Abstract

Using hot water treatment of sol–gel derived precursor gel films, Co–Al and Ni–Al layered double hydroxide (LDH) thin films were prepared. The precursor gel films of Al2O3–CoO or Al2O3–NiO were prepared from cobalt or nickel nitrates and aluminum tri-sec-butoxide using the sol–gel method. Then, the precursor gel films were immersed in a NaOH aqueous solution of 100 °C. Nanocrystallites of Co–Al and Ni–Al LDH were precipitated with the hot water treatment with NaOH solution. The largest amounts of nanocrystals were obtained with a solution of pH = 10 for Co–Al LDH, and with that of pH = 9 for Ni–Al LDH. X-ray diffraction measurements confirmed that this process formed CO3 2− intercalated LDHs. Both Co–Al and Ni–Al LDH thin films were confirmed to work as electrodes for electrochemical devices by cyclic voltammogram measurements.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

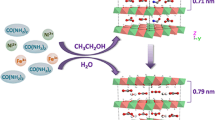

Layered double hydroxides (LDHs) consist of positively charged brucite (Mg(OH)2)-like sheets with intercalated compensation anions and water molecules. Many studies have been conducted of LDH over the past several decades for their potential application as anion-exchangers, catalysts, electrochemical sensors, and as immobilization hosts of biological materials by intercalation of various anions into layers [1, 2]. In these studies, LDH is usually prepared through co-precipitation. However, formation of LDH thin films on substrates is favorable for application of LDH to functional materials and for evaluation of their optical properties or intercalation reaction of LDH crystals. Actually, many recent reports have described LDH thin-film formation [3–23]. We directly immobilized Zn–Al LDH or Mg–Al LDH nanocrystals on substrates through hot water treatment of sol–gel derived amorphous Al2O3–ZnO or Al2O3–MgO thin films, respectively [11–13]. We also found that nanocrystals of Zn–Al LDH with various organic anions were precipitated on Al2O3–ZnO gel films through immersion of the gel films in hot water containing organic salts [14, 15].

Among the LDHs, transition-metal-containing LDHs have been regarded as new electrode materials for use in various electrochemical devices [16–24]. As described above, LDHs are usually prepared using the co-precipitation process and are obtained as powders. However, for application of LDHs to electrochemical devices, formation of LDH thin films on substrates is sometimes favorable.

In this study, Co–Al and Ni–Al LDH thin films, which have been studied as electrodes for electrochemical devices, were prepared directly by the hot-water treatment of sol–gel derived precursor gel films. These thin films were obtained simply through formation of precursor gel films using the sol–gel process and consequent immersion of the precursor gel films in NaOH aqueous solution. Preparation conditions and electrochemical properties of those LDH thins were investigated.

2 Experimental procedure

LDH thin films were prepared from aluminum tri-sec-butoxide (Al(O-sec-Bu)3) and nickel or cobalt nitrate (M(NO3)2·6H2O (M = Co, Ni)) according to the following procedure: Al(O-sec-Bu)3, ethyl acetoacetate (EAcAc) and isopropyl alcohol (i-PrOH) were mixed and stirred at room temperature for 1 h. A mixture of water, i-PrOH, and ethylene glycol was then added dropwise to the solution for hydrolysis. Separately, M(NO3)2·6H2O (M = Co, Ni), ethylene glycol and i-PrOH were mixed and stirred at room temperature for 2 h. The two solutions were mixed together, and the resultant solution was used for coating. The molar ratios of i-PrOH, EAcAc, H2O, and M(NO3)2 to Al(O-sec-Bu)3 were, respectively, 20, 1, 1, and 1. The coatings were conducted on soda-lime silica glass plates by dipping; the withdrawal speed was 3 mm/s. The obtained coating films were heat-treated at 200 °C for 60 min to obtain amorphous Al2O3–CoO or Al2O3–NiO gel films. The Al2O3–CoO or Al2O3–NiO gel films were then immersed in hot NaOH aqueous solution of pH 8–13 at 100 °C in the ambient atmosphere. After hot water treatment, the films were dried at 50 °C overnight. Thickness of the films in the present study was about 200 nm.

