Abstract

Magnetoelectric (ME) xLa0.6Ca0.4MnO3–(1 − x)Bi3.4Nd0.6Ti3O12 (LCMO–BNT) composite thin films have been prepared by a sol–gel process and spin-coating technique. The effects of LCMO content on the microstructure, leakage current density, ferroelectric properties, fatigue endurance and ME voltage coefficient of LCMO–BNT thin films derived by sol–gel method were studied. It was found that the composite thin films have better fatigue endurance properties and lower leakage current densities compared with pure BNT thin films, as well as large ME voltage coefficients.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Multiferroic materials, which exhibit both ferroelectric and ferromagnetic properties in a single phase, have attracted increasing interest due to their potential application in multifunctional devices and their fascinating fundamental physics [1–3]. Examples of the potential applications include multistate memories and logical devices, tunable filters, sensors and new types of electromechanical devices [4, 5]. However, the magnetoelectric (ME) coupling coefficient in single-phase compounds at ambient conditions is typically too small to be useful in applications [6]. The primary requirement for the observation of the ME effect is the coexistence of magnetic and electric dipoles. Based on this outline, the ME effect could be realized in a composite consisting of both ferroelectric phase and ferromagnetic phase by using the product property, which is first proposed by Van Suchetelene [7]. Up to now, various ME composites have been developed [8, 9]. Most of them are bulk materials, e.g., the sintered composites of BaTiO3–NiCuZn and CuFe2O4–PbZr0.53Ti0.47O3, [10, 11] multilayer composites of NiFe2O4–PZT and Terfenol-D-PZT, [12, 13] etc. Recently, interest in multiferroic composite materials has gradually been focused on composite thin films [14–17]. Compared to bulk composites, ME composite thin films exhibit unique advantages. Their composition and connectivity could be modulated at the microscopic scale, and the artificial thin film heterostructures can thus be achieved, which have potential applications in all kinds of microdevices and integrated units [16]. ME coupling has been measured in thin films with ferromagnetic nanoparticles embedded in the ferroelectric matrix [16, 17]. Many studies have revealed that Nd-substituted Bi4Ti3O12 is the most promising candidate for use in Pb-free piezoelectrics because of its excellent piezoelectricity and polarization behaviors [18–20]. Nanoparticulate Bi3.15Nd0.85Ti3O12–CoFe2O4 composite films with CoFe2O4 nanoparticles embedded in Bi3.15Nd0.85Ti3O12 matrix have been prepared by a chemical solution deposition method [21]. It was found that the conductivity has a great effect on the quality of the multiferroic composites and, [22, 23] doping with magnetic ions as acceptor dopants can reduce the conductivity of the ferroelectric thin film [24, 25]. Based on the above reasons, perovskite Bi3.4Nd0.6Ti3O12 (BNT) and perovskite La0.6Ca0.4MnO3 (LCMO) are selected as the ferroelectric and ferromagnetic phases in the present composite thin films respectively and, the effects of LCMO content on the electrical properties and the ME coupling behaviors of the LCMO–BNT composite thin films are investigated in the present work.

