Abstract

The aim of this study was to use DSC and X-ray diffraction measurements to determine the pore size and pore wall thickness of highly ordered SBA-15 materials. The DSC curves showed two endothermic events during the heating cycle. These events were due to the presence of water inside and outside of mesopores. The results of pore radius, wall thickness and pore volume measurements were in good agreement with the results obtained by nitrogen adsorption measurement, XRD and transmission electron microscopy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the 90’s years researchers of the Mobil Oil Corporation developed a new family of ordered mesoporous sílica/aluminosilicate and designated this family of mesoporous materials as M41S [1, 2]. This discovery has, indeed, inspired scientists on a global scale to research creatively into the characterization, design, synthesis, modification, and application of these materials [3–5].

Since the pioneering research of Mobil scientists a whole new range of mesoporous materials have been synthesized. Recently, block copolymers have been used for synthesis of mesoporous materials, such as SBA-15 [6, 7] block copolymer template have been used for synthesis of mesoporous silica with large ordering and a variety of morphologies. Depending on the polymers used as template and synthesis process mesopores with different structures, however, with uniform pore diameters between 10 and 30 nm were formed. This silica is useful for application running from microelectronics to medical diagnosis, opening a wide variety of utilities beyond the traditional areas of materials for catalysis and absorbers [1–7].

Thermoporometry is a method of textural characterization which is based on the thermal analysis of the liquid-solid transformation of a pure capillary condensation inside the porous [8]. Recent articles report the low temperature constant rate thermodesorption as a tool to characterize porous solids [9, 10], melting and freezing behavior of water [11], benzene and cyclohexane [12] inside ordered mesoporous materials. Other techniques of thermal analysis were also used as tools to estimate the surface area and porous volume in ordered mesoporous materials [13, 14]. Thermoanalytical techinques have also been used for sorption studies [15], characterization of mesoporous materials synthesized in different matrices [16], and determination of acid properties of semicristaline zeolitic mesoporous UL-ZSM-5 aluminesilicate [17].

From the synthesis of these materials with open cylindrical mesopores of uniform size it was possible to evaluate textural properties. The aim of this study was to use this technique to evaluate pore radius, wall thickness and porous volume of highly ordered mesoporous SBA-15 silica completed with the results of XRD studies, and comparing these results with those obtained by nitrogen adsorption and HRTEM.

Experimental

Materials

SBA-15 silica was synthesized as reported by Zhao et al. [6, 7], using Pluronic P123 triblock copolymer (EO20PO70EO20) in acid media. DSC curves were recorded in a DSC-50 cell (Shimadzu) using open aluminum crucibles with about 20 mg of sample (SBA-15 silica + water, 1:3 in mass) under dynamic nitrogen atmosphere (100 mL min−1) and cooling rate of 0.5 K min−1 from room temperature to 223 K and heating at a heating rate of 0.5 K min−1 to 298 K. DSC cell was cooled down using controlled liquid nitrogen flow by the aid of a TAC-50 (Shimadzu) cooling unit.

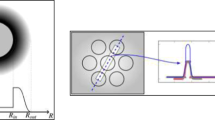

The small angle X-ray diffraction studies (XRD) were carried out using a rotating anode at 10 kW. The wavelength of the copper monochromatic X-ray beam was λ = 1.5418 Å. An image plate detector was utilized to record the scattering vector q = (4πsin θ)/λ, where θ denotes the half the scattering angle. The intensity was recorded for 1 h.

The pore width and pore wall thickness of SBA-15 were evaluated from the XRD unit cell parameter and primary mesopore volume using the geometrical method [18].

Adsorption isotherms were measured with Micromeritics ASAP 2010 volumetric adsorption analyzer using nitrogen of 99.998% purity. Measurements were performed in the range of relative pressure from 10−6 to 0.99 liquid nitrogen on the samples degassed for 2 h under reduced pressure at 473 K. The specific surface area was evaluated using BET method [19]. The total pore volume was estimated from the amount adsorbed at the relative pressure of 0.99. The pore size distribution (PSD) was calculated using BJH algorithm [20], with the relation between the capillary condensation pressure and the pore diameter established by Kruk et al. [21].

