonium (OTMA) bromide (≥98%, Fluka) and octadecyltrimethylammonium (ODTMA) bromide (≥97%, Aldrich), were used to prepare the organo-clays TMA-JP A030, OTMA-JP A030 and ODTMA-JP A030. The method of clay modification was very similar for all the surfactants. The solutions of appropriate concentrations were obtained by dissolving the organic salts in a required amount of 1:1 mixture of water and ethanol heated up to 60 °C. The amount of the alkylammonium cations used was twice the CEC (ODTMA- and OTMA-JP A030) and five times the CEC for TMA+ cations to force complete exchange. The solid/liquid ratio was 1 g clay in 100 mL of the sorbate solution. The clay was carefully dispersed in deionized water using a magnetic stirrer at 60 °C and the organic solution was slowly added into the clay suspension under agitation. The reaction mixture was intensively stirred for 2 h (TMA-JP A030 for 24 h) at 60 °C. Then it was left to stand at room temperature for 24 h, after decantation the solution was replaced with fresh organic solution. The formed white precipitate was isolated by filtration and all organoclay products were washed free of bromide and chloride anions, dried in air first at room temperature, then at 50 °C and ground to particles smaller than 200 μm.

Techniques

Mechanochemical treatment of 5 g dry powder of parent clay and organoclays was performed in a high-energy TB-1 planetary mill (Kadaň Ltd., Slovakia) with two stainless steel jars cooled with water during operating (1.7 kW, 890 rpm). 90 chromium steel balls (8 mm diameter) and jars (0.3 dm3 volume) were used for grinding. The ball to powder mass ratio was 40:1. The centrifugal force under these conditions was 60 g. The time of grinding varied from 1 to 20 min.

The X-ray powder diffraction (XRD) profiles were recorded on a Philips PW 1050 diffractometer (Cu-Kα radiation, Ni filter, 35 kV/20 mA).

The morphology of the samples was studied by scanning electron microscopy using a CARL ZEISS-EVO 40 HV microscope. Before scanning process, all samples were coated with gold to enhance the electron conductivity. Selected samples were examined by energy dispersive X-ray analysis (EDX) with spectrometer QUANTAX 400 to analyse the chemical composition in the samples coated with carbon.

The thermogravimetric analysis (TG) and derivative thermogravimetry (DTG) were carried out on a Mettler TG50 thermobalance equipped with a TClOA processor (sample mass ~10 mg; 35–1000 °C; heating rate 30 °C/min; dynamic nitrogen atmosphere with flowing rate 20 mL/min) and evaluated by Mettler Toledo Star SW 7.01 software.

Results and discussion

X-ray diffraction analysis

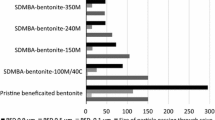

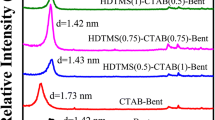

Figures 1, 2, 3, 4 show the XRD profiles of the original and mechanochemically treated clay and organoclays. All patterns indicate the presence of montmorillonite and a few wt% of ancillary quartz (Q) which has the most intense diffraction (101) with d 101 = 0.33 nm and diffraction (112) with d 112 = 0.18 nm. According to Makó et al. [25] high content of quartz causes the acceleration of mechanochemical activation of kaolinite. Similar effect of acceleration can be expected for montmorillonite in bentonite JP A030. The traces of starting material JP A030 display symmetric (001) diffractions with d 001 = 1.49 nm. This value corresponds to the sum of the height of a montmorillonite’s layer and a gallery and it is typical for Ca-montmorillonite containing calcium cations surrounded by two layers of water molecules. The arrangement adopted by the intercalated alkylammonium ions depends on the charge of the silicate layers and on the length of the alkyl chain. Alkylammonium ions adsorbed on smectites are typically arranged as monolayers (d 001 ~ 1.35 nm), bilayers (d 001 ~ 1.76 nm), pseudo-trimolecular (d 001 ~ 2.17 nm) or paraffin-type (d 001 > 2.20 nm) structures. TMA- and OTMA-JP A030 with d 001 of 1.40 and 1.43 nm correspond to monomolecular arrangement. These values are slightly lower than that of parent JP A030 in consequence of displacing water molecules from the interlayer space by intercalation of organic cations. ODTMA-JP A030 corresponds to pseudo-trimolecular arrangement, where some chain ends are shifted above one another, and the spacing of 2.10 nm becomes the thickness of the layer with three alkyl chains in the gallery. Intercalation of organic surfactants with short alkylammonium chains between the clay layers only changed the surface properties from hydrophilic to hydrophobic, while long-chain ODTMA+ cations also significantly increased the basal spacings.