2 Experimental details

The ME LCMO–BNT (x = 0.3, 0.4, and 0.5) composite thin films were fabricated on Pt/Ti/SiO2/Si(100) substrates by sol–gel method and spin-coating process. The detailed preparation procedure of precursor solution of BNT has been described elsewhere [26]. To obtain the precursor solution of LCMO, lanthanum acetate, calcium acetate and manganese acetate were dissolved in an aqueous solution of citric acid with the metal atomic ratio La/Ca/Mn of 0.4:0.6:1. After the chelating reaction, polyethylene glycol as a kind of surfactant and ethanol were added into LCMO solution. The final concentration of two kinds of precursor solutions was approximately 0.1 M. The preparation of the films consisted in spin coating the Pt(111)/Ti/SiO2/Si(100) substrates with the stock solution at 3,000 rpm for 30 s. The wet film samples were then fully dried in a rapid thermal processor (RTP-500) at 180 °C for 3 min followed by another 3 min at 400 °C to remove residual organic compounds. This coating process is referred to as one deposition. The coating and preheating process should be repeated several times to obtain the desired film thickness. Post annealing was performed at 750 °C for 15 min under an oxygen atmosphere by a rapid thermal annealing process. For comparison, pure BNT thin film (x = 0) were fabricated simultaneously. The phase structure characterization of the LCMO–BNT thin films was carried out by a D/max-rA X-ray diffractometer with Cu Kα radiation. For electrical measurements, Au top electrodes with a diameter of 200 μm were coated on the composite thin films by DC sputtering using a shadow mask. The ferroelectric measurements were performed using a Radiant Technologies Precision Workstation ferroelectric tester. Both the AC magnetic field of H (10 Oe) generated by a pair of Helmholtz coils and the DC magnetic field generated by an electromagnet were parallel to the thin film plane. The Helmholtz coils were driven by a signal generator (Agilent 33120A) and a power amplifier (HAS 4014). The induced electrical field E was measured using a lock-in amplifier (SRS Inc., SR830).

3 Results and discussion

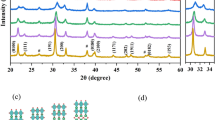

Figure 1 shows the typical X-ray diffraction (XRD) patterns of the BNT–LCMO composite thin films with x = 0, 0.3, 0.4 and 0.5. The pure BNT thin film (x = 0) is polycrystalline and has a single-phase of bismuth-layered perovskite structure. Two evident sets of well defined peaks are observed in the thin films with x = 0.3, 0.4 and 0.5, which belong to polycrystalline bismuth-layered perovskite structure BNT and perovskite LCMO. As expected, the intensity of LCMO diffraction peaks increases with the increase of LCMO content (x) in composite films. There are no additional or intermediate phase peaks apart from LCMO and BNT, confirming the preparation of a material containing both ferromagnetic and ferroelectric phases.

The DC leakage current characteristics for LCMO–BNT thin films with different x values are shown in Fig. 2. The leakage current densities of LCMO–BNT thin films with x = 0, 0.3, 0.4, and 0.5 are 1.3 × 10−5, 6.6 × 10−6, 3.2 × 10−6, and 1.6 × 10−6 A/cm2 at 250 kV/cm, respectively. From Fig. 2 one can see that the leakage current is determined by the LCMO content, which decreases with the increase of LCMO content. This is attributed to the fact that doping with acceptor dopants can reduce the conductivity of the ferroelectric thin films [24, 25].

The polarization versus electric field (P-E) hysteresis loops of the composite films with x = 0, 0.3, 0.4 and 0.5, under the applied electric field of 300 kV/cm is shown in Fig. 3. The well-defined ferroelectric loops are observed. This indicates good ferroelectric properties of the composite films. As shown in Fig. 3, the remanent polarization (P r) decreases with the increase of x, that is, with the increase of the ferromagnetic phase. The P r values are 12.4, 10.4, 9.1, and 7.1 μC/cm2 under the condition of about 300 kV/cm electric field for the composite films with x = 0, 0.3, 0.4, and 0.5.

Considering the NvFeRAM application of magnetoelectric thin films, fatigue characteristic is an important factor that should be considered. The fatigue characteristic of LCMO–BNT composite thin films with x = 0, 0.3, 0.4 and 0.5 are displayed in Fig. 4. The test was performed at room temperature, using 100 kHz bipolar square pulses with a 240 kV/cm electric field. As shown in Fig. 4, all the samples possess good ferroelectric fatigue endurance. The fatigue endurance property is improved by adding LCMO phase, and a fatigueless performance up to 109 switching cycles is obtained for the LCMO–BNT composite thin film with x = 0.5, which is attributed to the fact that acceptor dopants can strongly improve the endurance characteristics of the thin film [27, 28].

