Abstract

Interpenetration of wood samples of pine sapwood (Pinus sylvestris L.) with hybrid inorganic–organic silica xerogels bearing amine functions able to coordinate copper(II) cations has been successfully carried out. These materials have been prepared by sol–gel processing TEOS/APTES mixtures inside the wood. Solid state 29Si NMR data provide evidence that the interpenetrated xerogel material has the same degree of condensation of the corresponding xerogel formed outside the wood. Copper(II) is effectively vehiculated inside the wood by coordination linkages with two ammine functions well evidenced by ESR measurements. SEM/EDX investigations show that the chlorine/copper atomic ratio inside the wood is lower than that of the starting salt CuCl2, suggesting an exchange reaction with silanol groups with the formation of Si–O–Cu linkages and HCl. This reaction could be promoted by the excess of amine functions with formation of ammonium chloride species which remain onto the surface of the wood and in the mother solution owing to a higher degree of condensation. Sodium silicate was tested in place of TEOS in order to have a cheaper and ethanol-free formulation. However, gel penetration results significantly lower than that of the corresponding formulation containing TEOS and preservation performance are lower than that of TEOS formulation against brown-rot fungal decay.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Wood is conveniently used as material for a variety of human artifacts in virtue of its advantageous characteristics, such as high tensile strength, high elastic modulus, low density and insulation properties. However, its organic constitution is subjected to combustion and to long-term oxygen light and water degradation. Moreover wood is a source of nutrients for fungi and insects leading to its complete biological destruction [1]. Therefore, a lot of treatments have been essayed in the past trying to overcome these drawbacks and enhacing wood durability. This can be obtained by improved moisture sorption characteristics, dimensional stability, strength and hardness, weathering performance and flame resistance. Among them, a wide variety of compounds have been tested for wood modification, including anhydrides, carboxylic acids, isocyanates, aldehydes, alkyl chlorides, lactones, nitriles, and epoxides [2–4]. Also many types of silicon compounds have been used for this purpose [5–7], in particular alcoxysilanes as starting materials for the sol–gel process [8, 9]. In this regard, treatments showing resistance to water sorption [10], to photochemical degradation [11], to combustion [12], especially if in combination with boron compounds [13, 14], and to swelling [15] have been reported. In a recent paper, many ways in which the properties of wood might be improved by application of silica and other inorganic nanosols have been reviewed [16].

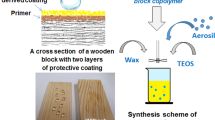

The most convenient method for modifying wood is to impregnate the cell walls with monomers which are then polymerised in situ. Polymerisation of the alkoxysilanes monomers can be achieved by the sol–gel process, i.e. via condensation of the silanol Si–OH groups to form siloxane bonds after hydrolysis of the alkoxy groups. The so formed siloxane polymers can penetrate into the wood texture and interact, mainly via hydrogen bonds, with the wood biopolymers of the cell walls. The possible formation of Si–O–C covalent bonds, by reaction between the silanol groups and the hydroxyl groups of cell wall polymers (transesterification), has been also suggested [17]. The siloxane materials can polymerize both onto the cell walls and inside the lumina. In the last case they behave as simple filling materials exhibiting a sort of barrier effect. In the first case, the presence of silica in the cell walls, rather than in the lumina, strongly influences the biotic resistence of the wood by modifying its physico-chemical characteristics. By this way, wood results less recognizable by biodeteriogens as a substrate adequate for their development. In addition, these treatments could reduce the moisture sorption properties hence limiting biological attacks and enhancing natural durability [18, 19].

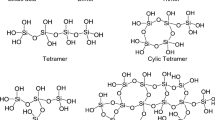

Polymeric siloxane materials can be obtained by sol–gel processing both tetraalkoxyslanes, like Si(OEt)4, (TEOS) and trialkoxysilanes, like RSi(OEt)3, bearing organic functional groups with Si–C bonds which are stable against hydrolysis. The use of trialkoxysilane leads to the formation of inorganic–organic hybrid materials containing organic functions with desired properties [20, 21]. Also by using TEOS alone a significant resistance to fungal [22] and to insect attack has been observed [23, 24]. Modification of wood by sol–gel siloxane materials has been proved to limit the release of certain preservatives, such as metals, boric acid and boron compounds, hence increasing resistance against wood biological degradation by insects [25, 26]. The presence of amino groups in siloxane materials can also improve wood biological resistance. In fact, the efficacy of quaternary ammonium silicone micro-emulsions [27], different aminofunctional silanes [28] and amino-polydimethylsiloxanes [29] against fungal decay is reported.

