Abstract

A novel CH3-functionalized mesoporous silica material (PTM) with nearly spherical morphology was synthesized by a one-step synthesis route using polymethylhydrosiloxane and tetraethoxylsilane in the presence of triblock copolymer P123 as structure-directing agent. Thus-obtained material possessed highly-ordered mesopore arrays and texture with highly CH3-functionalized surface. As compared with pure siliceous SBA-15, PTM showed the high performance for gas chromatographic separation of hexene isomers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Higher α-olefins, mainly 1-hexene, are very useful comonomers in the production of polymers like linear low density polyethylene (LLDPE) [1]. The predominant production route for α-olefins is based on the oligomerization of ethylene. The typical by-products formed via this production route are paraffins, linear internal olefins, and branched olefins [2]. Alternative sources of α-olefins are Fischer–Tropsch product streams. Though the Fischer–Tropsch process looks interesting for the production of α-olefins, it also co-produces many olefin isomers [2].

The separation of α-olefin and the corresponding olefin isomers is a difficult and expensive operation due to their low relative volatilities that render normal distillation impractical and uneconomical [3]. Also, extractive distillation can not significantly improve their separation since the entrainer has almost the same effect on each of the isomeric mixtures and then does not change their relative volatilities [4]. Selective etherification of the branched isomer was commonly used to increase the relative volatility to a level that normal distillation could be applied [5]. However, such an approach still required a number of additional separation steps to remove the remaining components before the high purity α-olefin (1-hexene) was obtained [6]. Thus, the π-complexation technology was considered to achieve their separation, in which a certain transition metal ion (especially Ag+ or Cu+) reversibly and selectively complexes with the close-boiling olefin isomers. Wentink et al. [3] presented a promising alternative, reactive extractive distillation that is the combination of π-complexation with extractive distillation. Silver nitrate dissolved in ethylene glycol was investigated as a potential reactive solvent for the separation of 1-hexene from a Fischer–Tropsch stream. Kuipers et al. [2] also investigated the feasibility of metal–ligand complexes as functionalized solvents applied in the novel separation technology, reactive extractive distillation for the separation and purification of α-olefins like 1-hexene from other C6-olefin isomers (internal, branched, cyclic and diolefins) and paraffins. Zhu et al. [1] used room temperature ionic liquids as potential solvents for the separation of hexene isomers in either extraction or extractive distillation. Song et al. [7] reported several potential reactive extractants for their selectivity of both 1-hexene to 2-hexene and 1-hexene to 3-hexene. Unfortunately, there exist some disadvantages in the aforementioned separation methods of hexene isomers, such as complicated processes with high energy consumption, the low solubility of olefin isomers in the reactive solvents and the low stability of silver ion complexes in the separation processes. Thus, further improvement is still needed.

In the last decade, mesoporous silica materials such as MCM-41 [8] and SBA-15 [9], which are of high specific surface areas, narrow pore size distributions, and adjustable pore sizes, have been employed as stationary phases for size-exclusion chromatography [10], normal-phase HPLC [11], reversed-phase HPLC [12], chiral HPLC [13], capillary gas chromatography [14], and gas–solid chromatography [15–17]. They showed high separation efficiency and then the tremendous potential in the separation field. To our knowledge, however, gas chromatographic technique has not been used to separate these hexene isomers.

Considering the weak polarity of C6-olefin isomers, hydrophobic mesoporous silica was chosen as gas chromatographic stationary phase to separate the target isomeric mixtures of 1-hexene, trans-2-hexene and 3-methyl-1-pentene in the present work. According to Gaussian Computation, they have different dipole moments (field-independent basis, Debye), 0.4580, 0.0284 and 0.3297, respectively, indicating their different molecular polarities. Maybe there exists a difference in the interactions between three types of olefin molecules and hydrophobic groups, which will lead to their different retention behaviors. For this purpose, mesoporous silica PTM was prepared for the stationary phase for gas chromatographic separation of hexene isomers.

2 Experimental

2.1 Synthesis

The novel CH3-functionalized mesoporous silica PTM was synthesized under acidic conditions by using mixed polymethylhydrosiloxane (PMHS) and tetraethoxylsilane (TEOS) in the presence of triblock copolymer P123 as template.

