Abstract

The present paper extensively demonstrates synthesis, characterization and optical properties of semiconductor indium tin oxide (ITO) thin films on glass substrate using sol–gel technique for gas sensor applications. Turbidity, pH values, wettability and rheological properties of the prepared solutions were measured to determine solution characteristics by turbidimeter, pH meter, contact angle goniometer and rheometer machines prior to coating process. Thermal, structural, microstructural, mechanical and optical properties of the coatings were characterized by differential thermal analysis–thermogravimetry (DTA/TG), fourier transform infrarared, X-ray diffraction (XRD), scanning electron microscopy, scratch tester, refractometer and spectrophotometer. Four different solutions were prepared by changing solvent concentration. Turbidity, pH, contact angle and viscosity values of the solutions were convenient for coating process. Glass substrates were coated using the solutions of InCl3, SnCl2, methanol and glacial acetic acid. The obtained gel films were dried at 300 °C for 10 min and subsequently heat-treated at 500 °C for 10 min in air. The oxide thin films were annealed at 600 °C for 60 min in air. DTA/TG results revealed that endothermic and exothermic reactions are observed at temperature between 70 and 560 °C due to solvent removal, combustion of carbon based materials and oxidation of Sn and In. The spectrum of ITO precursor film annealed at 500–600 °C shows an absence of absorption bands corresponding to organics and hydroxyls. In2Sn2O7−x phase was dominantly found as well as SnO2 with low intensity from XRD patterns. It was found that surface morphologies of the film change from coating island with homogeneous structures to regular surface and thinner film structures with increasing solvent concentration. The films prepared from the solutions with 8 mL methanol have better adhesion strength to the glass substrate among other coatings. Refractive index, thickness and band gap of ITO thin films were determined to be 1.3171, 0.625 μm and 3.67, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Many attempts have been performed to introduce thin semiconducting metallic oxide films in gas sensing. Sensors for toxic gases have attracted much attention due to the growing concern of environmental protection and safety [1]. The major applications of gas sensors are domestic or industrial security, environmental and emission monitoring, medical and agribusiness controls, etc. [2, 3]. Several semiconductive oxides such as TiO2, MoO3, γ-Fe2O3, WO3, ZnO, SnO2, In2O3 and ITO are used for different gas sensors [1–4]. Most of these sensors are based on the resistance variation when the semiconductor oxide films are exposed to target gases. Recent research has shown that In2O3 is a promising material for gas-sensor applications. In2O3 offers a new advantage in design of metal oxide-based gas sensors, linked with an essential difference in electro-physical and chemical properties between SnO2 and In2O3. Thus, gas sensors based on In2O3 are very sensitive to detection of low concentrations of oxidizing gases. Although In2O3 has been less popular than SnO2, it is a unique sensing material that allows detection of ozone and highly selective detection of reducing gases [1, 5].

It is known that the sensitivity, selectivity and response of thin films to gas strongly depend on the conditions of deposition, which determine structure, crystallinity and composition. Along with other parameters, the rate of deposition, substrate temperature and the nature of substrate are perhaps the most critical parameters determining the structure and properties of thin solid films produced by vacuum or non-vacuum techniques [6, 7]. Of various attempts, thin-film fabrication has brought interests because film sensors have high sensitivity, low production cost and low power consumption compared to the sintered polycrystalline sensors. In addition, the grain-size effects on the sensitivity of oxide semiconductor gas sensors are very important. According to the results of a theoretical study, the gas sensitivity was significantly increased for the sensors with fine grains smaller than 40 nm. The effects of the grain size have been explained by the changes in the ratio between the thickness of the depletion layer and the grain size compared to the bulk materials that may or may not exhibit a nanocrystallite structure, the nano-grained thin films are prepared by magnetron sputtering, evaporation, pulsed laser deposition, chemical vapor deposition or sol–gel processes [3, 5, 8, 9].

Since sol–gel process is the high cost of In and Sn alkoxides used as precursors, this problem can be overcome by using the cheap commercially available indium III chloride (InCl3) and tin chloride (SnCl2) without further purification or modification. With this regard, synthesis, characterization and optical properties of ITO thin films on glass substrate from the solutions of InCl3, SnCl2 precursors, methanol and glacial acetic acid using sol–gel technique were evaluated for gas sensor applications. Turbidity, pH measurement, wettability and rheological properties of the prepared In- and Sn-based solutions were determined. To use suitable process regime and to define chemical structure and reaction type of intermediate temperature products, differential thermal analysis-thermogravimetry (DTA–TG) and fourier transform infrarared (FTIR) devices were used in the film production. Structural analysis of the films was performed by multipurpose X-ray diffraction (XRD) and surface morphology was investigated using scanning electron microscopy/energy dispersive spectroscopy (SEM/EDS). Adhesion properties of ITO films were determined by scratch tester. Optical properties of the films were investigated using refractometer and spectrophotometer devices.

