Abstract

The preparation of TiO2-coated polyester fabrics for purposes of photocatalytic water purification requires coating agents with crystalline TiO2 particles preferably in the anatase modification. The resulting coatings should exhibit a high water resistance and high photocatalytic activity according to reaction with structurally different dyestuffs. For this, the synthesis of anatase sols by hydrolysis of tetraisopropyltitanate in acidic medium under reflux was optimized. By precoating or addition of polymeric epoxysilanes a good adhesion on the polyester support could be realized. The photocatalytic activity was tested with different dyestuffs as: Methylene blue, Rhodamine B and the azo dyes AcidOrange 7 and C.I. Reactive red 158. The rate of photodestruction depends strongly on the type of used dye and its structure. Surprisingly, no differences in photodegradation were found in case of investigations with Rhodamine B, if the photoreaction is performed under exposure with UV or with visible light. A possible explanation of the similar behavior of photoreaction under different light sources could be a photodestruction by electron transfer from Rhodamine B to TiO2. Therefore, Rhodamine B seems to be generally not suitable for the evaluation of the photoactivity of TiO2 under irradiation with visible light.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

It is alarming to learn that at present approximately 10,000 different dyes and pigments are produced annually world-wide, but up to 20% of which may be found in wastewater [1]. Because of their potential toxicity for living beings and damage to the environment it is great challenge to find out suitable technologies to destruct these dye pollutions in the waste water.

Because of the high stability of synthetic dyes and the high salinity of wastewater containing dyes, conventional biological treatment processes [2–5] are mostly ineffective and time-consuming, require great treatment areas and steady control of the microbial process conditions. Moreover, under anaerobic conditions azo dyes are readily reduced to potentially hazardous aromatic amines. Alternative adsorption and coagulation processes are also applied to remove dyes from wastewater, which then again result in secondary pollution.

Consequently, a more effective technology could be an efficient oxidation process which mineralizes quickly and non-selectively a broad range of organic dyes. Compared with conventional water treatment processes like chlorination, ozonation, UV-radiation the most promising technology is now photocatalytic oxidation, especially when solar light can be used [6–10]. Amongst various oxide semiconductor photocatalysts, the low-cost titanium dioxide is highly favourable to use due to non-toxicity and strong oxidizing power for the total mineralization of the most of organic pollutants which will be converted to harmless inorganic products like CO2, H2O etc. Under UV exposure (<380 nm) solid TiO2 produces electron–hole pairs. The holes are able to oxidize either directly the dyes or after reaction with water or hydroxide ions, hydroxyl radicals are formed which are also strong oxidants. The generated photoelectron can react with absorbed oxygen to produce superoxide radical anions which suppress the electron–hole recombination and also contribute to the dye destruction.

Many efforts were made in last years to improve the efficiency of the photocatalytic degradation process. The interest was mainly focussed on:

-

1.

the improvement of TiO2 photoactivity in the visible range of the solar spectrum. For this, many modifications were investigated using doping with noble metals, transition metal and lanthanide metal compounds and non-metals (nitrogen, fluorine, sulphur, carbon, etc.), cp. [1].

-

2.

the improvement of the long-term photoactivity of the photocatalyst because the activity decreases slowly during long-time use due to the adsorption of contaminations on the TiO2 surface [11].

-

3.

the development of an optimal immobilization and support of the photocatalyst to avoid the removing of the photocatalyst by filtration. The immobilization should be long-time stable and well adhering on the support. It should ensure a high photoactive surface of the catalyst and be suitable to the used reactor design.

In the recent years, fiber material has been proposed as an interesting immobilisation support, because it is a lightweight, inexpensive and mechanically stable material. It is flexible, drapable, can be flowed through and enables a combination of filter and remediation properties. Mostly to generate photo-induced self-cleaning or disinfection properties cotton textiles [12–18], non-woven tissue made from cellulose fibers [19], polyacrylonitril fibers [20], activated carbon fiber [21, 22], glass fibers [23–25] were coated with photoactive TiO2. Also photocatalytic fibers for environmental applications were prepared by sintering processes based on silica core structure with a gradient-like surface titania layer [26].

