Abstract

In the present study, a possibility to realize a transparent sol by zinc-based precursors in a neutral medium without acidic or alkaline catalyst was investigated. Moreover, to study the influence of an inorganic–organic hybrid polymer on the proposed antibacterial finishing, the Zn-based sol was mixed with 3-glycidoxypropyltrimethoxysilane (GPTMS), a hybrid sol–gel precursor, to produce zinc-containing silica coatings on the cotton fibres. An optimization of functionalization process parameters was performed by monitoring survival rate of Escherichia coli bacteria. Finally, selected finishes were tested in respect to their antibacterial activity using potential pathogenic bacteria Staphylococcus aureus and Klebsiella pneumoniae. Sol–gel synthesized cotton finishes based on nano-Zn acetate without and with GPTMS showed larger bactericidal and bacteriostatic activities. The both types of finishes also show hydrophobic effect within the first eliminates the hydrophobicity effect and reduces antibacterial activity. The results are very promising, since the antibacterial activity of cotton is comparably high and the finishing procedure is cheap and can be easily performed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Recent developments in the field of nanotechnology, i.e. the ability to prepare highly ionic metal oxide nanoparticles of any size and shape may lead to the development of new antibacterial agents [1] which is of considerable interest on the part of textile industry. Particularly, it has been demonstrated that nanoparticulate ZnO exhibit strong antibacterial activities on a broad spectrum of bacteria [2, 3], even against spores that are high-temperature and high-pressure resistant. Moreover, the antibacterial activity of ZnO powder increases with decreasing particle size, i.e. increasing specific surface area, and increasing powder concentration [4]. Smaller ZnO particles have a better antibacterial activity and it is not affected by surface modifications such as silane surfactant and gold nanoparticle attachments as shown in [2]. In [5], it was shown that sol–gel synthesized nanocrystalline ZnO shows larger bactericidal activities tested with Escherichia coli than commercial ZnO nanoparticles. The photocatalytic generation of hydrogen peroxide was suggested to be one of the primary factors concerned in the antibacterial activity of ZnO as measured by conductimetric assay [1]. Moreover, among the range of compounds whose antibacterial activity being investigated, ZnO nanoparticles appear to be the most promising new unconventional antibacterial agent that could be helpful to confront methicillin-resistant Staphylococcus aureus (MRSA) and other drug-resistant bacteria [6]. Finally, ZnO can degrade dirt and, therefore, can be used also as an inexpensive self-cleaning material [7]. At the same time, this inorganic agent has attracted increasing attention due to its long-lasting, no drug resistance generation, and heat resistance [8].

A survey of up-to-date literature [9] reveals that sol preparation procedure to obtain ZnO textile finishing is basically comparable to that of Spanhel and Anderson [10]. The two-step conventional synthesis consists in the aqueous suspension and hydrolysis of the precursor to form the zinc oxide nanoparticles. Particularly, in the first step the precursor is uniformly dispersed in a solvent (methanol, ethanol or isopropanol) by reflux heating for few hours. Then, after cooling, the precursor suspension is added by alkaline aqueous solution under vigorous stirring. Finally, the precipitate is generally collected by filtration and rinsed with high-purity water and ethanol, to obtain the ZnO nanoparticles ready for textile fabric treatments. Alternatively, antibacterial coating via sol–gel can be realized in strong alkaline conditions [11].

In the present study, a possibility to realize a transparent sol by zinc-based precursors according to their counter anion and concentration in a neutral medium without acidic or alkaline catalyst was investigated. Moreover, to study the influence of an inorganic–organic hybrid polymer on the proposed antibacterial finishing, the Zn-based sol was mixed with 3-glycidoxypropyltrimethoxysilane (GPTMS), a hybrid sol–gel precursor, to produce zinc-containing silica coatings on the cotton fibres. The feasibility of introducing functional molecules into a GPTMS sol–gel matrix onto textile fabrics, have been recently demonstrated in previous studies [12–14].

A preliminary study was performed to evaluate different hydrated zinc salts—acetate, nitrate, perchlorate.

