Abstract

Spectroscopic ellipsometry (SE) with its fast, precise, non-destructive and non-contact nature, working both ex situ and in situ, is the ideal characterization tool for thin films in terms of optical, struactural and electrical information obtained over wide application domains. The review aims to prove the versatility of such a powerful technique, starting with the basic knowledge of the ellipsometry, extending the application field from UV–vis-NIR to VUV and IR domains, and then advancing to the analyses of porosity, anisotropy, surface mapping and bowing parameter. The examples shown in this review illustrate the complementarity of ellipsometry with other characterization techniques, highlighting the sensitivity and the quality of the results especially in the domain of the sol–gel films.

Spectroscopic ellipsometry: all-in-one technique for a variety of material characteristics.

Highlights

-

Versatility of the ellipsometry is illustrated on sol–gel films.

-

SE, all-in-one technique, for the study of a variety of material characteristics.

-

Possibility to obtain optical constants on a large spectral range (0.193–33 μm) is shown.

-

Suitability of SE for anisotropy, porosity, vibrational, mapping, and bowing parameter analysis is presented.

-

Detailed complementary information is obtained combining SE with other characterization methods.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The light is a fascinating subject of study, even the ancient Greeks were intrigued by its nature. But only later in the 1600s there was a real progress in the understanding of the mathematical and physical principles of the light. This led to the study of the thin films in the early 1900s by employment of classical optics. The term “ellipsometry” was established only in the mid-1900s. The founder of the basic principles of ellipsometry is Paul Drude, which derived in 1887 the equations of ellipsometry, a remarkable achievement if we think that these equations are still used today. The model which describes the optical properties of metals is named after him. Despite its simplicity and its accuracy, ellipsometry was not so popular until 1970s, when ellipsometers moved from manually operated and hence very time-consuming to automate instruments. The first complete automation of spectroscopic ellipsometry (SE) was realized by Aspnes et al. [1] in 1975, followed in 1984 by the first real-time monitoring with a spectroscopic ellipsometer achieved by Müller and Farmer [2]. Development of computer technology led to an increase in the number of measurement data and degree of precision. It was just a matter of time until ellipsometry became the most essential characterization technique for coatings. With every development step ellipsometers led to a shorter measuring time and more precise analysis data, as the real-time instrument developed in 1990 by Kim et al. [3], which utilizes a photodiode array (PDA) detector, that allows simultaneous measurement of light intensities at multi-wavelengths.

Nowadays, application of ellipsometry in various domains is a current practice. From microelectronics to medicine and biology, ellipsometry is focused on improving accuracy and sensitivity, and on corroborating with complementary data obtained from multiple techniques [4].

Ellipsometry is an optical measurement technique that characterizes light reflection or transmission from a sample. The name “ellipsometry” is given by the polarized light which becomes “elliptical” upon light reflection. By measuring the change in polarization of the reflected light, ellipsometry determines the amplitude ratio (Ψ) and phase shift (Δ) between p- (parallel) and s- (perpendicular) polarized light waves. The values of these two ellipsometric parameters are measured in the ultraviolet, visible and infrared spectral ranges.

Ellipsometry is a non-destructive and non-contact measurement technique, which requires two conditions in order to perform a successful measurement on any sample, namely: (1) surface roughness of samples should be <30% of a measurement wavelength, otherwise the scattering occurs and the intensity of the reflected light will be reduced, making harder the determination of the polarization state, and (2) depending on the optical constants of samples, the incidence angles must be chosen in order to maximize the measurement sensitivity.

From the absolute values of Ψ and Δ is difficult to give an interpretation of measurement results, thus, construction of an optical model is needed for data analysis and to determine the physical properties of a sample. Ellipsometry allows the evaluation of the refractive index n and extinction coefficient k of the material under study, and the complex refractive index defined by \(\tilde N \equiv n - ik\) is determined. The complex dielectric constant \(\tilde \varepsilon\) and absorption coefficient α can also be obtained from the following relations: \(\tilde \varepsilon = \tilde N^2\) and\(\alpha = \frac{{4\pi k}}{\lambda }\), respectively.

Measurements carried out in different parts of the spectral domain give specific optical characteristics. In the UV–visible region, ellipsometry can characterize the interband transitions and make an estimation of the bandgap (Eg) from the variation of α with hυ, where h is the Planck’s constant, and υ is the light frequency. Moreover, from the spectral analysis of the optical constants, the alloy composition, crystal grain size and phase structure can be determined.

In the infrared spectral range, properties like lattice vibration modes (LO and TO phonon) can be determined by ellipsometry [5]. Determination of electrical properties, including carrier concentration, carrier mobility and conductivity, and local atomic structures is also possible [6].

The ellipsometric measurements can be performed not only in air but also in situ (vacuum [7], liquid [8], or in a controlled atmosphere [9,10,11,12,13]); they can be static or dynamic (in real time). In the last mode, the ellipsometry can be used as a control technique of different processes [14,15,16,17,18,19].

Like any other method, the ellipsometry has its advantages and drawbacks, which are summarized in Table 1. The high sensitivity of ∼0.1 Å [20] of ellipsometric measurements makes this technique to be very useful and precise in determining thin film thickness, surface and interfacial roughness. Its sensitivity refers also to the optical (dielectric) constants of the layer and hence to the bandgap energy, to the uniformity of the layer, to the anisotropy, porosity and density of the layer, to the conductivity-resistivity and to molecular vibrations, to the growth or etching kinetics in real-time monitoring, and to any other physical effect that induces changes in the optical properties of the materials.

Spectroscopic ellipsometry finds applications in a wide area of domains, mentioning semiconductor industry (substrates, thin films, lithography, gate dielectrics) [21, 22], chemistry (self-assembled monolayers, polymer films, proteins) [23, 24], optical coatings (high and low dielectrics) [25, 26], displays (TCOs, TFT films, organic LEDs) [27] and data storage (phase change media, magneto-optic layers) [28, 29].

The use of spectroscopic ellipsometry in areas of biology for the study of organic layers was also reported, including applications such as protein monolayer spectroscopy, in situ monitoring of protein adsorption on planar surfaces and in porous layers and ellipsometric imaging for determination of thickness distributions [30], in the study of chiral nanocrystalline cellulose films [31].

For biological studies were developed ellipsometers like FPE (fixed polarizer ellipsometer) [32] and MIE (microscopic imaging ellipsometry) [33], with different measurement capabilities.

Many approaches were proposed for maximizing the measurement spot size and for optimizing the measurement time in order to achieve more reliable results in a short time for conventional ellipsometers, including a snap-shot ellipsometric configuration by Lee et al. [34]. The co-axial optical structure allows high magnification (100×) objective lens, which lead to a spot size of a 62 μm and coupled with snap-shot ellipsometry lead to real-time measurements with high precision over various thickness values of samples, thus solving the issues of large spot size and long measurement time of conventional ellipsometry, maintaining the accuracy.

Recent papers on sol–gel film ellipsometry underline the influence of precursor concentrations [35], pH of the sol [36], annealing procedure (type and time) [37] and dopants [38] on their optical properties.

Among the methods used in the characterization of nanomaterials, ellipsometry has proven by its versatility and its sensitivity to be the right choice for the complex characterization of thin films [39].

In the review are exemplified with predilection three oxidic materials: ZnO, TiO2 and ITO which are among the most studied semiconductor materials due to their multifunctional properties different from other transition metal oxides or III-V, II-VI semiconductors. They have similar properties, like wide bandgap, good optical transparency, high electrical conductivity, antibacterial behavior, thus they can be used in a huge number of applications as: photocatalysts, gas sensors, wastewater treatment, film transistors, liquid crystal displays, LEDs and OLEDs, solar cells, photovoltaics, flat panel displays, smart windows, antistatic coatings and many more. They can be easily prepared as thin film not only by physical methods but also by less expensive chemical ones. All of them can be doped or even co-doped, resulting materials with improved properties and can be prepared in the shape of nanoparticles, nanowires, nanorods and other 2D dimensional shapes, presenting unique features.

NOTE: The following sections of the review will guide the reader through the theory, principles and applications of spectroscopic ellipsometry (SE). The main issues to which the review presents solutions are: what is ellipsometry and how it can be used in the investigation of the sol–gel thin films;what are the physical properties measured by SE; what is an optical model and how it can be used to simulate a real sample; what are the method limitations and how can we get additional information from extreme parts of the spectral regions; how can we apply ellipsometry to non-ideal samples and how to get complex features out of ellipsometric analysis. Finally, the review aims at highlighting the versatility and sensitivity of SE by the selected examples in connection with the sol–gel deposition method.

2 Theory

2.1 Basic knowledge of the ellipsometry theory

Ellipsometry measures the change of the polarization of the light after reflection on a surface. In general, the light after the reflection on a surface is elliptically polarized, but for a special position of the analyzer (Δ), the reflected light is linearly polarized. In this case, the polarizer can extinguish the light at a certain orientation (Ψ) (Fig. 1). The electric vector of both the incident and reflected light can be decomposed in parallel (p) and perpendicular (s) components on the incidence plane. The ratios of the reflected and incident electric components, parallel and normal to the incidence plane, represent the Fresnel (Rp, Rs) coefficients, which contain information about material and layer structure.