The use of fiber-coated materials with high transparency, high flexibility, high surface area and large porosity offers the possibility for the construction of improved photoreactors for water treatment [27] (but also for air purification [19]) which overcome some of the actual shortcomings like low light utilization due to absorption and scattering of the light by the reaction medium and mass transport limitations [28].

Among textile materials polyester fabrics are of special interest as supporting material. Polyester fibers are mechanically and thermally very stable (up to 200 °C), resistant to stretching, wrinkling, shrinking and abrasion, resistant to water and the most chemicals. Because of these advantages, polyester fiber materials are used for purposes as water and air filters on industrial scale. Now the equipment of a commercial filter fabrics with a water-resistant, highly photoactive TiO2 layer was the aim of the presented work. To fulfil these demands, following problems had to be solved:

-

1.

the preparation of crystalline TiO2 coating solutions (preferably in the anatase modification) at low temperatures, because the post-annealing temperatures of the coated polyester fabric should not exceed 180 °C

-

2.

the coating should be water-resistant for a long time

-

3.

the coated material should be tested with structurally different dyes for the evaluation of the general applicability as photoactive filter because in practice the wastewater of textile industry can daily change color and composition depending on the actually driven production process.

In the following some results for the solution of the mentioned problems will be described.

2 Experimental

2.1 Sample preparation

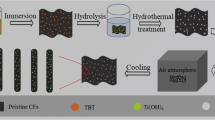

Following the preparation by Yun et al., [29] a mixture of 30 mL Ti(OC3H7)4 (TYZOR TPT/DuPont) was dropped into stirred 180 mL water. Then 2 mL of 70% HNO3 were added and the turbid solution heated under reflux for 8 h at 80 °C, respectively. By dip-coating the milky sols were applied onto a dense polyester fabric (Junker filter fabric 5090; Junker Filter GmbH, Germany). The polyester fabric was used as gained from the supporter and no further pre-treatment or pre-cleaning was performed. After application of the coating solution, the treated fabrics are dried at room temperature and afterwards a thermal treatment is performed for 1 h at 120 °C.

2.2 Methods

2.2.1 Electrochemical measurements

Cyclic voltametry of test dye C.I. Reactive Red/Ciba (see Chap. 2.2.2.) was performed using a potentiostat VSP/BIOLOGIC. As working electrode a glassy carbon disk electrode, a platinum wire as counter electrode and Ag/AgCl in 3 M NaCl as reference electrode were used. For the measurement a solution of 0.005 M dye in 0.1 M NaClO4 (supporting electrolyte) was used.

2.2.2 Determination of photocatalytic activity

The photocatalytic activity of the coated textile samples (1 × 5 cm²) was determined by decomposition of four different dyes in aqueous solution Acid Orange 7 (AO), Rhodamin B (RB), Methylene Blue (MB) and Reactive Red (RR) (for detailed information see Table 1 and Fig. 1). For testing photoactivity, each textile sample was placed in 15 mL of dye solution then illuminated for 4 h under agitation with a commercial 18 W light source (Omnilux, Eurolite) in a distance of 40 cm whose maximum intensity was at a wavelength of 365 nm. The remaining dye concentration (cexp) was determined using a UV/VIS spectrometer (MCS 501 UV-NIR, Zeiss, Germany) at the absorption maximum of the used dye. Reference measurements were performed in the same way without illumination (cdark).

From this, the bleaching rate (BR) of the dye can be calculated by

For evaluation of photoactivity of the coated textiles by exposure with visible light a setup with a white lamp 18 W (Omnilux, Eurolite) was used. The spectra of light intensity of both used lamps are given in Fig. 2. It is clearly seen that the intensity of the UV-source is mainly in the range of 320 to 400 nm with the maximum at 365 nm. In that area of UV light, the used dyes contain only small absorption, so a direct interaction and destruction by UV light absorption should not be expected. The UV-light emitted by the white lamp was fully deleted by using a cut off filter semaSORB PET 400 (semaGmbH, Coswig, Germany). This filter is only transparent for light >400 nm and was placed between sample and UV lamp. Reference measurements were also performed in the analogous set-up with analogous aqueous dye solution but without any textile fabrics or TiO2 material.