Unfortunately, neither nitrate nor perchlorate were able to give a suitable sol, in agreement with other recent reports [15]. Conversely, zinc acetate in hydroalcoholic media allowed to produce a stable and reproducible system under a great variety of experimental conditions. Methanol was selected to realize a hydroalcoholic solution since the precursor is more soluble in this solvent than in ethanol or isopropanol, according to dielectric constants of these alcohols. The aim of the studies described in the paper was to develop a one-step deposition via sol–gel technique in a neutral hydro-alcoholic medium, without using base such as NaOH or LiOH, to realize an antibacterial surface on cotton fabric.

2 Experimental

2.1 Materials

A standard plain weave cotton fabric with a weight of 170 g/m2 (yarn count of 295/295 dtex and pick count of 270/270 pick/dm) was purchased from wfk Testgewebe (Brüggen, Germany). The fabric was rinsed up to 30 times with deionized water in order to remove residual surfactants from the fabric until the surface tension of rinse water was measured to 72 mN/m. The cleaned and dried cotton samples were conditioned under standard atmospheric pressure at 65 ± 4 % relative humidity and 20 ± 2 °C for at least for 24 h prior to all the experiments. Zinc acetate dihydrate ZnAc2·2H2O, a GPTMS precursor containing methoxysilane groups and an epoxy group, and methanol were obtained from Aldrich. All chemicals were used without further purification. E. coli (ATCC® CRM-11229™) was obtained from LGC Standards (UK). Culture broth (Lurie–Bertani broth, LB) and culture agar (Luria–Bertani agar) were obtained from Sigma Aldrich for the use as culturing nutrient sources. Tryptone, Nutrient broth and Plate Count Agar for testing according to EN ISO 20743 were obtained from AES Laboratoire (France). Staphylococcus aureus (CCM 4516) and Klebsiella pneumoniae (CNCTC 6120) were derived from the National Institute of Public Health and Czech Collection of Microorganisms.

2.2 Sol preparation and application process

In order to test antibacterial properties of textile samples treated by the sol obtained by the hydrolysis of the precursor, in spite of the neutral solution, ZnAc2·2H2O was slowly added to a 25 % v/v methanol aqueous solution under vigorous stirring to form 5, 15, 30 g/L sols. Transparent sols obtained were left under magnetic stirring for 5 h before application.

The reaction mechanism involves the sequence of solvation, complex formation, hydrolysis, polymerization, and crystallization, which are typically involved in the sol–gel processing of non-silicate metal oxides. The pH of the as-prepared solution was measured to be about 6.5 at 25 °C.

Usually, organic–inorganic hybrid materials are suitable to immobilize molecules onto textile fabrics and to make finishing more homogeneously distributed on the fibre surface. For this reason and to improve the properties of zinc-based coating applied onto textile fabric, hybrid finishes were also prepared by adding GPTMS to two ZnAc2·2H2O sols. The Zn-based sols mentioned above were prepared by adding an amount of the precursor necessary to obtain 5 and 30 g/L of final concentration into half of the calculated volume of water/methanol solution (75:25 %); they were then stirred for 3 h. In the following, 5 mL of GPTMS was slowly added into the two sols, separately, and finally the residual hydroalcoholic solution was added to the precursor mixtures to reach a 100 mL final volume. After a further stirring for 2 h, the sols were ready for textile treatments.

Cotton fabric samples (20 cm × 30 cm) were impregnated by the obtained sols and afterward passed through a two-roll laboratory padder (Werner Mathis, Switzerland) working with 3 bar nip pressure in order to achieve a 75–85 % wet pick-up. After drying at 80 °C for 10 min, the fabrics were cured (at 170 °C for 4 min) in a gravity convection oven. The total dry solids add-on on cotton samples (A, wt%) was calculated according to the following equation and reported in Table 1:

where W1 and W2 are the dry weights of the fabric specimens respectively before and after the impregnation with the sol solution and the subsequent thermal treatment. The experiments were repeated four times for each material investigated to ensure reproducible and significant data; the experimental error was within 5 %.

Test pieces of the fabric were washed at 40 °C in aqueous solution of 300 mL Marseille soap (2 % w/w) using a Labomat (Werner Mathis, Zurich, Switzerland) for 30 min. After washing, the samples were dried over night at room temperature. Textile samples treated with Zn finishing were subjected up to 20 washing cycles, GPTMS–ZnAc were subjected to 1 and 5 washing cycles.

