Abstract

Titanium dioxide (TiO2) is an inorganic compound used as sunscreen in cosmetic/pharmaceutical formulations as a way to prevent the skin cancer. In this work we have used surface modified titania nanoparticles obtained by thermo-reversible sol–gel transition showing transparency in the range of temperature typical for sunscreen use (between 20 and 45 °C). The goal of this work was to develop and characterize liquid crystalline cosmetic formulations containing surface modified titania nanoparticles. We have analyzed the citotoxicity of the nanoparticles, their zeta potential and the liquid crystalline phase behavior of the formulations. The violet crystal assay has shown no citotoxicity associated to the presence of surface modified groups on the two cell lines tested, human keratinocytes and fibroblasts, presenting more than 70% of cell viability for all analyzed nanoparticles. The zeta potential measurements revealed a negative charged surface for TiO2 nanoparticles at pH values in the range of 6.5–7.0, preventing the aggregation and maintaining the final transparency of the liquid crystalline sunscreen formulations. The polarized light microscopy, associated to SAXS, have shown the presence of liquid crystalline phases both with and without TiO2 nanoparticles. The charged surface of TiO2 nanoparticles maintains the stability of the formulations and the liquid crystalline structure. This renders this system a good candidate for being used simultaneously as sunscreen and as controlled release system of anti cancer drugs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The number of skin cancer cases increases exponentially in the world especially in countries where strong ultraviolet (UV) radiations are occurring: A (UVA region—320–400 nm) and B (UVB—290–320 nm). The prevention of skin cancer can be done using sunscreens that scatter, reflect and absorb UVA and UVB radiations responsible for dangerous modifications in the skin cells DNA as well as for inducing photoaging and sunburn. UV filters used in sunscreen formulations can be classified as organic or inorganic photoprotective agents. TiO2 reflects and absorbs the UV radiation, is a non-toxic, non-allergenic, hypo-sensitive and photostable [1] material being successfully used as inorganic filter. Among the three polymorphic crystalline forms of titanium dioxide (anatase, rutile and brooquite), the anatase one presents more photoprotection activity efficiency [2]. The absorption and reflection intensities of the UV radiations depend on the size of TiO2 particles. The particle size also influences the optical properties of the sunscreen formulations. In general, smaller nanoparticles (15–50 nm) are used to produce transparent material [3] but it is necessary to evaluate the efficiency of these nanoparticles for the solar protection. As TiO2 presents high refractive index (2.6), an increase on the UV–visible radiation reflection can be observed with the nanoparticles size growing [1]. For this reason, researches have been done aiming to optimize the optical properties of TiO2 in commercial products by the incorporation of TiO2 microparticles based systems and TiO2 surface coated with silica, alumina and/or polymers [4]. Moreover, the safety of TiO2 evaluated by penetration skin experiments and TiO2 citotoxicity assays in different cell lines are conditions necessary to ensure the safe use of these nanoparticles in sunscreen formulations [5–9].

To obtain TiO2 nanoparticles presenting adequate size and optical properties different synthesis routes have been applied. The sol–gel process is very relevant to produce nanoparticles with controlled size, surface and shape [10, 11]. The reactions involved in this process are hydrolysis followed by condensation of a metal alkoxide solubilized in an organic solvent. The structural feature of nanoparticles is strictly related to the control of the parameters involved in the sol–gel reactions [12]. Moreover the use of surface modifier agent like complexing compounds is an emerging strategy to control the secondary policondensation and enhance the stability of nanoparticle dispersion. In this way p-toluene sulfonic acid (PTSH) has been demonstrated to be a good candidate to modify the TiO2 nanoparticles surface, allowing to the control of the size, shape and aggregation of TiO2 nanoparticles obtained by the sol–gel process [12, 13]. Structural analysis of sample prepared with different hydrolysis ratio (H = [H2O]/[Ti]) and acidity ratio (P = [PTSH]/[Ti]) demonstrated that PTSH involves TiO2 surfaces preventing the nanoparticles aggregation and allowing the achievement of transparent and high concentrated suspensions [13, 14].

There are many vehicles used in sunscreens products to become TiO2 based formulations cosmetically attractive. Moreover, nowadays the demand for products formulated with functional components and innovative delivery systems is increasing exponentially, creating multifunctional products able to protect the skin from sun radiation dangerous effects and simultaneously to deliver anti-oxidant, anti-aging, moisturizing and anti-cancer agents in a controlled way [15]. Liquid–crystal formulations are transparent materials presenting attractive attributes to cosmetic products, being good candidates for application in topic release as controlled drug delivery systems [16].