2.2.3 Water resistance

The water resistance of the coated textiles were evaluated by a washing process with a commercial washing machine according to DIN EN ISO 6330. An ECE washing powder (according to ISO 105-C08/C09, supplied by EMPA) was used. The washing cycles were repeated at 40 °C. After washing, the textile fabrics were dried at room temperature and their photoactivity was tested again.

2.2.4 X-ray investigations

The presence of the crystalline species in the metal oxide sols was determined by means of wide-angle X-ray scattering (WAXS) of the dried sol powders as described in [30].

3 Results and discussion

3.1 Low-temperature preparation of crystalline TiO2 coating solution

For the preparation of photoactive TiO2 coatings of fabric, liquid-phase processing is one of the most convenient and utilized methods. However, the photocatalytic activity of TiO2 materials can be influenced by many factors, including crystal structure, particle size, surface area, porosity, density of surface hydroxyl groups, surface acidity, number and nature of trap sites and adsorption–desorption characteristics [33–35]. The most decisive factor is the proper crystal modification, because only crystalline anatase preferably combined with rutile phases (like the high-photoactive commercial P25/Degussa, in which spatial charge separation hinders charge recombination), show a high photoactivity. In comparison amorphous TiO2 as a result of a fast hydrolysis of titanium alkoxides or halides (sol–gel process) is mostly photoinactive [36]. The amorphous TiO2 can be converted by annealing at temperatures >400 °C in photoactive TiO2 but this procedure is not suitable for organic substrates, e.g. papers, polymer foils or textiles due to their thermal decomposition. Now in last years various efforts have been made to develop different low-temperature methods to prepare highly crystalline TiO2 coating solutions:

-

(i)

by the long-time hydrolysis of titanium alkoxides [29, 37–42] or halides [35, 43] with a great excess of water and temperatures between 50 and 100 °C. It has been shown that the phase composition of TiO2 materials can be tuned by varying synthetic parameters, such as process time, acidity and water content,

-

(ii)

by hydrolysis of Ti(OPr)4 or TiCl4 using solvothermal methods, i.e. in autoclaves at temperatures between 100 and 300 °C in aqueous or alcoholic solvents. In addition to the thermal treatment of the sols, a hydrothermal aftertreatment of amorphous sol–gel titania coatings can also be used to realize the anatase formation, see references in [30].

-

(iii)

by dispersing of commercial mixed-phase nanoparticular TiO2 materials, such as Degussa P25 [44], which show high photocatalytic activity due largely to the synergistic effect between anatase and rutile phases, in inorganic SiO2 [45] or TiO2 sols [46–48].

In order to find out which procedure of variant (i) is especially suitable for the preparation of highly photoactive textile coatings [49], different published TiO2 preparation methods based on the acid hydrolysis of titanium tetraisopropoxide have been compared. The results of the photoactivity tests by bleaching of MB are seen in Table 2 and the corresponding XRD spectra which give information on the crystallinity of the obtained titania products are shown in Fig. 3.

XRD pattern of TiO2 samples A-G (see Table 2), each peak is identified with diffraction plane of anatase (a) or brookite (b)

The comparison of the different TiO2 preparation reveals some interesting results.

-

in all HNO3 catalyzed TiO2 samples A–F crystalline anatase diffraction planes were detectable by WAXS investigations whereas sample G with HCl catalysis has an amorphous structure, and therefore a low photoactivity.

-

in case of TiO2 sample B beside of the presence of anatase also brookite crystals can be observed.

-

for a high photoactivity the optimal reaction conditions are 4 to 8 h reaction time and temperatures between 50 and 80 °C. A prolongation of the reaction time from 4 h up to 24 h does not yield higher bleaching rates (see sample B in Table 2) and an improved crystallinity. The XRD patterns (pronounced anatase and weak brookite and rutile reflexes) shown in Fig. 4 are nearly the same.

Fig. 4 XRD pattern of TiO2 sample B (see Table 2) after different reaction times, each peak is identified with diffraction plane of anatase (a) or brookite (b)

From the investigated variants the prescription of Yun [29] was selected for further investigations. The procedure by stirring and refluxing of Ti(OC3H7)4 in aqueous nitric acid is very simple. After 8 h the resulting TiO2 sol B8 contains about 16% isopropanol. For the preparation of pure aqueous TiO2 sols it is possible to remove the alcohol by passing an air stream. The resulting aqueous TiO2 sol shows a comparable photoactivity like sol B8.