2.3 Characterization

2.3.1 Scanning electron microscopy

For qualitative assessment, the samples were studied by scanning electron microscopy (SEM). The images were recorded by a Phenom Desktop SEM (PhenomWorld, The Netherlands) after sputtering the surfaces with a 7 nm thickness gold layer, using magnifications of 3,500× and 7,000×.

2.3.2 Surface roughness analysis

Surface topography of the samples was examined using two different optical non-contact methods: (1) stereophotogrammetry and (2) high resolution scandisc confocal microscopy. The stereophotogrammetry method was used to characterize meso-topography of the fabric samples (5 mm × 5 mm) by means of a TRACEiT (Innowep, Germany). To measure the micro-roughness of fibres, a high resolution scandisc confocal microscope µSurf (Nanofocus, Germany) was used. A detail description of this equipment and measuring procedure is provided in [16].

2.3.3 Wettability characterization

To estimate the degree of fabric’s hydrophilicity/hydrophobicity, dynamic wetting measurements were carried out with a contact angle measuring device OCA 40 Micro (DataPhysics, Germany) equipped with a high speed video camera. The initial water contact angle and total absorption time (drop life time) were used to evaluate the wettability of fabrics before and after treatment by the sol. More details about dynamic contact angle measurements are provided in [17].

2.3.4 Determination of antibacterial activity

First, an optimization of functionalization process parameters by monitoring survival rate of E. coli bacteria was performed. Second, selected finishes were tested in respect to their antibacterial activity using potential pathogenic bacteria S. aureus and K. pneumoniae.

A microbiological study with E. coli bacteria was performed in respect to evaluate the cotton fabrics modified with Zn precursor and organic–inorganic hybrid nanomaterials before and after washing about their antibacterial properties. For that, a quantitative measurement of the bacterial population on a textile material was used which compares actual numbers of organisms surviving on treated fabrics to untreated control fabrics. The amount of bacterial growth in inoculated and incubated textiles was determined through serial dilutions and subsequent inoculations of sterile agar.

A suspension of E. coli bacteria was prepared using LB broth with a concentration of 0.02 of optical density measured with a spectrophotometer a WPA CO-8000 Cell Density Meter at 600 nm. A 30 μL of bacterial suspension in form of 4 droplets were applied on a textile sample of 20 × 20 mm size. The samples were placed into Petri dishes with agar plates above them at 37 °C for 24 h. After incubation, each textile sample—treated with bacteria as a reference and those after washing—was placed in a tube with a small amount (5 mL) of LB each. After 30 times shaking, each suspension was applied according to the spread plate method onto a sterile agar plate. The plates were incubated at 37 °C for 24 h. The minimal bactericidal concentration (MBC)—a minimum concentration showing no viable cell growth—of the sols used were determined by a dilution test. If no colony was observed, the corresponding zinc-based sol solution was considered as being bactericidal at that concentration. All tests were carried out in triplicate.

For the determination of antibacterial activity of selected finishes with S. aureus and K. pneumoniae bacteria, absorption method according to EN ISO 20743:2007 was used, in which test bacterial suspension is directly inoculated onto textile samples. The aim of this test is to determine and compare the number of bacteria on sample at 0 h and after 24 h incubation bacteria on sample. The test was carried out separately on two strains of bacteria—S. aureus and K. pneumoniae. The bacterium was adjusted to a concentration of 1 × 105 to 3 × 105 CFU/mL by a McFarland nephelometer using nutrient broth after it has been diluted 5 times with distilled water. 0.2 mL of this inoculum suspension was pipetted on each test sample placed in a closed vial. Immediately after inoculation, 20 mL of SCDLP—a shake-out medium—was added to each of three vials (all tests were carried out in triplicate), containing treated samples and each of three vials containing untreated (reference) sample, and bacteria were shaken-out from textile samples. The number of bacteria (at 0 h) was determined by the plate count method (see description below). The remaining vials were incubated at 37 °C for 24 h. After incubation, 20 mL of SCDLP medium was added to each of six vials (three with treated samples and three for untreated samples) and shaken-out. The number of bacteria (at 24 h) was calculated by the plate count method, i.e. a method in which the number of bacteria present after incubation is calculated by counting the number of colonies according to a tenfold serial dilution. Tryptone was used as a dilution medium. 1 mL of each dilution was pipetted into Petri dishes and approximately 15 mL of PCA (Plate Count Agar) was added to the dishes and mixed. After incubation of the Petri dishes at 37 °C for 24–48 h, the number of bacteria in 1 mL was counted (c B in CFU/mL). The final number of bacteria (M in CFU) is calculated according to the equation

where M is the number of bacteria per specimen, c B is the bacteria concentration obtained by the plate count method (CFU/mL) and 20 is the volume of the shake-out solution (mL).