The coating film surface was examined using field emission type scanning electron microscopy (FE–SEM, S-4500; Hitachi Ltd.). Then X-ray diffraction (XRD) patterns were recorded using an X-ray diffractometer (RINT 1100; Rigaku Corp.) with Cu Kα radiation. The XRD patterns were measured in the 2θ/θ mode.

The thin films used for the cyclic voltammetry measurement were formed on a Pt plate. The cyclic voltammograms were recorded in an undivided three-electrode cell using Pt plate with LDH precipitated film as working electrode, with scan speed of 5 mV/s. The counter electrode was Pt plate, and Hg/HgO electrode (1 M NaOH) was used as the reference electrode. As the electrolyte, 0.1 M NaOH solution was used.

3 Results and discussion

3.1 Co–Al LDH

Figure 1 presents the XRD patterns of Al2O3–CoO precursor gel film prepared using the sol–gel method and films with immersion in dilute NaOH solution of pH = 9, 10, and 11. The sol–gel derived precursor gel film is amorphous. After immersion of NaOH solution (pH 9, 10, and 11), peaks were observed in the XRD patterns. In all films, the interplanar spacing is about 0.78 nm, which can be assigned to Co–Al LDH with carbonate anion [25]. Consequently, Co–Al LDH crystals are formed on sol–gel derived amorphous gel films by hot water treatment under basic conditions. The strongest peak intensity is observed for the sample immersed in water of pH = 10.

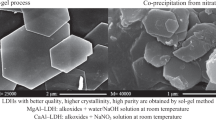

Some FE–SEM images of the surface of Al2O3–CoO precursor film immersed in hot water with pH = 9, 10, and 11 are depicted in Fig. 2. Small amounts of nanocrystals were observed on the surface. The most nanocrystals were observed on the film treated in hot water of pH = 10.

The precipitation behavior of nanocrystals with different pH suggests that partial dissolution of precursor gel films plays an important role for the precipitation of nanocrystals. In addition, in the LDH structure, the M2+/M3+ moral ratio between 2 and 4 is known to exist stably. In the Al2O3–CoO amorphous gel film (Co/Al = 1), much more Al2O3 constituent must be dissolved in the hot water, than with the CoO constituent. In the hot water with pH = 9–10, partial dissolution of the Al2O3–CoO amorphous gel film was enhanced. The dissolved constituents were presumed to be precipitated immediately as hydroxides at the surface with larger Co/Al ratio. However, after hot water treatment with a NaOH solution of pH 11, the XRD peak intensity of the film decreased. Under strong basic conditions such as pH 11, too much constituent of Al2O3 must be dissolved in the hot water, and the reprecipitation of Co–Al LDH must be prevented. These results indicate that the formation mechanism of LDH through the hot water treatment of sol–gel-derived films in this study is based on a dissolution–reprecipitation process.

Figure 3 shows cyclic voltammograms of Co–Al LDH precipitated thin film on a Pt plate in 0.1 M NaOH solution. The cyclic voltammograms Al2O3–CoO precursor film is also shown for comparison. In Co–Al LDH thin film, the broad anodic and cathodic peaks in the potential range 0.2–0.4 V (vs Hg/HgO) correspond to Eq. 1 [17].

In the potential range of 0.4 and 0.55 V (vs Hg/HgO), broad anodic and cathodic peaks corresponding to Eq. 2 [17] are observed.

After 20 cycles, the current response was kept almost constant, and the peak potential position was not changed. Electrochemical capacity calculated using the cyclic voltammogram is about 400 F/g, which is larger than that of Al2O3–CoO precursor film with about 250 F/g. The cyclic voltammogram of the thin film in this study resembles that of co-precipitated Co–Al LDH powder [16] or films [17–19], indicating that the Co–Al LDH thin film in the present study is useful for electrodes for electrochemical devices.