3.2 Improvement of the water-fastness of the coatings

An important prerequisite of the technical utilization of the coated fabrics for the photocatalytic purification of waste water is the long-time stability in flowing water. For testing of the water resistance, the decrease of photoactivity was determined after an ISO standard washing process at 40 °C in a commercial washing machine. In Table 3 it is presented that without any additives the photoactivity is considerably decreased after 5 washing cycles. Therefore, different precoatings were tested to ensure the adhesion of the TiO2 coating by cross linking with the polyester support.

Following coupling agents were tested which are often used:

-

1.

Aminosilanes (like aminopropyltriethoxysilane) which are well-known coupling agents which promote the adhesion between inorganic substrates and organic polymers, cp. also [50].

-

2.

Fixapret CP/BASF, a crosslinking agent on base of dimethyloldihydroxyethylene urea which is frequently used for the refinement of cellulose fibers [51, 52].

-

3.

Ebecryl 600/Fluka, an oligomeric crosslinker on base of bisphenol-A epoxy diacrylate [53, 54].

-

4.

Lupamin 5095/BASF, a low molecular weight poly(vinylamine-vinylformamide) copolymer [55, 56].

-

5.

Polymers with reactive terminal epoxy groups (like Tegomer 2330 or Silikopon EF/Evonik Tego Chemie) [57, 58].

The impregnation of the polyester fabric with these coupling agents (a)–(e) and following drying at 120 °C/1 h reveals that good adhesion and water-resistent TiO2 coatings with the sol B8 (Table 2) can only be obtained by precoating with epoxysilanes (e). A good adhesion of the coating can be considered in case of good wash fastness under ECE conditions as reported in Table 3. Best results are gained with products containing reactive terminal epoxide groups ensure an effective cross-linking of different ingredients. It could be expected that these reactive epoxygroups could either react with functional groups (like OH) on the fiber surface but also with not saturated hydroxygroups on the surface of the afterwards applied TiO2 particles. The results in Table 3 demonstrate that the precoated samples (shaded) even after 5 wash cycles remain or even enhance their photoactivity. It should be mentioned that often the photoactivity is increased after the first washing process due to an increasing degree of the TiO2 crystallization. Such a growth of anatase nanocrystallites during the hot water treatment was also observed with ethanol-based colloidal sols using a simple hot water treatment at a temperature of 97 °C [12].

Because the precoating with epoxysilanes requires an additional coating process, the possibilities were tested to add the epoxysilanes directly to the coating solution. The bleaching rates in Table 3 reveal that the water resistance can be also increased. However, this improvement is not as perfect as in case of precoating. How far this simpler variant meets the requirements for practical applications, prospective application tests should check it.

3.3 Testing of the TiO2 coated polyester fabric for the photocatalytic dye destruction

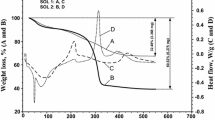

To evaluate the general suitability of the TiO2 coated polyester fabric, similar to investigations of various dye types in TiO2 suspensions [60] or films [61], four different, frequently used dyes were tested: Methylene blue, Rhodamine B and the azo dyes AcidOrange 7 and C.I. Reactive red 158. The time-dependent decrease of the light absorption of the aqueous solution in presence of the TiO2 coated fabric was measured (Fig. 5)

-

1.

in the dark to evaluate the absorption loss in the dye solution due to possible adsorption of the dye onto the textile or coating.

-

2.

at UV exposure to evaluate the intrinsic photosensitivity of the TiO2 coating.

-

3.

at exposure with a white lamp behind a UV cut off filter to evaluate the sensitivity in the visible spectral range, especially in view of a prospective practical use with sunlight exposition.