3 Results and discussion

Using the sol–gel process described above, ZnO films can be obtained starting from inorganic salts (i.e. chlorides, nitrates, perchlorates) or organic salts (i.e. acetates), dissolved in alcoholic media. The use of additives, as acid or basic and/or chelating agent, is promoted to facilitate zinc salt dissolution in some alcoholic media. Moreover, they can play a role of chelating and stabilizing ligands, avoiding rapid precipitation of zinc hydroxide and allowing any formation of stable dispersions or solutions. Lithium (or sodium) hydroxide is often used to form stable dispersions of colloids. In the innovative way proposed for sol–gel finishing of cotton fabric, in the absence of other nucleophilic species competing for the Zn2+ Lewis acid center (i.e. HO− or bidentate ligand), the acetate group plays a very relevant role. According to [15], the progressive condensation of the hydrolyzed moieties gives rise to colloids or precipitates. Stable acetate-capped colloidal nano-sized to sub-micrometer-sized particles can be formed in dilute solutions (Fig. 1). This is in agreement with the present research where the analyzed solutions resulted in homogeneous, clear and stable sols that were selected as the optimum compositions.

In order to find evidence of any relevant changes in the fabric surface due to treatment with the hybrid sols, analysis by scanning electron microscopy (SEM) was performed. Figure 2 shows two magnifications of treated and untreated cotton fabrics. As is well known, pure cotton fibres are characterized by a certain inhomogeneity level due to the natural growing, as depicted in Fig. 2a. When the fibres are sol–gel treated, their surface becomes slightly rougher (Fig. 2b, c), due to the presence of coating covering the fibres completely. The textile surfaces treated by sol obtained using ZnAc precursor shows several fractures in the coating, that disappear when GPTMS is added in the sol, indicating excellent inter-particle connectivity and high inter-layer attachment. The presence of GPTMS in sol makes the hybrid thin film more homogeneously distributed on the fibre surface (Fig. 2c). No agglomerated particles are visible on the surface of both treated samples, which indicates an homogeneous distribution of the coating and the absence of unwanted agglomerations on the finished fibres.

Surface roughness plays a critical role in surface wettability. It influences the behaviour of liquid drops in both thermodynamic and hydrodynamic aspects. Enhanced surface roughness can increase the static contact angle of water making the surface water repellent or superhydrophilic. Generally speaking, surface roughness influences the wetting behaviour of a liquid on a surface and therefore, complicates a quantitative interpretation of the wetting results. In this study, surface roughness parameters S a and S rl were obtained from topographical measurements according to ISO/DIS 25178-2. The parameter Sa is the arithmetic mean surface roughness being the arithmetic average of all distances between Z-value and mean height inside a range of captured data. S a is usually used to describe the surface roughness. The parameter S rl is a hybrid parameter originally introduced by Wenzel [18] to describe wetting of rough surfaces. The roughness factor of a surface is the ratio between the real surface area and the projected one. It is obvious, that the roughness factor determined is bound by the resolution of the measuring device.

Topographical characteristics of cotton fabrics functionalized by Zn precursor using sol–gel method are presented in Table 2. The fabric roughness is quite unaffected by the type of treatment independently on washing. In case of the cotton functionalization by 3 % of ZnAc and 3 % of GPTMS–ZnAc, the roughness factor of fibres is slightly increased after washing. In general, cotton fibres have not altered after their modification by 3 % ZnAc, whereas they became slightly smoother in case of 3 % GPTMS–ZnAc modification, according to SEM characterization.

Wettability, depending on the geometrical structure and the chemical composition of the materials, was examined by water contact angle (WCA) measurements. In Fig. 3, water droplet images placed on differently functionalized cotton surfaces are shown. The untreated cotton fabric has been rapidly wetted by water due to the abundant hydroxyl groups in its structure. On contrary to the pristine cotton sample, the treated cotton fabrics showed a certain water repellency. The modification of wetting behaviour of samples after treatments at different compositions was characterised. The water droplet behaviour indicated a decrease in water repellency for 3 % Zinc acetate GPTMS with respect to the 3 % Zinc acetate. This decrease is supported by the roughness factor values of the fibres that decreased from 1.558 to 1.262, due to the presence of silica coating able to reduce the roughness factor making slightly smoother the cotton fibres. From dynamic contact angle measurements data, initial contact angle and total penetration time, also known as droplet life time, are summarized for textile substrates under investigation in Table 3. The experimental error was within 10 %.