Diffraction with d 060 = 0.149 nm is characteristic for dioctahedral smectites. Both diffractions (001) and (060) provide information on the periodicity of the montmorillonite structure perpendicular to the layers and in the layers, respectively, in various stages of decomposition upon grinding. The structure of all materials suffers significant degradation during the prolonged grinding process. Diffraction (001) disappears from the XRD patterns after following grinding times: JP A030 2 min, OTMA- and TMA-JP A030 5 min, ODTMA-JP A030 10 min. Diffraction (060) becomes extinct for all samples except for ODTMA-JP A030 after 5 min. It seems that presence of quartz or lower content of montmorillonite in bentonite JP A030 in comparison with Ca-form of JP [26] does not affect the structural stability of montmorillonite towards grinding.

Scanning electron microscopy and EDX analysis

SEM micrographs of all original and 5 min ground materials characterising the morphological changes of different samples are shown in Fig. 5. Mechanochemical treatment destroys the original particle shape of clay and organoclays and produces particles with a spherical shape and reduced size formed mainly in globular ragged agglomerates. The product of 5 min ground ODTMA-JP A030 is much less destroyed than the JP A030 and other organic samples ground in the same way. The particle size reduction is not as significant as that obtained for organoclays with shorter alkylammonium chains.

The semiquantitative elemental analysis of the clays surface provided by EDX detects elements creating the structure of montmorillonite: Si, Al, O, Mg, Ca, Na, K and Fe (Fig. 6). Au and C are associated with the coating of samples before testing, which has an influence on the amount of C in organoclays. Although the parent material JP A030 is produced from non-activated bentonites selectively extracted and processed, it is not a homoionic form; it contains mainly hydrated Ca2+ cations but also exchangeable Mg2+, Na+ and K+ cations. The source of K+ can be in feldspars which are one of the auxiliary materials in JP A030 bentonite. Ca band disappears from EDX spectra of samples after organic modifications; Na and K bands are still present as well as Mg2+; however, Mg2+ is also in montmorillonite layers. This confirms successful ion exchange on the expense of Ca2+ cations. The higher contents of iron and chromium appear in samples JP A030, TMA- and OTMA-JP A030 after 20 min of grinding in consequence of contamination during the grinding process. These results clearly demonstrate that the modification with long-chain ODTMA+ cations could alleviate the problem related to the contamination of the compound during the mechanochemical treatment in planetary ball mills.

Thermogravimetric analysis

Figures 7, 8, 9, 10 show the thermogravimetric (TG) and derivative thermogravimetric (DTG) curves of parent material JP A030, organoclays and their ground products. The TG curve of bentonite has three mass loss steps, the first and the second occur between 80 and 150 °C and the third at about 650 °C, corresponding to the peaks on the DTG curves. These mass loss steps are attributed to desorption of free water from the particle surfaces, dehydration of the hydrated cations in the interlayers and the loss of OH units through dehydroxylation of the montmorillonite layers (structural water), respectively [27]. Thermal decomposition of bentonite modified with the quaternary ammonium surfactants takes place in more mass loss steps.