Another advantage of the presence of amino functions is their ability to fix copper(II) cations through coordinative interactions. In this regard, copper is a common fungicide largely used in many wood preservatives [30] owing to a favourable efficacy/cost ratio and a broad spectrum of activity. However, its unsatisfactory fixation to wood [31] is the major drawback. It was overcome in the past by using combinations of copper with chromium and organic ligands, now banned for their toxicity. Just with the aim to improve copper fixation avoiding its significant leaching, we have impregnated wood blocks of Pinus sylvestris L. with homogeneous sol mixtures of TEOS, APTES (aminopropyltriethoxysilane) and copper (II) salts. Sol–gel polymerization occurred into the wood promoted by water present inside the cell walls, giving a siloxane/wood composite material linking copper through coordinative interactions. This treatment exhibits efficacy in wood protection against the brown rot fungus Coniophora puteana [32, 33]. In order to obtain informations about the degree of polymerization of the siloxane materials, the coordination environment of the copper(II) cations and the penetration of the gel into the wood, we have performed spectroscopic (solid state NMR, ESR, FTIR) and microscopic (SEM) investigations and this paper deals with the complete characterization of these materials. In addition, the efficacy of the xerogels derived by silicon akoxides is compared with the analogous material obtained by hydrolysis of sodium metasilicate.

2 Experimental

2.1 Treatments of wood specimens

Wood samples of pine sapwood (Pinus sylvestris L.) were employed. They were cut from the same board in blocks of 30 mmlong lenght, 10 mmtang wide, 5 mmrad thick (long, longitudinal; tang, tangential; rad, radial directions along the grain). Each sample was oven dried (103 ± 5 °C) for 18 h, in order to determine the anhydrous mass, and then conditioned to constant mass at 20 °C and 65% relative humidity (RH) before to be treated.

Four stock ethanol solutions were prepared to be utilized for the samples treatment, containing tetraethoxysilane, (TEOS) and 3-aminopropyltriethoxysilane (APTES) in two different ratios, with or without copper(II) chloride. They were maintained under dry atmosphere until their use as sol–gel precursors.

-

Solution S1: TEOS/APTES 1:1 v/v : TEOS (10 mL, 44.8 mmol), (APTES, 10 mL, 42.8 mmol) and ethanol (20 mL).

-

Solution S2: TEOS/APTES 1:1 v/v, APTES/CuCl2 5:1 molar ratio: TEOS (10 mL, 44.8 mmol), (APTES, 10 mL, 42.8 mmol), copper (II) chloride CuCl2·2H2O (1.454 g, 8.53 mmol) and ethanol (20 mL).

-

Solution S3: TEOS/APTES 10:1 v/v :TEOS (19.1 mL, 85.5 mmol), APTES (1.9 mL, 8.1 mmol) and ethanol (20 mL).

-

Solution S4: TEOS/APTES 10:1 v/v, APTES/CuCl2 5:1 molar ratio: TEOS (19.1 mL, 85.5 mmol), APTES (1.9 mL, 8.1 mmol), CuCl2·2H2O (0.290 g, 1.7 mmol) and ethanol (20 mL).

In addition, another stock solution (solution SS) was prepared where sodium metasilicate Na2SiO3·5H2O was used instead of TEOS as silica precursor. It contained sodium metasilicate, APTES and CuCl2 in 5:5:1 molar ratios, prepared as follows: a water solution of sodium Na2SiO3·5H2O (3.88 g, 18.2 mmol in 30 mL, pH 12) was added with a solution of CuCl2·2H2O (0.614 g, 3.6 mmol) in APTES (4.2 mL, 18.0 mmol), under stirring. The mixture was acidified with HCl 37% (0.6 mL) until pH 9 was reached. This solution can be preserved for a few days before use, without phase separation or gelation.

The wood samples were treated with the sol–gel precursor solutions described above by impregnation procedure. After a vacuum exposure (55 mbar) of 45 min, the wood blocks were dipped in the sol–gel solutions and maintained under vacuum for 15 min. Subsequently the mixture was gently stirred for 30 min under dry nitrogen atmosphere (1 atm). Eight replicates were prepared for each treatment group.

After impregnation, the wood samples were removed from the treatment solutions, lightly wiped to remove trace of solution from the surface, weighed to determine the solution retention and conditioned at 20 °C and 65% relative humidity and atmospheric pressure for a week, allowing the sol–gel process to take place with the water adsorbed by wood.

After the removal of the samples, the solutions were allowed to undergo the sol–gel process at room temperature (it took about 1 h). The gels were dried and the obtained xerogels were used for comparative characterization. In particular xerogel S1 was investigated by solid-state 13C and 29Si NMR, xerogel S2 by SEM and ESR.

2.2 Characterization of the impregnated wood

The efficacy of impregnation was evaluated both by measuring of the solution absorption and by calculating the weight percent gain (WPG). WPG is the standard parameter for this kind of experiments.