The Fresnel coefficients are linked to the angles Ψ and Δ by the fundamental equation of the ellipsometry:

In the case of a film, Fresnel coefficients contain information about all three media (Fig. 2):

-

medium 1 is in general air (or vacuum or a liquid)

-

medium 2 is the film with a complex refractive index \(\tilde N = n - ik\), and a thickness d

-

medium 3 is the substrate

Φ1 and Φ2 are incident and refracted angles, respectively.

where:

β being the film phase thickness

An ellipsometric experiment consists of the following steps:

-

the measurement of Ψ and Δ parameters

-

building an optical model

-

calculating the response from the model

-

fitting the calculated data with the experimental measurements, using regression analysis

-

choosing the model to match the measurements. The best fit is obtained when the Mean Squared Error-MSE (which quantifies the difference between experimental and model-generated data) has the smallest value corresponding to the best fit.

$$MSE = \frac{1}{{2N - M}}\mathop {\sum }\limits_{i = 1}^N \left[ {\left( {\frac{{{{\Psi }}_i^{mod} - {{\Psi }}_i^{exp}}}{{\sigma _{{{\Psi }},{\mathrm{i}}}^{exp}}}} \right)^2 + \left( {\frac{{{{\Delta }}_i^{mod} - {{\Delta }}_i^{exp}}}{{\sigma _{{{\Delta }},{\mathrm{i}}}^{exp}}}} \right)^2} \right] = \frac{1}{{2N - M}}\chi ^2$$(3)where:

N is the number of (Ψ, Δ) pairs

M is the number of variable parameters in the model

σ are the standard deviations on the experimental data points

-

from the best fit, n, k and d are obtained

To be consistent, the ellipsometric equations must obey the Kramers–Kronig (KK) rule [20], where the real and imaginary part of the dielectric constants (ε1 and ε2) depend on each other.

2.2 Some important models in ellipsometric characterization of sol–gel films

From an ellipsometric measurement results only two values, Ψ and Δ, which are insufficient to obtain all physical parameters of the sample under study, so a model based on regression analysis must be used.

To fit the ellipsometric experimental spectra are used either the tabulated optical constants of materials stored in the fitting software or different models based on optical oscillators. Since generally the optical constants of a material depend on the preparation method, a fit model based on oscillators is more adequate. In the simulating data a model needs to be as close to the real sample as possible.

In the simplest case of transparent materials, one can use Cauchy equation [40], which describes well the dispersion for materials which are essentially non-absorbing over the measured spectral range. The Cauchy relation is most effective when curve fitting a normal dispersion (n decreasing with wavelength). The Cauchy equation for the refractive index is given by

where An, Bn, Cn are called Cauchy parameters. The “An” term is a constant and describes the long-wavelength asymptotic index value, while the “Bn” and “Cn” are the dispersion terms that add upward slope to the index value as wavelengths become shorter (Bn and Cn ≥ 0).

Since the Cauchy equation involves no absorption, it is not Kramers–Kronig consistent. In the IR range, the absorption bands are due to molecular vibrations and in the UV due to electronic vibrations, while in the visible region the occasional absorptions are for organic films, for example. For the materials which are slightly absorbing in the UV, a convenient representation of the extinction coefficient (not zero) is given by the Urbach equation [41], namely

where Ak is the amplitude and B is the exponent, both being called Urbach parameters. This exponential function represents an Urbach absorption tail. The limitations of the Cauchy and Urbach parameterization of the optical response are clearly seen for strongly absorbing materials, like thin metal films (more details in the paragraph 4.4)

In the case of small particles of one material embedded in a matrix of the host material is suitable to use Effective Medium Approximation (EMA) [42]. In this case, the assumptions are

-

each material retains bulk-like optical properties (grain size large enough to ignore quantum size effects),

-

sufficient mixing over a macroscopic area (grain size small enough to appear homogenous compared to the wavelength of light—no scattering).

-

There are different types of equations based on Effective Medium Approximation, such as:

-

Lorentz–Lorenz (LL) where the host is air,

-

Maxwell–Garnett (MG) where the host is not air and describes the inclusion of small volume fraction in a host material,

-

Bruggeman where the host is the effective medium.

All these approximations use the same equation with different “host” material

where, ε is the complex dielectric function for: effective medium (eff), host (h), and constituent materials (1, 2, …); f1 and f2 are volume fractions of each constituent.

This model is particularly useful to simulate surface roughness, intermix layers, gradient layers, or doped layers [12, 43,44,45,46,47,48].

For more complex films, oscillator models are more suitable because they can describe optical constants in transparent and absorbing regions in the same time, maintains Kramers–Kroning consistency and used a reduced number of “fit” parameters.

For a normal dispersion, the refractive index increases toward higher frequencies when there is no absorption. For an anomalous dispersion, absorption causes changes in real part (n).

Different type of absorptions matches different oscillators:

-

organic and dielectrics: UV resonant absorptions—Gaussian [49], Tauc-Lorentz [50]

-

semiconductors: direct bandgap—Psemi-E0 [51]

indirect gap / amorphous—Tauc-Lorentz or Cody-Lorentz [50]

higher energy transitions—Gaussian or PSEMI [51]

Lorentz oscillator is a classic harmonic oscillator, with long absorption tails which can cause unwanted absorption in transparent regions. The model is best suited for phonons or metals, where absorption exists over all wavelengths.

where, A is the amplitude, E0 is the center energy, γ is the broadening of the oscillator, while E is the photon energy in eV.

Gaussian oscillator is an oscillator with shorter absorption tails than Lorentz—the absorption drops rapidly to zero; used for materials with band gaps, infrared absorptions in amorphous materials, multiple UV absorptions in amorphous materials.

Drude oscillator is a Lorentz oscillator with E0 = 0; it describes free carries because of no restoring force; used for metals, doped semiconductors and conductive dielectrics; method for non-contact measurement of resistivity, thus obtaining directly the electrical parameters without Hall measurements.

Tauc-Lorentz oscillator includes bandgap energy (Eg), with no absorption allowed below gap energy, good for amorphous semiconductor and other UV absorptions.

Another combination of oscillators used in semiconductor-type materials characterization is Tauc-Lorentz (which describes the absorption in UV) and Drude (which describes the effect of the electric charge carriers on the dielectric function when passing from the visible to the infrared wavelength range) oscillators. The carrier concentration (ND), the mobility (µ), resistivity (ρ) and the optical conductivity (σ) were determined using the equation:

where: ρ—optical resistivity (Ω cm)

γ—relaxation rate or damping coefficient of free carriers (1/s)

ωp—plasma frequency (1/s)

τ—electron scattering time (sec) (τ = 1/ γ)

m*—effective electron mass (Kg)

ND—carrier concentration (cm−3)

μ—carrier mobility (cm2/Vs)

εo—vacuum dielectric constant (F/m)

q—electron charge (C)

σ—optical conductivity (1/ Ω cm)

Optical absorptions in a material occur in different parts of the light spectrum, having different shapes, depending on the cause that generates them, like the free carriers (mostly in IR), electronic transitions (in UV–vis–NIR), molecular vibrations and lattice vibrations (in mid-IR). To describe the spectral behavior of the optical functions for the absorbing materials, one or more oscillators are usually used.

The General Oscillator Layer (shortly “GenOsc”) models the dielectric function of a film or substrate as a linear summation of real or complex terms, each of them being a function of wavelength (nm) [wavenumber (cm-1) or photon energy (eV)]. This model was developed in the WVASE® software, to simplify the analysis of the optical constants. The GenOsc model allows the user to choose more oscillators (Lorentz, Drude, Gauss, Tauc–Lorentz, Gauss–Lorentz, Cody-Lorentz, etc.) to simulate more accurately the dielectric functions of a material [57]. This formalism uses K–K consistent oscillator equations.

The multitude of oscillator types used to fit directly the reference dielectric functions, which allows the user to build models fast and accurate, makes the GenOsc a powerful and flexible model.

Several other important oscillators used in the ellipsometric simulations are: harmonic (classic harmonic oscillator), ionic (phonon absorption for IR), TOLO [58] (optical phonon absorption with both TO—transverse mode and LO—longitudinal mode broadening), CPPB [59] (Critical Point Parabolic Band): oscillator for semiconductors), CPM [60] (Adachi models for critical point functions), Tanguy [61] (provides an analytical expression of Wannier excitons), Herzinger-Johs “P-Semi” (4 connected functions to model each peak) [51].