The initial contact angle was almost 89° for untreated cotton and, after treatment, it increased to 132° for both ZnAc and GPTMS–ZnAc sols. Treated surfaces showed a more pronounced hydrophobic character which can be explained by the reduction of hydroxyl sites due to the presence of finishes.

The functionalization led to an increase of the initial water contact angle, while the total penetration time also depends on washing cycles. After one washing cycle, the initial WCA on the cotton fabrics coated with ZnAc sol and GPTMS containing ZnAc sol were 121° and 143°, respectively; the same behaviour was observed also after 5 washing cycles. However, the total absorption time decreased remarkably after repeated washing, modifying drastically the drop life time and making functionalized cotton surfaces hydrophilic.

This could be due to the swelling property of cellulose fibre in washing process. As a result, the compatibility and adhesion between cellulose fibres and inorganic layer decreased during laundering. This decrease is more important for samples treated with ZnAc-based sol, that already after one washing cycle show an absorption rate similar to the untreated one, probably due to the inorganic nature of this films that tend to crack during the laundering. Crack formation, resulting in bare fibre areas, leads to ineffectiveness of the repellency, allowing the absorption of water into the fibre due to capillary forces [19]. When an epoxide group containing silane, GPTMS, was added in the ZnAc sol, the total absorption time and, consequently, hydrophobicity of the obtained coating is slightly decreased; at the same time the laundering durability was slightly higher compared to ZnAc-based sol.

A typical contact angle curve measured as a function of time is shown in Fig. 4 as an example. Two wetting regimes are clearly seen—quasi-static wetting where the drop base and, consequently, contact angle remains approximately constant and penetration which is marked by liquid drop absorption into fabrics. The wetting behaviour of a liquid droplet on a textile surface has been extensively studied by the authors and described previously in [20].

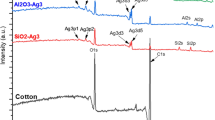

Antibacterial activity of cotton fabrics coated with both ZnAc-based sols and hybrid GPTMS–ZnAc solutions were evaluated respect to the untreated sample to assess the effectiveness of finishing. Antibacterial activity was evaluated qualitatively and quantitatively. There are several possible mechanisms for the antibacterial action of Zinc against bacteria, but to date, the process underlying their antibacterial effect is not completely clear. However, few studies have suggested that the Zinc particles are attached on the bacterial cell wall through electrostatic interaction, rupturing the cell walls, increasing the permeability, causing the leakage of cytoplasm, and leading to bacterial cell death [21]. Another possibility could be the induction of intercellular reactive oxygen species, including hydrogen peroxide (H2O2), a strong oxidizing agent harmful to bacterial cells [22, 23]. In this study, the evaluation of antibacterial activity of textile finishings against a gram-negative bacterium, E. coli, was studied qualitatively in aqueous LB broth by halo method (zone of inhibition) (Fig. 5). As expected, no reduction of the bacteria E. coli was found on the unfinished cotton sample. On the contrary, antibacterial activity results revealed that Zn precursor on cotton acted as excellent antibacterial agent against Gram-negative bacteria. After the E. coli (Gram-negative) suspension was applied onto a sterile agar plate and they were incubated at 37 °C for 24 h, their viable colonies vanished. The results showed that when bacterial colonies of E. coli interact with the unwashed cotton samples treated with both ZnAC and GPTMS–ZnAc solutions, they are almost completely suppressed.

The results reported in Fig. 6 show that a complete reduction in growth of bacterium was reached for the unwashed sample treated with 3 % ZnAc sol. In the same way, after one and five washing cycles, the finished fabrics exhibited a complete reduction of E. coli. A distinct zone of inhibition was observed indicating complete inhibition of the bacterial growth. Only a small numbers of colonies are visible after 10 washing cycles, while bacterial growth after 20 washing cycles is evident.