Samples were weighed before and immediately after the impregnation treatment and the absorption was determined as difference between the wood sample before and after the treatments.

WPG was calculated by the formula:

where M0 and Mt are the oven dried (103 ± 5 °C, 24 h) mass of untreated and sol–gel treated wood respectively.

The determination of the total copper content was carried out by dipping chips of samples representative of each copper treatment (formulations S2, S4 and SS) in a bath containing 20% H2SO4 in bidistilled water (10 mL H2SO4, 40 mL H2O) for 40 h, under stirring. The samples were rinsed with bidistilled water, then mother solutions were added with respective rinse waters, filtered and brought 100 mL. The obtained solutions were analyzed by Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP-AES) with a Jobin Ivon Ultima 2 equipment. Operating conditions: Power Generator normal condition 1,000 W, Plasma Gas Flow rate 12 L/min, Nebulization Pressure 3 bar, Nebulization Flow rate 0.50 L/min and pump speed of 20 rpm; wavelength used: 324.754 nm. Concentration results, in mg/L, were referred to the 100 mL of solution and to the sample volume, and expressed in kg/m3.

Fourier-Transform Infrared (FT-IR) spectroscopy investigations were carried out on the xerogel powders obtained from solutions S1 and S2 and on wood chips obtained from the surface of the longitudinal cross section of the impregnated specimens. Spectra were collected with a Thermo-Nicolet Nexus spectrometer equipped with a Thermo Smart Orbit ATR diamond accessory, operating at 4,000–400 cm−1.

Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray micronanalysis (EDX) was used to investigate on the xerogel penetration inside the wood microstructures. Distributions of silicon and copper onto the surfaces and in the insides of the wood specimens were determined. In particular the depth of silicon and copper penetration was determined by X-ray microanalysis carried out on the cross sections of two specimens representative of the different formulation treatments. The contents of silicon and copper in the residual xerogels were also measured for comparison. A Jeol 6400 SEM (tungsten filament) with a Si(Li) EDS windowless detector (Oxford INCA EDX) was used with 1.2 nA electron beam current and 15 kV acceleration voltage; the electron beam is about 1 μm in diameter and 100 s counting time; errors are ±2–5% for major elements and ±5–10% for minor components. Standards comprise pure elements, simple oxides or simple silicate compositions. Impregnated specimens were cut along the cross section to obtain two parts of the same length. The cut was performed using a CO2 Laser (power max 2 kW El. En), with emission wave length 10.6 μm and power 500 W, laser beam diameter width 3 mm, air flow pressure 0.5 bar. During the cutting the sample was positioned at a distance of 10 mm from the lens focus of laser source to obtain two equal cross sections. Microanalyses were carried out on the surface area of the cross section.

Electron Spin Resonance (ESR) measurements (cw X-band at 9.4 GHz) on chips of the wood samples treated with solution S2 and on the xerogel obtained from the same solution were carried out with a Bruker Elexsys E500 series using the Bruker ER4122 SHQE cavity. The low temperature spectra (120 K) were recorded using the Bruker ER 4111VT variable temperature unit. Low temperature spectra were simulated using software for fitting EPR frozen solution spectra, that is a modified version of a program written by J. R. Pilbrow (Cusimne) [34]. All spectra were recorded at 9.45 GHz microwave frequency, with 0.5 mT modulation amplitude and 2 mW power.

Solid-state 29Si and 13C Nuclear Magnetic Resonance (NMR) spectra of chips of wood samples impregnated with formulation S1 and of the corresponding residual xerogel were recorded at room temperature with a Bruker Avance 400 WB NMR spectrometer operating at a carrier frequency of 400.13 MHz (1H) equipped with a double resonance 4 mm magic angle spinning (MAS) probe. Samples were packed in 4 mm zirconia rotors and spun at 9.5 kHz for silicon and 11 kHz for carbon. 29Si cross-polarization (CP) MAS spectra under proton decoupling were obtained with a 90° pulse length for protons of 4.3 μs, and a contact time of 5 ms. 6,000 scans were accumulated with delay time of 10 s. 29Si NMR spectra for quantitative analysis were recorded with single pulse (SP) excitation. Here, the 90° pulse length for 29Si was 3.8, 12,000 scans were accumulated and the delay time was 30 s. Q8M8 was used as external secondary reference. Si units are labelled according to the usual NMR notation: Qn, Tn where capital letters refers to the number of Si–O-bonds (Q : 4; T : 3) and n is the number of Si–O–Si units. 13C CPMAS spectra were acquired with proton 90° pulse length of 3.36 μs, contact time of 2 ms, 2,000 accumulated scans, and a scan delay of 5 s. Adamantane was used as external secondary reference.