3 Versatility of the ellipsometry

3.1 The correspondence between the results obtained by SE and other techniques

In this chapter the high versatility of the spectroscopic ellipsometry is emphasized, by drawing a parallel between SE on the one hand and several different methods on the other hand [62], in determining film characteristics such as (Fig. 3):

-

(a)

optical constants (n, k), optical band gap (Eg) and transmission (T) of the films which are usually determined by UV–vis spectroscopy and optical transmission,

-

(b)

film thickness (d) which is normally measured by Scanning Electron Microscopy (SEM) or Transmission Electron Microscopy (TEM) analyses,

-

(c)

roughness (drough) determined mainly by Atomic Force Measurements (AFM),

-

(d)

crystallization state signaled by X-ray diffraction (XRD) technique,

-

(e)

information on the chemical components existing in the film, which is the domain of Fourier Transform Infrared Spectroscopy (FTIR),

-

(f)

vibrational properties obtained mainly by Raman Spectroscopy,

-

(g)

resistivity (ρ), conductivity (σ), carrier concentration (ND) and mobility (μ) which are usually obtained from Hall measurements.

The following examples illustrate the correspondence between the results obtained by SE and other techniques.

3.1.1 SE vs optical transmission

The refractive index can be obtained by SE, as through optical transmission [63] with the same results. Such an example is offered by Stoica et al.[64]. who modeled sol–gel nanocrystalline ITO multilayer films by both methods. The modeling of SE spectra was performed using a multilayer and multicomponent Bruggemann effective medium approximation (BEMA) as well as a dispersion equation combining the Drude theory, with a double Drude–Lorentzian oscillator (DL) model. As can be seen from Fig. 4, the two estimations agree well.

The comparison of the refractive indices obtained by optical transmission and ellipsometry for four-layer sol–gel ITO film [Reproduced from reference [64] with the permission of Elsevier]

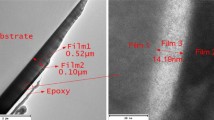

3.1.2 SE vs TEM

The thickness obtained by Cross-Sectional Transmission Electron Microscopy—XTEM (a very expensive method) can be obtained also by SE (an inexpensive method) as showed by Covei et al.[65].. In the UV–vis ellipsometric data analysis of the Nb doped TiO2 sol–gel film with 10 layers, the “General Oscillator” model was applied, considering one Tauc-Lorentz oscillator (see Section 1.2). The surface roughness was taken into account, considering the top layer consisting of 50% voids and 50% film material within the effective medium approximation model (see Section 1.2), even though the films are very smooth. The thickness obtained from the best fit (Fig. 5a) was 339.9 nm and agrees well with the thickness obtained by XTEM analysis, 340 nm (Fig. 5b).

The film thicknesses obtained from TEM investigations are in good agreement with SE results, also in the paper of Zaharescu et al.[67]. who study the change of the sol–gel HfO2 thin film properties function of used precursor (hafnium ethoxide, hafnium 2,4-pentadionate and hafnium chloride).

3.1.3 SE vs XRD

The formation of anatase (A) and rutile (R) phases in thin TiO2(Ni2+) films (deposited by sol–gel on Al thin film/glass and Si substrates) were observed in parallel by XRD and ellipsometry methods. The as-deposited films were amorphous, but after thermal treatment (TT) they react differently [68]. The TiO2(Ni2+) films (30 nm thick) deposited on Al substrate after 1 h TT at 300 °C crystallize in the anatase form which can be visualized in SE spectrum at 370 nm (Fig. 6a), together with the transfer charge (TC) band from 320 nm. It is known that in the case of very thin films the anatase is formed after treatment at low temperature. For the same type of film deposited on Si substrate (Fig. 6b) and higher TT (700 °C), besides the anatase, the rutile band also appears at 377 nm. The veracity of these assignations is proved by the XRD analysis (Fig. 6b inset figure).

a SE spectrum of Ψ parameter of TiO2(Ni2+)/Al/glass, TT 1 h at 300 °C. b SE spectrum of Ψ parameter of TiO2(Ni2+) /Si, TT 1 h at 700 °C. Inset: XRD difractogram. Reproduced from reference [68] with the permission of Elsevier

Moreover, a shift of charge transfer adsorption band (TC) from 350 nm (glass) to 330 nm (Si) and 320 nm (Al) is also observed in the ellipsometric spectra of TiO2(Ni2+) deposited on Al, Si and glass substrates, due mainly to the lowering of the film thickness and the increase in the refractive index [68].

3.1.4 SE vs FTIR

Vibrational bands of film components can be evidenced by FTIR as well as by IRSE. A good example is that of sol–gel ITO films with 15 layers, deposited on Si where the vibrational bands were determined by IRSE (see in details in Section 3.2).

3.1.5 SE vs Hall

Electrical properties can be determined by SE as well as by Hall measurements. An example is the sol–gel ITO films with 15 layers deposited on glass and SiO2/glass [69] which was modeled by a combination of Tauc -Lorentz (to describe the absorption in UV) and Drude (to describe the effect of the electric charge carriers on the dielectric function when passing from the visible to the infrared wavelength range) oscillators (see Section 1.2).

As can be seen in Table 2, the values of the electrical parameters obtained by Hall measurements validate, as order of magnitude, the ellipsometric results.

In terms of absolute values, the results are not always very close. A possible explanation could be that the ellipsometry is an indirect technique which requires data modeling (the dielectric function using the Tauc-Lorentz and Drude oscillator models), while the electrical parameters values are obtained directly through Hall measurements [70,71,72].

Despite the inherent differences, comparable values for the properties of interest could be obtained. SE method proves to be useful in this case to obtain a large view of the electrical parameters.

In conclusion, the two ellipsometric parameters (Ψ, Δ) were measured in a wide spectral range (0.19–33 μm) and were fitted by combining the Gaussian, Tauc-Lorentz, Lorentz and Drude oscillators to obtain the complex optical constants (e.g. complex refractive index, complex dielectric function). With these values were further estimated the thickness, free-carrier contribution and vibration modes. The frequencies TO and LO modes are related through the Lyddane–Sachs–Teller (LST) relation [73]:

Where:ωLo — the longitudinal vibration frequency (cm−1)

ωTo — the transverse vibration frequency (cm−1)

ε0 — the low-frequency dielectric constant

ε∞ — the high-frequency dielectric constant

The results presented in this study show that Spectroscopic Ellipsometry is complementary with other techniques (Fig. 3) and their combination provides a better understanding of the experimental data.

3.2 Information obtained directly from ellipsometric spectra, prior to the data modeling

3.2.1 Visualization of different bands was already described above (Section 2.1.3) in UV spectral range [68]

Estimation of the film’s thickness

Interference oscillations of the spectra of the ellipsometric parameters Ψ and Δ are affected by the thickness (d) and refractive index (n) of the film. For the films with the same material characteristics, but having different thicknesses, the parameter d can be estimated from ellipsometric spectra by counting the numbers of oscillations. As the thickness increases, the number of oscillations grows. At the same time, the maxima of thicker film shift to higher wavelengths. One example can be seen in Fig. 7 representing the oscillations of Ψ parameter with the thickness of oxide ternary alloys Zn–Ir–O (ZIRO) [74].

3.2.2 Checking the stabilization of the films

One of the most important ellipsometric applications for film technology is the monitoring of the surface stability of the films. The changes of the film surface can be viewed directly by tracking the evolution of the ellipsometric parameter (Ψ and Δ) spectra.

A comparison between the experimental ellipsometric spectra taken on the as-deposited film, the annealed one and after some months can offer us information about the changes happening on the film surface. The efficiency of a rapid thermal annealing treatment (RTA) for 1 min up to 400 °C in N2 atmosphere on an ITO film deposited by reactive sputtering on Si(100) substrate is shown by Stroescu et al. [75]. They observed that the ellipsometric spectra taken after RTA treatment remain practically unchanged (Fig. 8—the measurements are performed in the same area) even after 4 months. This result proves that the RTA treatment stabilized well the sample surface.

Experimental ellipsometric spectra (a) Ψ and (b) Δ presented comparatively for sputtered ITO/Si(100) film before and after the RTA treatment (1 min, 400 °C) [Reproduced from reference [75] with the permission of Elsevier]

In comparison with the RTA treatment for 1 min up to 400 °C, a normal thermal annealing treatment (NTA) for 1 h at 400 °C in nitrogen atmosphere is not so efficient. In the case of ITO films deposited by sol–gel method on Si(111) substrate (Fig. 9—will be published), the stabilization of the film by NTA was less efficient than by immersion of the film for 24 hours in an alcoholic solution containing 2 mM 1-Octadecanethiol/CH3(CH2)17SH. The ellipsometric spectra of Ψ parameter (before and after stabilization treatment with 1-Octadecanethiol) are almost unchanged (see Fig. 9), while the Ψ spectra for the film after a normal thermal annealing treatment (1 h, 400 °C) shifted to smaller wavelengths, thus means that the film thickness was changed.

In conclusion, in this case a Thiol protective surface layer is more efficient for the stabilization of the surface and for a longer time than the normal thermal annealing treatment in nitrogen.