The purpose of this work is to develop transparent, safe and stable liquid crystalline formulations containing surface modified TiO2 nanoparticles for a future application as multifunctional sunscreen and drug delivery system.

2 Materials and methods

2.1 TiO2 nanoparticles synthesis

To obtain surface modified TiO2 nanoparticles we used a recently developed thermo-reversible sol–gel transition described elsewhere [13, 14]. We have used nominal hydrolysis ratio (H = [H2O]/[Ti]), which is identified after the letter “H”, from 0.05 to 5 and the nominal acidity ratio (P = [PTSH]/[Ti]), which is identified after the letter “P”, between 0.05 and 2. The xerogel was formed after solvent evaporation at 60 °C.

2.2 Citotoxicity assay

2.2.1 Preparation of TiO2 suspensions

Six formulations of xerogels obtained by sol–gel process were evaluated by changing the nominal acidity ratio (P) and nominal hydrolysis ratio (H): P0.05H2.3, P0.2H0.5, P0.2H2.3, P0.2H3, P0.2H5 and P2H2.3. The xerogels were dispersed in ultrapure water by sonication in a concentration of 15% (m/v) and these suspensions were sterilized with ionized energy of 20 kGy by EMBRARAD (Jarinu, SP, Brazil). In a second step they were diluted in phosphate buffered saline (PBS) and after in Dulbecco’s Modified Eagle’s Medium (DMEM; Sigma Aldrich). In all these dissolutions the suspensions were vortexed to ensure homogenization.

To evaluate the influence of PTSH surface modifier on the total citotoxicity, PTSH aqueous solutions presenting 5 different concentrations were prepared: 10.0 × 10−9 mol L−1, 5.0 × 10−9 mol L−1, 2.5 × 10−9 mol L−1, 1.2 × 10−9 mol L−1 and 0.6 × 10−9 mol L−1

2.2.2 Cell culture

Two cell lines, HaCaT (human skin keratinocyte) and MRC-5 (human lung fibroblast), obtained from Ludwig Institute for Cancer Research and Laboratory of DNA Repair (Institute of Biomedical Sciences—USP—Brazil), respectively, were used. The growth of cells was performed in culture bottles with DMEM media and Ham’s F10 (Sigma, St. Louis, MO) pH 7.2–7.4, supplemented with 10% fetal bovine serum, antibiotics and antimycotics. The culture bottles were maintained in an incubator at 37 °C containing 5% CO2. Passage-numbers 3–8 were used to perform the experiments.

2.2.3 Crystal violet assay

The cell viability was analyzed by crystal violet assay which determines viable cells by colorimetric measurements. The assay was performed in 96-well plates in a density about 1 × 104 cells/mL, three independent experiments each one in triplicate. When 70% of cell confluence was reached, cells were treated with 100 μL of the TiO2 suspensions and PTSH solutions for 24 h. The TiO2 suspension and PTSH solutions were removed and cells were incubated with 100 μL of 0.2% crystal violet (Sigma Aldrich) solution in 2% of ethanol for 5 min. Subsequently, the colorant was rejected and the plates were carefully washed with water. 200 μL of 0.5% sodium dodecyl sulfate (SDS, Sigma Aldrich) in 50% ethanol were added to solubilize the colorant for 10 min. The absorbance of each well was measured at 595 nm by a plate reader (iMark Microplate Absorbance Reader, model 168–1135, Bio-Rad, USA). The positive control (PC) was hydrogen peroxide (Merck) 20 mM and the negative one (NC) was DMEM medium. Three independent experiments were performed and the TiO2 concentrations were tested in triplicate for each experiment. Citotoxicity was calculated and data are presented as mean ± standard error media (SEM). Statistical analyzes were carried out by one-way analysis of variance (ANOVA), followed by Tukey’s post-test (p < 0.001). All statistical tests were performed by Graph Pad Prisma software (version 5.01, 2007).

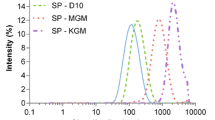

2.3 Zeta potential

Zeta potential of nanoparticles dispersions were measured with a ZetaSizer Nano ZS Zen3600 (Malvern Instruments) and determined by acid–base titration. Before the measurements four xerogel formulations (P2H2.3, P0.5H1, P0.1H2.3 and P0.05H1) were dispersed in water solutions with concentration of 320 μg/mL and then sonicated during 5 min using a bath sonicator. NaNO3 solution (0.05 mM) was used as inert electrolyte. The pH during the acid–base titration was adjusted with HNO3 and NaOH 0.25 M solutions within the pH range 2–11. The experiments were performed in triplicate.