The ME effect is determined by the ME voltage coefficient α E = dE/dH measured in terms of the induced electric field E under an applied AC magnetic field of H superimposed onto a DC bias magnetic field H bias. Figure 5a shows the variations of ME voltage coefficient α E as a function of applied magnetic bias H bias at a fixed AC magnetic frequency f = 20 kHz for the LCMO–BNT composite films with x = 0.3, 0.4, and 0.5, measured at room temperature. From Fig. 5a, one can see that the α E value increases by increasing LCMO content in LCMO–BNT composite thin films (from x = 0.3 to 0.5) at any fixed H bias in the range of 0–6 kOe. Figure 5b shows the variations of α E with H bias at different frequencies f for the LCMO–BNT thin film with x = 0.5. An overall α E increase by increasing f from 5 to 40 kHz is observed. The variation of α E with f is most likely due to the frequency dependence of the dielectric constant for the individual phases, [19, 29] because a reduction in dielectric constant will increase the ME voltage coefficient [28] One of the most important issues related to multiferroic thin films is the origin of the ME effects. In the multiferroic composite system, it is well-known that the ME coupling mainly arises from the magnetic-mechanical-electric interaction through the interface between the ferroelectric phase and the ferromagnetic phase. The composite thin films prepared with a lower content of ferromagnetic or ferroelectric phase result in the reduction of magnetostriction or piezoelectricity, respectively, leading to a decrease in the ME voltage coefficient as predicted theoretically [30]. The proper molar proportion of BNT and LCMO in the LCMO–BNT composite thin films causes the large ME voltage coefficient. A model aimed at studying the ME effect and its dependence on the conductivities of both inclusion and matrix phases of particulate composites predicts that the conductivity of either inclusion or matrix material is one of the possible key factors determining the magnetoelectric behavior of particulate composites [23]. From the model, one can deduce that the α E value of the composite with low ferromagnetic concentration will increase with increasing ferromagnetic concentration [23]. This prediction is consistent with the present experiments. In this work, the leakage current density decreases with increasing x value, and the LCMO–BNT thin film with x = 0.5 has the lowest leakage current density, because the proper ferromagnetic concentration in the thin film reduces the leakage current. The LCMO–BNT thin film with x = 0.5 has the maximum ME voltage coefficient of about 29.1 mV/(cm Oe) at a magnetic field frequency of 20 kHz. It was found that doping with acceptor dopants such as Co and other magnetic ions can reduce the conductivity of the ferroelectric films and then to improve its fatigue endurance performance [24, 25]. Our results show that LCMO–BNT composite thin films possess better fatigue endurance properties compared with pure BNT thin film, which may be primarily related to the effects of acceptor dopants such as Ca and Mn ions and fine grains in the thin films. The composite thin film with x = 0.5 has the maximum ME voltage coefficient of about 40.1 mV/(cm Oe) at magnetic field frequencies below 40 kHz, which is ascribed to the proper LCMO concentration.

4 Conclusions

In conclusion, magnetoelectric LCMO–BNT composite thin films with x = 0.3, 0.4, and 0.5 were fabricated on Pt/Ti/SiO2/Si(100) substrates by a sol–gel process and spin-coating technique. The effects of LCMO content on the microstructure, leakage current density, ferroelectric properties, fatigue endurance and ME voltage coefficient of LCMO–BNT thin films derived by sol–gel method were studied. Our results show that the composite thin films have better fatigue endurance properties and lower leakage current densities compared with pure BNT thin films, and the composite thin films possess large ME voltage coefficients, which foreshow a new promising ME devices.