3.2.3 Optical phonon contribution

In the usual way, E1(TO) frequency mode can be visualized in the spectrum of the imaginary part of dielectric constant (ε2) and A1(LO) in the dielectric loss functions Im(−ε−1) of IR ellipsometric spectra (IRSE), but they can be also visualized directly in the ellipsometric spectra of Ψ and Δ parameters, which is a substantial advantage. Such an example is offered by Nicolescu et al.[76]. on ZnO:N films deposited by reactive sputtering in a 10% nitrogen atmosphere on Si(100) substrate. The authors show comparatively the assignations of E1(TO) and A1(LO) modes directly from the spectra of Ψ and Δ (Fig.10a, b) and from dielectric constants spectra (Fig. 10c, d).

a, b Experimental and simulated IR spectra of the Ψ and Δ ellipsometric parameters and (c, d) E1(TO) and A1(LO) frequency modes for ZnO:N film deposited by reactive sputtering in atmosphere with 10% N2 and treated at 550 °C [Adapted from reference [76] with the permission of Elsevier]

This advantage of the ellipsometry is shown also by Bundesmann [77] on amorphous hafnium aluminate film deposited by metal organic chemical vapor deposition on silicon substrate; by Ashkenov et al. [78] on ZnO films deposited by pulsed-laser deposition (PLD) on c-plane sapphire substrates and by Kang [79] on PZT films grown on platinized silicon substrates by using the sol–gel method and on (0001) sapphire by using radio-frequency sputtering deposition.

4 Extensions of the basic ellipsometry

4.1 Vacuum UV Ellipsometry (VUV)

A spectral region of high interest for ellipsometric measurements is represented by VUV domain, which denotes the spectroscopic range below 190 nm or energy above 6.5 eV. It was first applied at the BESSY synchrotron in Berlin [80] at photon energies up to 35 eV. Any transparent dielectric and wide band gap semiconductor is suitable for VUV ellipsometry, which comes with an increased sensitivity to film thickness and increased access to unique spectral features, like distinguishing between similar grown materials and correlating their mechanical, optical and electrical properties [81]. The importance of VUV ellipsometry consists in analyzing materials used in optoelectronics, high-power and high-temperature devices. There are several deposition methods used to achieve thin films characterized by VUV ellipsometry, like PLD [82], sputtering [83], sol–gel combined [84], epitaxy [85], atomic layer deposition (ALD) [86]. VUV ellipsometry may be applied to lithography (157 nm), front end (high-k thin films) and back end (porous low-k interlayer dielectrics) processing. There is a continuous search in lithography industry to minimize the feature sizes, which led to the development of new materials, with new optical constants, making the lithography process a more feasible one [87]. Due to setup complexity and costs, commercial instruments do not allow measurement above 9.5 eV, and the number of VUV ellipsometers is still small. Consequently, the number of publications in this field is still small, most of them not dealing with sol–gel films. An example of applying VUV is the study of ZnO dielectric function, experimentally and theoretically obtained, in the 4.0–9.5 eV by Schmidt-Grund et al. [88]. The authors found for ZnO films deposited by PLD on Al2O3 substrate that the differences between both dielectric functions can be related to the strong excitonic contributions near the band gap. Also, it is known that Wurtzite-structure ZnO is optically uniaxial, and the authors found that the anisotropy is more pronounced in the theoretical dielectric function spectra. Other materials measured and characterized by VUV ellipsometry were SiC [89], GaN [90], AlN [91], AlGaN [92] and AlInN [93], due to the electronic transitions that occur at these photon energies, and due to possibility to differentiate between ordinary and extraordinary dielectric functions.

4.2 Infrared spectroscopic ellipsometry (IRSE)

The results of this chapter form the subject of a future paper (to be published).

Since IRSE technique (analysis) developed considerably, it is possible nowadays to have optical (dielectric) constants on a large spectral range from UV to Mid IR. To this end, we performed an ellipsometric study of ITO thin films deposited by sol–gel dip-coating method. The films, containing 15 layers were deposited on three different substrates: glass, SiO2/glass and SiO2/Si and analysed separately in the UV–vis–NIR (0.19–1.7 µm) and in the Mid IR (2–33 µm) spectral ranges.

Ellipsometric simulations were based on the general oscillator model (see the models in Fig. 11) which contains Tauc-Lorentz oscillators for UV spectral range and Gaussian and Drude for IR range (see definition of the models in Section 1.2) in both cases. The ellipsometric parameters Ψ and Δ (experimentally measured and computed with the models shown in the first row), the film thickness and the optical constants (obtained from the best fit), together with the Mean Squared Error (MSE) are presented in Fig. 11 for the range 0.35–33 µm (0.03–3.5 eV).

The transition between the spectral regions of the two ellipsometers (from 1700 nm alias 0.72 eV) is hardly noticeable in the data, indicating a good agreement between these two separately fitted regions.

The vibrational bands of ITO films were obtained directly by IRSE (300–1400 cm−1) spectra of Ψ and Δ (Fig. 12 and Table 3).

The Infrared spectra of the ITO thin films reveal the presence of vibrational bands which were attributed to In–O–In, In–OH, Si–OH, and Si–O–Si, respectively [94,95,96,97,98,99]. The observed infrared modes are in good agreement with the vibrational bands from literature.

5 Complex features of ellipsometric analysis

5.1 Porosity and porosimetry

5.1.1 Porosity

It is well known that by sol–gel method pores are easily achieved in the thin film structure. Duta et al. [69]. showed that the ITO films obtained by sol–gel have a porosity of 11–19% in comparison with the ITO films prepared by sputtering (2–10%). The values of porosity were calculated from ellipsometry, knowing the refractive index, as it is shown in the following equation:

where n is the refractive index of current material and nd- the refractive index of the material without pores.

Generally, there are two kinds of porosities in the films: intrinsic and extrinsic. The intrinsic one is related to the preparation method and is formed by small micropores (< 2 nm) of similar size as crystallite size (~10 nm). One suitable example is of TiO2 sol–gel film doped with PEG [100]. This film has an intrinsic porosity due to the preparation method and doping with PEG (polyethylene glycol) leads to an extrinsic one, where the pore size is determined by PEG molecular weight. The extrinsic porosity is very significant after the first layer deposition.

SE measurements have shown that the total porosity (intrinsic and extrinsic) has similar values for all doped films after the deposition of a second layer, independent of the molecular weight of the PEG used, due to the densification of the films, that confines extrinsic porosity to the film outer surface. Cross-section SEM analysis of the films confirmed that in multilayer films extrinsic porosity remains located mostly at the outer layer of the film [101]. It was observed also that the pore size is influenced by the nature of the substrate, thus the pores are larger (50–200 nm) when the films are deposited on FTO (Fluorine doped Tin Oxide coated glass) compared to glass (microscope standard slides) or silicon (below 20 nm) [102].

Some examples of porous films investigated by ellipsometry can be found in the application of mesoporous sol–gel silica thin film as vapor sensor in humid environments [103], inorganic sol–gel films obtained from organic precursors (evaluated by SE and TEM showing small pore dimension and regular arrangement) [104], sol–gel polyfluoroalkyl-silica films with antireflection properties for photovoltaic application [105].

On the other hand usage of the Effective Medium Approximation (EMA) model (see Section 1.2) in ellipsometric spectra simulation is a direct and fast determination of the volume fractions of the film components and their porosity (void content). An example in this regard is the analysis of Er-doped SiO2-TiO2 binary system (used in planar optical waveguides). The films were deposited on oxidized silicon wafers by sol–gel dipping and spinning methods and annealed 30 min at 900 °C. By fitting the ellipsometric spectra with EMA model, the volume fractions of SiO2, amorphous TiO2, anatase, rutile, and voids were obtained [106]. In Table 4 are exemplified some papers related to the porosity calculations on the TiO2 sol–gel films.

5.1.2 Porosimetry

The stringent necessity to find out the porosity of thin films led to the construction of an independent apparatus, Ellipsometric Porosimeter (EP), which is a device that couples the classic spectroscopic ellipsometer with an adsorption tool. An important feature of EP is the obtaining of the amount adsorbed during the experiment through the evolution of the optical properties of the porous material [114].

The uniqueness of the EP technique relies on its capacity to measure the porosity of extremely thin films, <10 nm, on its speed of measurement and reproducibility. It is well matched for extremely thin film pore size and pore distribution measurements, but the most fundamental feature of EP is to determine the open film porosity.

Löbmann highlighted the general features of the EP on TiO2 [115] and TiO2-MgF2 [116] sol–gel films. In his review [117] he showed the possibility to evaluate open porosity, pore radius distribution and elastic properties in situ measurements. More than that, in this review the authors present a comparison between results obtained by EP and UV–vis Spectroscopy and SEM. The porosity depends on the sol–gel synthesis, number of depositions, thermal treatment and type of dopants. AZO thin films were deposited on borosilicate glass in coating-firing cycles (intermediary thermal treatment at 550 °C for 10 min after each layer deposition, followed by the final thermal treatment at 500 °C for 1 h in forming gas) [118] until the desired thickness is achieved. The authors showed that the porosity of a sol–gel Aluminum doped Zinc Oxide (AZO) film, with 90 - 125 nm thickness, containing 3 layers decreases from 14 to 5% after 7 depositions, arriving at 3% after 15-fold coating. The decrease in AZO porosity with the number of layers is related to the thermal treatment of the samples, during sol–gel synthesis.