As shown in Fig. 7, the antibacterial activity of finished fabric treated with ZnAc is independent on the concentration used. In fact, the antibacterial activity against E. coli shows a clear zone of inhibition within and around the disc impregnated with ZnAc-based sol at (A) 0.5 %, (B) 1, 5 and (C) 3 %.

The results of the antibacterial test according to the absorption method using pathogenic S. aureus and K. pneumoniae bacteria, are summarized in Table 4. Judgment of the test effectiveness was done according to three criteria: (1) concentration of the test inoculum was 1.4 × 105 CFU/mL; (2) the difference in extremes for the three control fabrics immediately after inoculation and after incubation was 0.22 and 0.36 for S. aureus and 0.23 and 0.25 for K. pneumoniae, respectively; (3) the growth value obtained according to lg(arithmetic average of CFU after incubation, control fabrics; 24 h) − lg(arithmetic average of CFU immediately after inoculation, control fabrics, 0 h) was 3.43 and 3.91 for S. aureus and K. pneumoniae, respectively. Inspection of the results revealed that the bacteria did not grow on all the finished samples. Importantly, only sample treated just with 0.5 % of ZnAc sol did not show full bacteria reduction after 5 consecutive washings, suggesting the effective prevention of bacterial on cotton fabrics. In fact, for each pathogenic bacterium, the treatment of cotton by Zn acetate has shown the bactericidal effect independently of the concentration of Zn acetate under study with a reduced number of 4 logarithmic grades for both bacteria types compared to the untreated sample. It should be noted that the growth of bacteria was visible in the case of cotton treated with ZnAc at 0.5 % after five washing cycles as compared to the other coated fabrics. These results demonstrate that, after repeated laundering, the antibacterial activity of the treated samples at lowest concentration is limited to the biostatic, rather than the biocidal. They inhibit the growth of bacteria, but do not kill them. The results furthermore show that the unwashed 3 % ZnAc sample, tested on S. aureus, has immediately shown, after first contact with sample (in 0 h), an antibacterial effect. Moreover, also after five laundering cycles, non negligible bactericidal property for the 3 % ZnAc sample has been observed.

4 Conclusion

In this paper, zinc-based coatings for antibacterial finishing of cotton fabric were successfully synthesized using an innovative sol–gel route in neutral hydro-alcoholic media. Compared to the conventional methods to obtain ZnO powder by zinc precursors in alkaline solution with reflux heating, the one-step coating system reported is simple and reproducible for the preparation of transparent antibacterial surfaces. The coating proposed might provide a novel, easy alternative to conventional methods for the manufacturing of protective textile fabrics, highlighting that precipitation of ZnO is not necessary. The most important advantages of the present method are the low-temperature process, the neutral media and the formation of the unique morphology on the treated textile fabrics. In fact, sol–gel synthesized cotton finishes based on nano-Zn acetate without and with GPTMS show larger bactericidal and bacteriostatic activities, tested with E. coli, S. aureus and K. pneumoniae bacteria, even after five cycles of washing in case of highest concentration. The both types of finishes also show hydrophobic effect within the first laundering cycle eliminates the hydrophobic. The results are very promising, since the antibacterial activity of cotton is comparably high and the finishing procedure is cheap and can be easily performed.

References

Sawai J (2003) Quantitative evaluation of antibacterial activities of metallic oxide powders (ZnO, MgO and CaO) by conductimetric assay. J Microbiol Methods 54:177–182

Tam KH, Djurišić AB, Chan CMN, Xi YY, Tse CW, Leung YH, Chan WK, Leung FCC, Au DWT (2008) Antibacterial activity of ZnO nanorods prepared by a hydrothermal method. Thin Solid Films 516:6167–6174

Zhang L, Ding Y, Povey M, York D (2008) ZnO nanofluids—a potential antibacterial agent. Prog Nat Sci 18:939–944

Yamamoto O (2001) Influence of particle size on the antibacterial activity of zinc oxide. Int J Inorg Mater 3:643–646

Karunakaran C, Rajeswari V, Gomathisankar P (2011) Enhanced photocatalytic and antibacterial activities of sol–gel synthesized ZnO and Ag–ZnO. Mater Sci Semicond Process 14:133–138