The determination without presence of TiO2 coated polyester shows only small dye degradation even in case of illumination with UV light. For this, it can be stated that under the chosen measurement set-up the dyes itself are quite stable under illumination and a degradation is the result of a photoactive reaction in presence of TiO2. The result presented in Figure 5 reveals a very different behaviour of the investigated dyes in presence of the TiO2 coated polyester. The dyes AO and MB show the expected behaviour for photocatalytic degradation. Both these dyes exhibit a slight dye adsorption in the dark, not any dye destruction with visible light and a continuous decay of the dye absorption at UV exposure due to the photocatalytic dye destruction. In comparison, the frequently used reactive dye RR is very stable and its photodestruction is very slow. Moreover, after multiple use in RR solution the photoactivity of the coated fabric was strongly reduced due to an increasing reddish coloring. Due to the dyeing, the photoactivity is reduced both by the light filter effect and by hindering of the photooxidation process at the TiO2 surface. First results show that the TiO2 coated fabric can be regenerated after multiple use by short-time immersing in 5% acetic solution of sodium dithionite or disulfite.

By using the dye Rhodamin B for evaluating the photoactivity a considerably different behaviour is observed. As shown in Fig. 5 by using Rhodamin B, a strong decrease of the absorption of the dissolved dye already appears without light exposure, probably as result of an intensive dye adsorption onto the coated fabric. Under UV exposition the stepwise de-ethylation and destruction of Rhodamin B [62–64] is very fast and the same fast destruction is found for the exposition with visible light.

This unusual behaviour could be confirmed with other TiO2 coatings (e.g. sol A in Table 2) and other polyester substrates (e.g. lattice-like polyester knitting 30886/supported by Mattes & Ammann). In all cases the photodegradation is similar for UV light or visible light exposure. This behavior can be explained by consideration of the energy term scheme of the different dye stuffs and TiO2 (see Fig. 6). Comparing the energies of LUMO of the four dyes and the conduction band of TiO2, only the LUMO of Rhodamin B is nearly on the same level than the conduction band of TiO2. For this, after exposure of Rhodamin B with visible light and the transition of an electron from highest occupied molecular orbital (HOMO) to the lowest unoccupied molecular orbital (LUMO) or its higher vibration levels an electron transfer to the nearly isoenergetic conduction band (cb) of anatase could be possible. The electron in conduction band produced by visible light can consecutively react with oxygen (and further to peroxide species which oxidize and destroy the dye) like the excited electrons which are produced by direct transition from TiO2 valence band (vb) to cb at UV exposure. Recently the assumed electron transfer from excited RB molecule to TiO2 could be proved directly by fluorescence quenching experiments [65]. Because with UV light the excitation of TiO2 and of the dye occurs simultaneously, the photodestruction proceeds very fast.

Altogether, for degradation of Rhodamin B in presence of TiO2 the exposition with UV light is not necessary, because the degradation can be also driven by visible light which is absorbed by the dye itself. A similar process was earlier also claimed for the degradation of colored stains like red wine on TiO2 coated fabrics [13].

In case of the other used dyes, the energetic position of their LUMOs is considerably lower compared to those of Rhodamin B, so that an electron transfer to the TiO2-cb is not possible and a photodestruction with visible light can not occur.

Under these considerations, from these results it can be concluded that generally Rhodamin B is not suitable as testing dye for the evaluation of doping effects of TiO2 to extend the photosensitivity in the visible spectral range (e.g. in [66–68]), because even in undoped systems already a high photodegradation occurs with visible light which is caused by an electron injection from RB excited states.

4 Conclusions

It could be demonstrated that by simple hydrolysis of Ti(OPr)4 in diluted nitric acid at 80 °C in 4–8 h anatase-containing TiO2 sols can be prepared which can form highly photoactive coatings on polyester fabric. By precoating or addition of polymeric epoxysilanes a good adhesion on the polyester support could be realized. The photocatalytic activity was proved by the photocatalytic destruction of Methylene blue, Rhodamine B and the azo dyes Acid Orange 7 and C.I. Reactive red 158. In dependence of dye structure the rate of photodestruction is very different. The fast photodestruction of Rhodamine B occurs both with UV light and also with visible light nearly with the same rate caused by electron injection from the excited dye to TiO2. Further investigation will be focused on the improvement of the long-time stability and effectiveness of the coated TiO2 fabrics and the improvement of the photoactivity in the visible spectral range.