Recently, Reid et al. [119] used EP in the study of the mesoporous inorganic thin films and Loizillon et al. [120], with the help of EP get advanced insights on the pores interconnectivity in the mesoporous silica.

The thickness and porosity both play an important role in the electrical (electrochemical) properties of thin films and/or substrates, which could be useful for a lot of applications, such as: gas and biosensor, solar cell, and so on [69, 114, 117].

5.2 Anisotropy

Anisotropy is defined as the characteristic of a material to exhibit variations in physical properties along different molecular axes. So, if we think about a material that exhibits different optical properties depending on the polarization direction of a light beam propagating through that material, then we can consider it optically anisotropic. Anisotropic samples were first characterized by ellipsometry in the 1970s with the development of generalized ellipsometry [121], and later, the anisotropy study was enhanced due to the development of a new 4 × 4 matrix method [122, 123] in the 1990s.

The optical properties of a material depend on the underlying atomic or molecular structure. In addition, in an anisotropic material the light traveling in different directions leads to different values for n and k (Fig. 13). This means that the propagation speed of light varies with the oscillating direction of the electric field, as a result of the refractive index variation. According to these refractive indices, anisotropic materials are classified into two categories, i.e., uniaxial with two different optical properties (nx = ny ≠ nz), and biaxial with three different optical constants (nx ≠ ny ≠ nz), respectively.

Schematic view of the refractive index ellipsoid for a uniaxial material [124]

An important cause of uniaxial properties in sol–gel films is the in-plane tensile stress [125]. The stresses will influence the film microstructure during drying and sintering processes, which in the end will cause the mechanical failure of the films. This makes difficult to achieve the desired thickness of single sol–gel coating for inorganic films.

Birefringence is a measure of optical anisotropy, defined as the maximum algebraic difference between two refractive indices measured in two perpendicular directions. If we consider a birefringent material, then the incident light splits into two beams as it travels through the material. The propagation speed is constant when the oscillating direction is perpendicular to the optical axis and such light beam is called the ordinary ray, which experiences constant refractive index no. But the light beam whose oscillatory direction is parallel to the optical axis and its speed varies with the direction is called the extraordinary ray and experience refractive index ne that varies with the direction of propagation of the light.

Examples of anisotropic materials consist of crystalline materials with tetragonal (rutile), hexagonal (sapphire), rhombohedral (BiFeO3) orientations, crystalline organic chains, liquid crystals, sugars, materials that may be strained during processing, like PET sheets and spin-on films and materials with preferred orientation growth, especially columnar films. Anisotropic thin films are used in devices that rely on the manipulation of polarized lights, like liquid crystal displays, beam splitters, wave plate designs, just to name a few. Therefore, an improvement of the birefringence is desirable. We find such an example in the study of Xiao et al. [126]. on SiO2 thin films. They found that the as-deposited SiO2 thin films are porous with a tilted-columnar structure and low refractive index. By infiltrating ZrO2 into SiO2 columnar films, the linear birefringence is greatly enhanced. The transmission measurement results showed an increment in transmission difference (ΔT) of about ten times larger than that of as-deposited films.

Anisotropy can be natural or induced (for example by thickness-strain [127] or thermal treatment). One example of natural anisotropy is presented by Gartner et al.[128]. in the case of multilayer Fe2O3 films, deposited by the sol–gel method on glass substrate (Fig. 14).

The dispersion of ordinary (no) and extraordinary (ne) refractive index of Fe2O3 film with two depositions and thermally treated 1 h at 300 °C [Reproduced from reference [128] with the permission of Springer]

The ellipsometric measurements showed that the birefringence values (Δn = n0–ne) of the sol–gel films (0.05–0.08) are smaller than the values of the α-Fe2O3 single crystal [129] (which are around 0.28), but increase with the crystallization of the films.

An induced anisotropy by the strain of different thickness and substrates of VO2 sol–gel films was studied by Wan et al.[130].. They used in the ellipsometric fitting procedure of the film, grown on c-plane-oriented sapphire the anisotropic model because the sapphire in the mid- and far infrared presents a significant dispersion.

To study the growth kinetics of thin films during fabrication processes, both ex situ and in situ spectroscopic ellipsometry can take the anisotropy and the porosity of the films into account, as Laha et al. showed in the case of ZnO nanocrystalline layers [12]. They found that the asymmetric shape of the in situ curves, just as for the ex situ measurements, demonstrates the anisotropic nature of the layer, which in itself can be considered as a first indication of ZnO nanocrystal array growth.

Evtushenko et al. [131] reminded that TiO2-based films may have anisotropy which can be used in many integrated optics applications. To this end they prepared sol–gel TiO2 films and thermally treated them at different temperatures (350, 400, and 450 °C) to follow the crystallization process of the samples and the induction of anisotropy. They found by ellipsometric studies that optical anisotropy increases strongly, upon formation of anatase, yielding in-plane birefringence values that doubled from 0.11 to 0.22 in the case of TiO2 thin films deposited at 60° and annealed at 400 °C. Raising the annealing temperature to 900 °C to form rutile, the thin film birefringence increased further, but also led to low optical transparency due to increased absorption and diffuse scattering.

Koziara et al. [132] studied spin-coated polymer films and found that water sorption reduces the internal stresses in such polymeric membranes, and, therefore, it reduces the optical anisotropy, which is strongly correlated with the density of the films. Also, a high concentration of the deposition solution may increase the optical anisotropy of the resulting films, associated with the preferred orientations in the in-plane direction of the polymer chains.

The emerging class of low-symmetry two-dimensional (2D) materials, crucial for creating diverse nanoscale devices, involves the study of the optical anisotropy, as one of the most fundamentally physical characteristic. The evaluation of anisotropic features of 2D materials requires a highly sensitive optical method and ellipsometry is one of them [133]. It is a very challenging approach due to the very small thickness of such materials and also the technological process of achieving 2D materials must be very pure.

Nowadays, spectroscopic ellipsometry is employed widely to study the anisotropic properties of insulators, semiconductors and organic materials [20] and provide exciting new challenges to ellipsometry researchers.

5.3 Mapping

For the characterization of thin films, the mapping technique is very useful in order to evaluate the uniformity of the sample thickness and/or optical distribution. The software uses a predetermined rectangular or circular model for scanning the surface and generates a thickness map. The spot size is 250 × 600 µm (on sample) and the data acquisition rate (per measurement spot, entire spectrum, in s): 0.3 (fastest), 1-2 (typical).

For example in the case of thin reactive sputtered ZnO films [76], the mapping analysis showed the influence of the substrate and the nitrogen amount (from the deposition atmosphere, which is a mixture of N2, O2, and Ar) on as-deposited film thickness (Fig. 15, Table 5). In this case the uniformity of thickness determined by ellipsometric mapping is around 90% for the sample deposited on fused silica and 96% for those deposited on silicon substrate [76].

Uniformity of ZnO:N as-deposited films on fused silica and silicon, resulted from ellipsometry mapping [Reproduced from reference [76] with the permission of Elsevier]

The mapping analysis was also used with good results in the last years on films prepared by sol–gel [134, 135], ALD [136,137,138] and Plasma Enhanced Chemical Vapor Deposition (PECVD) films [139, 140].

5.4 Bowing parameter

In general, the variation of band gap (Eg) in alloyed materials is a linear function of component concentration, respecting the Vegard’s law:

where EgA, EgB, and Egalloy are the corresponding band gap of pure A, pure B, and of the alloy

x is the fraction of one ingredient in a composite AxB1–x material

However, there are a lot of cases where the variation of Eg is not linear. In these cases, the Vegard’s law is transformed in the parabolic equation:

where b is denoted as “bowing parameter”.

For example in the case of AlInN alloy [141], using this formula it was obtained b = 10.36, which is a valid value for pseudomorphically grown layers with an indium content between 13 and 24% only. A comparison with literature is shown in Fig. 16.

As can be seen in Fig. 16, in the case of AlInN alloy, but not only, the Eg values available in the literature vary significantly from publication to publication depending mainly on the deposition method. While Lukitsch et al. [149] report on samples grown by MBE, Peng et al. [143] and Guo et al. [144] used a sputtering technique. Samples grown by MOVPE were investigated by Yamaguchi et al. [145], Hums et al. [150]. and Kim et al. [146]. Theoretical calculations were performed by Goano et al. [147] as well as Wright and Nelson [151].

The bowing parameter concept was expanded from the films obtained by physical methods to the films deposited by chemical methods. It is known that the Eg value is a compositional and structural phase dependent parameter which varies with precursor concentration and aging conditions (time, temperature) and with dopant concentration for the doped films. Due to the fact that the design of the sol–gel film function of doping is one of the keys in obtaining a film with desired properties, we tabulated the papers from literature, which are dealing with this subject. Table 6 shows how the bowing parameter varies with the type and concentration of the dopant in the case of ZnO, TiO2 and ITO sol–gel films in some of the recent papers [35, 152, 153].