The maximum of peak representing the release of free surface water of JP A030 appears at 90 °C and evolving of interlayer water has a maximum at 125 °C. However, the dehydration of bentonite is not completely finished until about 150 °C; some mass loss is also observed over the temperature of 200 °C on the TG curve. After 1 min grinding both dehydration peaks coalesce into one peak with maximum at 90 °C. Dehydroxylation peak initially at 685 °C shifts to lower temperatures (645 °C) after 1 min and disappears after 2 min of grinding. This is connected with breaking of the bonds between the adjacent montmorillonite layers. After 5 min of treatment, the material obtained is highly amorphous, the water is the only component releasing from JP A030 and its release is continual. Supposed that dehydroxylation process of montmorillonite occurs between 500 and 800 °C, the unground sample contains 4.6% of structural water, which corresponds well to the structural formula of Jelšový Potok montmorillonite [28]. The amount of structural water strongly decreases with grinding for 1, 2, 5, 10 and 20 min to 2.6, 2.15, 2.0, 2.2 and 1.6%, respectively, what is related with rapid amorphization of the materials.

The TG and DTG curves of all unground organoclays show the first step attributed to desorption of water shifted to lower temperature because of hydrophobic character of organoclays. The last step, assigned to the loss of structural hydroxyl groups from the organoclays, is shifted to lower temperatures as well. It is clearly seen that the amount of water in organoclays reduces as the size of the organic cation increases (Figs. 8, 9, 10). The second dehydration step does not occur on the curves of any analysed organoclays, as they do not probably contain hydrated cations in their galleries. Next thermal peaks in the range of 200–500 °C on the DTG curve do not occur for the parent bentonite, and represent desorption of the surfactant molecules from the surface of the clay particles. The temperature of this release is higher than the boiling point of surfactants [29]. The maximum of the single peak attributed to the removal of TMA surfactant is at 475 °C, showing that TMA-JP A030 is the organoclay with the highest thermal stability among the organoclays used in this work. First dehydration peak on the DTG curve of TMA-JP A030 sample occurs at 75 °C and dehydroxylation peak at 625 °C (Fig. 8). While the mass loss of the parent JP A030 is about 5% for dehydration, for TMA-JP A030 bentonite it is less than 1.5%. 2-min treatment causes intensity decrease and downward shift of all peaks; mainly the peak of surfactant release becomes broader and shifted to lower temperatures. Dehydroxylation peak disappears after 5 min of grinding.

Three conspicuous peaks appear on the DTG curve of OTMA-JP A030 at 255 and 440 °C for desorption of organic cations and at 640 °C for dehydroxylation of organoclay (Fig. 9). Two successive peaks in the temperature range 250–500 °C may reveal that the release of OTMA surfactant is from different mechanisms than that of TMA. Almost invisible peak of surface water desorption appears at 100 °C and corresponds to the first step on the TG curve with mass loss of 1%. All these peaks are completely changed after 1 min of grinding. The dehydroxylation peak becomes extinct; the peak near 440 °C is the clearest and slightly shifted to lower temperatures and a broad peak appears near 200 °C. Only two sharp peaks remain on the DTG curve after 2 min treatment. The peak near 140 °C is caused by release of water molecules adsorbed from mill atmosphere. Further grinding deepens the changes on DTG curves of material and downward shifts desorption processes of water and organic molecules. 10 min of mechanochemical treatment produces material totally ground to fine powder capable to adsorb air humidity more easily. It is displayed in the sharp peak near 100 °C. Desorption of organic cations is shifted to about 300 °C, similarly to the sample ground for 20 min. A new broad peak is observed at relatively high temperature above 800 °C, where most likely CO2 is released or some high temperature reactions of the carbon run through [17].

