Abstract

The objective of this research was to investigate the effect of different clay composition and concentrations on the thermal behaviour and kinetics of heavy crude oil in limestone matrix by thermogravimetry (TG/DTG). In TG/DTG experiments, three distinct reaction regions were identified in all of the crude oil + limestone mixture known as low temperature oxidation (LTO), fuel deposition (FD) and high temperature oxidation (HTO) respectively. Addition of clay to porous matrix significantly affected the reaction regions. Significant reduction of activation energy due to addition of clay to crude oil indicates the catalytic effect of clay on crude oil combustion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, thermal analysis techniques became highly important research tools for crude oil characterization and combustion. Differential scanning calorimeter (DSC), thermogravimetry (TG/DTG), differential thermal analysis (DTA) techniques have been used as screening tools for crude oil combustion. Vossoughi and El-shoubary [1] studied the effect of sand, silica and kaolinite on crude oil combustion. Three distinct regions namely distillation and two combustion/cracking regions were observed. Significant reduction of activation energy was caused by addition of kaolinite to crude oil. Burger and Sahuquet [2] studied the effect of some metallic derivatives on crude oil combustion by differential thermal analysis (DTA). Three reaction regions were observed in DTA curves namely low temperature partial oxidation, combustion of crude oil fraction and coke combustion. Fassihi et al. [3] studied crude oil combustion in sand pack containing clay. They observed a significant effect of clay on frontal behavior. Higher fuel deposition found in the presence of clay due to its absorption characteristics. Hardy and Raiford [4] studied crude oil combustion in the presence of 95–5% quartz-kaolinite mixtures by differential thermal analysis (DTA). They observed similar curves to the mixture of natural core crude oils. Rashidi and Bağcı [5] studied the effect of clay on the combustion of crude oils at different pressures. It was observed that more fuel was deposited as the clay content increased. Uniform trend of decrease in activation energy of the crude oils samples were observed as the clay content increased. Kok et al. [6–18] applied differential scanning calorimetry (DSC) and thermogravimetry (TG/DTG) on fossil fuel combustion and pyrolysis. Three distinct reaction regions were identified in all crude oil samples studied, known as low temperature oxidation, fuel deposition and high temperature oxidation. Effect of heating rate, metallic additives and clay content on the kinetics of the other fossil fuel samples were also studied by different kinetic models.

Experimental

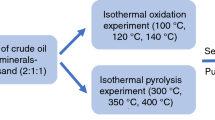

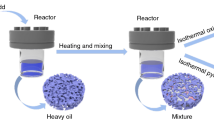

In this research low °API gravity of crude oil (15 mass% crude oil) in limestone matrix was studied by thermogravimetry, with the addition of different clay concentrations (5, 10 and 20 mass%). Properties of crude oil, limestone and the chemical analysis of the clay samples are given in Tables 1, 2, respectively.

Thermal analysis experiments were performed TA 2000 thermal analysis system with thermogravimetry (TG/DTG) module. The experiments were carried out with a sample size of ~10 mg and airflow rate through the sample was kept constant at 50 ml/min. Experiments were conducted in the temperature range of 20–900 °C at 10 °C min−1 heating rate. Prior to experiments, it was essential to calibrate the balance for buoyancy effects for the quantitative estimation of mass changes. The material chosen for the investigation of such effects was silver. TG/DTG was also calibrated for temperature readings with calcium oxalate monohydrate. Duplicate experiments were performed to ensure reproducibility.

Results and discussion

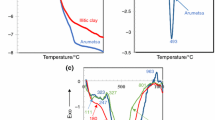

Theoretically, combustion of crude oil can be initiated whenever oxygen comes in contact with fuel. Temperature, composition of the fuel and the oxygen supply dictate the nature of combustion of crude oil in different matrix. In combustion reactions of heavy crude oil sample, three distinct reaction regions were identified (Fig. 1). A reaction up to ~375 °C is known as low temperature oxidation (LTO). This region is characterized by the low levels of carbon oxides in the effluent gas stream and low peak temperatures. A second reaction region which is observed between ~375 and 490 °C, is called fuel deposition (FD). During this reaction the crude oil is coked and deposited on the solid matrix as fuel. The third reaction which takes place between ~490 and 590 °C contributes most of the exothermic heat of reaction known as high temperature oxidation (HTO).

It is known that, clay fractions of the reservoir matrix possess the highest surface area and catalytic properties toward various organic fluids. In crude oil with treated clay samples; three different reaction regions known as low temperature oxidation (LTO), fuel deposition (FD) and high temperature oxidation (HTO) are observed only in 5 mass% mixture. In 10 and 20 mass% mixtures, fuel deposition region is merged with high temperature oxidation region same as in crude oil with non-treated clay samples. On the other hand, in crude oil with test clay samples; fuel deposition region is observed in all mixtures (Figs. 2, 3 4). It is observed that the addition of clay to porous matrix significantly affects the fuel deposition and high temperature oxidation regions. Reaction intervals of the samples are given in Table 3. The peak and burn-out temperatures of samples did not change significantly with addition of different clay contents.

The mass loss values of the samples in different reaction regions were also studied. It was observed that the mass loss in low temperature oxidation region were in the range of 5.42–12.56% and in high temperature oxidation region 5.0–10.8% respectively. The reaction region which is observed in the temperature range of ~600–840 °C is related to the decomposition of limestone, and the average mass loss was around 30% in this region (Table 4).

Kinetic analysis

Mass loss kinetics during crude oil combustion is a complex phenomenon since numerous reactions proceed simultaneously, therefore the kinetic data calculated should be regarded as apparent data representing complex and consecutive reactions.