2.3 Accelerated efficacy tests

After impregnation, conditioning and sterilization, four replicates for each formulation were exposed to the fungus Coniophora puteana (Schumacher ex Fries) Karsten strain BAM Ebw. 15. Each treated sample was placed side by side with an untreated reference sample (called control) of sapwood of Pinus sylvestris L. in a Petri dish, measuring 90 mm of diameter and containing the brown rot fungus grown on 20 mL of 4% malt, 2.5% agar medium. At the same time, the strain virulence was assessed by placing six pairs of untreated wood blocks on Petri dishes inoculated with the same fungus. The wood blocks were incubated with the fungus for 6 weeks at 22 °C and 75% RH. According to Bravery [35], toxic values obtained after such incubation time were comparable with those obtained after 12 weeks using sample sizes described in EN 113 [36]. Furthermore, two wood blocks for each treatment were put in contact with culture medium without fungal strains. These specimens were utilized for the determination of the correction coefficient. The correction coefficient permits calculation of the mass variation due to factors that are different from fungal decay.

The resistance against C. puteana was evaluated through the measurement of the mass loss of wood, which was calculated for each individual block as the difference between the dry mass before the impregnation process and after the fungal exposure, corrected by the WPG and by the correction coefficient.

One set of wood specimens impregnated by treatment 1 (two-steps process), was subjected to the leaching procedure according to EN 84 [37]. Wood specimens were put in a glass beaker, which was filled up with deionised water conforming to EN ISO 3696 (1996). Wood specimens were prevented from floating by the use of weights. The beaker was put in a desiccator and vacuum was applied corresponding to a residual pressure of 4 kPa. Vacuum was maintained for 20 min, and then released to return to normal pressure. Wood specimens were maintained in water (ratio of water to wood 5:1) for 14 days with 9 water changes, and then conditioned to constant mass. Dry weight was measured after 18 h desiccation in the oven at 103 ± 2 °C.

3 Results and discussion

3.1 Weight gain and copper retention

The stock solution S1–5 prepared in anhydrous conditions can be kept for weeks without any evidence of sol–gel processing. When exposed to the wood samples, the sol–gel-process takes place mainly on the cell walls owing to the presence of adsorbed water (12% at 20 °C and 65% relative humidity) from atmospheric humidity. The formed gel is expected to interpenetrate the wood texture mainly interacting via hydrogen bond with hemicellulose and cellulose polymers.

The efficacy of wood impregnation for all the treatments was evidenced by the high values of absorption (g) and weight percent gain WPG (%) quoted in Table 1. Both parameters exhibit similar values for alkoxysilane impregnations which appear dependent only on the total content of silicon in the sol–gel solutions (S1–4). In particular, WPG is the expression of the increase of mass due to the presence of the genuine xerogel into the wood after thermal drying. In the case of treatment SS, beside a high value of absorption, one observe a significantly lower value of WPG. This could be due to the lower concentration of silicon in the starting solution and the high absorption value is mainly due to the absorption of water present as solvent.

The average copper content, determined by ICP analysis, results 5.4 kg/m3 in the samples treated with solution S2 and 0.6 kg/m3 in those treated with S4. These figures appear in agreement with the starting copper contents of the solutions. On the other hand in samples treated with solution SS the copper content is lower (1.5 kg/m3) than that of S2, as expected considering the lower WPG value.

3.2 Characterization of the interpenetrated wood without copper (treatment S1)

3.2.1 FTIR and SEM/EDX investigations

The stock solution S1 contain only TEOS and APTES in 1:1 volume ratio. In spite of the absence of copper it shows efficacy against fungal degradation (vide infra) and can be conveniently investigated by NMR spectroscopy in virtue of the absence of paramagnetic metal complexes.

As reported previously [32, 33], the presence of the xerogel into the wood affects only to a very limited extent its infrared spectrum. The very strong band centered at about 1,030 cm−1, due to the C–O stretching in the wood, appear slightly broadened owing to the contribution of the S–O–Si linkage. Peaks around 790 cm−1 can also be attributed to Si–O vibrational modes. On the other hand, the very large band centered at about 3,300 cm−1, due mainly to OH stretching of the wood biopolymers, does not allow to clearly observe the NH stretching bands of the xerogel.

The deep interpenetration of the functionalized xerogel in the wood texture was evidenced by SEM-EDX investigations. Silicon appears uniformly distributed inside the wood sample. This is shown by the values of the Si/C atomic ratio measured by EDX over five regions of the cross sections of sample S1 (spectra1-5) shown in Fig. 1 and quoted in the relevant caption. These regions of different depth exhibit nearly the same Si/C atomic ratio. Figure 2 shows a typical X-ray fluorescence spectrum obtained by EDX microanalysis over the central region of the cross section of sample S1.