2.4 Preparation of liquid–crystals

Liquid crystalline formulations were prepared with two surfactants currently used in cosmetic formulations differing by their hydrophilic–lipophilic balance (HLB): Brij56 (Ceteth 10) with HLB = 12.9 and Procetyl AWS (PPG-5 Ceteth 20) with HLB = 16) [17, 18]. They enable to obtain the liquid crystals in concentrations not dangerous for the skin. It is possible to evaluate the influence of the surfactant hydrophilic lipophilic character on the stability of the formulations with and without TiO2 nanoparticles. Liquid crystals were prepared by mixing the surfactant Procetyl AWS, isopropyl palmitate (IP) used as oil phase and ultrapure water in different ratios at 25 °C. TiO2 nanoparticles were incorporated in the liquid-crystal formulations using mechanical stirring (TURRAX) at 7,000 rpm. Liquid crystalline formulations with Brij56 were prepared in the same way. All formulations were adjusted to the pH 5–7. Table 1 groups all the formulation composition within the samples notation.

2.5 Polarized light microscopy

To identify the liquid crystalline arrangement, samples were analyzed by polarized light microscopy at 23 °C using a Carl Zeiss Jenamed 2 microscope equipped with a digital camera. An aliquot of the formulations was placed in a glass microscope slide, covered with a coverslip and carefully distributed by application of pressure.

2.6 Small-Angle X-ray Scattering (SAXS)

The structural aspects of liquid crystals prepared with and without TiO2 nanoparticles were analyzed by SAXS measurements carried out at SAXS1 beamline of the National Laboratory of Synchrotron Light (LNLS, Campinas, Brazil) and at the SWING beamline of the French synchrotron source SOLEIL (Soleil, Saint Aubin, France). The LNLS beamline is equipped with a monochromator (λ = 1.488 Å), a vertical detector localized 1,496.8 mm from the sample and a multichannel analyzer to register the scattering intensity I(q) as a function of the scattering vector, q. At the SWING beamline, SAXS experiments were carried out at an energy of 15 keV with a sample to detector distance of 500 mm, using the 2D AVIEX CCD detector. Data were normalized to take into account the beam decay (for LNLS data), detector sensitivity and sample transmission. The parasitic scattering intensity (cell windows and air) was subtracted from the total scattering intensity. The radial integration of the 2D SAXS at SWING was performed using the FOXTROT software developed at Soleil.

3 Results and discussions

The aim of the in vitro cytotoxicity assays was to evaluate the security of the surface modified TiO2 nanoparticles applied in human cells. Two cell lines were chosen, HaCaT a keratinocite cell line present in considerable amount in the skin, in order to evaluate the nanoparticle citotoxicity when applied to the skin. The second one was MRC-5, a lung cell line, used to evaluate the cytotoxicity effects related with possible nanoparticles inhalation. Figures 1 and 2 show the cell response against different TiO2 formulation in percentage of cell viability in HaCaT cells and in MRC-5 cells, respectively. Irrespective from the TiO2 concentration, results and statistic analysis have shown that all TiO2 nanoparticles present no significant citotoxicity: cells cultures were not greatly modified as compared to the negative control (ANOVA p < 0.001 followed by Tukey’s test). The toxicity of the PTSH solutions is more accentuated than that observed for nanoparticles containing this same acid as surface modifier especially in the case of HaCaT cells, however, when the acid is grafted to the nanoparticles surface there is not a linear dependence of the cell viability and the PTSH concentration. The TiO2 nanoparticles presenting the highest concentration of PTSH (P2H2.3), in comparison to the negative control, present 70.5 and 81.5% cell viability in HaCaT and MRC-5 cells, respectively, evidencing the safe use of these nanoparticles in sunscreens.