3.2 Ni–Al LDH

Figure 4 presents XRD patterns of Al2O3–NiO precursor gel film before immersion, the film after immersion in distilled water, and the film after immersion in dilute NaOH solution with pH = 8. No peaks are observed after immersion in distilled water. However, a very weak peak is observed with immersion in water with pH = 8. Although the intensity of the peak is low, the position of the peak agrees with that for Ni–Al LDH powder with carbonate anions prepared by the co-precipitation process, shown in Fig. 4, or previously reported Ni–Al LDH with carbonate anions [22], indicating that this peak is attributed to Ni–Al LDH intercalated with carbonate ions.

Figure 5 portrays FE–SEM images of the film before and after immersion. Before immersion, the surface is very smooth, but after immersion in hot water with pH = 8, precipitation of nanocrystals is observed on the surface. Both the density and size of nanocrystals in the Ni–Al system are much larger than those of Co–Al system presented in Fig. 2. Although a large amount of LDH plate-like nanocrystals was formed on the surface by the hot water treatment, the intensity of the peak attributed to Ni–Al LDH was very weak in the XRD pattern portrayed in Fig. 4. Because most plate-like nanocrystals grow in a direction perpendicular to the substrate, the XRD pattern peak intensity must be weak.

Figure 6 shows FE–SEM images of the films immersed in different pH solution. Very large amounts of nanocrystals are observed on the films with immersion in hot water with pH = 8 and 9. However, the amount of crystals decreased with immersion in hot water with pH = 10. In the XRD patterns of those films, only a very weak peak attributed to Ni–Al LDH intercalated with carbonate ions was observed.

In the Ni–Al system, under the basic condition with pH = 10, the dissolution of the Al2O3–NiO films accelerated excessively, and the reprecipitation of Ni–Al LDH must be prevented. As presented in Fig. 2, in the Co–Al system, the largest amount of nanocrystals was observed on the film with the hot water treatment of pH = 10. In our previous studies, Zn–Al LDH nanocrystals were precipitated with hot water treatment under a neutral condition, whereas Mg–Al LDH nanocrystals were precipitated under the basic condition of pH = 12. Because the formation process of LDH crystals with the hot water treatment must be a dissolution–reprecipitation process, the difference in the pH of the hot water used for precipitation should arise from the difference in solubility of hydroxides such as Mg(OH)2, Zn(OH)2, Ni(OH)2, and Co(OH)2 in the hot water. For example, the solubility product constant at 25 °C for Mg(OH)2, Zn(OH)2, Ni(OH)2, and Co(OH)2 is 5.61 × 10−12, 3 × 10−17, 5.48 × 10−16, and 5.92 × 10−15, respectively [26]. Thus, LDHs containing these hydroxides with the larger solubility product constant are expected to precipitate at larger pH. In fact, Mg–Al LDH, where Mg(OH)2 has the largest solubility product constant among those hydroxides, precipitates the highest pH of 12, and Zn–Al LDH, where Zn(OH)2 has the smallest solubility product constant, precipitates the lowest pH of 7.

Figure 7 portrays cyclic voltammogram of Ni–Al LDH thin film on a Pt plate in 0.1 M NaOH solution. The cyclic voltammogram of Al2O3–NiO precursor gel film is also shown for comparison. In Ni–Al LDH thin film, the broad anodic and cathodic peaks in the potential range 0.6–0.7 V (vs Hg/HgO) correspond to Eq. 3 [20].

The cyclic voltammogram of Ni–Al LDH thin film is fundamentally identical to that of co-precipitated Ni–Al LDH powder [20] or films [21–24]. Consequently, the Ni–Al LDH thin film in the present study can be used also for electrodes for electrochemical devices.

In this process, precursor gel films were formed using the sol–gel process, and nanocrystals of LDH were precipitated on the surface. The precursor gel films are formed easily on widely various substrate shapes, such as plate, mesh, fiber, etc., because the coating solution easily wets or penetrates those substrates. Consequently, this process presents advantages for the formation of electrodes for electrochemical devices, compared with the coating using particle-dispersed solutions.