References

Spaldin NA, Fiebig M (2005) Science 309:391

Nan CW, Bichurin MI, Dong SX, Viehland D, Srinivasan G (2008) J Appl Phys 103:031101

Eerenstein W, Mathur ND, Scott JF (2006) Nature 422:759

Scott JF (2007) Nat Mater 6:256

Levin I, Li JH, Slutsker J, Roytburd AL (2006) Adv Mater 18:2044

Gehring GA (1994) Ferroelectrics 161:275

Suchetelene Van (1972) J Philips Res Rep 27:28

Zhao HQ, Peng X, Zhang LX, Chen J, Yan WS (2013) Appl Phys Lett 103:082904

Gatel C, Warot-Fonrose B, Matzen S, Moussy JB (2013) Appl Phys Lett 103:092405

Qi XW, Zhou J, Yue ZX, Gui ZL, Li LT, Buddhudu SA (2004) Adv Funct Mater 14:920

Dai YR, Bao P, Zhu JS, Wan JG, Shen HM, Liu JM (2004) J Appl Phys 96:5687

Ryu J, Carazo AV, Uchino K, Kim HE (2001) Jpn J Appl Phys Part 1(40):4948

Srinivasan G, Rasmussen ET, Gallegos J, Srinivasan R, Bokhan YuI, Laletin VM (2001) Phys Rev B 64:214408

He HC, Zhou JP, Wang J, Nan CW (2006) Appl Phys Lett 89:052904

Zhou JP, He HC, Shi Z, Nan CW (2006) Appl Phys Lett 88:013111

Wan JG, Wang XW, Wu YJ, Zeng M, Wang Y, Jiang H, Zhou WQ, Wang GH, Liu JM (2005) Appl Phys Lett 86:122501

Ryu H, Murugavel P, Lee JH, Chae SC, Noh TW, Oh YS, Kim HJ, Kim KH, Jang JH, Park JG (2006) Appl Phys Lett 89:102907

Maiwa H, Iizawa N, Togawa D, Hayashi T, Sakamoto W, Yamada M, Hirano SI (2003) Appl Phys Lett 82:1760

Wu D, Li AD, Ming NB (2004) J Appl Phys 95:4275

Chon U, Jang HM, Kim MG, Chang CH (2002) Phys Rev Lett 89:087601

Zhong XL, Wang JB, Liao M, Huang GJ, Xie SH, Zhou YC (2007) Appl Phys Lett 90:152903

Devan RS, Chougule BK (2007) J Appl Phys 101:014109

Zhou Y, Shin FG (2006) J Appl Phys 100:043910

Wang SY, Cheng BL, Wang C, Dai SY, Lu HB, Zhou YL, Chen ZH, Yang GZ (2004) Appl Phys Let 84:4116

Ahn KH, Baik S, Kim SS (2002) J Appl Phys 92:265

Zhong XL, Wang JB, Zheng XJ, Zhou YC, Yang GW (2004) Appl Phys Lett 85:5661

Majumder SB, Mohapatra YN, Agrawal DC (1997) Appl Phys Lett 70:138

Klissurska RD, Brooks KG, Setter N (1999) Ferroelectrics 225:171

Zhou JP, He HC, Shi Z, Liu G, Nan CWJ (2006) Appl Phys 100:094106

Nan CW (1994) Phys Rev B 50:6082

Acknowledgments

This work was supported by Key Project of National Natural Science Foundation of China (NSFC) (Grant No. 11032010), NSFC (Grant Nos. 51072171, 61274107, 61176093 and 11275163), PCSIRT (IRT1080), 973 Program (2012CB326404), Key Project of Scientific Research Fund of Hunan Provincial Education Department (12A129), Hunan Provincial Innovation Foundation for Postgraduate (CX2011B248), the Doctoral Program of Higher Education of China (Grant No. 20104301110001) and the Aid Program for Science and Technology Innovative Research Team in Higher Educational Institutions of Hunan Province, and the Opening Project of Science and Technology on Reliability Physics and Application Technology of Electronic Component Laboratory (ZHD201304).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cheng, C.P., Tang, M.H., Tang, Z.H. et al. Electrical properties of La0.6Ca0.4MnO3–Bi3.4Nd0.6Ti3O12 thin films derived by a sol–gel process. J Sol-Gel Sci Technol 68, 346–350 (2013). https://doi.org/10.1007/s10971-013-3176-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3176-5