Abstract

Samples of an organic–inorganic hybrid were prepared by solvolysis and polycondensation in formic acid of tetraethoxysilane and diethylbenzyl phosphonate, simultaneous with the oxidative polymerization of aniline. The thermal behavior of the samples in dynamic air atmosphere and non-isothermal conditions was determined by a coupled thermogravimetric/evolved gas analysis. Two significant thermal events were established: the elimination from the polymeric matrix of low mass molecules, respectively the thermooxidative degradation of the organic part of the matrix. The kinetic analysis was performed with the Flynn-Wall-Ozawa, Friedman and modified Non-Parametric-Kinetic methods. Only the last one allowed an objective analysis of the first process as a process of two simultaneous thermally induced phenomena with the kinetic functions of the type αm(1 − α)n.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The combination of organic and inorganic components into one certain material give them new and attractive properties [1–3].

Most of the properties of these materials are based on the synergism between the properties of the components, are a direct result from their chemical and structural composition and so they can be tailored. For instance, coatings based on organic–inorganic hybrid materials are capable to combine the flexibility and easy processing of polymers with the interesting properties of the inorganic part: hardness, thermal stability, electrical and electrochemical distinguished properties [4].

The combination of silica, organophoshorus compounds and polyaniline (PANI) is attractive because:

-

ceramics exhibits excellent mechanical and optical properties such as surface hardness, modulus, strength, transparency, high refractive index;

-

organophosphorous acids and their derivatives are highly promising coupling molecules that allow the anchoring of organic groups to inorganic solids [5];

-

PANI as conducting polymer is attractive due to its electrical and optical characteristics [6–9].

PANI/silica matrices have been obtained by sol–gel technique [10–12] and it was observed that it is difficult to polymerize aniline once the dried gel was obtained [13].

The topic of the present work is to investigate the thermal behavior of an hybrid organic–inorganic material obtained by a non-hydrolytic sol–gel method from tetraethoxysilane (TEOS), diethyl-benzyl phosphonate esther (DEBF) and aniline. The thermal behavior was investigate by the coupled TG-FTIR-EGA method and by a kinetic analysis of the TG data obtained in air under non-isothermal conditions. The immediate interest is on the thermal behavior in air, because such a material is dedicated to work in normal atmosphere. At higher temperature the oxygen has a significant degradative potential.

Experimental

Synthesis

The hybrids were prepared by the solvolysis and polycondensation of TEOS with DEBF, simultaneous with the oxidative polymerization of aniline. The formic acids plays two roles: non-aqueous solvent and catalyst for the polysilicate-poly-phosphonate network.

Reagent grade aniline, tetraethoxysilane, formic acid (Sigma Aldrich), ammonium peroxidisulphate (Merck) and diethyl-benzyl-phosphonate esther (Merck) were used as received, except aniline which was double distilled a priori to use.

The hybrid composites were obtained in one pot synthesis. First, in formic acid the oxidant (ammonium peroxidisulphate) was added and vigorously stirred until complete dissolvation. After this the aniline was added, the mixture vigorously stirred until the slightly blue color appears and then the TEOS and DEBF were added. The final mixture was stirred 5–30 min (depending on the quantity of DEBF added) at room temperature and the reaction was finished after 1 day at 75–85 °C. The quantities of reagents are presented in Table 1.

Thermal analysis

The thermoanalytical curves, i.e. TG, DTG, and DTA were obtained on a Perkin Elmer Diamond device, in dynamic air atmosphere (100 cm3 min−1), using Al crucibles. The measurements were performed at four heating rates: 10, 12, 15 and 20 °C min−1, in order to carry out a kinetic analysis.

Supplementary information on the decomposition process were obtained using the EGA technique, i.e. by coupling the furnance outlet to an IR gas chamber of a Perkin Elmer Spectrum 100 device. The FTIR spectra were analyzed by means of the Sadtler Gas Vapour Library.

