Abstract

B-doped TiO2 nanotubes (B/TiO2 NTs) were prepared by the combination of sol–gel process with hydrothermal treatment. The prepared catalysts were characterized by XRD, TEM and XPS. The photocatalytic activity of B/TiO2 NTs was evaluated through the photodegradation of aqueous methyl orange. The results demonstrated that the 1.5% B/TiO2 NTs calcined at 300 °C possessed the best photocatalytic activity. Compared with pure TiO2 nanotubes, the doping with B significantly enhanced the photocatalytic efficiency.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Semiconductor photocatalysis is a promising technology in air purification, water disinfection, hazardous waste remediation, and water purification [1]. Among various candidates, TiO2 is proved to be the most suitable catalyst in view of its strong oxidation activity. However, its photocatalytic oxidation rates for many target pollutants are too slow to be of practical utility [2–4]. Doping with suitable nonmetals has been attempted to improve its performances. Many nonmetals, such as nitrogen [5], carbon [6, 7], sulfur [8], phosphorus [9], fluorine [10] and boron [11], etc. have been used to modify the properties of TiO2.

Among them, boron doping is observed to be a potential method and improved performance can be obtained. For example, In et al. [12] reported that an optimal level of boron doping induces a larger absorption of visible light and enhanced photocatalytic activity. Su et al. [13] revealed that B-doped TiO2 nanotubes that were prepared by chemical vapor deposition (CVD) displayed stronger absorption in both UV and visible range. The experimental results of Chen et al. [14] indicated that all B-doped TiO2 nanoparticles prepared by sol–gel method showed higher photocatalytic activity than pure TiO2 sample in the photocatalytic reaction of nicotinamide adenine dinucleotide (NADH) regeneration under UV light irradiation. Yang et al. also reported that B-doped anatase models were investigated by spin-polarized density functional theory. It is reported that the radii of the boron atom is very small and can site at an interstitical position. In this B-doped TiO2 system, that B replacing an O atom induces some gap states close to the bottom of the conduction band, and may account for redshift of the absorption edge [11]. From these researches, it can be inferred that the photocatalytic activity of TiO2 can be improved by the doping of boron.

Recently, extensive researches have been conducted on the synthesis and characterization of TiO2 nanotubes because of their novel properties, such as unique shape, size confinement in radial-direction and large specific surface area [15–20]. Furthermore, the high sedimentation rate of the nanotubes facilitates their reuse as photocatalysts [21]. By modifying with different ions, the photocatalytic activity of the tubular TiO2 can be improved. In our group, different elements, such as gold [22], platinum [23], palladium [24], nitrogen [25], Chromium [26], fluorine [10], have been used to modify the TiO2 nanotubes and enhanced photocatalytic activity is obtained. However, to our knowledge, photocatalysis upon anatase B/TiO2 NTs has not been reported. Higher photocatalytic activity can be expected on the B/TiO2 NTs. In this paper, B/TiO2 NTs were prepared by using B-doped anatase TiO2 powder as precursors. The products were characterized by XRD, TEM and XPS. Their photocatalytic activity under UV–Vis light irradiation was evaluated by the degradation of methyl orange.

2 Experimental

Tetrabutyl titanate (C16H36O4Ti, AR), which was used as titanate (TiO2) precursor, was purchased from Tianjin Kermel chemical Co., Ltd, China. Boric acid (H3BO3, AR), which was used as the doped agent, was purchased from Tianjin Guangfu chemical Co., Ltd, China. Ethanol (C2H5OH, AR), which was used as a solvent, was purchased from Tianjin Guangfu chemical Co., Ltd, China. All the reagents were used without any further purification.