SEM image of the cross section of wood sample impregnated with solution S1; the five rectangles indicates the regions of the section analysed by EDX. The surface of the sample is visible on the top of the image. Si/C atomic ratios (× 10−2) from spectrum 1–5 1.4, 1.3, 1.5, 1.4, 1.5 (errors are ± 2–5% for major elements and ± 5–10% for minor components)

X-ray fluorescence pattern of the central region (spectrum 3) of the cross section of sample S1 shown in Fig. 1; atomic ratios found: Si/C 1.5 × 10−2, Si/Ca 8.7

3.2.2 Solid-state NMR investigations

Besides microscopic characterization, solid state NMR investigations were performed to evaluate the texture of the siloxane xerogel, in particular the degree of condesantion, inside the wood compared with that obtained in absence of wood substrates. 29Si CP/MAS solid NMR spectra of the pure TEOS-APTES 1/1 xerogel (solution S1) and of the same impregnated into the wood are reported in Fig. 3. The similarity among the two spectra suggests that siloxane reticulation of the two materials is analogous.

Two intense groups of signals are visible in a ratio of 41:59 and 46:54, respectively. This is in agreement with the nominal concentrations of the two reagents. They are related to condensed TEOS (T) (Q units at around −100 ppm) and APTES (A) (T units at around −60 ppm). The molecular structures of the binary matrix both in the xerogel and in the treated wood samples are similar. The structural units are Q4 [Si(OSi)4], Q3 [RO-Si(OSi)3], Q2 [(RO)2-Si(OSi)2] belonging to TEOS-based gel and T3 [RNSi(OSi)3], T2 [RNSi(OSi)2OR], T1 [RNSi(OSi)(OR)2] belonging to APTES-based gel; where R could be H or Et, RN refers to aminopropyl group [38]. Both samples show a high degree of condensation, DOC, which was calculated from the corresponding 29Si NMR spectra from single pulse excitation. These results indicate that the matrix is quite stable and will not change significantly upon ageing. Considering the different rate of hydrolysis and condensation of the two silanes, the higher amount of fully condensed species T3 with respect to Q4 is expected (Table 2).

13C CP-MAS NMR measurements were performed to determine the existence of organic group RN and possible residual OEt, due to a possible non-complete hydrolysis. The sample of the impregnated wood gives rise to a spectrum (Fig. 4) that is the superimposition of the spectra of the main wood components, i.e. cellulose, hemicelluloses and lignin [39] and the organic part of APTES consisting in three peaks at 9.8 ppm (1), 20.9 ppm (2), and 41.7 ppm (3) assigned to the three methylene carbons of the aminopropyl fragment. Main peaks are identified (Fig. 5) taking into account of literature data [40] and listed in Table 3. The two peaks related to ethoxy groups belonging to both APTES and TEOS are not detectable, but this does not ensure that the synthetic process leads a complete hydrolysis of the two silanes, as the peak broadening could mask small contributions of residual ethoxy groups.

Furthermore, the fact that the peaks belonging to wood components are not changed (shifted or broadened or reduced) after the treatment underline that the coating procedure does not damage the structure of the substrate. Thus, the composite material could increase its properties without loosing the original ones.

Unfortunately, the intrinsic broadening of the solid state spectra of both silicon and carbon doesn’t let to evaluate the existence of a real chemical bond between wood and silica matrix.

3.3 Characterization of the interpenetrated wood with copper (treatment S2)

3.3.1 SEM/EDX investigations

Solution S2, before exposure to wood with its natural humidity content, is expected to contain copper(II) complexes of APTES mainly in its monomeric form along with intact TEOS molecules. After impregnation into the wood samples, the sol–gel process takes place mainly onto the cell walls leading to the formation of an inorganic–organic hybrid xerogel which should preserve the same Si/Cu and Cl/Cu molar ratio of the starting solution. Our preliminary SEM investigations on this system [32, 33] showed that actually copper penetrates into the wood drawn by the coordinative interactions with the amino groups of APTES. In fact, the values found for the Si/Cu molar ratios are close to the nominal ratio 10:1. Nevertheless the Cl/Cu ratio is significantly lower than that of the starting CuCl2 salt. This suggested that, when exposed to the wood samples, at the beginning of the of the sol–gel process, the silanol groups Si–OH could interact with copper cations and substitute chloride anions by forming Si–O–Cu linkages through a simple exchange reaction schematized below:

The hydrochloridric acid formed could be neutralized by the excess of amine functions of the sol giving anchored alkylamonium chloride species. Copper cations are also coordinated by two amine functions as suggested by ESR data (vide infra). This reaction could take place also in the stock solution before exposition to wood owing to the presence of adventitious water. Furthermore, the chlorine deficit in the inner wood suggests that these amonium species could polymerize more rapidly becoming less able to penetrate into the wood and hence remaining both on the surface of the wood sample and in the external sol mixture.