Results and discussions

Thermal decomposition

The thermoanalytical curves at 10 °C min−1 for the prepared samples are presented in Fig. 1. The thermal behavior is rather similar: two decomposition steps, both endothermic, the first one in the range of 140–250 °C, the second between 250 and 350 °C and a total mass loss of 47–54%.

The peculiarities are in connection with the values of the DTG/DTA peaks and especially with the shape of the TG curves: by samples A1 and A2 there are two well-separated steps, whereas by A3 the first step presents one clear TG curve.

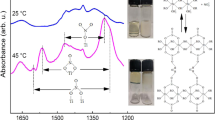

Regarding the EGA, in Fig. 2 one example is given and in Table 2 the significant data are summarized. Remarkable is the symmetry between the DTG and the Gramm-Schmidt curves.

According to the data in Table 2, the first process corresponds to the endothermic elimination of the low molecule of unreacted reagents (formic acid, respectively aniline) or secondary reaction products (primary alcohols).

Indeed, the initial step of solvolysis of TEOS and DEBF lead to ethanol as secondary reaction product (see Schemes 1, 2).

Not too surprising is the high amount of aniline in the E.G by sample A2. The absence of DEBF increases the solvolysis rate in formic acid, which already is higher in comparison with the rate of hydrolysis [14]. Therefore the gaps available for PANI trapping are small and the time available for the oxidative polymerization is short. Consequently an important quantity of aniline remain unreacted and untrapped inside the matrix, being easy eliminated.

Regarding the second process, a complex mixture of gases and vapours was evolved. The identification of carbon dioxide, water, benzoic acid and phenol is an indication of a more or less deep oxidative destruction of the organic component of the matrix, i.e. the benzyl radical.

Kinetic analysis

The kinetic analysis was performed on the first process of the thermal degradation. For the kinetic analysis a strategy based on three different methods was used, all of them in agreement with the ICTAC protocol 2000 [15]. This strategy was successfully used in a recent paper [16].

Considering isoconversional conditions, i.e. for a certain conversion αi the corresponding temperature Tij at different heating rates βj, the equation

allows to determine the activation energy (Ei) for each αi, when the data at different heating rates were processed. Because the conversion function g(α) is not explicit, the FWO method is considered a “model free” kinetic.

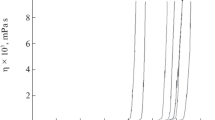

In Fig. 4. the variation of E vs. α is presented. The variation of E vs. α is rather significant. The integral methods take into consideration the “history” of the samples, therefore a main value of E would be of interest for a possible first discrimination between the samples.

The main values of E were 72.9 ± 24.8 kJ mol−1 for A1, 77.1 ± 23.7 kJ mol−1 for A2, respectively 79.4 ± 24.6 kJ mol−1 for A3 sample, this values being near. By means of the EGA, the first process was assigned to the elimination of low molecules entrapped in the matrix. This elimination process being rather similar by the three samples, the near value of E are not surprising, if E is considered a general characteristic of the thermal events.

-

(ii)

The differential method of Friedman [19]

At isoconversional conditions, the differential form of the reaction rate is

Being a differential method, this offer the actual value of E and a possible strong influence of α can be evidenced. According to Fig. 5 an important and non-monotonous variation of E vs. α is the case of our samples and this is a doubtless sign of a complex multi-step process. So, a more sophisticated method of data processing is necessary.

This method was selected due to some facilities proved in our previous papers [22–30].

Considering as a fundamental hypothesis that the reaction rate can be described by a product of two functions [a temperature dependent function f(T), respectively a conversion function g(α)] the proper value of the reaction rate at a temperature Ti and a conversion αj represents an element of matrix

Using the Singular Value Decomposition (SVD) [31], the matrix M is decomposed according to

A vector u1 given by the first column of the matrix U is analysed in respect of conversion; for this one we suggest the equation by Šestak-Berggren [32]:

A similar vector v1, corresponding to matrix V, is checked for an Arrhenius type temperature dependence.