2.1 Preparation of B/TiO2 NTs

B-doped TiO2 powder was prepared by the sol–gel route using tetrabutyl titanate and boric acid as the precursors. Under constant stirring, ethanol solution of tetrabutyl titanate was added drop-wise to the mixture of ethanol and a desired amount boric acid solution. The transparent sol was obtained when the mixture was hydrolyzed at room temperature for 2 h under vigorous stirring. Then, gel was obtained by aging the sol for 12 h at room temperature. The resulting gel was dried at 80 °C in oven for 12 h to remove the solvents and then calcined at 500 °C in muffle furnace for 3 h. Then the B-doped TiO2 powder was obtained. The calculated boron concentrations were 1.0, 1.25, 1.5, 1.75%, respectively. Pure TiO2 powder was synthesized with the same process except that distilled water instead of boric acid solution is used. Pure titanate nanotubes and doped nanotubes with different boron concentration were synthesized via a simple hydrothermal chemical process. 1.0 g B-doped TiO2 powder or pure TiO2 powder was mixed with 50 mL 10 mol/L NaOH aqueous solution in a Teflon vessel and maintained at 150 °C for 12 h. The resulting materials were washed with 0.1 mol/L HNO3 solution and distilled water, respectively, and then dried at 80 °C overnight in an oven. After the prepared material was calcined at 300 °C for 2 h, B/TiO2 NTs were obtained. The corresponding B concentrations obtained in the photocatalysts were expressed as wt%.

2.2 Samples characterization

The powder X-ray diffraction (XRD) experiments were carried out at room temperature using a Rigaku D/Max-2500 X-ray diffractometer (CuKα λ = 0.154 nm) to identify the crystal phase of the products. TEM images were obtained with a Philips T20ST transmission electron microscopy working at 200 kV. The charge state of doped TiO2 at the surface was investigated by X-ray photoelectron spectroscopy (XPS) using an Al X-ray source (Al Kα-150W, Kratos Axis Ultra DLD).

2.3 Photoactivity measurement

The photocatalytic activity under UV–Vis light irradiation of the prepared catalysts was evaluated by the degradation rates of methyl orange (20 mg/L) in an aqueous solution (100 mL) containing 50 mg of sample. The reaction mixture was ultrasonically dispersed for 30 min, and then irradiated by using a 300 W High-Pressure Mercury Lamp under stirring. The radiation range of the High-Pressure Mercury Lamp is from 200 to 1,000 nm, and the full spectrum was used for experiments. After every given irradiation time, a sample of 5 mL suspension was withdrawn, centrifugated and filtered. The obtained solution was then measured for checking the residual concentration of methyl orange with a UV–Vis spectrophotometer (TU-1901) at 463.8 nm, which is the maximum absorption of methyl orange. The results are corrected for the decomposition of methyl orange in the absence of catalysts and for absorption of methyl orange on the catalyst. In the irradiation experiments, air or O2 bubbling was not used.

3 Results and discussion

Figure 1 shows the XRD patterns of 1.5% B/TiO2 NTs and pure TiO2 nanotubes calcined at 300 °C for 2 h. Diffractions that are attributable to anatase TiO2 are clearly detectable in pure TiO2 nanotubes and B/TiO2 NTs (JCPDS 21-1272). The diffraction peaks for boron or boron containing phases were not observed, which indicated that boron was highly dispersed on TiO2, or XRD was not sensitive enough to detect such minor changes to TiO2.

Figure 2 shows TEM images of 1.5% B/TiO2 NTs. Tubular structures are clearly observed. Figure 2a indicates that nanotubes are hollow and open-ended. Their diameters are nearly uniform and their length is more than hundreds of nanometers, similar to the results reported by Kasuga et al. [15, 16]. Figure 2b shows the TEM image of the obtained B/TiO2 NTs calcined at 300 °C for 2 h. It can be seen that most of the nanotubes keep their tubular shape after the calcination process.

