Abstract

We present recent studies on amorphous and crystalline TiO2 resistive switching nonvolatile memory devices. A chemical sol–gel process is demonstrated for preparing amorphous and crystalline TiO2 thin films with different calcination temperature. Glass/SnO2:F/TiO2/Cu sandwich structures are fabricated and their current–voltage characteristics are examined. We found that the switching voltage goes from 4.8 to 3.5 V and the current compliance also drops from 10 to 1 mA when calcination temperatures increased. Smooth surface of TiO2 thin films are also observed by XRD, AFM and XPS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, resistance random access memories (RRAM) have attracted a lot of attention in nonvolatile memories [1–3]. Particularly they are low cost, low power consumptions, show fast speed operation, and high density. Many materials such as PCMO, TiO2 and SiO2 have been reported to show resistive switching behavior. Resistive switching behavior in thin films was first reported during the last century. Since then, the electrical properties of these materials have been studied intensively. Lots of the published papers demonstrate the switching properties of transition metal binary oxides, especially TiO2 which are among the most studied [4–6]. On the other hand, most of the results deal with polycrystalline oxides and this leads to an improvement of resistive switching characteristics [7]. And You et al. [8] demonstrated that the resistance switching in amorphous NiO films is comparable to the one observed in polycrystalline oxides. In this work we investigated the switching properties of polycrystalline and amorphous TiO2 films deposited by sol–gel technology. The bistable resistive switching phenomenon was observed in amorphous and crystalline TiO2 thin films. A sol–gel process has been used for TiO2 thin film fabrication. The sol–gel method has the advantage of chemical uniform. The resistive switching behavior associated with the annealing temperature of TiO2 thin films was studied using XRD, XPS and AFM.

2 Experiments

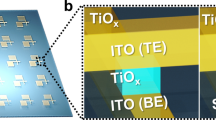

The whole process of fabrication is shown in Fig. 1. The substrate we used is self-made ATO glass which is transparent and conductive with transmission 92.0% and resistivity 3.5 × 10−3 Ω cm on normal glass [9]. It was cleaned by propanol and acetone. After that TiO2 thin films were fabricated by sol–gel process. We used tetraethylorthosilicate (TBT) and ethanol (EtOH) as starting materials while acetylacetone (AcAc) as chemical modifier. The components TBT, EtOH and AcAc were mixed in terms of molar ratio 1:20:3. TiO2 solution could be obtained after stirring for 8 h. Then a dip-coating method was used to make a TiO2 gel film on the ATO glass substrate. After heat treating the gel films for 15 min, organic compounds were evaporated and 20 nm thick TiO2 thin films were obtained. Then the TiO2 thin film was covered by a mask and the copper (99.99%) was evaporated by high vacuum thermal evaporation with a speed of 20 nm/min at 2.0 × 10−4 Pa for 1 min. Finally, the metal-oxide-semiconductor structure Cu 20 nm/TiO2 20 nm/ATO was achieved.

All electrical measurements were performed with Keithley 2400 analyzer at room temperature. The micro structural characterization was carried out by atomic force microscopy (AFM). Depth profile and chemical bonding state were investigated by XPS (Kratos, UK). The thicknesses of the films were measured by surface profilometer Surfcorder SE3500 Kosaka (Japan).

3 Results and discussion

3.1 XRD analyses

Figure 2 presents the XRD patterns of TiO2 thin films at various temperatures. The three samples were calcined at 300, 400 and 500 °C. Figure 2a and b did not show any peaks of TiO2. That means the TiO2 thin film is amorphous. The XRD pattern of amorphous TiO2 thin film showed a broad peak extending from 20 to 35° which was due to the glass substrate and the phase could not be accurately assigned. When the temperature increased to 500 °C, the TiO2 thin film showed anatase phase occurring at 2θ = 25.28, 37.80 and 48.05, which are attributed to (101), (004), (200) reflections, respectively. It was in close agreement with the JCPDS cards 24-1272.

3.2 XPS analyses

XPS spectra were investigated in order to interpret the relation of the switching behaviors and the binding states of TiO2 calcined at different temperatures. XPS spectra were obtained with monochromatic Al Kα(1,486.71 eV) line at a power of 150 W (10 mA, 15 kV). The charge neutralizer was applied to compensate for surface charge effects, and binding energies were calibrated using the C1s hydrocarbon peak at 284.8 eV. Figure 3a shows the wide scan XPS spectra and Fig. 3b, c show the high resolution spectra of Ti 2p and O1s, respectively. As shown in Fig. 3c, in addition to the O1s photopeaks of the TiO2 at 530.0 eV, the binding states for C–O at a binding energy of 533.0 eV are found on the surfaces of the TiO2 thin films [10]. The intensity of C–O state decreased when the calcination temperatures increased.