References

Han F, Kambala VSR, Srinivasan M, Rajarathnam D, Naidu R (2009) Appl Catal A 359:25

Pandey A, Singh P, Iyengar L (2007) Int Biodeter Biodegr 59:73

Whiteley CG (2007) Ind Bioprocess 29:7

Pazdzior K, Klepacz-Smolka A, Ledakowicz S, Sojka-Ledakowicz J, Mronzinska Z, Zylla R (2009) Chemosphere 75:250

Couto SR (2009) Biotechnol Adv 27:227

Watanabe T (1993) Photocatalytic Purification and Treatment of Water and Air. Elsevier, New York

Hoffmann MR, Martin ST, Choi W, Bahnemann DW (1995) Chem Rev 95:69

Herrmann J-M (1999) Catal Today 53:115

Blanco-Galvez J, Fernández-Ibánez P, Malato-Rodriguez S (2007) J Solar Energy Eng 129:4

Rauf MA, Ashraf SS (2009) Chem Eng J 151:10

Rao KVS, Subrahmanyam M, Boule P (2004) Appl Catal B 49:239

Daoud WA, Xin JH (2004) J Am Ceram Soc 87:953

Bozzi A, Yuranova T, Guasaquillo I, Laub D, Kiwi J (2005) J Photochem Photobiol A 174:156

Daoud WA, Xin JH, Zhang YH (2005) Surf Sci 599:69

Qi K, Daoud WA, Xin JH, Mak CL, Tang W, Cheung WP (2006) J Mater Chem 16:4567

Uddin MJ, Cesano F, Bonino F, Bordiga S, Spoto G, Scarano D, Zecchina A (2007) Photochem Photobiol A 189:286

Abidi N, Hequet E, Tarmala S, Dai LL (2007) J Appl Polym Sci 104:111

Abidi N, Cabrales L, Hequet E (2009) Appl Mater Interface 1:2141

Taranto J, Frochot D, Pichat P (2009) Separ Purif Technol 67:187

Liuxue Z, Peng L, Zhixing S (2006) Mater Chem Phys 98:111

Fu P, Luan Y, Dai X (2004) J Mol Catal A 221:81

Herbig B, Löbmann P (2004) J Photochem Photobiol A 163:359

Robert D, Piscopo A, Heintz O, Weber JV (1999) Catal Today 54:291

Yu H, Lee SC, Ao CH, Yu J (2005) J Cryst Growth 280:612

Danion A, Bordes C, Disdier J, Gauvrit J-Y, Guillard C, Lanteri P, Jaffrezic-Renault N (2004) J Photochem Photobiol A 168:161

Ishikawa T (2006) Adv Sci Technol 45:2118

Kaur S, Gopal R, Ng WJ, Ramakrishna S, Matsuura T (2008) MRS Bull 33:21

Van Gerven T, Mul G, Moulijn J, Stankiewicz A (2007) Chem Eng Process 46:781

Yun YJ, Chung JS, Kim S, Hahn SH, Kim EJ (2004) Mater Lett 58:3703

Mahltig B, Gutmann E, Meyer D, Reibold M, Dresler B, Günther K, Faßler D, Böttcher H (2007) J Mater Chem 17:2367

Zille A, Ramalho P, Tzanov T, Millward R, Aires V, Cardoso MH, Ramalho MT, Gübitz GM, Cavaco-Paulo A (2004) Biotechnol Progr 20:1588

Becker HGO (ed) (1991) Einführung in die Photochemie. Deutscher Verlag der Wissenschaft, Berlin

Carp O, Huisman CL, Reller A (2004) Prog Solid State Chem 32:33

Chen X, Mao SS (2007) Chem Rev 107:2891

Liu G, Wang L, Wang HG, Cheng H-M, Lu GQ (2010) J Mater Chem 20:831

Khataee AR, Aleboyeh H, Aleboyeh A (2009) J Exp Nanosci 4:121

Yang J-H, Han Y-S, Choi J-H (2006) Thin Solid Films 495:266

Han S, Choi S-H, Kim S-S, Cho M, Jang B, Kim D-Y, Yoon J (2005) Small 1:812

Watson S, Beydoun D, Scott J, Amal R (2004) J Nanoparticle Res 6:193

Qi K, Chen X, Liu Y, Xin JH, Mak CL, Daoud WA (2007) J Mater Chem 17:3504

[41] Daoud WA, Xin JH (2005) Chem Commun 2110

Nolph CA, Sievers DE, Kaewgun S, Kucera CJ, McKinney DH, Rientjes JP, White JL, Bhave R, Lee BI (2007) Catal Lett 117:102