Figure 3 shows the XPS survey spectra before and after Ar+ etching of B/TiO2 NTs with 1.5 wt% boron calcined at 300 °C for 2 h. There are Ti, O, B, and C on the surface of B/TiO2 NTs. The presence of C element should mainly come from residual carbon from the organic precursors used in the sol–gel method and the adventitious hydrocarbon from XPS. It should be noted that the intensity of peak corresponding C 1s appeared in the sample after etching was obviously weaker than that appeared in the sample before etching, indicating that the adventitious hydrocarbon from XPS itself was partly removed by Ar+ etching. The doping concentration of B analyzed by XPS was 1.15 wt% before etching and 0.61 wt% after etching, which implies that B dopant has a much higher concentration at the exterior than that at the interior of TiO2 nanotubes. After the hydrothermal process, the B-doped nanoparticles turned into tubular structures and the doped boron was mainly dispersed in the outer layer of the nanotubes, which results in the difference of the boron concentration before and after Ar+ etching. However, the measured concentrations are smaller than the calculated one. It should be attributed to the boron loss during the hydrothermal process.

Figure 4 shows the high resolution XPS spectra of Ti 2p. The Ti 2p1/2 and Ti 2p3/2 spin-orbital splitting photoelectrons are located at binding energies of 464.1 and 458.3 eV, respectively, which was in agreement with the values in the reported literatures [27, 28], showing the presence of Ti4+. However, the surface spectrum of the etched sample revealed two shoulder regions. The peak at 456.7 and 455.2 eV should be ascribed to Ti3+ 2p3/2 and Ti2+ 2p3/2 in the sample, respectively [27]. The presence of low valence Ti might be attributed to Ar+ etching.

Figure 5 shows the O 1s XPS spectra of B/TiO2 NTs. The O 1s spectrum was asymmetric. The main peak of O 1s located at about 529.6 eV, corresponding to lattice oxygen of TiO2. The shoulder located at 531.2 eV indicates a great amount of surface hydroxyl groups and chemical adsorbed oxygen [27, 28]. After Ar+ etching treatment, the shoulder peak approximately disappeared. That indicates the removal of water and adsorbed oxygen from the TiO2 surface.

Figure 6 shows the B 1s XPS spectra of B/TiO2 NTs before Ar+ etching. The B 1s region contains one peak at 191.6 eV. The standard binding energy of B 1s is 193.0 eV (B–O bond) in B2O3 or H3BO3 and 187.5 eV (B–Ti bond) in TiB2. So the binding energy of B 1s is between that of B2O3 and TiB2. This indicates the boron atom was probably incorporated into TiO2 and the chemical environmental surrounding might be Ti–B–O [14, 29].

B-doping obviously affects light absorption characteristics of TiO2, as shown in Fig. 7. The absorption spectra of the 1.5% B/TiO2 NTs calcined at 300 °C for 2 h showed a stronger absorption in the UV–Visible range. Meanwhile, the absorption edge is changed from 407 nm (pure TiO2 nanotubes) to 422 nm for B/TiO2 NTs. It suggested that the incorporation of boron with TiO2 induces an obvious red shift and makes the band gap energy smaller [30]. Yang et al. [11] reported that substitution B replacing an O atom induces some gap states close to the bottom of the conduction band and this may account for the redshift of the adsorption edge in TiO2. The narrower band gap will facilitate the excitation of an electron from the valence band to the conduction band in the doped TiO2 catalyst, and enhance the photocatalytic performance of TiO2 consequently.

Figure 8 shows the degradation rates of methyl orange for 1.5% B/TiO2 powder and 1.5% B/TiO2 NTs calcined at 300 °C for 2 h. 78.2% of the methyl orange is degraded after 2 h irradiation in the presence of B/TiO2 powder, while 97% of the methyl orange is degraded in the presence of B/TiO2 NTs. Obviously, the photocatalytic activity of the B/TiO2 NTs is better than that of B/TiO2 powder. The reason is that TiO2 nanotubes have their novel properties, such as unique shape, size confinement in radial-direction and large specific surface area [15–20]. These induce the better photocatalytic activity of the B/TiO2 NTs than that of B/TiO2 powder.