In conclusion the Bowing parameter is a useful factor for predicting the content of dopant necessary to obtain a specific value for film bandgap.

The optical band gap is given by the following relation:

where α is the absorption coefficient, hν is the photon energy, A is a constant, Eg is the band gap and n denotes the type of transition (n = 2 for direct gap semiconductors) [165, 166] while the Urbach absorption tail is described by the following relation:

where, α is the absorption coefficient, α0 is a constant, hν is the photon energy, and Eu is the Urbach energy.

The Urbach energy represents the width of the tail of localized states inside the band gap, which leads to absorption below the fundamental band gap. It is the largest in materials that are amorphous and have a large number of defects. As the defect density decreases, the Urbach energy should also decrease.

Miao et al. [156] studied the effect of Er doping and annealing on optical properties of ZnO sol–gel spin-coated thin films, deposited on a quartz substrate, and they found for the pure ZnO films a steep Urbach tail, while the films with 0.05 at.% of Er showed a slight broadening tail. A more broadening effect was observed for samples treated at 1000 °C. These effects might be due to alternation of band gap due to local strain or change of structure disorder and crystallinity and due to the non-homogeneous distribution of the minor impurities.

The doping effect on the Urbach energy was investigated also by Ali et al. [159]. In their work La and Sm doped ZnO films were deposited by spin coating on Si substrates, the concentration of La and Sm being varied between 0.2 and 5 wt%. They found that the optical bandgap of ZnO thin films shifts towards higher wavelengths (red shift) on incorporating La and Sm, due to their increased absorption ability for visible light, Sm doped films being more absorbing in the visible region as compared to La-doped ZnO films. This decreasing trend of Eg is due to the introduction of energy levels within the forbidden band just below the conduction band. By doping with La and Sm, high concentration of defects is introduced, which is responsible for the perturbation in band structure. These defects can be determined by Urbach relation. Eu dependence on the dopant concentration is opposite to that of Eg: higher Eu values indicate the higher concentration of defects, which creates more impurity levels within the forbidden gap, which leads to Eg decreasing. The red shift observed in this case suggests that the doped ZnO films may be used as visible light photocatalysts.

An opposite shifting effect (namely, a blue shift) was observed in the case of Er-doped ZnO films in the work of Chen et al. [167], due to the Burstein-Moss effect [168]. In a semiconductor if we have some populated states closed to the conduction band, then this might lead to an increase in the band gap, as the absorption edge is pushed to higher energies; this phenomenon is known as Burstein-Moss effect. The effect occurs when the electron carrier concentration exceeds the conduction band edge density of states, which corresponds to degenerate doping in semiconductors, meaning that an electron from the top of the valence band can only be excited into conduction band above the Fermi level since all the states below the Fermi level are occupied states. Thus, the main observation in the work mentioned above, is that the optical band gap increases after Er doping and the blue shift of the band gap is due to the amorphous phase in the films.

Another example concerning the blue shift of the band edge is found in the work of Speaks et al. [153]. Al-doped ZnO and ZnO thin films were spin coated on glass substrates followed by annealing. The results showed that at higher concentration of sol gels, the obtained films aged more quickly and presented better properties, had larger grain sizes and the blue shift of the band edge became larger. As the grain size increases, the Urbach energy decreases, and the band gap of the doped ZnO films is higher that the un-doped films, thus a blue shift occurs. The annealing is necessary to obtain highly crystalline films, and it must be done above 450 °C for 1 h. Otherwise, low quality films are obtained, which will cause an increase in the band gap of ZnO, due to changes in crystallinity, in defect density or in tensile or compressive stress.

6 Prospects and drawbacks

A future challenge in ellipsometry is the further development of the available databases in order to cover the effects of composition, stress and defects, mainly in the topic of solar cells [169].

Also, future ellipsometric studies are expected to provide a greater understanding in important fields such as biology and medicine. A higher accuracy or extended wavelength ranges are necessary in these fields in order to overcome the difficulty represented by the similarity of visible-near UV spectra among organic materials [170].

In biological analysis, measurements at multiple angles of incidence are difficult to be performed in situ at the solid/liquid interface due to the cellular limitations compared to the measurements in air, which can be considered a disadvantage of the ellipsometric method.

Moreover, the use of ellipsometry during heating/cooling process of a sample offers the possibility to study the dielectric properties of films during glass transition, as Hajduk et al. [171] showed for polymer films designed for organic optoelectronic devices. The advantage of this approach is to determine the temperature dependence of the thermal expansion coefficient and the spectral dependence of the thermo-optic coefficient, thus the ability to determine the thermal transition depth profiles, and to separate the reversible from irreversible processes. The drawback of the method consists of its complex modeling and time-consuming.

7 Summary

Our intention in this review was to prove that the spectroscopic ellipsometry is a versatile characterization technique for thin films, which can be used in a wide variety of applications. The following aspects were highlighted:

-

basic knowledge of the appropriate models for fitting the experimental data, depending on the sample structure, composition, and appropriate application of the studied materials

-

the versatility of the ellipsometry in the characterization of thin films

-

the reliable results offered by SE in agreement with complementary methods, concerning film thickness and optical constants, as well as composition, structure and electrical parameters

-

the direct information obtained from SE spectra, including visualization of different bands, estimation of film thickness, stability of the films and optical phonon contributions

-

the spectral features of the films in VUV and IR spectral ranges. The possibility to obtain, for a certain film, the optical constants over a wide spectral domain

-

the porosity evaluation by SE. Examples presented in this review illustrate the suitability of SE in determining extrinsic and intrinsic porosity of sol–gel thin films. The porosimeter, as a spin-off independent device starting from SE, was also mentioned

-

the possibility of SE to offer information on the film anisotropy, which is a particularly challenging task for 2D materials, crucial for creating nanoscale devices

-

the surface mapping over large areas, which can be extremely useful not only in the Si wafer manufacturing, but also in the evaluation of uniformity of some film parameters (thickness, optical constants)

-

the nonlinear variation of Eg with different technological parameters (like dopants, precursor concentration and aging conditions) via the bowing parameter (the nonlinear term of Eg variation) in connection with these factors. Knowing the bowing parameter of each material is very helpful in the design of films with predetermined properties

-

the evaluation of Urbach energy and its dependence on the optical band gap, a very useful approach in describing the phenomena in the adsorption region

As a general comment we can say that the correspondence between the results obtained by SE and other techniques is a very good one, highlighting the sensitivity and versatility of ellipsometry, a useful characterization technique in the field of sol–gel thin films.

References

Aspnes DE, Studna AA (1975) High precision scanning ellipsometer. Appl Opt 14:220–228

Muller RH, Farmer JC (1984) Fast, self-compensating spectral-scanning ellipsometer. Rev Sci Instrum 55:371–374

Kim Y-T, Collins RW, Vedam K (1990) Fast scanning spectroelectrochemical ellipsometry: In-situ characterization of gold oxide. Surf Sci 233:341–350

Aspnes DE (2014) Spectroscopic ellipsometry—Past, present, and future. Thin Solid Films 571:334–344

Röseler A, Korte E-H (2006) Infrared spectroscopic ellipsometry. In: Chalmers JM (ed) Handbook of Vibrational Spectroscopy. John Wiley & Sons, Ltd, Chichester, UK, p 1065–1090

Bruynooghe S, Bertin F, Chabli A et al. (1998) Infrared spectroscopic ellipsometry for residual water detection in annealed sol–gel thin layers. Thin Solid Films 313–314:722–726

Gartner M, Stanica N, Vass M (1990) Ellipsometric spectroscopy of pure oxygen and carbon monoxide covered copper films. Rev Roum Chim 35:713–720

Lazarescu V, Gartner M, Scurtu R et al. (2006) Fermi Level pinning at n-GaAs(110) electrodes. In: Marcus P, Maurice V (eds) Passivation of metals and semiconductors, and properties of thin oxide layers. Elsevier, Amsterdam, p 257–262

Hrabovsky D, Berini B, Fouchet A et al. (2016) Strontium titanate (100) surfaces monitoring by high temperature in situ ellipsometry. Appl Surf Sci 367:307–311

Kaspar TC, Reiser JT, Ryan JV, Wall NA (2018) Non-destructive characterization of corroded glass surfaces by spectroscopic ellipsometry. J Non Cryst Solids 481:260–266

Skopin EV, Deschanvres J-L, Renevier H (2020) In situ ellipsometry study of the early stage of ZnO atomic layer deposition on In0.53Ga0.47As. Phys Status Solidi 217:1900831

Laha P, Nazarkin MY, Volkova AV et al. (2015) In-situ ellipsometric characterization of the growth of porous anisotropic nanocrystalline ZnO layers. Appl Phys Lett 106:101904

