Abstract

Magnetoelectric (ME) Bi3.25Nd0.75Ti3O12–La0.6Ca0.4MnO3 (BNT–LCMO) composite thin films were deposited on Pt/Ti/SiO2/Si(100) substrates by a simple SOL–GEL method and spin-coating process with two different deposition sequences: BNT/LCMO/Pt/Ti/SiO2/Si(BLP) and LCMO/BNT/Pt/Ti/SiO2/Si(LBP). Our results show the composite thin films exhibit both good ferroelectric and magnetic properties, as well as a ME effect. BLP thin films have larger maximum ME voltage coefficient values than LBP structured thin films. The deposition sequence has a notable effect on the ferroelectric and magnetic properties and ME coupling behavior of the bi-layer thin films.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Multiferroics, which have electric, magnetic, and structural order parameters in the same phase, have attracted tremendous fundamental and practical interest for their simultaneous ferroelectricity, ferromagnetism, and ferroelasticity [1–4]. As is known to all, magnetoelectric (ME) effect is a cross two-field effect, characterized by appearance of an electric polarization P upon applying a magnetic field H or with the change of magnetization M on applying an electric field E [5–7]. Besides the ferroelectromagnets as the longtime objects of the related researches, ME-composite materials represent the systems where strong ME effect is predicted based on the idea of product property of composite materials [8]. A lot of research work has indicated that developing composite multiferroics by artificially making ferroelectrics and ferromagnets into nanoscale heterostructures may be an effective technique for obtaining the large ME effect [9–19]. In constructing the layered ME composite film structures, there are many parameters to be optimized, in which the growth sequence of these two phases on the substrate should result in an influence on the properties of the resultant composite films [20]. Based on the above, perovskite Bi3.25Nd0.75Ti3O12(BNT) and La0.6Ca0.4MnO3(LCMO) are selected as the ferroelectric and ferromagnetic phases in the present composite thin films respectively and, the effects of deposition sequence on the electrical properties and the ME coupling behaviors of the BNT–LCMO composite thin films are investigated.

2 Experimental details

We have succeeded in synthesizing BNT–LCMO composite films with both ferroelectric and ferromagnetic properties, as well as ME effect at room temperature. In this article, we report effects of deposition sequence on the properties of BNT–LCMO composite thin films derived by SOL–GEL method. ME BNT–LCMO composite thin films were deposited on Pt/Ti/SiO2/Si(100) substrates by SOL–GEL method with two different deposition sequences: BNT/LCMO/Pt/Ti/SiO2/Si(BLP) and LCMO/BNT/Pt/Ti/SiO2/Si(LBP). To obtain the precursor solution of BNT, bismuth nitrate [Bi(NO3)3·5H2O], neodymium nitride [Nd(NO3)3], and titanium butoxide [Ti(OC4H9)4] were used as starting materials for Bi, Nd and Ti, respectively. Separately, in a beaker, Bismuth nitrate (10 mol% excess) and neodymium nitride were dissolved at 40 °C in glacial acetic acid [CH3COOH], titanium butoxide was dissolved in glacial acetic acid, and acetylacetone [CH3COCH2–COCH3] was used as the chelating agent. The titanium solution was added to the bismuth-dysprosium solution with continuous stirring, and the final mixture was stirred for an additional 30 min. Then, acetylacetone was added to the solution as a stabilizing agent. Finally, 2-methoxyethanol was added to adjust the concentration. A clear purple sol was obtained. A 10 mol % excess amount of bismuth nitride was used to compensate for the Bi evaporation during annealing. To obtain the precursor solution of LCMO, lanthanum acetate, calcium acetate and manganese acetate were dissolved in an aqueous solution of citric acid with the metal atomic ratio La/Ca/Mn of 0.4:0.6:1. After the chelating reaction, polyethylene glycol as a kind of surfactant and ethanol were added into LCMO solution. The final concentration of two kinds of precursor solutions was approximately 0.1 M. The preparation of the films consisted in spin coating the Pt(111)/Ti/SiO2/Si(100) substrates with the stock solution at 3,000 rpm for 30 s. The wet film samples were then fully dried in a rapid thermal processor (RTP-500) at 180 °C for 3 min followed by another 3 min at 400 °C to remove residual organic compounds. This coating process is referred to as one deposition. The coating and preheating process should be repeated several times to obtain the desired film thickness. Both BNT and LCMO layers were fabricated using six depositions. Post annealing was performed at 750 °C for 15 min under an oxygen atmosphere by a rapid thermal annealing process. The final composite thin films were formed with a thickness of ~1 μm (see Fig. 2c), accompanying with the deep diffusion between the LCMO layers and BNT layers. The crystal structure was characterized by X-ray diffraction (XRD). The microstructures of the films were examined by scanning electron microscopy (SEM). For electrical measurements, Au top electrodes with a diameter of 200 μm were coated on the composite thin films by DC sputtering using a shadow mask. The ferroelectric and leakage current measurements were performed using a Radiant Technologies Precision Workstation ferroelectric test system. Magnetic properties and ME effects of the films were measured using a vibrating sample magnetometer and a ME measuring system at room temperature, respectively.