Sunscreen formulations for skin application require some aspects related to appropriate conditions, that is, provide an efficient photoprotective activity, prevent skin irritation and present consumers acceptability. To reach these requirements the formulation must be transparent and, therefore, avoid large aggregates formation and, at the same time, present suitable pH (5–7). The presence of superficial charges can be calculated by zeta potential measurements and, consequently, determine the attraction/repulsion phenomenon among nanoparticles that will influence aggregation. The zeta potential was measured for xerogels with different nominal hydrolysis ratio H and nominal acid ratio P. The dependence of zeta potential with pH for these samples is shown in Fig. 3. For the same H value the isoelectric point (IP) is higher for samples with higher PTSH amount: the IP of P2H2.3 and P0.5H1 is about 5.65 and 5.62, respectively, while the IP of P0.1H2.3 and P0.05H1 is about 3.15 and 3.83, respectively. It can be observed that samples containing more amount of PTSH reach more accentuated variation of zeta potential. This behavior can be explained by the higher electronic charge density at the surface of the particles containing higher amount of PTSH molecules. The aggregation and consequently the stability of dispersions are dependent on the sum of the attractive and repulsive forces between individual particles [19]. The displacement of the zeta potential to highly positive or highly negative values is suited by an increase in the electrostatic repulsive interactions [20]. At pH values far from the IP the absolute value of zeta potential becomes generally more negative or positive and the electrostatic repulsive forces are superior to the attractive ones [21]. The presence of dominant repulsive forces is important to obtain monodispersed suspensions. In Fig. 3 we can observe that for pH values between 6.5 and 7.0 (acceptable for topical formulations), the zeta potential present strong negative values for all the analyzed samples, indicating the predominance of repulsive forces. Thus, we can conclude that TiO2 nanoparticles agglomeration prevention can be reached working at pH range usually used to avoid skin irritation. Moreover, the transparency is directly related to the systems dispersibility, close to IP the agglomeration of TiO2 nanoparticles tend to increase as well as the reflection of UV–visible radiation. Thus, non agglomerated TiO2 systems means transparent systems important to cosmetic segments. Based on the zeta potential results the TiO2 nanoparticles based liquid crystal formulations were adjusted at pH about 5–7.

Polarized light microscopy was used as preliminary identification of liquid crystalline arrangements [22]. The photomicroscopies of the formulations listed in Table 1 are shown in Figs. 4c–f and 5b, c. We can observe for all samples (with or without TiO2) the presence of fanlike structures characteristic of hexagonal phase [23]. In order to confirm the presence of hexagonal liquid crystals the samples were analyzed by SAXS [24]. According to the relation between the distances of the Bragg peaks on the scattering vector (q) it is possible to calculate structure parameters and to determine the liquid crystalline phase [25, 26]. To calculate the correlation distance between the scattering objects we used the equation d = 2π/qmax, where qmax is the q value at the diffraction peak [23]. The relation between the distance d calculated for each peak must attend to the relation √1: √3: √4 for hexagonal phase [27]. Figures 4a, b and 5a exhibits SAXS profile: peaks identified by * indicate the presence of hexagonal structure in the liquid crystal formulations. For samples formulated with Procetyl (Fig. 4a, b with and without TiO2) SAXS curves confirmed the hexagonal phase observed at the microscopy. However, it is interesting to note that even though the liquid crystalline phase does not change with the presence of TiO2, the nanoparticles promote the formation of a more organized structure, revealed by the presence of thinner and more defined peaks. This behavior can be explained by the surfactant—oil phase—water phase interaction in the presence of PTSH and indicates that the presence of acid on the nanoparticles surface acts as structuring agent of the surfactant molecules organization on the cylinders walls of the hexagonal phase, independent on the xerogel composition. For samples prepared with the Brij56 surfactant with and without TiO2 (Fig. 5a), the presence of nanoparticles does not change the liquid crystal phase, but causes the peaks broadening suggesting the formation of a less ordered hexagonal structure. It is important to note that these formulations present some unidentified intense peaks. This behavior can indicate the presence of a mixture of different phases, but under the experimental conditions used in this work especially the q region chosen to perform the SAXS experiments, it was not possible to identify each arrangement. Liquid crystalline structures more organized with the presence of TiO2 can be obtained with surfactants of predominant hydrophilic character (higher HLB). This behavior can be explained by the presence of an accentuated interaction of nanoparticles containing acidic species as surface modifier with the hydrophilic part of the surfactant molecule that exhibits higher HLB leading to a superior organization.

In summary, these results evidence that the presence of TiO2 nanoparticles has not modified the hexagonal liquid crystalline structure of the formulations. Liquid crystalline formulations present advantages for drug delivery systems due to their controlled release property [23, 27], improved skin penetration [28], stabilization [15] and hydrophobic and hydrophilic drugs solubilization capacity [29]. Furthermore, the modification of nanoparticles surface by PTSH renders possible to obtain transparent and non citotoxic TiO2 based formulations. In this way, formulations developed herein have been proven to be potential candidate to be applied as controlled anticancer drug delivery in near future: the presence of TiO2 nanoparticles does not change the liquid crystal phase which is essential to the controlled release property. Moreover, the TiO2 nanoparticles photoprotection enables the formulation of a multifunctional system protecting and preventing skin cancer.