Here we present new evidence confirming this unexpected behaviour. In fact, data summarized in Fig. 6, for a inner wood sample cross section, show that the starting Si/Cu molar ratio 10:1 is substantially maintained, differently to the Cl/Cu ratio, which again results significantly lower.

SEM investigations performed on the surface of samples impregnated with solution S2 show the presence of silicon, copper and chlorine homogeneously distributed over the surface area. Figure 7 shows a representative SEM image of the surface and the relevant X-ray spectrum with the relative atomic percentages. As a support of the hypothesis formulated above, the Cl/Cu molar ratio on the surface results significantly higher (3.3) than that of the starting salt.

Further evidence for this hypothesis comes from the data collected for the residual S2 xerogel, i.e. the hybrid material obtained by allowing the residual S2 solution to undergo hydrolysis/condensation reactions in the air. EDX data show a value of the Cl/Cu molar ratio much higher (4.2) than that observed in the inner wood.

Figure 8 summarizes these results, by comparing the Si/Cu and Cl/Cu atomic ratios found in the residual xerogel, on the wood surface and in the inner wood derived by solution S2. Whereas the Si/Cu ratio appears near the same on the surface and in the inner, the Cl/Cu ratio displays a clear trend to decrease by passing from the residual xerogel to the surface and to the inner, according to the formation of Si–O–Cu linkages and consequently of amonium chloride species remaining in prevalence out of the inner wood.

As regards the Cu/siloxane micro-distribution into the wood sample, SEM/EDX investigations, summarized in Figs. 9 and 10, have shown that the xerogel is present in the innermost wood mainly by penetrating the texture of cell wall (and middle lamella) (Fig. 9). This is a necessary requirement for a preservative formulation to warrant durability and dimensional stability. Figure 10 emphasizes that the siloxane xerogel is also present in some lumina as compact flakes. Microanalytical data reported in the figure captions suggest that copper/chlorine distribution is not as uniform as it appears on a larger scale, the Cl/Cu ratio ranging from 0.6 to 2.1 in Fig. 10.

SEM image (secondary electrons) of the cross section of a sample treated with solution S2 emphasizing the presence of the siloxane xerogel also into the cell lumina. Cl/Cu atomic ratios found in A and B (wall and lamella) and in C and D (lumen) are respectively 0.6, 0.6, 0.8 and 2.1. The corresponding Si/Cu atomic ratios are 13.5, 10.1, 8.6 and 16.2 respectively

3.3.2 ESR investigations

In order to gain insight about copper coordination in the composite xerogel/wood material, ESR investigations have been performed. Figure 11 shows the low temperature ESR spectra, paired with the best fit simulations, of (a) a wood sample impregnated with solution S2, (b) the corresponding xerogel (solution S2 sol–gel processed without wood) and (c) a wood sample impregnated with a two-step procedure. This procedure was adopted in the initial approach to this research field [32] and consists first in the impregnation of the wood sample with a TEOS/APTES 6:1 ethanol solution; then, after drying for 24 h, the impregnated sample is dipped for 2 h in a copper sulfate (0.1 M) solution. This procedure was abandoned because does not permit penetration of copper inside the wood and ESR data suggest an explanation for this behaviour (vide infra). The anisotropic magnetic parameters for the experimental spectra refined with computer simulations are reported in Table 4. All spectra are characteristic of an axial geometry around the metal coordination site and computed spectra suggest that two nitrogen atoms coordinate copper in (a) and (b), and three nitrogens coordinate in (c). The assignment of coordination site is also in agreement with Peisach-Blumberg plots that relate the parallel magnetic parameters towards the number of nitrogen and/or oxygen atoms present in the coordination sphere of the copper ion [41–44]. From the comparison of spectra (a) and (b) in Fig. 11, it appears that the copper environment in the wood sample treated with S1 is identical to that of the xerogel blank, as confirmed by the corresponding magnetic parameters reported in Table 4, suggesting that coordination of two nitrogen atoms to copper is not affected by the wood substrate and should be present also in the starting sol. It could have facilitated copper vehicolation deep inside wood. In addition, these strong coordinative interaction should be able to minimize copper leaching. On the other hand, for the two-step sample a completely different lineshape of the EPR signal, with different magnetic parameters, is observed being due to different coordination to copper. In the sample impregnated with the two-step procedure copper is added after the formation of the xerogel and therefore it is strongly adsorbed onto the surface by coordinative interactions with three nitrogen atoms. These strong interactions with the consolidated xerogel prevent copper to penetrate beyond the first layers of the composite material as observed in a previous paper [32].