Three-fold peak in the range of 250–500 °C, assigned to a loss of surfactant, changes the intensity during the whole grinding process and appears as the most distinctive on the DTG curve of ODTMA-JP A030 (Fig. 10). With increasing length of organic cations, the DTG curves of the organoclays become more complex with more types of bonding of surfactant molecules, which corresponds with the results obtained from XRD analysis mentioned above (monolayers, pseudo-trimolecular arrangement). Dehydroxylation is presented by a broad peak near 600 °C with mass loss of about 3.4% and the dehydration peak is negligible with mass loss of less than 0.5% in this material. The amount of hydration water increases with the increase of the grinding time. Mass loss step of dehydration is about 1% after 2 min, 1.4% after 5 min, 2.2% after 10 min and 2.4% after 20 min of grinding. However, in consequence of degradation of montmorillonite structure, the amount of structural dehydroxylation water decreases with the increase of grinding time. The decomposition process of organic molecules is still separated on the TG/DTG curve in two peaks after 20 min of grinding, but opposite tendency of intensity of individual peaks is observed. The first peak apart on two of the DTG curve is united after 1 min of grinding and mass loss on TG curve for responsible step decreases from 18 to 6.8% upon grinding. The intensity of the second peak due to the removal of organic molecules increases with grinding time as well as increases mass loss from 9.4 to 15% and the maximum of this peak is shifted to 410 °C. In conclusion, a range of interesting results is observed; however, not all are currently understandable. More extensive interpretation of thermal decomposition of organoclays and their ground products is not possible without combination of TG with another analyser such as mass spectrometer or infrared spectrometer.

Conclusions

All organoclays used in this work are more resistant against mechanical destruction upon dry grinding than the initial JP A030; ODTMA-JP A030 seems to be the most resistant among the organoclays. DTG and TG analysis confirm hydrophobic character of organoclays, which increases with raising length of alkyl chains and decreases with prolonged grinding. The molecular structure, such as alkyl chain length, is also the determining factor of the thermal stability of organoclays. The release of organic compounds from organoclays is staged and shows the different mechanisms in dependence on length of alkyl chains and their arrangement in interlayer. Grinding causes significant changes in releasing of organic compounds from organoclays investigated by thermal analysis. SEM micrographs showed that the particles of ODTMA-JP A030 got less damaged than those of JP A030, TMA- and OTMA-JP A030 upon grinding. Organoclays modified by long-chain alkylammonium cations do act as a lubricant and protect material before friction during grinding in high-energy planetary ball mill. Our results suggest that structural changes induced by grinding are highly influenced by character of organic surfactant and the length of alkylammonium chain. Modification of bentonite with quaternary ammonium salts leads to deceleration of deformation and amorphization of the montmorillonite structure.

References

He M, Wang Y, Forssberg E. Slurry rheology in wet ultrafine grinding of industrial minerals: a review. Powder Technol. 2004;147:94–112.

Boldyrev VV. Mechanochemistry and mechanical activation of solids. Russ Chem Rev. 2006;75:177–89.

Heinicke G. Tribochemistry. Berlin, Germany: Akademie Verlag; 1984.

Indris S, Bork D, Heitjans P. Nanocrystalline oxide ceramics prepared by high-energy ball milling. J Mater Synth Process. 2000;8:245–50.

Billik P, Plesch G. Mechanochemical synthesis of anatase and rutile nanopowders from TiOSO4. Mater Lett. 2007;61:1183–6.

Haber J, Zazhigalov VA, Stoch J, Bogutskaya LV, Batcherikova IV. Mechanochemistry: the activation method of VPO catalysts for n-butane partial oxidation. Catal Today. 1997;33:39–47.

Suryanarayana C, Ivanov E, Boldyrev VV. The science and technology of mechanical alloying. Mater Sci Eng A Struct. 2001;304:151–8.

Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci. 2001;46:1–184.

Mingelgrin U, Kliger L, Gal M, Saltzman S. The effect of grinding on the structure and behavior of bentonites. Clays Clay Miner. 1978;26:299–307.

Yariv S, Lapides I. The effect of mechanochemical treatments on clay minerals and the mechanochemical adsorption of organic materials onto clay minerals. J Mater Synth Process. 2000;8:223–33.