Ansari MA, Khan HM, Khan AA, Sultan A, Azam A (2012) Characterization of clinical strains of MSSA, MRSA and MRSE isolated from skin and soft tissue infections and the antibacterial activity of ZnO nanoparticles. World J Microbiol Biotechnol 28:1605–1613

Wang H, Xie C, Zhang W, Cai S, Yang Z, Gui Y (2007) Comparison of dye degradation efficiency using ZnO powders with various size scale. J Hazard Mater 141:645–652

Dastjerdi R, Montazer M (2010) A review on the application of inorganic nano-structured materials in the modification of textiles: focus on anti-microbial properties. Colloids Surf B Biointerfaces 79:5–18

Farouk A, Moussa S, Ulbricht M, Schollmeyer E, Textor T (2013) ZnO-modified hybrid polymers as antibacterial finish for textiles. Text Res J. doi:10.1177/0040517513485623

Spanhel L, Anderson MA (1991) Semiconductor clusters in the sol–gel process: quantized aggregation, gelation and crystal growth on concentrated ZnO colloids. J Am Chem Soc 113:2826–2833

Gao D-G, Chen C, Ma J-Z, Lv B, Jia X-L (2013) Preparation, characterization and application of ZnO sol containing quaternary ammonium salts. J Sol-Gel Sci Technol 65:336–343

Caldara M, Colleoni C, Guido E, Re V, Rosace G (2012) Development of a textile-optoelectronic pH meter based on hybrid xerogel doped with Methyl Red. Sens Actuator B Chem 171–172:1013–1021

Van der Schueren L, De Clerck K, Brancatelli G, Rosace G, Van Damme E, De Vos W (2012) Novel cellulose and polyamide halochromic textile sensors based on the encapsulation of Methyl Red into a sol–gel matrix. Sens Actuator B Chem 162:27–34

Guido E, Colleoni C, De Clerck K, Plutino MR, Rosace G (2014) Influence of catalyst in the synthesis of a cellulose-based sensor: kinetic study of 3-glycidoxypropyltrimethoxysilane epoxy ring opening by Lewis acid. Sens Actuator B Chem 203:213–222

Znaidi L (2010) Sol–gel-deposited ZnO thin films: a review. Mater Sci Eng B 174:18–30

Calvimontes A, Dutschk V, Stamm M (2010) Advances in topographic characterization of textile materials. Text Res J 80:1004–1015

Dutschk V (2013) Surface wetting. From a phenomenon to an important analytical tool. In: Rubio RG, Rjyzantsev YS, Starov VM, Huang G-X, Chetverikov AP, Arena P, Nepomnyashchy AA, Ferrus A, Morozov EG (eds) Without bounds: a scientific canvas of nonlinearity and complex dynamics. Springer, Berlin, pp 227–257

Wenzel RN (1949) Surface roughness and contact angle. J Phys Colloid Chem 53:1466–1467

Mahltig B, Textor T (2008) Nanosols and textiles, 1st edn. World Scientific, London

Calvimontes A, Badrul Hasan MM, Dutschk V (2010) Effects of topographic structure on wettability of differently woven fabrics. In: Dubrovski PD (eds) Woven fabric engineering. Sciyo, Rijeka, Croatia, pp 71–92

Sun T, Hao H, Hao WT, Yi SM, Li XP, Li JR (2014) Preparation and antibacterial properties of titanium-doped ZnO from different zinc salts. Nanoscale Res Lett 98:1–11

Xie Y, He Y, Irwin PL, Jin T, Shi X (2011) Antibacterial activity and mechanism of action of zinc oxide nanoparticles against campylobacter jejuni. Appl Environ Microb 77:2325–2331

Farouk A, Moussa S, Ulbricht M, Schollmeyer E, Textor T (2012) ZnO nanoparticles-chitosan composite as antibacterial finish for textiles. Int J Carbohydr Chem. doi:10.1155/2012/693629

Acknowledgments

This study is related to the activity of the European networks COST MP1106 ‘Smart and Green Interfaces’ and CM1101 ‘Colloidal Aspects of Nanoscience for Innovative Processes and Materials’.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Poli, R., Colleoni, C., Calvimontes, A. et al. Innovative sol–gel route in neutral hydroalcoholic condition to obtain antibacterial cotton finishing by zinc precursor. J Sol-Gel Sci Technol 74, 151–160 (2015). https://doi.org/10.1007/s10971-014-3589-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-014-3589-9