3 Results and discussion

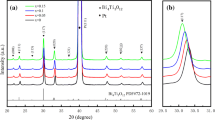

Figure 1 shows the typical XRD patterns of BLP and LBP composite thin films. All the diffraction peaks were identified and indexed according to the standard powder diffraction data of BNT and LCMO. Two evident sets of well defined peaks are observed in the thin films, which belong to polycrystalline bismuth-layered perovskite structure BNT and LCMO. There are no additional or intermediate phase peaks apart from BNT and LCMO, which confirming the preparation of a material containing both ferromagnetic and ferroelectric phases. For the chemical interaction between the ferroelectric and ferromagnetic phases would lead to their ferroelectric or magnetic properties degrading, it is very important that no additional or intermediate phase exist for the preparation of ferroelectric-ferromagnetic composites [21].

Figure 2 displays the SEM surface morphologies of (a) BLP and (b) LBP composite thin films, and (c) the cross section of BLP composite thin films. From Fig. 2a, b, one can see that smooth surface and better crystallization degree of the composite thin films were obtained on Pt/Ti/SiO2/Si substrates. The surface of the BLP film with the BNT as the top layer is more compact and smoother than that of LBP film, and the crystal particle size of BNT is smaller than LCMO, which implies that BNT layer is more compact than LCMO layer. So the electrical properties will be sensitively influenced by the deposition sequence of the different layered structures, which will be discussed later. From Fig. 2c, one can see that the final composite thin films were formed with a total thickness of ~1 μm, in which BNT and LCMO are both about 500 nm in thickness, accompanying with the deep diffusion between the LCMO layers and BNT layers.

The DC leakage current characteristics for LCMO-BNT composite thin films with different deposition sequences, i.e., the BLP and LBP structured composite thin films are shown in Fig. 3. From Fig. 3 one can see that compared with the LBP film, the BLP film has a smaller leakage current density. This is consistent with the fact that the surface of the BLP film is more compact than that of the LBP film, which indicates that the insulating property of BLP is better than that of LBP.

Figure 4a displays the polarization versus electric field (P-E) hysteresis loops of BLP and LBP structured composite thin films. As shown in Fig. 4a, the well-defined ferroelectric loops are observed in the BLP and LBP films. The remnant polarization (2P r) values of the deposited BLP and LBP composite thin films are 21.6 and 12.8 μC/cm2, corresponding to the coercive fields of 84.9 and 76.5 kV/cm, respectively. Obviously, compared with the LBP film, the BLP film exhibits a higher P r value, which is maybe owing to the better insulating property of the BLP film.