120 K CW-ESR spectra (solid lines) paired to best fit simulations (dotted lines) of (top) a wood sample impregnated with solution S2, (middle) the genuine xerogel derived from sol–gel processing S2, (bottom) a wood sample impregnated with a two-step procedure, adopted in a previous work (Ref. [32]) and described in the text (Sect. 3.3.2)

On the other hand, from an accurate inspection of the parallel region of spectrum (c) the presence of more than one species can not be ruled out; therefore the magnetic parameters reported in Table 4 for that specimen refer to the most abundant species formed which has been spectroscopically characterised.

3.4 Characterization of the interpenetrated wood with solution SS (sodium silicate/APTES/copper)

Sodium silicate was tested in place of TEOS in order to have a cheaper and ethanol-free formulation. However, the obtained results are not particularly encouraging, as gel penetration results significantly lower than that of the corresponding formulation containing TEOS (S2) and preservation performance does not equal that of S2 against brown-rot decay (see Sect. 3.5 below). Lower penetration should be due to the formation of soluble oligomers in the stock solution acidified by HCl until pH 9 was reached.

Evidence for scarce penetration of formulation SS comes from SEM/EDX data reported in Fig. 12. First, differently from the corresponding TEOS formulation, the presence of silicon measured as Si/C ratio, significantly decreases from 2.4 near the surface to 0.6 in the inner (ca. 2 mm depth). In addition, copper and chlorine penetrate only in the first layers under the surface (ca. 0.3 mm depth). The high Cl/Cu ratio measured near the surface (Figs. 12 and 13) is likely due to the presence of grafted alkylammonium chloride species produced by reaction of APTES with HCl added in the formulation.

SEM image (secondary electrons) of the cross section of a wood sample impregnated with solution SS; the three rectangles indicates the regions of the section analysed by EDX. The surface of the sample is visible on the top of the image. Si/C atomic ratios (× 10−2) from spectrum SP1 to SP3: 2.4, 1.7, 0.6. Copper and chlorine are detectable only near the surface (rectangle SP1), Si/Cu and Cl/Cu atomic ratio being 13.4 and 8.6 respectively

3.5 Accelerated efficacy tests against brown-rot decay (Coniophora puteana L)

The efficacy of the TEOS/APTES/Cu treatment against fungal decay has been shown on preliminary reports [32, 33]. For the shake of comparison, we report here the efficacy tests carried out with the sodium metasilicate/APTES/Cu formulation (SS) by means of accelerated tests [35] against the brown rot fungus Coniophora puteana. Table 5 displays the efficacy data in terms of percent mass loss (ML%) exhibited by formulation SS before and after leaching treatment in comparison with those of S2.

Formulation SS with sodium metasilicate in place of TEOS appear effective (WL% 4.07 ± 0.23) if compared to the control samples, however its efficacy is slightly lower than that of the corresponding TEOS formulation S2 (WL% 1.1 ± 0.3). The superior efficacy of the S2 formulation is likely due to the highest sol penetration and copper retention. The leaching procedure on samples treated with SS formulation do not influence the effectiveness of the treatment.

4 Conclusions

In conclusion, interpenetration of wood samples of pine sapwood (Pinus sylvestris L.) with hybrid inorganic–organic silica xerogels has been successfully carried out, by sol–gel processing TEOS/APTES mixtures inside the wood. These xerogels are able to coordinate copper(II) cations and result active against the brown rot fungus Coniophora puteana. Solid state 29Si NMR data, ESR measurements and SEM/EDX investigations provide evidence for the interpenetration of the condensed xerogel and for the vehiculation of copper inside the wood, by complexation with the amine functions. In addition, sodium silicate was tested in place of TEOS in order to have a cheaper and ethanol-free formulation. However, the obtained results are not particularly encouraging, as gel penetration results significantly lower than that of the corresponding formulation containing TEOS and preservation performance does not equal that of TEOS formulation against brown-rot fungal decay.