4 Conclusions

We demonstrated a very simple process for the preparation of Co–Al and Ni–Al LDH thin films that can be used for electrochemical devices. Thin films of Co–Al and Ni–Al LDH were prepared using hot-water treatment of sol–gel derived precursor gel films. Nanocrystallites of Co–Al and Ni–Al LDH were precipitated using hot water treatment with NaOH solution. The largest amounts of nanocrystals were obtained with NaOH solution of pH = 10 for Co–Al LDH, and with that of pH = 9 for Ni–Al LDH, respectively. The XRD measurements confirmed that CO3 2− intercalated LDHs were formed in this process. Both Co–Al and Ni–Al LDH thin films were confirmed to work as electrodes by cyclic voltammetry. Results show that these thin films are useful as electrodes for various electrochemical devices such as electrochemical capacitors.

References

Leroux F, Besse JP (2001) Chem Mater 13:3507–3515

Khan AI, O’Hare D (2002) J Mater Chem 12:3191–3198

Guo X, Zhang F, Evans DG, Duan X (2010) Chem Commun 46:5197–5210

Gardner E, Huntoon KM, Pinnavaia TJ (2001) Adv Mater 13:1263–1266

Lei X, Yang L, Zhang F, Evans DG, Duan X (2005) Chem Lett 34:1610–1611

Okamoto K, Sasaki T, Fujita T, Iyi N (2006) J Mater Chem 16:1608–1616

Wang L, Li C, Liu M, Evans DG, Duan X (2007) Chem Commun 123–125

Iyi N, Ebina Y, Sasaki T (2008) Langmuir 24:5591–5598

Gao YF, Nagai M, Masuda Y, Sato F, Seo WS, Koumoto K (2006) Langmuir 22:3521–3527

Katagiri K, Goto Y, Nozawa M, Koumoto K (2009) J Ceram Soc Jpn 117:356–358

Yamaguchi N, Nakamura T, Tadanaga K, Matsuda A, Minami T, Tatsumisago M (2006) Chem Lett 35:174–175

Yamaguchi N, Nakamura T, Tadanaga K, Matsuda A, Minami T, Tatsumisago M (2006) Cryst Growth Des 6:1726–1729

Yamaguchi N, Ando D, Tadanaga K, Tatsumisago M (2007) J Am Ceram Soc 90:1940–1942

Yamaguchi N, Tadanaga K, Tatsumisago M (2007) Diffus Defect Data Pt B Solid State Phenom 124–126:635–638

Tadanaga K, Yamaguchi N, Tatsumisago M (2009) Res Chem Intermed 35:949–956

Scavetta E, Berrettoni M, Nobili F, Tonelli D (2005) Electrochim Acta 50:3305–3311

Scavetta E, Ballarin B, Gazzano M, Tonelli D (2009) Electrochim Acta 54:1027–1033

Liu Z, Ma R, Osada M, Iyi N, Ebina Y, Takada K, Sasaki T (2006) J Am Chem Soc 128:4872–4880

Wang Y, Yang W, Chen C, Evans DG, Power J (2008) Sources 184:682–690

Scavetta E, Berrettoni M, Giorgetti M, Tonelli D (2001) Electrochim Acta 46:2451–2461

Roto R, Yamagishi A, Villemure G (2004) J Electroanal Chem 572:101–108

Roto R, Yu L, Villemure G (2006) J Electroanal Chem 587:263–268

Mizuhata M, Hosokawa A, Beleke AB, Deki S (2009) Chem Lett 38:972–973

Wang J, Song Y, Li Z, Liu Q, Zhou J, Jing X, Zhang M, Jiang Z (2010) Energy Fuels 24:6463–6467

Pérez-Ramírez J, Mul G, Kapteijn F, Moulijn JA (2001) J Mater Chem 11:821–830

Lide DR (ed) (2006) CRC handbook of chemistry and physics, 87th edn. CRC Press, Boca Raton, pp 8-119–8-120

Acknowledgments

This work was partly supported by a Grant-in-Aid for Scientific Research from the Ministry of Education, Culture, Sports, Science and Technology of Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tadanaga, K., Miyata, A., Ando, D. et al. Preparation of Co–Al and Ni–Al layered double hydroxide thin films by a sol–gel process with hot water treatment. J Sol-Gel Sci Technol 62, 111–116 (2012). https://doi.org/10.1007/s10971-012-2692-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-012-2692-z