Pshinko GN, Timoshenko TG, Kornilovich BY, Terlikovskii EV. Sorption purification of 90Sr and its immobilization on ceramic matrices. J Water Chem Technol. 2007;29:144–51.

Dellisanti F, Valdre G, Mondonico M. Changes of the main physical and technological properties of talc due to mechanical strain. Appl Clay Sci. 2009;42:398–404.

Theng BKG. The chemistry of clay-organic reactions. London: Adam Hilger; 1974.

Alther G. Using organoclays to enhance carbon filtration. Waste Manag. 2002;22:507–13.

Alther G. Removing oil from water with organoclays. Filtr Sep. 2008;45:22–4.

Hrachová J, Komadel P, Chodák I. Natural rubber nanocomposites with organo-modified bentonite. Clays Clay Miner. 2009;57:444–51.

Xie W, Gao Z, Liu K, Pan WP, Vaia R, Hunter D, et al. Thermal characterization of organically modified montmorillonite. Thermochim Acta. 2001;367:339–50.

Araújo EM, Barbosa R, Morais CRS, Soledade LEB, Souza AG, Vieira MQ. Effects of organoclays on the thermal processing of PE/clay nanocomposites. J Therm Anal Calorim. 2007;90:841–8.

Leszczynska A, Pielichowski K. Application of thermal analysis methods for characterization of polymer/montmorillonite nanocomposites. J Therm Anal Calorim. 2008;93:677–87.

Hlavatý V, Fajnor VŠ. Thermal stability of clay/organic intercalation complexes. J Therm Anal Calorim. 2002;67:113–8.

Xi Y, Frost RL, He H. Modification of the surfaces of Wyoming montmorillonite by the cationic surfactants alkyl trimethyl, dialkyl dimethyl, and trialkyl methyl ammonium bromides. J Colloid Interface Sci. 2007;305:150–8.

Hedley CB, Yuan G, Theng BKG. Thermal analysis of montmorillonites modified with quaternary phosphonium and ammonium surfactants. Appl Clay Sci. 2007;35:180–8.

Önal M, Sarıkaya Y. Thermal analysis of some organoclays. J Therm Anal Calorim. 2008;91:261–5.

Zidelkheir B, Abdelgoad M. Effect of surfactant agent upon the structure of montmorillonite. X-ray analysis and thermal analysis. J Therm Anal Calorim. 2008;94:181–7.

Makó É, Frost RL, Kristóf J, Horváth E. The effect of quartz content on the mechanochemical activation of kaolinite. J Colloid Interface Sci. 2001;244:359–64.

Hrachová J, Madejová J, Billik P, Komadel P, Fajnor VŠ. Dry grinding of Ca and octadecyltrimethylammonium montmorillonite. J Colloid Interface Sci. 2007;316:589–95.

Fajnor VŠ, Jesenák K. Differential thermal analysis of montmorillonite. J Therm Anal Calorim. 1996;46:489–93.

Hrachová J, Chodák I, Komadel P. Modification and characterization of montmorillonite fillers used in composites with vulcanized natural rubber. Chem Papers. 2009;63:55–61.

Xi Y, Martens W, He H, Frost RL. Thermogravimetric analysis of organoclays intercalated with the surfactant octadecyltrimethylammonium bromide. J Therm Anal Calorim. 2005;81:91–7.

Acknowledgements

The authors are grateful to the Slovak Grant Agency VEGA (Grant 2/6177/06) and the Slovak Research and Development Agency (Grant APVV-51-050505) for financial support and Materials and Engineering Research Institute (MERI) at Sheffield Hallam University (UK) for technical support of TG/DTG equipment. Dr. Peter Komadel is acknowledged for his helpful comments on this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hrachová, J., Billik, P. & Fajnor, V.Š. Influence of organic surfactants on structural stability of mechanochemically treated bentonite. J Therm Anal Calorim 101, 161–168 (2010). https://doi.org/10.1007/s10973-009-0575-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0575-5