In Arrhenius model [13], it is assumed that the rate of mass loss of the total sample is dependent only on the rate constant, the mass of the sample remaining and the temperature with reaction order of unity. Application of this model to the TG/DTG curves is easy and fast. So the equation of Arrhenius-type kinetic model takes the following form. The rate equation of thermal decomposition of dolomite is given by;

where α is the amount of sample undergoing the reaction, n is the order of reaction and k is the specific rate constant. The temperature dependence of k is expressed by the Arrhenius equation:

In this model, rate of mass change with respect to time is equal to:

Assuming first-order kinetics,

where T = temperature (K); A = pre-exponential factor (s−1); R = gas constant (8.314 J mol−1K−1); E = activation energy (kJ mol−1); dw/dt = the loss in mass from unit area in the period of time, n is the reaction order and assumed as unity. When log [(dW/dt)/W] is plotted against 1/T, a straight line is obtained which will have a slope equal to E/2.303R where activation energy can be obtained.

In general, some metallic additives and clay present in matrix exerts a catalytic influence on the reactions. Therefore, the presence of clay in matrix can influence the kinetic parameters. Activation energy values of the low temperature oxidation region varied between 5.9 and 14.1 kJ/mol for all the samples studied and seems to be affected by clay in the mixture. On the other hand, activation energies generated for the high temperature oxidation region for crude oil and crude oil/clay mixtures are in the range of 56.3–98.6 kJ/mol. As the clay content in the porous matrix increased from 5 to 20 mass%, activation energy values are decreased which is the indicative of catalytic properties of clay. It was observed that, non-treated clay type influenced the kinetic parameters more than the other clay types (Table 5; Figs. 5, 6, 7).

Conclusions

In this research, non-isothermal combustion and kinetic analysis of crude oil in limestone matrix was studied with different clay concentrations. The following conclusions were derived from the research conducted.

-

In TG/DTG experiments, a series of reactions were observed during the oxidation of crude oil in porous media by air injection known as, low temperature oxidation (LTO), fuel deposition (FD) and high temperature oxidation (HTO) reactions. It is observed that the addition of clay to porous matrix significantly affects the reaction regions.

-

Arrhenius kinetic methods were applied and the kinetic parameters are determined for LTO and HTO regions. It was observed that as the clay content in the porous matrix increased from 5 to 20 mass%, activation energy values are decreased which is the indicative of catalytic properties of clay.

References

Vossoughi S, El-shoubary Y. Kinetics of crude oil coke combustion. SPE Reserv Eng. 1989;8:201–6.

Burger JG, Sahuquet BC. Chemical aspects of in situ combustion: heat of combustion and kinetics. Soc Pet Eng J. 1972;5:410–22.

Fassihi MR, Ramey HJ, Brigham WE. Reaction kinetics of in situ combustion. Soc Pet Eng J. 1984;24(4):399–407.

Hardy WC, Raiford JD. High recovery in oil sands fire-flood optimization. World Oil. 1976;182(1):80–8.

Rashidi F, Bağci S. Effect of clay on crude oil combustion. 5th UNITAR International Conference on Heavy Crude and Tar Sands, Caracas 1992; 10(3): 323–7.

Kok MV, Letoffe JM, Claudy P, Martin D, Volle JL. Comparison of wax appearance temperatures of crude oils by differential scanning calorimetry, thermomicroscopy and viscometry. Fuel. 1996;75(7):787–90.

Kok MV, Karacan O. Pyrolysis analysis and kinetics of crude oils. J Therm Anal Calorim. 1998;52:781–8.

Kok MV, Karacan O, Pamir R. Kinetic analysis of oxidation behavior of crude oil SARA constituents. Energy Fuels. 1998;12(3):580–8.

Kok MV, Keskin C. Comparative combustion kinetics for in situ combustion process. Thermochim Acta. 2001;369(2):143–7.

Kok MV. An Investigation into the combustion curves of lignites. J Therm Anal Calorim. 2001;64(3):1319–23.

Altun E, Kok MV, Hicyilmaz C. Effect of particle size and heating rate on the pyrolysis of Silopi asphaltites. J Therm Anal Appl Pyrolysis. 2003;67:369–79.

Altun E, Kok MV, Hicyilmaz C. Effect of particle size and heating rate on the combustion of Silopi asphaltite. Energy Fuels. 2002;16(3):785–90.

Kok MV. Non-isothermal kinetic analysis and feasibility studies of medium grade crude oil field. J Therm Anal Calorim. 2008;91(3):745–8.

Altun E, Kok MV. Investigation of the influence of pressure on the combustion of Alpagut lignite. J Therm Anal Calorim. 2008;94(1):235–40.

Kok MV. Recent developments in the application of thermal analysis techniques in fossil fuels. J Therm Anal Calorim. 2008;91(3):763–73.

Kok MV. Heating rate effect on the DSC kinetics of oil shales. J Therm Anal Calorim. 2007;90(3):817–21.

Kok MV, İscan AG. Oil shale kinetics by differential methods. J Therm Anal Calorim. 2007;88(3):657–61.

Kok MV. Non-isothermal DSC and TG/DTG analysis of the combustion of Silopi asphaltites. J Therm Anal Calorim. 2007;88(3):663–8.

Acknowledgements

The authors would like to express their appreciation for the financial support of TUBITAK (The Scientific and Technological Research Council of Turkey).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kok, M.V., Gundogar, A.S. Effect of different clay concentrations on crude oil combustion kinetics by thermogravimetry. J Therm Anal Calorim 99, 779–783 (2010). https://doi.org/10.1007/s10973-009-0377-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0377-9