Jolivet J-P, Cassaignon S, Chaneac C, Chiche D, Tronc E (2008) J Sol Gel Sci Technol 46:299

Salinero A, Emeline AV, Zhao J, Hidaka H, Ryabchuk VK, Serpone N (1999) Pure & Appl Chem 71:321

Nakamura K, Yamaoka T, Nagatsuka T, Taga Y (2009) J Adv Oxid Techn 12:122

Balasubramanian G, Dionysiou DD, Suidan MT, Baudin I, Laıné J-M (2004) Appl Catal B Environ 47:73

Medina-Valtierra J, Garcia-Servin J, Frausto-Reyes C, Calixto S (2006) Appl Surf Sci 252:3600

Risse G, Matys S, Böttcher H (2008) Appl Surf Sci 254:5994

A publication about the comparison between variants (i)–(iii) is in preparation and will be submitted to J Sol-Gel Sci Technol

Sójka-Ledakowicz J, Lewartowska J, Kudzin M, Leonowicz M, Jesionowski T, Siwińska-Stefańska K, Krysztafkiewicz A (2009) J Mater Sci 44:3852

Nelson ML, Rousselle M-A (1973) Textile Res J 43:218

Xie Y, Krause A, Mai C, Militz H, Richter K, Urban K, Evans PD (2005) Polym Degrad Stab 89:189

Albareda-Sirvent M, Merkoci A, Alegret S (2001) Anal Chim Acta 442:35

Farrell JR, Iles PJ, Dimitrakopoulos T (1996) Anal Chim Acta 334:133

Fouda MMG, Wittke R, Knittel D, Schollmeyer E (2009) Int J Diabetes Mellitus 1:61

Rupp S, von Schickfus M, Hunklinger S, Eipel H, Priebe A, Enders D, Pucci A (2008) Sens Actuators B Chem 134:225

Celikbilek C, Akovali G, Kaynak C (2004) Polym Bull 51:429

Qian M, Soutar AM, Tan XH, Zeng XT, Wijesinghe SL (2009) Thin Solid Films 517:5237

Sakai N, Ebina Y, Takada K, Sasaki T (2004) J Amer Chem Soc 126:5851

Lachheb H, Puzenat E, Houas A, Ksibi M, Elaloui E, Guillard C, Herrmann J-M (2002) Appl Catal B Environ 39:75

Song X-M, Wu J-M, Yan M (2009) Thin Solid Films 517:4341

Wu T, Liu G, Zhao J, Hidaka H, Serpone N (1998) J Phys Chem B 102:5845

Qu P, Zhao J, Shen T, Hidaka H (1998) J Mol Catal A Chem 129:257

Li J, Ma W, Lei P, Zhao J (2007) J Environ Sci 19:892

Kathiravan A, Anbazhagan V, Asha Jhonsi M, Renganathan R (2007) Z Phys Chem 221:941

Xiahong W, Peibo S, Huiling L, Lili Q (2009) J Rare Earths 27:739

Li R, Lu X, Zhang J (2009) J Nanosci Nanotechn 9:1

Libanori R, Girali TR, Longo E, Leite ER, Ribeiro C (2009) J Sol Gel Sci Technol 49:95

Acknowledgments

The authors would like to thank Prof. Dr. Dirk C. Meyer and Dipl.-Phys. Emanuel Gutmann, Technische Universität Dresden, Institut für Strukturphysik, for the WAXS measurements, and the Evonik Tego Chemie GmbH Essen for the sampling of actual epoxysilanes. For help with determination of redox potentials the authors owe thanks to Dr. A. Bund (Technische Universität Dresden, Department of Electrochemistry). The work was supported by the German Federal Ministry for Economics and Labour, program InnoNet, project 16IN0565.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Böttcher, H., Mahltig, B., Sarsour, J. et al. Qualitative investigations of the photocatalytic dye destruction by TiO2-coated polyester fabrics. J Sol-Gel Sci Technol 55, 177–185 (2010). https://doi.org/10.1007/s10971-010-2230-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-010-2230-9