For TEM observations, the samples were studied using a JEM-3010 (Cs) 0.6 mm, resolution 0.17 nm) at 300 kV. High resolution transmission electron microscopy (HRTEM) images were recorded with a slow scan CCD (Gatan 794). The SBA-15 sample was dispersed in isopropyl alcohol and put on a holey carbon film on a Cu grid.

Results and discussion

Figure 1 shows the diffractogram for the SBA-15 silica sample. The diffraction peaks were indexed for (100), (110), (200), (210) and (300) reflections based on a hexagonal structure, space group p6 mm [6, 7]. The interplanar spacing (d hkl ) and the lattice parameter (a) were calculated for the (100), (110), (200) and (210) reflections. Figure 2a shows that Nitrogen adsorption isotherm for SBA-15 sample is similar to those ones reported by Zhao et al. [6, 7] and, Kruk and Jaroniec [22]. The isotherm of SBA-15 sample has shown hysteresis loop with sharp adsorption and desorption branch. The sharpness of the branched adsorption is an indicative of a narrow porous size distribution (PSD) shown in Fig. 2b. The branched adsorption was located at relative pressures in the 0.64–0.8 range, a high relative pressure, similarly to good-quality mesoporous materials [21, 22]. The BET specific surface area of the SBA-15 sample was 610 m2 g−1 with pore size of 7.4 nm to the SBA-15 sample, these parameters were similar to the mesopore size for materials with honeycomb structures in good agreement with those reported by Zhao et al. [6, 7].

The uniform channels characteristics of the SBA-15 silica obtained was confirmed by the HRTEM image as shown in Fig. 3a. The pore size and the wall thickness average obtained were 6.7 and 6.1 nm, respectively, whose results were obtained by Fourier Transformed without image corrections (Fig. 3b). The DSC curve of water in SBA-15 sample exhibited two peaks upon heating. This event showed a sharp exothermic peak that corresponds to water melting inside mesopores at 260.03 K.

The second endothermic peak is observed at 271.88 K, regarding to the melting of water outside of the mesopores.

The first peak that corresponds to the melting point of water inside of mesopores (Fig. 4a) was used in Eq. 1 of Laundry [9] and Ishikiriyama et al. [23] to calculate the pore radius of the SBA-15 sample.

where, ∆T = (T 0 − T) is the decrease of melting temperature of water in mesopores and δm = 1.12 nm is the presence a thin film of non-freezable liquid adjacent to pore wall.

Total pore volume V p (e.g., cm3 g−1) is another important parameter for characterizing porous materials [9]. A simple calculation of V p can be made from a single thermoporometry heating experiment using the Eq. 2:

where liquid mass (m liq), water density (ρliq), porous solid mass (m sol), pore melt area (∆H porous) and excess melt peak areas (∆H Total) are parameters obtained from the DSC melt endotherms and their ratio is related to the fraction of liquid contained in the pores.

Equation 2 assumes a temperature-independent heat ∆H fusion and liquid density, as well as a sufficient separation of the pore and excess melt peaks to independently integrate their areas. It is also assumed that all of the liquid has frozen during the initial quench cooling step and melts during heating, i.e., the contribution of the thin liquid layer adjacent to pore walls and other non-frozen liquid is negligible. Figure 4b shows a porous size distribution with a mean radius of 4.25 nm. Applying a heating rate to a melting sample an turning a nearly known mass of water gives a measure of the amount of pore liquid undergoing phase transition.

Table 1 shows comparative results between pore size and wall thickness average, with were obtained by analysis of nitrogen adsorption isotherm, transmission electronic microscopy and thermoporometry. The values of these parameters clearly show that data obtained by thermoporometry showed estimated values near to ones those obtained by conventional methods.

Conclusions

The water melting temperature determined by DSC inside and outside the pores allowed us to evaluate the radii of mesopores and wall thickness of SBA-15 sample. The current study demonstrates that DSC studies are important for characterization of ordered mesoporous materials and to evaluate their textural and structural quality properties. It is possible to estimate the porous radius and volume, wall thickness and surface area, associating DSC, XRD and TEM techniques. DSC gives preliminary information on the material properties that can be useful to decide if they are worth to perform further characterization by nitrogen adsorption isotherm and TEM, which are more accurate techniques, but require longer analysis time and imply in much more expensive measurements.

References

Kresge CT, Leonowics ME, Roth WJ, Vartuli JC, Beck JS. Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature. 1992;359:710–2.