The magnetic hysteresis loops of BLP and LBP composite thin films are presented in Fig. 4b. As shown in Fig. 4b, magnetic hysteresis loops with saturation magnetization M s ~ 330 emu/cm3 of the BLP film and ~289 emu/cm3 of the LBP film are observed, which hints the present thin films of an ordered magnetic structure. From Fig. 4b one can see that the BLP film shows a larger saturation magnetization M s value than the LBP film. This is consistent with the fact that the BLP film has a smaller leakage current density compared with the LBP film.

The coexistence of the ferroelectric BNT and ferromagnetic LCMO phases in the present composite thin films gives rise to a ME effect, which is characterized by the ME voltage coefficient α E = dE/dH. The ME effect is determined by the ME voltage coefficient α E measured in terms of the induced electric field E under an applied AC magnetic field of H superimposed onto a DC bias magnetic field H bias. The AC magnetic field H (10 Oe) generated by a pair of Helmholtz coils and a DC bias magnetic field H bias generated by an electromagnet were superimposed and parallel to the film plane. The induced electric field E was measured using a lock-in amplifier (SRS Inc., SR830). Figure 5 shows the variations of ME voltage coefficient α E as a function of applied magnetic bias H bias at a fixed AC magnetic frequency f = 1 kHz for the BLP and LBP composite films, measured at room temperature. From Fig. 5 one can see that the composite films exhibit ME effect which is dependent on H bias. As shown in Fig. 5, α E values increase rather steeply with increasing H bias that is below 110 Oe, when H bias reaches 110 Oe, α E reaches its largest values. However, it is noticeable that when H bias reaches more than 110 Oe, the α E value shows a rapid decline and then a gradual decrease to near zero with further increase of H bias. This behavior may be explained by following discussions. Since the ME coupling in ME composites is arose from the AC field initiated dynamic Joule magnetostriction, caused by domain wall motion (at low fields close to coercivity) and rotation (at large fields far from coercivity), the magnetostrictive layer of high permeability, simultaneously showing large magnetostriction constant, would expect to produce a large ME effect [22]. This might explain the sharp increase of α E in the low field. When the bias magnetic field reaches 110 Oe, α E reaches its largest value, which has a larger magnitude than the coercivities. The maximum values of the α E for the BLP and LBP structures are 69 and 63 mV/cm Oe, respectively. At higher bias fields, the magnetostriction of the LCMO layer gets saturated and producing a nearly constant electric field in the BNT ferroelectric phase and led to a slow reduction of α E. In addition, it is obvious that α E values of BLP film are larger than that of LBP film at any fixed H bias in the range of 0–1,000 Oe, while they exhibit a similar rise-and-fall trend. This may be due to the enhancement of the interfacial coupling in the BLP film, characterized by the magnetic-mechanical-electric interaction between the magnetic and ferroelectric phases through the stress/strain in the interface [23], for top BNT layer in the BLP film has a more compact structure and less defects and better crystallization than LCMO, while the substrate layer has a smaller lattice mismatch with LCMO than with BNT.

4 Conclusion

In conclusion, the ME BNT–LCMO composite thin films were deposited on Pt/Ti/SiO2/Si(100) substrates by SOL–GEL method and spin-coating process with two different deposition sequences: BLP and LBP. Our results show that the present two kinds of double-layered composite thin films exhibit both good ferroelectric and magnetic properties, as well as a ME effect at room temperature. Some differences in their ferroelectric and magnetic properties and ME coupling behavior are exhibited depending on their structures. The maximum ME voltage coefficient value of the BLP thin film is larger than the LBP structure. The composite thin films exhibit distinct ME coupling behaviors, while the ME voltage coefficient α E of the BLP composite film is larger than that of the LBP composite film due to a possible enhancing of interface coupling. The BLP structured films have better ferroelectric properties and higher saturation magnetization than the LBP structured films. These results indicated that the deposition sequence has an obvious influence on the ferroelectric and magnetic properties and ME coupling behavior of the bi-layer thin films.