4 Conclusions

The PTSH surface modified TiO2 nanoparticles obtained by the sol–gel process are safe for skin application presenting no great modifications of cells culture as compared to the negative control. The aggregation relied to non-transparent sunscreen formulation can be controlled at pH values between 5 and 7, usually used for topical creams and cosmetics. Transparent liquid crystalline formulations containing high TiO2 percentage were prepared indicating the possibility to associate the photoprotection of TiO2 simultaneously to the control of drug delivery profiles.

References

Wang SK, Balagula I, Osterwalder U (2010) Dermatol Ther 23:31–47

Serpone N, Dondi D, Albini A (2007) Inorg Chim Acta 360:794–802

Allena NS, Edgea M, Ortega A, Liauwa CM, Strattonb J, McIntyreb RB (2002) Polym Degrad Stab 78:468–478

Jacobs JF, Poel EVD, Osseweijer P (2010) Nanoethics 4:103–113

Senzui M, Tamura T, Miura K, Ikarashi Y, Watanabe Y, Fujii M (2010) J Toxical Sci 35:107–113

Filipe P, Silva JN, Silva R, Castro JLCD, Gomes MM, Alves LC, Santus R, Pinheiro T (2009) Skin Pharmacol Physiol 22:266–275

Zhang LW, Yu WW, Colvin VL, Monteiro-Riviere NA (2008) Toxicol Appl Pharmacol 228:200–211

Jin CY, Zhu BS, Wang XF, Lu QH (2008) Chem Res Toxicol 21:1871–1877

Sayes CM, Wahi R, Kurian PA, Liu Y, West JL, Ausman KD, Warheit DB, Colvin VL (2006) Toxicol Sci 92:174–185

Alphonse P, Varghese A, Tendero C (2010) J Sol-Gel Sci Technol 56:250–263

Zhou J, Zhao G, Ren X, Song B, Han G (2011) J Sol-Gel Sci Technol 58:148–155

Scolan E, Sanchez C (1998) Chem Mater 10:3217–3223

Kaminski RCK, Pulcinelli SH, Santilli CV, Meneau F, Blanchandin S, Briois V (2010) J Eur Ceram Soc 30:193–198

Kaminski RCK, Pulcinelli SH, Judeinstein P, Meneau F, Briois V, Santilli CV (2010) J Phys Chem C 114:1416–1423

Patravale VB, Mandawgade SD (2008) Int J Cosmet Sci 30:19–33

Lopes L, Ferreira DA, Paula DD, Garcia MTJ, Thomazini JA, Fantini MCA, Bentley MVLB (2006) Pharm Res 23:1332–1342

Hait SK, Moulik SP (2001) J Surfactants Deterg 4:303–309

Croda (2002) Procetyl AWS Material Safety Data Sheet, Campinas. http://www.croda.com.br. Accessed 20 Jan 2011

Ott LS, Finke RG (2007) Coord Chem Rev 251:1075–1100

Stumm W, Morgan JJ (1996) Aquatic chemistry. Wiley-Interscience, New York

Jiang J, Oberdörster G, Biswas P (2009) J Nanopart Res 11:77–89

Gaisin NK, Gnezdilov OI, Pashirova TN, Zhiltzova EP, Lukashenko SS, Zakharova LY, Dzhabarov VI, Galyamedinov YG (2010) Colloid J 72:764–770

Carvalho FC, Sarmento VHV, Chiavacci LA, Barbi MS, Gremião MPD (2009) J Pharm Sci 99:2367–2374

Dong YD, Boyd BJ (2011) Int J Pharm 417:101–111

Wang Z, Zhou W (2009) J Solut Chem 38:659–668

Klug HP (1954) X-ray diffraction procedures. Wiley, New York

Negrini R, Mezzenga R (2011) Langmuir 27:5296–5303

Lopes LB, Speretta FFF, Bentley MVLB (2007) Eur J Pharm Sci 32:209–215

Vicentini FTMC, Casagrande R, Verri WA Jr, Georgetti SR, Bentley MVLB, Fonseca MJV (2008) AAPS J 9:591–596

Acknowledgments

The authors thank the LNLS and SOLEIL for SAXS measurements, the professor Miguel Jafelicci Junior for the use of ZetaSizer Nano equipment, FAPESP, CNPq and PADC/FCF-UNESP for the financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Manaia, E.B., Kaminski, R.C.K., Soares, C.P. et al. Liquid crystalline formulations containing modified surface TiO2 nanoparticles obtained by sol–gel process. J Sol-Gel Sci Technol 63, 251–257 (2012). https://doi.org/10.1007/s10971-011-2673-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-011-2673-7