In a typical synthesis, 2 g of P123 was completely dissolved in 15 mL of deionized water and 30 mL of a 2 mol/L HCl solution at 40 °C. 3.12 g of TEOS and 1.56 g of PMHS were added to the above solution under vigorous stirring at the constant temperature. After 24 h of stirring, the mixture was allowed to age at 100 °C for another 24 h under quiescent conditions. Then the white precipitate was recovered by filtration, washed with deionized water, and dried at 80 °C. Finally, the template inside the as-synthesized mesoporous material was removed by Soxhlet extraction with ethanol for 48 h.

Pure siliceous SBA-15 was prepared according to the procedure reported by Zhao et al. [9].

2.2 Characterization

Powder X-ray diffraction (XRD) patterns were recorded on a D8 Advance Bruker AXS diffractometer using Cu Kα radiation. N2 adsorption–desorption isotherms were measured at 77 K on a Micromeritics Tristar 3000 Sorptometer. The samples were degassed at 353 K and under a vacuum of 10−6 Torr for at least 12 h prior to the measurement. The specific surface areas were calculated using the multiple-point Brunauer-Emmett-Teller (BET) method. The pore size distributions were calculated from the adsorption branch via the Barrett-Joyner-Halenda (BJH) method. The pore channels were observed by high resolution transmission electron microscopy (HRTEM) images on JEM-2010. Field emission scanning electron microscopy (FESEM) images were obtained on LEO 1530VP. 29Si MAS NMR experiments were performed on a Varian Infinityplus-300 spectrometer using 7.5 mm probe under magic-angle spinning.

In a typical chromatographic column preparation, a stainless steel pump (1 m long, 3 mm id) was filled with about 1.0 g of the synthesized mesoporous silica particles (particle diameter of 0.18–0.25 mm). And then the packed column was aged for 24 h at 100 °C. The separation performances of the samples were investigated on GC-8A (FID). All the chromatographic separation experiments were carried out under the same conditions: column temperature at 90 °C, detector temperature at 140 °C, injector temperature at 140 °C, and the flow rate of carrier gas (N2) at 30 mL/min.

3 Results and discussion

3.1 Mesoporous structure determination

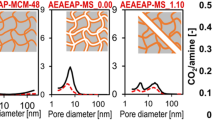

The mesopore orderliness of the obtained PTM was investigated by XRD and N2 adsorption–desorption. The small-angle XRD pattern of the sample PTM showed three well-resolved peaks (see Fig. 1), which were indexable as (100), (110), and (200) reflections associated with p6mm hexagonal symmetry. This indicated highly-ordered hexagonal mesopore arrays. Furthermore, the sample PTM showed a type IV isotherm with a type H1 hysteresis loop, characteristic of a mesoporous solid (see Fig. 2), and the hysteresis loop appeared in a relatively high P/P 0 range (0.6–0.9), suggesting a large mesopore size as illustrated in the inset of Fig. 2. With BJH pore size distribution located at 7.3 nm, the sample had BET surface area of 728 m2/g and pore volume of 1.19 cm3/g, respectively. Obviously, so-produced material displayed a similar texture to pure siliceous SBA-15, indicating that the addition of PMHS had little impact on the mesostructure of SBA-15.

The representative HRTEM images of the sample PTM are illustrated in Fig. 3. The sample showed a well-ordered mesopore array structure similar to that of SBA-15, possessing a long-range ordering in the mesopore packing. However, the coiled rod with the parallel orientation of mesochannels indicated a significant difference in the morphology between PTM and SBA-15 (see Fig. 3a), the latter generally having a fiber-like morphology.

3.2 29Si MAS NMR

Solid-state 29Si MAS NMR provides information about the silicon environment and the degree of CH3 functionalization on SBA-15 [18]. Fig. 4 depicts the 29Si MAS NMR spectrum of the sample PTM, which displayed five main resonance signals at −33.2, −63.2, −94.9, −102.0 and −110.4 ppm, corresponding to D 2 [CH3(H)Si(OSi)2], T 3 [CH3-Si(OSi)3], Q 2 [Si(OSi)2(OH)2], Q 3 [Si(OSi)3(OH)] and Q 4 [Si(OSi)4], respectively. It is well-known that with NaOH as the catalyst, the active Si–H groups in PMHS could be rapidly hydrolyzed to form Si–OH groups which would come into the consequent co-condensation with TEOS. Because of the weaker catalysis of HCl and the strong interface tension between oil phase and water phase caused by the introduction of PMHS into the aqueous solution system, however, the incomplete hydrolysis of Si–H groups took place and led to the existence of the D2 resonance signal.