In case of a multi-step process, the initial matrix M will be decomposed according to:

the contribution of each step to the observed process being expressed by the individual explained variance λi, so that \( \sum {\lambda_{\text{i}} } = 100\% \).

The results of data processing with this strategy are systematized in Table 3.

By inspecting the data in Table 3, the following observations are noticeable:

-

in all cases, the first process of the thermal degradation is a complex two step process;

-

by samples A1 and A3, containing DEBF, the kinetic behaviour is similar, (the values of E for the process 1 and 2 are very near) and from these two process, one depends on both α and (1 − α), the another depends only on (1 − α);

-

by A2 the two process presents significant different values of E and the conversion dependence is also different, i.e. one depends only on α, the another only on (1 − α).

This different kind of kinetic behaviour, the samples A1 and A3 on the one hand and the sample A2 on the other hand, can be in connection with the peculiarities of A2: synthesis without DEBF (high gelation rate), respectively majority aniline in the gases evolved by this process. But we consider that a deeper discussion or other attempts of correlation are risky with these data. However, by means of the NPK method it was possible to separate the two simultaneous steps of an apparent simple thermodegradation process.

Conclusions

By the thermal decomposition in air, under non-isothermal conditions, of an organic-inorganic hybrid containing silica, organic phosphonate and aniline, two processes were observed.

The first one corresponds to the elimination of low molecular compounds of reagents and/or secondary reaction products. By the sample prepared without the phosphonic ester, due to a high gelation rate, a great part of aniline is not polimerizated and is easy eliminated.

The second process correspond to the oxidative thermodegradation of the organic part of the hybrid matrix.

For a deeper and lees speculative understanding of processes involved by thermal decomposition under non-isothermal conditions of complex compounds, a kinetic analysis using different data processing strategies was necessary.

The NPK method allowed a separation between the temperature, respective the conversion dependence of a reaction rate and at the same time allowed an objective analysis of the relevance of the two steps of the first process, assigned to the endothermic elimination of small molecules.

References

Judeinstein P, Sanchez C. Hybrid organic–inorganic materials: a land of multidisciplinarity. J Mater Chem. 1996;6:511–26.

Loy DA, Shea KJ. Bridged polysilsesquioxanes. Highly porous hybrid organic-inorganic materials. Chem Rev. 1995;95:1431–42.

Sanchez C, Ribot F, Lebeau B. Molecular design of hybrid organic-inorganic nanocomposites synthesized via sol-gel chemistry. J Mater Chem. 1999;9:35–44.

Judeinstein P, Livage I, Zarudiansky JA, Rose R. An “all gel” electrochromic device. Solid State Ionics. 1988;28–30:1722–5.

Mutin PH, Guerrero G, Vioux A. Organic–inorganic hybrid materials based on organophosphorus coupling molecules: from metal phosphonates to surface modification of oxides. C.R. Chimie. 2003;6:1153–64.

Matsunaga T, Doifuku H, Nakajima T, Kawagoe T. Development of polyaniline-lithium secondary battery. Polym Adv Technol. 1990;1:33–9.

Duek EAR, De Paoli M-A, Mastragostino M. An electrochromic device based on polyaniline and prussian blue. Adv Mater. 1992;4:287–91.

Santhiyanarayanan S, Muthukrishnan S, Venkstachari G, Trivedi DC. Corrosion protection of steel by polyaniline (PANI) pigmented paint coating. Prog Org Coat. 2005;53:297–301.

Boonstra AH, Bernardes INM. The dependence of the gelation time on the hydrolysis time in a two-step SiO2 sol-gel process. J Non Cryst Solids. 1988;105:207–13.

Mattes BR, Knobble ET, Fuqua PD, Nishida F, Chang EW, Pierce BM. et al. Polyaniline sol-gels and their third-order nonlinear optical effects. Synth Met. 1991;43:3183–7.

de Azevedo WM, Brondani DJ. Formic acid an efficient solvent to prepare polyaniline/silicate glass composite using sol–gel technique. J Non Cryst Solids. 2001;296:224–9.