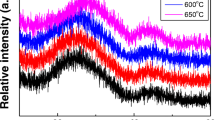

Calcination is an effective treatment method to enhance the photocatalytic activity of nanosized TiO2 photocatalysts. Figure 9 shows the photocatalytic performance of B/TiO2 NTs without calcination and calcined at different temperatures. As shown in Fig. 9, 60.3, 66.3, 99.7 and 87.4% of the methyl orange is degraded after 3 h irradiation in the presence of 1.25% B/TiO2 NTs without calcination, calcined at 200, 300 and 400 °C, respectively. It is obviously that B/TiO2 NTs without calcination show much lower photocatalytic activity. It can be attributed to the existence of titanate. When calcined at 200 °C, B/TiO2 NTs show higher photocatalytic activity, which should due to the formation of anatase. After the calcination treatment, titanate in the nanotubes turn into anatase TiO2 and higher photocatalytic activity is obtained. The B/TiO2 NTs calcined at 300 °C possess the best photocatalytic activity. This result is also in accordance with the result reported by Zhang et al. [20]. The photocatalytic activity of B/TiO2 NTs decreases with a further increase in calcination temperature (Fig. 9d). That is probably due to the agglomeration and sintering damage of nanotubes caused by calcination at high temperature [31].

Figure 10 shows the photodegradation of methyl orange for B/TiO2 NTs as a function of B-doping concentration. All the catalysts were calcined at 300 °C. 69.1, 76.5, 99.7, 99.9, 86.1% of the methyl orange is degraded after 3 h irradiation in the presence of TiO2 NTs with 0, 1.0, 1.25, 1.5, and 1.75% boron doping, respectively. It can be observed that B/TiO2 NTs exhibit much higher photocatalytic activity for the photodegradation of methyl orange than pure TiO2 nanotubes. The results reveal that the photocatalytic performance of TiO2 NTs can be improved by the boron doping.

As has been reported, the doped-B atoms can promote the formation of oxygen vacancies [12]. The role of oxygen vacancies is to directly provide the sites of the formation of active species for photocatalytic reaction. The formation of O ·−2 upon chemisorbed oxygen or OH· upon adsorbed water requires the presence of surface oxygen vacancies. The presence of Ti3+ also can apparently enhance the photocatalytic activity. The boron doping converts some Ti4+ to Ti3+ by charge compensation. The existence of a certain amount of Ti3+ can act as an active site to assist the adsorption of reactant and trap the photogenerated electron to reduce the recombination of photoexcited electrons and holes [14]. As a result, the photocatalytic activity of TiO2 nanotubes is improved by boron doping.

4 Conclusions

B/TiO2 NTs are prepared by the combination of sol–gel process with hydrothermal treatment. The prepared nanotubes are hollow and open-ended, and their length is more than hundreds of nanometers. Most of the nanotubes keep their tubular texture after the calcination process. B/TiO2 NTs with 1.5% boron doping in the initial solution calcined at 300 °C possess the best photocatalytic activity. The high photocatalytic activity of B/TiO2 NTs is ascribed to several beneficial effects produced by B-doping: intense absorption in the UV–Visible range and a red shift in the band gap transition, creation of oxygen vacancies, presence of Ti3+, and so on.