Beck JS, Chu CT, Johnson ID, Kresge CT, Leonowicz ME, Roth WJ, Vartuli JC. US Patent 5,108,725 to Móbil Corporation; 1992.

Corma A, Kumar D. In: Catlow R, Cheethan A, editors. New trends in materials chemistry, NATO ASI Series, vol 498. Dordrecht: Kluwer Academic Publishers; 1997. p. 403.

Sayari A, Liu P. Non-silica periodic mesostructured materials: recent progress. Microporous Mater. 1997;12:149–77.

Anotelli DM, Ying JY. Curr Opin Colloid Interface Sci. 1996;1:523.

Zhao DY, Feng JL, Huo QS, Melosh N, Fredrickson GH, Chmelka BF, et al. Science. 1998;279:548.

Zhao DY, Huo QS, Feng JL, Chmelka BF, Stucky GD. Nonionic triblock and star diblock copolymer and oligomeric surfactant syntheses of highly ordered, hydrothermally stable, mesoporous silica structures. J Am Chem Soc. 1998;120:6024–36.

Quinson JF, Brun M. Charact Porous Solids. 1988;39:548.

Laundry MR. Thermochim Acta. 2005;433:433.

Chevrot V, Llewellyn PL, Roquerol F, Godlewski J, Roquerol J. Low temperature constant rate thermodesorption as a tool to characterise porous solids. Thermochim Acta. 2000;360:77–83.

Schreiber AF, Ketelsen I, Findenegg GH. Melting and freezing of water in ordered mesoporous silica materials. Phys Chem Chem Phys. 2001;3:1185–95.

Dosseh G, Xia Y, Alba-Simionesco C. Cyclohexane and benzene confined in MCM-41 and SBA-15: confinement effects on freezing and melting. J Phys Chem B. 2003;107:6445–53.

Mercuri LP, Matos JR, Jaroniec M. Thermogravimetric estimation of adsorption properties of europium-incorporated MCM-41 materials. Thermochim Acta. 2002;383:79–85.

Mercuri LP, Matos JR, Jaroniec M. Improved thermogravimetric determination of the specific surface area for cerium-incorporated MCM-41 materials. J Alloys Compd. 2002;344:190–4.

Goworek J, Kierys A, Iwan M, Stefaniak W. Sorption on as-synthesized MCM-41. J Therm Anal Calorim. 2007;87:165–9.

Berezovska IS, Yanishpolskii VV, Tertykh VA. Synthesis of mesoporous silicas inside large pores of inorganic matrix. J Therm Anal Calorim. 2008;94:649–53.

Ungureanu A, Thang HV, On DT, Dumitriu E, Kaliaguine S. Acid properties of semicrystalline zeolitic mesoporous UL-ZSM-5 materials. J Therm Anal Calorim. 2007;87:417–22.

Kruk M, Jaroniec M, Sakamoto Y, Terasaki O, Ryoo R, Ko CH. Determination of pore size and pore wall structure of MCM-41 by using nitrogen adsorption, transmission electron microscopy, and X-ray diffraction. J Phys Chem B. 2000;104:292–301.

Brunauer S, Emmet PH, Teller E. Adsorption of gases in multimolecular layers. J Am Chem Soc. 1938;60:309–19.

Barret EP, Joyner LG, Halenda PH. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J Am Chem Soc. 1951;73:373–80.

Kruk M, Jaroniec M, Sayari A. Application of large pore MCM-41 molecular sieves to improve pore size analysis using nitrogen adsorption measurements. Langmuir. 1997;13:6267–73.

Kruk M, Jaroniec M. Characterization of the porous structure of SBA-15. Chem Mater. 2000;12:1961–8.

Ishikiriyama K, Todoki M, Motomura K. Pore size distribution (PSD) measurements of silica gels by means of differential scanning calorimetry: I. Optimization for determination of PSD. J Colloid Interface Sci. 1995;171:92–102.

Acknowledgements

The Authors acknowledge financial support from the Brazilian agencies FAPESP, CNPq and CAPES. The authors would like to thanks the LME/LNLS for technical support during electron microscopy work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cides da Silva, L.C., Araújo, G.L.B., Segismundo, N.R. et al. DSC estimation of structural and textural parameters of SBA-15 silica using water probe. J Therm Anal Calorim 97, 701–704 (2009). https://doi.org/10.1007/s10973-009-0334-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0334-7