Ita M, Uchida Y, Matsui K. Polyaniline/silica hybrid composite gels prepared by the sol-gel process. J Sol-Gel Sci Technol. 2003;26:479–82.

Panitz IC, Wokaum A. Characterization of the sol-gel process using raman spectroscopy organically modified silica gels prepared via the formic acid-alkoxide route. J Sol-Gel Sci Technol. 1997;9:251–63.

Sharp GK. A two-component, non-aqueous route to silica gel. J Sol-Gel Sci Technol. 1994;2:35–41.

Brown ME, Maciejewski M, Vyazovkin S, Nomen R, Sempere J, Burnham A, et al. Computational aspects of kinetic analysis: Part A: The ICTAC kinetics project-data, methods and results. Thermochim Acta. 2000;355:125–43.

Vlase T, Doca N, Vlase G, Bolcu C, Borcan F. Kinetics of non-isothermal decomposition of three IRGANOX-type antioxidants. J Therm Anal Calorim. 2008;92(1):15–8.

Flynn IH, Wall LA. A quick, direct method for the determination of activation energy from thermogravimetric data. Polym Lett. 1966;4:323–8.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6.

Friedman HL. Kinetics of thermal degradation of char-foaming plastics from thermogravimetry: application to a phenolic resin. J Polym Sci. 1965;6C:183–95.

Serra R, Nomen R, Sempere J. The non-parametric kinetics a new method for the kinetic study of thermoanalytical data. J Thermal Anal Calorim. 1998;52:933–43.

Sempere J, Nomen R, Serra R. Progress in non-parametric kinetics. J Thermal Anal Calorim. 1999;56:843–9.

Vlase T, Vlase G, Birta N, Doca N. Comparative results of kinetic data obtained with different methods for complex decomposition steps. J Thermal Anal Calorim. 2007;88(3):631–5.

Vlase T, Vlase G, Doca N, Bolcu C. Comparative kinetic analysis with NPK method. J Thermal Anal Calorim. 2005;80:59–64.

Vlase T, Vlase G, Doca N. Thermal stability of food additives of glutamate and benzoate type. J Thermal Anal Calorim. 2005;80:425–8.

Vlase T, Vlase G, Doca N. Kinetics of thermal decomposition of alkaline phosphates. J Thermal Anal Calorim. 2005;80:207–10.

Ioiţescu A, Vlase G, Vlase T, Doca N. Kinetics of decomposition of different acid calcium phosphates. J Thermal Anal Calorim. 2007;88(1):121–5.

Vlase T, Vlase G, Modra D, Doca N. Thermal behaviour of some industrial and food dyes. J Thermal Anal Calorim. 2007;88(2):389–93.

Vlase G, Vlase T, Doca N. Thermal behavior of some phenitoine pharmaceuticals. J Thermal Anal Calorim. 2008;92(1):259–62.

Birta N, Doca N, Vlase G, Vlase T. Kinetic of sorbitol decomposition under non-isothermal conditions. J Thermal Anal Calorim. 2008;92(2):635–8.

Doca N, Vlase G, Vlase T, Ilia G. Thermal behavior of Cd2+ and Co2+ phenyl-vinyl-phosphonates under non-isothermal condition. J Thermal Anal Calorim. 2008;94(2):441–5.

Wall ME. ME. Singular value decomposition and principal component analysis. In: Berrar DP, Dubitzky W, Granzow M, editors. A practical approach to microarray data analysis, vol. 9. MA: Kluwer-Norwel; 2003; p. 91-109. LANL LA-UR-02.

Šesták J, Berggren G. Study of the kinetics of the mechanism of solid-state reactions at increasing temperatures. Thermochim Acta. 1971;3:1–12.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vlase, G., Vlase, T., Doca, N. et al. Thermal behavior of a sol–gel system containing aniline and organic phosphonates. J Therm Anal Calorim 97, 473–478 (2009). https://doi.org/10.1007/s10973-009-0216-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-009-0216-z