References

Hoffmann MR, Martin ST, Choi W, Bahnemannt DW (1995) Chem Rev 95:69–96

Linsebigler AL, Lu GQ, Yates JT (1995) Chem Rev 95:735–758

Fujishima A, Rao TN, Tryk DA (2000) J Photochem Photobiol C Photochem Rev 1:1–21

Diebold U (2003) Surf Sci Rep 48:53–229

Asahi R, Morikawa T, Ohwaki T, Aoki K, Taga Y (2001) Science 293:269–271

Nakano Y, Morikawa T, Ohwaki T, Taga Y (2005) Appl Phys Lett 87:052111-1–052111-3

Choi Y, Umebayashi T, Yoshikawa M (2004) J Mater Sci 39:1837–1839

Tian FH, Liu CB (2006) J Phys Chem B 110:17866–17871

Yu HF (2007) J Phys Chem Solids 68:600–607

Yu Y, Wu HH, Zhu BL, Wang SR, Huang WP, Wu SH, Zhang SM (2008) Catal Lett 121:165–171

Yang KS, Dai Y, Huang BB (2007) Phys Lett B 76:195201–195206

In S, Orlov A, Berg R, García F, Jimenez SP, Tikhov MS, Wright DS, Lambert RM (2007) J Am Chem Soc 129:13790–13791

Su YL, Han S, Zhang XW, Chen XQ, Lei LC (2008) Mater Chem Phys 110:239–246

Chen DM, Yang D, Wang Q, Jiang ZY (2006) Ind Eng Chem Res 45:4110–4116

Kasuga T, Hiramatsu M, Hoson A, Sekino T, Niihara K (1998) Langmuir 14:3160–3163

Kasuga T, Hiramatsu M, Hoson A, Sekino T, Niihara K (1999) Adv Mater 11:1307–1311

Yao BD, Chan YF, Zhang XY, Zhang WF, Yang ZY, Wang N (2003) Appl Phys Lett 82:281–283

Yang JJ, Jin ZS, Wang XD, Li W, Zhang JW, Zhang SL, Guo XY, Zhang ZJ (2003) Dalton Trans 20:3898–3901

Bavykin DV, Parmon VN, Lapkin AA, Walsh FC (2004) J Mater Chem 14:3370–3377

Zhang M, Jin ZS, Zhang JW, Guo XY, Yang JJ, Li W, Wang XD, Zhang ZJ (2004) J Mol Catal A Chem 217:203–210

Li H, Zhu BL, Feng YF, Wang SR, Zhang SM, Huang WP (2007) J Solid State Chem 180:2136–2142

Zhu BL, Li KR, Feng YF, Zhang SM, Wu SH, Huang WP (2007) Catal Lett 118:55–58

Zhu BL, Li KR, Wang SR, Zhang SM, Wu SH, Huang WP (2008) J Dispers Sci Technol 29:1408–1411

Zhu BL, Li KR, Zhou J, Wang SR, Zhang SM, Wu SH, Huang WP (2008) Catal Commun 9:2323–2326

Chen YY, Zhang SM, Yu Y, Wu HH, Wang SR, Zhu BL, Huang WP, Wu SH (2008) J Dispers Sci Technol 29:245–249

Zhang SM, Chen YY, Yu Y, Wu HH, Wang SR, Zhu BL, Huang WP, Wu SH (2008) J Nanopart Res 10:871–875

Liu HM, Yang WS, Ma Y, Cao YA, Yao JN, Zhang J, Hu TD (2003) Langmuir 19:3001–3005

Nagaveni K, Hegde MS, Ravishankar N, Subbanna GN, Madras G (2004) Langmuir 20:2900–2907

Zhao W, Ma WH, Chen CC, Zhao JC, Shuai ZG (2004) J Am Chem Soc 126:4782–4783

Lu N, Quan X, Li JY, Chen S, Yu HT, Chen GH (2007) J Phys Chem C 111:11836–11842

Xu JC, Lu M, Guo XY, Li HL (2005) J Mol Catal A Chem 226:123–127

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 20771061), 973 Program (2005CB623607) and Research Fund for the Doctoral Program of Higher Education (200800551036).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, L., Chen, Y., Yao, M. et al. Synthesis, characterization of B-doped TiO2 nanotubes with high photocatalytic activity. J Sol-Gel Sci Technol 53, 535–541 (2010). https://doi.org/10.1007/s10971-009-2128-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-009-2128-6