References

Hill NA (2000) J Phys Chem B 104:6694

Cheong SW, Mostovoy M (2007) Nat Mater 6:13

Wang KF, Liu JM, Ren ZF (2009) Adv Phys 58:321

Choi T, Lee S, Choi YJ, Kiryukhin V, Cheong SW (2009) Science 63:324

Nan CW (1994) Phys Rev B 50:6082

Nan CW, Li M (2001) Appl Phys Lett 78:2527

Srinivasan G, Rasmussen ET, Levin BJ, Hayes R (2002) Phys Rev B 65:134402

Van Suchtelen J (1972) Philips Res Rep 27:28

Wan JG, Wang XW, Wu YJ, Zeng M, Wang Y, Jiang H, Zhou WQ, Wang GH, Liu JM (2005) Appl Phys Lett 86:122501

Ding H, Cheah JW, Chen L, Sritharan T, Wang J (2012) Thin Solid Films 522:420

Wu YJ, Wan JG, Liu JM, Wang GH (2010) Appl Phys Lett 96:152902

Zhao SF, Wu YJ, Wan JG, Dong XW, Liu JM, Wang GH (2008) Appl Phys Lett 92:012920

Luo SJ, Wang KF, Li SZ, Dong XW, Yan ZB, Cai HL, Liu JM (2009) Appl Phys Lett 94:172504

Yu H, Zeng M, Wang Y, Wan JG, Liu JM (2005) Appl Phys Lett 86:032508

Wan JG, Zhang H, Wang XM, Pan DY, Liu JM, Wang GH (2006) Appl Phys Lett 89:122914

Murakami M, Chang KS, Aronova MA, Lin CL, Yu MH, Simpers JH, Wuttig M, Takeuchi I, Gao C, Hu B, Lofland SE, Knauss LA, Bendersky LA (2005) Appl Phys Lett 87:112901

Zhou JP, He HC, Shi Z, Nan CW (2006) Appl Phys Lett 88:013111

Ryu H, Murugavel P, Lee JH, Chae SC, Noh TW, Oh YS, Kim HJ, Kim KH, Jang JH, Kim M, Bae C, Park JG (2006) Appl Phys Lett 89:102907

Li JH, Levin I, Slutsker J, Provenzano V, Schenck PK, Ramesh R, Ouyang J, Roytburd AL (2005) Appl Phys Lett 87:072909

He HC, Zhou JP, Wang J, Nan CW (2006) Appl Phys Lett 89:052904

Zhong XL, Wang JB, Liao M, Huang GJ, Xie SH, Zhou YC, Qiao Y, He JP (2007) Appl Phys Lett 90:152903

Zhang N, Srinivasan G, Balbashov AM (2009) J Mater Sci 44:5120

Ma J, Hu J, Li Z, Nan CW (2011) Adv Mater 23:1062

Acknowledgments

This work was supported by Key Project of National Natural Science Foundation of China (NSFC) (Grant No. 11032010), NSFC (Grant Nos. 51072171, 61274107, 61176093 and 11275163), PCSIRT (IRT1080), 973 Program (2012CB326404), Key Project of Scientific Research Fund of Hunan Provincial Education Department (12A129), Hunan Provincial Innovation Foundation for Postgraduate (CX2011B248), the Doctoral Program of Higher Education of China (Grant No. 20104301110001) and the Aid Program for Science and Technology Innovative Research Team in Higher Educational Institutions of Hunan Province.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cheng, C.P., Tang, Z.H., Tang, M.H. et al. Magnetoelectric Bi3.25Nd0.75Ti3O12–La0.6Ca0.4MnO3 composite thin films derived by SOL–GEL method. J Sol-Gel Sci Technol 68, 136–140 (2013). https://doi.org/10.1007/s10971-013-3145-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-013-3145-z