The (D + T)/(D + T + Q) ratio calculated from the normalized peak areas was 0.322, namely, the CH3 functionalization degree of PTM was as high as 32.2%, which exceeded the conventional loading of methyl groups in the SBA-15 framework. In general, the overloading of organic functional groups led to a destruction of the pore channels in one-pot synthesis of inorganic–organic hybrid materials. Fortunately, the present CH3 functionalization almost caused no destruction of the mesostructure.

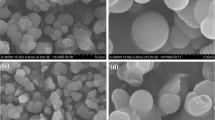

3.3 Particle morphology

The PTM particle morphology could be observed by field emission scanning electron microscopy (FESEM) (see Fig. 5). Clearly, the sample PTM was composed of nearly spherical clusters formed by coiled rods interweaved with floccules.

Hydrogen-containing silicone oil PMHS is distinctive in structure, possessing a long chain structure of repeating unit [CH3(H)SiO]n. The introduction of PMHS, containing a large amount of hydrophobic groups, into the synthesis system induced a strong interface tension between oil phase and water phase, and PMHS molecular chains in the aqueous solution showed a tendency to form loops in order to decrease the interface tension. As a result, the numerous CH3 groups should be enriched inside the loops because of their hydrophobic trait and outside the loops were the hydrophilic Si–OH groups under the weak catalysis of HCl. Simultaneously, the co-condensation of PMHS and TEOS led to toroidal bend of hybrid P123-siliceous species micelles and then the formation of coiled rods. Such coiled rods, similar to fiber-like SBA-15 sections, possessed well-ordered mesopores in the presence of the triblock copolymer P123 template. Thus, PMHS not only was a silicon source, but also played an important role as morphological and organic functional modifier, ensuring the nearly spherical particle morphology and high CH3 functionalization degree of the obtained mesoporous material PTM.

3.4 Chromatographic separation

To investigate the chromatographic property of the novel hydrophobic mesoporous silica, the PTM particles with particle size of 0.18–0.25 mm were used as stationary phase for gas chromatographic separation of hexene isomers. Three hexene isomers were mixed together according to their mass ratio of 1:1:1. The separation performance of pure siliceous SBA-15 as stationary phase was also evaluated for comparison.

Figure 6 shows the separation chromatograms of the target isomeric mixtures using SBA-15 and PTM as stationary phases, respectively. Obviously, the elution order of the three hexene isomers was highly consistent with the order of their boiling points. SBA-15-packed column hardly conducted a total separation (see Fig. 6a). This was related to its weak adsorption affinity for olefin molecules, although Newalkar et al. [19] ascribed the adsorption of light C1–C3 hydrocarbons on mesoporous-microporous SBA-15 materials to the presence of micropores in the walls of the SBA-15 framework. Also, Vinh-Thang et al. [20] indicated that the adsorption of C7 hydrocarbons on biporous SBA-15 mesoporous silica depended on the framework microporosity of SBA-15. In the present case, three hexene isomers almost have the same properties and then were hardly separated by SBA-15. However, hydrophobic PTM showed a better resolution and a higher efficiency for the tested hydrocarbon mixtures. The baseline separation of these hexene isomers with their extended retention times was achieved using PTM as chromatographic stationary phase (see Fig. 6b). This could be ascribed to the fact that the introduction of PMHS, which contains a large amount of methyl groups, led to the formation of the weak polar or nonpolar chromatographic stationary phase PTM. Obviously, the methyl groups had a strong interaction with olefin molecules by dispersion force within the confined space, which extended their retention times. Due to the difference in their molecular structures, there existed a difference in the interactions between three types of olefin molecules and hydrophobic groups incorporated into the siliceous framework.

4 Conclusions

A novel CH3-functionalized mesoporous silica PTM with nearly spherical morphology and highly-ordered mesostructure was prepared by using PMHS and TEOS as silica sources and P123 as structure-directing agent under acidic conditions. The separation performance of PTM was evaluated by gas chromatography, and in comparison to pure siliceous SBA-15, PTM showed the high performance as stationary phase for the separation of hexene isomers.