References

Eaton RA, Hale MDC (1993) Wood: decay, pests, and protection. Chapman and Hall, London

Rowell RM (1983) For Prod J 6:363–382

Militz H, Beckers EPJ, Homan WJ (1997) IRG/WP 40098. International Research Group on Wood Protection, Stockholm

Norimoto M, Hon DNS, Shiraishi N (eds) (2001) Wood and cellulosic chemistry, 2nd edn. Dekker, New York, pp 573–598

Kartal SN, Hwang WJ, Yamamoto A, Tanaka M, Matsumara K, Imamura Y (2007) Int Biodeterior Biodegr 60:189–196

Tingaut P, Weigenand O, Mai C, Militz H, Sèbe G (2006) Holzforsch 60:271–277

Saka S, Miyafuji H, Tanno F (2001) J Sol-Gel Sci Thechnol 20:213–217

Schneider MH, Brebner KI (1985) Wood Sci Technol 19(1):67–73

Ogiso K, Saka S (1994) Mokuzai Gakkaishi 40:1100–1106

Brebner KI, Schneider MH (1985) Wood Sci Technol 19:75–91

Tshabalala MA, Gangstad JE (2003) For Prod J 75:37–43

Saka S, Ueno T (1997) Wood Sci Technol 31:457–466

Furuno T, Uheara T, Jodai S (1992) Mokuzai Gakkaishi 38:448–457

Furuno T, Uheara T, Jodai S (1992) Mokuzai Gakkaishi 32:387–400

Donath S, Militz H, Mai C (2004) Wood Sci Technol 38:555–566

Mahltig B, Swaboda C, Roessler A, Böttcher H (2008) J Mater Chem 18:3180–3192

Sèbe G, Brook MA (2001) Wood Sci Technol 35:269–282

Hill CAS, Farahani M, Hale MDC (2004) Holzforsch 58:316–325

Terziev N, Panov D, Temiz A, Palanti S, Feci E, Daniel G (2009) IRG/WP 09 30510. International Research Group on Wood Protection, Stockholm

Brinker CF, Sherer GW (1990) Sol-gel science. Academic, San Diego

Shea KJ, Loy DA (2001) Chem Mat 13(10):3306–3319

Mai C, Militz H (2004) Wood Sci Technol 37:339–348

Feci E, Nunes L, Palanti S, Duarte S, Predieri G, Vignali F (2009) IRG/WP 09 30493. International Research Group on Wood Protection, Stockholm

Cookson LJ, Scown DK, McCarthy KJ, Chew N (2007) Holzforsch 61(3):326–332

Yamaguchi H (2003) Wood Sci Technol 34:287–297

Kartal SN, Yoshimura T, Imamura Y (2009) Int Biodeterior Biodegr 63:187–190

Ghosh SC, Militz H, Mai C (2009) Eur J Wood Prod 67:159–167

Donath S, Militz H, Mai C (2006) Holzforsch 60(2):210–216

Weigenand O, Humar M, Daniel G, Miltz H, Mai C (2008) Holforschung 62:112–118

Craciun R, Maier M, Habicht J (2009) IRG/WP 09 30499. International Research Group on Wood Protection, Stockholm

Humar M, Zlindra D, Pohleven F (2007) Holz Roh Werkst 65:17–21

Palanti S, Predieri G, Vignali F, Feci E, Casoli A, Conti E (2011) Wood Sci Technol. doi:10.1007/s00226-010-0396-5

Palanti S, Feci E, Predieri G, Vignali F (2010) Maderas. Ciencia y tecnología 12(3):259–266

Rakhit G, Antholine WE, Froncisz W, Hyde JS, Pilbrow JR, Sinclair JR, Sarkar B (1985) J Inorg Biochem 25:217

Bravery AF (1979) IRG/WP 2113. International Research Group on Wood Protection, Stockholm

European Committee for Standardization EN 113 (1996) Wood preservatives. Test method for determining the protective effectiveness against wood destroying basidiomycetes—determination of the toxic values

European Committee for Standardization EN 84 (1997) Wood preservatives—accelerated ageing of treated wood prior to biological testing. Leaching procedure

Rahman IA, Jafarzadeh M, Sipaut CS (2009) Ceram Int 5:1883–1888

Bardet M, Gerbaud G, Giffard M, Doan C, Heidiger S, Le Pape L (2009) Prog Nucl Magn Res Spectr 55:199–214

Bardet M, Foray MF, Maron S, Goncalves P, Tran QK (2004) Carbohydr Pol 57:419–424

Peisach J, Blumberg WE (1974). Arch Biochem Biophys 165:691–708

Pogni R, Baratto MC, Diaz A, Basosi R (2000) J Inorg Biochem 79(1–4):333–337

D’Amelio N, Gaggelli E, Gaggelli N, Molteni E, Baratto MC, Valensin G (2004) Dalt Trans 3:363–368

Fragoso A, Baratto MC, Diaz A, Rodriguez Y, Pogni R, Basosi R, Cao R (2004) Dalt Trans 1:1456–1460

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vignali, F., Predieri, G., Feci, E. et al. Interpenetration of wood with NH2R-functionalized silica xerogels anchoring copper(II) for preservation purposes. J Sol-Gel Sci Technol 60, 445–456 (2011). https://doi.org/10.1007/s10971-011-2557-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-011-2557-x