3.3 AFM analyses

AFM experiments were performed using an atomic force microscope SPM-400 (Seiko, Japan) with tapping mode. Figure 4 shows the area of 5 μm × 5 μm morphology of the TiO2 thin films which were annealed at 300, 400 and 500 °C. The roughness RMS (Root Mean Square) was 6.2, 7.6 and 8.6 nm respectively. The values increased when calcination temperatures increased. The bright parts correspond to higher features. And the shapes of TiO2 grains are more clearly when the temperature increased. From these measurements we observed uniformed thin films, formed at various temperatures.

3.4 Resistive switching behavior

For the electrical measurements, probes contact top electrode (Cu) and bottom electrode (ATO) respectively. The bottom electrode was grounded. A forming process is necessary to activate the Cu/TiO2/ATO structure at the fresh state. A Schottky barrier contact exists between Cu and TiO2 films. Therefore, stable and repeatable I–V curves can be observed after forming. Three samples, which were calcined at 300,400 and 500 °C, were measured. In Fig. 5 it shows the I–V characteristics of the Cu/TiO2/ATO structure. Figure 5a shows the I–V curve of the sample calcined at 300 °C. The current compliance (CC) is applied to 10 mA in the first I–V sweep which represents the OFF state. When the voltage goes to 4.8 V, the current increases rapidly which shows the OFF state switches to the ON state. During the second I–V sweep at the negative side, when the voltage goes to −4.2 V, the current decreases rapidly which shows the ON state switches to the OFF state. This behavior can be repeated more than several times. Figure 5b shows the I–V curve of the sample calcined at 400 °C. The current compliance is applied to 10 mA in the positive I–V sweep. When the voltage goes to 4.0 V, the current increases rapidly which shows the OFF state switches to the ON state. During the second I–V sweep at the negative side, when the voltage goes to −2.4 V, the current decreases rapidly which shows the ON state switches to the OFF state. This behavior can be repeated more than 50 times. Figure 5c shows the I–V curve of the sample calcined at 500 °C. The current compliance is applied to 1 mA in the positive I–V sweep. When the voltage goes to 3.5 V, the current increases rapidly which shows the OFF state switches to the ON state. During the second I–V sweep at the negative side, when the voltage goes to −0.4 V, the current decreases rapidly which shows the ON state switches to the OFF state. This behavior can be repeated more than 50 times. These three I–V curves all show bipolar resistive switching with different calcinations temperatures. The switching voltage goes from 4.8 to 3.5 V when calcination temperatures increased. The current compliance also drops from 10 to 1 mA.

4 Conclusions

In summary, we investigated the switching properties of polycrystalline and amorphous TiO2 films deposited by sol–gel technology. The bistable resistive switching phenomenon was observed in amorphous and crystalline TiO2 thin films. It can be concluded that resistance reduction in the devices is due to the existing Cu to form conduction Cu-rich pathways. An opposite bias takes the existing Cu back to the Cu electrode to its high resistance state. The samples were calcined at 300,400 and 500 °C. All amorphous and crystalline TiO2 samples show bipolar resistive switching. The switching voltage goes from 4.8 to 3.5 V and the current compliance also drops from 10 to 1 mA when calcinations temperatures increased. Binding states for C–O at a binding energy of 533.0 eV are found on the surfaces of the TiO2 thin films and the intensity of C–O state decreased when calcination temperatures increased. The roughness values increased when calcination temperatures increased.

References

Shima H, Tamai Y (2009) Microelectron J 40(3):628–632

Rozenberg MJ, Inoue IH, Sanchez MJ (2004) Phys Rev Lett 92(17):178302–178306

Choi BJ, Jeong DS, Kim SK et al (2005) J Appl Phys Lett 98:037715–037725

Waser R (2009) Microelectron Eng 86:1925–1928

Guo X, Schindler C, Stephan M, Waser R (2007) Appl Phys Lett 91(13):133513–133516

Gopalan C, Kozicki MN, Bhagat S et al (2007) J Non Cryst Solids 353:1844–1848

Wu X, Zhou P, Li J, Chen LY, Lv HB, Lin YY, Tang TA (2007) Appl Phys Lett 90:183507

Hwan You Y, So B-S, Hwang J-H, Cho W, Lee SS, Chung T-M, Kim G, An K-S (2006) Appl Phys Lett 89:222105

Zhi X, Zhao G, Zhu T, Li Y (2008) Surf Interface Anal 40:67–70

John FM et al (1992) Handbook of X-ray photoelectron spectroscopy. Perkin

Acknowledgments

This study was partly supported by the National Natural Science Foundation of China (No. 50772088), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Zhao, G., Zhou, X. et al. Resistive switching behavior in amorphous and crystalline TiO2 thin films by sol–gel process. J Sol-Gel Sci Technol 56, 61–65 (2010). https://doi.org/10.1007/s10971-010-2274-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-010-2274-x