Aryal P, Ibdah A-R, Pradhan P et al. (2016) Parameterized complex dielectric functions of CuIn1−xGaxSe2: applications in optical characterization of compositional non-uniformities and depth profiles in materials and solar cells. Prog Photovolt Res Appl 24:1200–1213

Trolier-McKinstry S, Chen J, Vedam K, Newnham RE (1995) In situ annealing studies of sol-gel ferroelectric thin films by spectroscopic ellipsometry. J Am Ceram Soc 78:1907–1913

Sengupta SS, Park SM, Payne DA, Allen LH (1998) Origins and evolution of stress development in sol-gel derived thin layers and multideposited coatings of lead titanate. J Appl Phys 83:2291–2296

Brinker CJ, Hurd AJ, Frye GC et al. (1990) Sol-gel thin film formation. J Non Cryst Solids 121:294–302

Hurd AJ, Brinker CJ (1988) Ellipsometric imaging of drying sol-gel films. MRS Proc 121:731–742

Hurd AJ, Brinker CJ (1988) Optical sol-gel coatings: ellipsometry of film formation. J Phys 49:1017–1025

Zudans I, Heineman WR, Seliskar CJ (2004) In situ dynamic measurements of sol−gel processed thin chemically selective PDMDAAC−silica films by spectroscopic ellipsometry. Chem Mater 16:3339–3347

Fujiwara H (2007) Spectroscopic ellipsometry: principles and applications. John Wiley & Sons, Ltd, West Sussex, England

Tompkins HG (2004) Industrial applications of spectroscopic ellipsometry. Thin Solid Films 455–456:772–778

Zollner S (2013) Spectroscopic ellipsometry for inline process control in the semiconductor industry. In: Ellipsometry at the Nanoscale. Springer Berlin Heidelberg, Berlin, Heidelberg, pp 607–627

Solano I, Parisse P, Cavalleri O et al. (2016) Investigating organic multilayers by spectroscopic ellipsometry: specific and non-specific interactions of polyhistidine with NTA self-assembled monolayers. Beilstein J Nanotechnol 7:544–553

Cobet C, Oppelt K, Hingerl K et al. (2018) Ellipsometric spectroelectrochemistry: an in situ insight in the doping of conjugated polymers. J Phys Chem C 122:24309–24320

Cody D, Babeva T, Madjarova V et al. (2020) In-situ ellipsometric study of the optical properties of LTL-doped thin film sensors for copper(II) ion detection. Coatings 10:423

Hilfiker JN, Pribil GK, Synowicki R et al. (2019) Spectroscopic ellipsometry characterization of multilayer optical coatings. Surf Coat Technol 357:114–121

Choi S, Kang C, Byun C-W et al. (2020) Thin-film transistor-driven vertically stacked full-color organic light-emitting diodes for high-resolution active-matrix displays. Nat Commun 11:1–9

Wang H, Madaan N, Bagley J et al. (2014) Spectroscopic ellipsometric modeling of a Bi–Te–Se write layer of an optical data storage device as guided by atomic force microscopy, scanning electron microscopy, and X-ray diffraction. Thin Solid Films 569:124–130

Hoffmann MA, Sharma A, Matthes P et al. (2020) Spectroscopic ellipsometry and magneto-optical Kerr effect spectroscopy study of thermally treated Co60Fe20B20 thin films. J Phys Condens Matter 32:055702

Arwin H (2000) Ellipsometry on thin organic layers of biological interest: characterization and applications. Thin Solid Films 377–378:48–56

Mendoza-Galván A, Muñoz-Pineda E, Ribeiro SJL et al. (2018) Mueller matrix spectroscopic ellipsometry study of chiral nanocrystalline cellulose films. J Opt (U Kingd) 20:024001. (1–10)

Ostroff RM, Maul D, Bogart GR et al. (1998) Fixed polarizer ellipsometry for simple and sensitive detection of thin films generated by specific molecular interactions: applications in immunoassays and DNA sequence detection. Clin Chem 44:2031–2035

Khaleel MI, Chen Y-D, Chien C-H, Chang Y-C (2018) Microscopic imaging ellipsometry of submicron-scale bacterial cells. Trop J Pharm Res 16:2713

Lee SW, Lee SY, Choi G, Pahk HJ (2020) Co-axial spectroscopic snap-shot ellipsometry for real-time thickness measurements with a small spot size. Opt Express 28:25879

Aghgonbad MM, Sedghi H (2019) Spectroscopic ellipsometry studies on zinc oxide thin films deposited by sol-gel method with various precursor concentrations. Surf Rev Lett 26:1–9

Akhtar MS, Riaz S, Naseem S (2015) Optical properties of sol-gel deposited ZnS thin films: spectroscopic ellipsometry. Mater Today Proc 2:5497–5503

Noh M, Seo I, Park J et al. (2016) Spectroscopic ellipsometry investigation on the excimer laser annealed indium thin oxide sol–gel films. Curr Appl Phys 16:145–149

Aghgonbad MM, Sedghi H (2019) Optical and electronic analysis of pure and Fe-doped ZnO thin films using Spectroscopic Ellipsometry and Kramers-Kronig Method. Int J Nanosci 18:1–9

Losurdo M, Hingerl K (2013) Ellipsometry at the Nanoscale. Springer Berlin Heidelberg, Berlin, Heidelberg

Tompkins HG, McGahan WA (1999) Spectroscopic ellipsometry and reflectometry: a user’s guide. Wiley, N.Y

Mia MNH, Pervez MF, Hossain MK et al. (2017) Influence of Mg content on tailoring optical bandgap of Mg-doped ZnO thin film prepared by sol-gel method. Results Phys 7:2683–2691

Aspnes DE (1982) Optical properties of thin films. Thin Solid Films 89:249–262

Bakkali H, Blanco E, Amrani M et al. (2018) An ellipsometric analysis to model the order-disorder transition in Au-SiO2 nano-granular thin films induced by thermal annealing. Thin Solid Films 660:455–462

Jaglarz J, Dulian P, Karasiński P, Winkowski P (2020) Scattering phenomena in porous sol-gel-derived silica films. Coatings 10:509

Ramirez-Rincon JA, Gomez-Heredia CL, Corvisier A et al. (2018) Thermal hysteresis measurement of the VO2 dielectric function for its metal-insulator transition by visible-IR ellipsometry. J Appl Phys 124:195102

Liu Y, Qiu J, Liu L (2018) Applicability of the effective medium approximation in the ellipsometry of randomly micro-rough solid surfaces. Opt Express 26:16560

Ngo D, Liu H, Sheth N et al. (2018) Spectroscopic ellipsometry study of thickness and porosity of the alteration layer formed on international simple glass surface in aqueous corrosion conditions. npj Mater Degrad 2:20

Kostruba A, Stetsyshyn Y, Mayevska S et al. (2018) Composition, thickness and properties of grafted copolymer brush coatings determined by ellipsometry: calculation and prediction. Soft Matter 14:1016–1025

De Sousa Meneses D, Malki M, Echegut P (2006) Structure and lattice dynamics of binary lead silicate glasses investigated by infrared spectroscopy. J Non Cryst Solids 352:769–776

Jellison GE, Modine FA (1996) Parameterization of the optical functions of amorphous materials in the interband region. Appl Phys Lett 69:371–373

Johs B, Herzinger C, Dinan J et al. (1998) Development of a parametric optical constant model for Hg1−xCdxTe for control of composition by spectroscopic ellipsometry during MBE growth. Thin Solid Films 313–314:137–142

Wooten F (1972) Optical properties of solids. Academic Press, New York

Noh M, Seo I, Park J et al. (2016) Spectroscopic ellipsometry investigation on the excimer laser annealed indium thin oxide sol–gel films. Curr Appl Phys 16:145–149

Jellison GE (1993) Data analysis for spectroscopic ellipsometry. Thin Solid Films 234:416–422

Kim SY, Vedam K (1988) Simultaneous determination of dispersion relation and depth profile of thorium fluoride thin film by spectroscopic ellipsometry. Thin Solid Films 166:325–334

Adachi S (1999) Optical properties of crystalline and amorphous semiconductors. Springer, US, Boston, MA

J.A. Woollam Co. (2012) Guide to using WVASE spectroscopic ellipsometry data acquisition and analysis software. J. A. Woollam Co., Inc. Lincoln, NE USA

Schubert M, Tiwald TE, Herzinger CM (2000) Infrared dielectric anisotropy and phonon modes of sapphire. Phys Rev B 61:8187–8201

Aspnes DE (1980) Modulation spectroscopy/electric field effects on the dieletric function of semiconductors. In: Balkanski M (ed) Handbook on Semiconductors, Vol. 2. pp 125–127

Adachi S (1987) Model dielectric constants of GaP, GaAs, GaSb, InP, InAs, and InSb. Phys Rev B 35:7454–7463

Tanguy C (1995) Optical dispersion by Wannier excitons. Phys Rev Lett 75:4090–4093