References

Zhu JQ, Chen J, Li CY, Fei WY (2006) Study on the separation of 1-hexene and trans-3-hexene using ionic liquids. Fluid Phase Equilib 247:102–106

Kuipers NJM, Wentink AE, de Haan AB, Scholtz J, Mulder H (2007) Functionalized solvents for olefin isomer purification by reactive extractive distillation. Chem Eng Res Des 85(A1):88–99

Wentink AE, Kockmann D, Kuipers NJM, de Haan AB, Scholtz J, Mulder H (2005) Effect of C6-olefin isomers on π-complexation for purification of 1-hexene by reactive extractive distillation. Sep Purif Technol 43:149–162

Terrill DL, Sylvestre LF, Doherty MF (1985) Separation of closely boiling mixtures by reactive distillation. 1. Theory. Ind Eng Chem Process Des Dev 24:1062–1071

Becker H (1999) Recovery of high purity alpha olefins from a Fischer Tropsch synthesis. German Patent DE 19825295 (A1)

Render C, Denga Z (1994) International meeting on chemical engineering and biotechnology Achema 94 Frankfurt

Song FX, Yu YM, Chen J (2008) Separation of C6-olefin isomers in reactive extractants. Tsinghua Sci Technol 13:730–735

Beck JS, Vartuli JC, Roth WJ, Leonowicz ME, Kresge CT, Schmitt KD, Chu CT-W, Olson DH, Sheppard EW, McCullen SB, Higgins JB, Schlenker JL (1992) A new family of mesoporous molecular sieves prepared with liquid crystal templates. J Am Chem Soc 114:10834–10843

Zhao DY, Huo QS, Feng JL, Chmelka BF, Stucky GD (1998) Nonionic triblock and star diblock copolymer and oligomeric surfactant syntheses of highly ordered, hydrothermally stable, mesoporous silica structures. J Am Chem Soc 120:6024–6036

Nassivera T, Eklund AG, Landry CC (2002) Size-exclusion chromatography of low-molecular-mass polymers using mesoporous silica. J Chromatogr A 973:97–101

Grün M, Kurganov AA, Schacht S, Schüth F, Unger KK (1996) Comparison of an ordered mesoporous aluminosilicate, silica, alumina, titania and zirconia in normal-phase high-performance liquid chromatography. J Chromatogr A 740:1–9

Martin T, Galarneau A, Renzo FD, Brunel D, Fajula F (2004) Great improvement of chromatographic performance using MCM-41 spheres as stationary phase in HPLC. Chem Mater 16:1725–1731

Thoelen C, Van de Walle K, Vankelecom IFJ, Jacobs PA (1999) The use of M41S materials in chiral HPLC. Chem Commun, pp 1841–1842

Raimondo M, Perez G, Sinibaldi M, De Stefanis A, Tomlinson AAG (1997) Mesoporous M41S materials in capillary gas chromatography. Chem Commun, pp 1343–1344

Guan LX, Li JP, Cao H, Zhao N, Wang XZ, Wei W, Sun YH (2006) Chloropropyl-modified MCM-41 as gas chromatography matrix for the separation of water-alcohol mixtures. Chem Lett 35:516–517

Guan LX, Li JP, Yang DJ, Wang XZ, Zhao N, Wei W, Sun YH (2007) Highly hydrophobic mesoporous materials as matrix for gas chromatography separation of water-alcohols mixtures. Stud Surf Sci Catal 165:885–888

Guan LX, Li JP, Wang XZ, Zhao N, Wei W, Sun YH (2007) Separation of benzene and its relatives by highly hydrophobic microporous/mesoporous materials. Stud Surf Sci Catal 170:988–993

Gao Q, Xu WJ, Xu Y, Wu D, Sun YH, Deng F, Shen WL (2008) Amino acid adsorption on mesoporous materials: influence of types of amino acids, modification of mesoporous materials, and solution conditions. J Phys Chem B 112:2261–2267

Newalkar BL, Choudary NV, Kumar P, Komarneni S, Bhat TSG (2002) Exploring the potential of mesoporous silica, SBA-15, as an adsorbent for light hydrocarbon separation. Chem Mater 14:304–309

Vinh-Thang H, Huang QL, Eić M, Trong-On D, Kaliaguine S (2005) Adsorption of C7 hydrocarbons on biporous SBA-15 mesoporous silica. Langmuir 21:5094–5101

Acknowledgments

This work is financially supported by Chemistry Department, King Saud University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Y., Xu, Y., Wu, D. et al. Hydrophobic mesoporous silica applied in GC separation of hexene isomers. J Sol-Gel Sci Technol 56, 93–98 (2010). https://doi.org/10.1007/s10971-010-2280-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-010-2280-z