Tompkins HG, Irene EA (2005) Handbook of ellipsometry. Norwich, NY

Grigorovici R, Stoica T, Vancu A (1982) Evaluation of the optical constants and thicknesses of weakly absorbing non-uniform thin films. Thin Solid Films 97:173–185

Stoica TF, Gartner M, Losurdo M et al. (2004) Spectroellipsometric study of the sol–gel nanocrystalline ITO multilayer films. Thin Solid Films 455–456:509–512

Covei M, Predoana L, Osiceanu P et al. (2016) Niobium/Vanadium doped TiO2 multilayered sol-gel films: Structure, surface chemistry and optical properties. Ceram Int 42:13805–13811

Duta M, Simeonov S, Teodorescu V et al. (2016) Structural and electrical properties of Nb doped TiO2 films prepared by the sol-gel layer-by-layer technique. Mater Res Bull 74:15–20

Zaharescu M, Teodorescu VS, Gartner M et al. (2008) Correlation between the method of preparation and the properties of the sol–gel HfO2 thin films. J Non Cryst Solids 354:409–415

Parlog C, Gartner M, Osiceanu P et al. (1996) Optical and microstructural properties of TiO2(Ni2+) thin films. Ceram Int 22:95–99

Duta M, Anastasescu M, Calderon-Moreno JM et al. (2016) Sol–gel versus sputtering indium tin oxide films as transparent conducting oxide materials. J Mater Sci Mater Electron 27:4913–4922

Fujiwara H, Kondo M (2005) Effects of carrier concentration on the dielectric function of ZnO:Ga and In2O3:Sn studied by spectroscopic ellipsometry: Analysis of free-carrier and band-edge absorption. Phys Rev B 71:075109

Lin K, Wu S-W, Li L-Y, Sawada Y (2016) Spectroscopic ellipsometry study of the optoelectrical properties of In2O3:Sn-ZnO:Al thin films deposited through alternating sputtering. J Ceram Soc Jpn 124:528–531

Schubert M (2004) Infrared ellipsometry on semiconductor layer structures: phonons, plasmons and polaritons. Berlin

Ossikovski R, Drévillon B, Firon M (1995) Infrared ellipsometry study of the thickness-dependent vibration frequency shifts in silicon dioxide films. J Opt Soc Am A 12:1797

Michail G, Kambylafka V, Kortidis I et al. (2016) On the growth of transparent conductive oxide ternary alloys Zn–Ir–O (ZIRO) by the means of rf magnetron co-sputtering. Thin Solid Films 617:3–8

Stroescu H, Anastasescu M, Preda S et al. (2013) Influence of thermal treatment in N2 atmosphere on chemical, microstructural and optical properties of indium tin oxide and nitrogen doped indium tin oxide rf-sputtered thin films. Thin Solid Films 541:121–126

Nicolescu M, Anastasescu M, Preda S et al. (2012) Influence of the substrate and nitrogen amount on the microstructural and optical properties of thin r.f.-sputtered ZnO films treated by rapid thermal annealing. Appl Surf Sci 261:815–823

Bundesmann C, Buiu O, Hall S, Schubert M (2007) Dielectric constants and phonon modes of amorphous hafnium aluminate deposited by metal organic chemical vapor deposition. Appl Phys Lett 91:121916

Ashkenov N, Mbenkum BN, Bundesmann C et al. (2003) Infrared dielectric functions and phonon modes of high-quality ZnO films. J Appl Phys 93:126–133

Kang TD, Lee GS, Lee HS et al. (2006) Infrared ellipsometric study on PZT thin films. J Korean Phys Soc 49:1604–1610

Barth J, Johnson RL, Cardona M (1998) Spectroscopic ellipsometry in the 6-35 eV region. In: Palik ED (ed) Handbook of optical constants of solids II. Academic Press, San Diego, CA

Edwards NV (2003) Status and prospects for VUV ellipsometry (applied to high k and low k materials). In: AIP conference proceedings. AIP, pp 723–737

Schmidt-Grund R, Schubert M, Rheinländer B et al. (2004) UV–VUV spectroscopic ellipsometry of ternary MgxZn1−xO (0≤x≤0.53) thin films. Thin Solid Films 455–456:500–504

Suchaneck G, Chvostová D, Kousal J et al. (2011) Vacuum-ultraviolet ellipsometry spectra and structural properties of Pb(Zr,Ti)O3 films. Thin Solid Films 519:2885–2888

Chvostová D, Pajasová L, Železný V (2008) Optical properties of PZT thin films by spectroscopic ellipsometry and optical reflectivity. Phys status solidi c 5:1362–1365

Dorywalski K, Lemée N, Andriyevsky B et al. (2017) Optical properties of epitaxial Na0.5Bi0.5TiO3 lead-free piezoelectric thin films: Ellipsometric and theoretical studies. Appl Surf Sci 421:367–372

Boher P, Defranoux C, Heinrich P et al. (2004) VUV spectroscopic ellipsometry applied to the characterization of high-k dielectrics. Mater Sci Eng B 109:64–68

Hilfiker NJ, Bungay CL, Synowicki RA et al. (2003) Progress in spectroscopic ellipsometry: Applications from vacuum ultraviolet to infrared. J Vac Sci Technol A Vac, Surf, Film 21:1103–1108

Schmidt-Grund R, Rheinländer B, Kaidashev EM et al. (2008) Vacuum ultraviolet dielectric function and band structure of ZnO. J Korean Phys Soc 53:88–93

Wagner T, Hilfiker JN, Tiwald TE et al. (2001) Materials characterization in the vacuum ultraviolet with variable angle spectroscopic ellipsometry. Phys status solidi 188:1553–1562

Peters S, Schmidtling T, Trepk T et al. (2000) In situ monitoring of GaN metal-organic vapor phase epitaxy by spectroscopic ellipsometry. J Appl Phys 88:4085–4090

Wethkamp T, Wilmers K, Cobet C et al. (1999) Dielectric function of hexagonal AlN films determined by spectroscopic ellipsometry in the vacuum-uv spectral range. Phys Rev B 59:1845–1849

Cobet C, Esser N, Zettler JT et al. (2001) Optical properties of wurtzite AlxGa1−xN (x<0.1) parallel and perpendicular to the c axis. Phys Rev B 64:165203

Kasic A, Schubert M, Rheinländer B et al. (2001) IR-VUV dielectric function of Al1−xInxN determined by spectroscopic ellipsometry. MRS Proc 639:G6.13

White WB, Keramidas VG (1972) Vibrational spectra of oxides with the C-type rare earth oxide structure. Spectrochim Acta Part. A Mol Spectrosc 28:501–509

Silva GM, Faria EH, de, Nassar EJ et al. (2012) Synthesis of indium tin oxide nanoparticles by a nonhydrolytic sol-gel method. Quim Nova 35:473–476

Zerdali M, Hamzaoui S, Teherani FH, Rogers D (2006) Growth of ZnO thin film on SiO2/Si substrate by pulsed laser deposition and study of their physical properties. Mater Lett 60:504–508

de Campos B, Freiria G, Ciuff K et al. (2017) ITO obtained by spray pyrolysis and coating on glass substrate. J Braz Chem Soc 28:2412–2420

Shahrokh Abadi MH, Delbari A, Fakoor Z, Baedi J (2015) Effects of annealing temperature on infrared spectra of SiO2 extracted from rice husk. J Ceram Sci Technol 6:41–45

Tian R, Seitz O, Li M et al. (2010) Infrared characterization of interfacial Si−O bond formation on silanized flat SiO2/Si surfaces. Langmuir 26:4563–4566

Zaharescu M, Crisan M, Simionescu L et al. (1997) TiO2-based porous materials obtained from gels, in different experimental conditions. J Sol-Gel Sci Technol 8:249–253

Calderon-Moreno JM, Preda S, Predoana L et al. (2014) Effect of polyethylene glycol on porous transparent TiO2 films prepared by sol–gel method. Ceram Int 40:2209–2220

Anastasescu M, Teodorescu VS, Buiu O et al. (2014) Substrate impact on optical and microstructural properties of TiO2–PEG sol–gel films. Ceram Int 40:11803–11811

Boudot M, Cattoni A, Grosso D, Faustini M (2017) Ethanol–water co-condensation into hydrophobic mesoporous thin films: example of a photonic ethanol vapor sensor in humid environment. J Sol-Gel Sci Technol 81:95–104

Brigo L, Faustini M, Pistore A et al. (2016) Porous inorganic thin films from bridged silsesquioxane sol–gel precursors. J Non Cryst Solids 432:399–405

Agustín-Sáenz C, Machado M, Tercjak A (2020) Polyfluoroalkyl-silica porous coatings with high antireflection properties and low surface free energy for glass in solar energy application. Appl Surf Sci 509:144864

Zaharescu M, Cristea D, Obreja P, et al. (2007) SiO2-TiO2 undoped or (Er3+) doped thin layers for integrate optics prepared by sol-gel method. In: International semiconductor conference. IEEE, pp 215–218