2 Experimental aspects

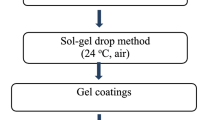

Indium tin oxide films were synthesized with the solutions, which were prepared as follows: InCl3 and SnCl2 precursors were weighed in stoichiometric ratio (In/Sn = 1) in fume hood. InCl3 and SnCl2 powders were dissolved in methanol and glacial acetic acid. Here, methanol and glacial acetic acid were used as solvent and chelating agent, respectively. Four solutions, including different solvent concentrations, were prepared to figure out the solvent concentration effects on film morphology. Then, the prepared solutions were mixed for 1 h in an open vessel kept at room temperature in air to gain clear and homogeneous solutions, as demonstrated in Fig. 1. Four different solutions were prepared by changing solvent concentrations such as 2, 4, 6 and 8 mL with the same amount of InCl3 and SnCl2 precursors and glacial acetic acid.

To determine solution characteristics, which affect thin film structure, turbidity, pH values, wettability and rheological properties of the prepared solutions were respectively measured by turbidimeter, pH meter, contact angle measurement and rheometer machines before coating process. Turbidity properties of the solutions were measured to use standard solutions for coating process by VELP TB1 Model turbidimeter. In this case, turbidity values can be expressed in the range of 0 and 1,000 ntu (nephelometric turbidity unit) for this application. After preparation of transparent solutions, pH values of the solutions were measured to determine their acidic and basis characteristics using a standard pH meter with Mettler Tolede electrode. Wettability properties of the solutions were determined by measuring their contact angle (θ) using KSV Glass 100 Instrument contact angle machine. In addition to pH value, wettability and turbidity properties, rheological behaviour of the solutions including viscosity, gel point, shear and storage modulus was determined by CVO 100 Digital Rheometer (Bohlin Instrument).

Prior to the coating process, glass slide substrates with dimension of 10 mm × 10 mm × 5 mm were rinsed in acetone using a standard ultrasonic cleaner and subsequently dried in air. After that, the solutions were deposited on glass substrates. The glass substrates were coated by solutions of In- and Sn-based precursors, glacial acetic acid and methanol. The deposited gel films were dried at 300 °C for 5 min, and subsequently heat treated to cause the removal of all organic components and also structural rearrangements at 500 °C for 5 min in air. We repeated this procedure for six cycles for each samples. After completing the drying and heat treatment processes of each coated samples, they were annealed at 600 °C for 60 min in air to make them polycrystalline and densify the film structure (Fig. 1).

Thermal behaviour of In- and Sn-based powders, which was dried at 300 °C for 3 h in air, was evaluated to gain decomposition and phase formation at a heating rate of 10 °C/min under oxygen atmosphere by using DTA/TG machine (DTG-60H Shimadzu). Al2O3 powder was used as a reference material. FTIR (Perkin Elmer) absorption spectra were measured over the range of 4,000–400 cm−1 at room temperature after the reactions in the temperature range of 25 and 600 °C for 30 min in air. After preparing powders at these temperatures, they were mixed with potassium bromide (KBr). All of this six samples were characterized by FTIR. According to the results, depending on temperature, variation of organic component’s concentration can be determined by Fluka library supplied by Perkin Elmer.

X-ray diffraction patterns of thin films were determined to identify phase structure with a Rigaku (D/MAX-2200/PC) diffractometer with a CuKα irradiation (wavelength, λ = 0.15418 nm) by both θ–2θ mode and 2θ scan mode. Thin-film XRD geometry where incident angle was fixed at 1° was used to collect data from only thin films. The surface topographies of ITO films were examined by using SEM (JEOL JSM 6060).

Adhesion properties of ITO films were determined by SHIMADZU Scanning Scratch Tester (SST-W101 Model). Scratch test is carried out to determine and analyze the adhesion strength of a coating to a substrate. In the test, a diamond stylus scratched over the coated surface with a constant speed under progressing normal load until a critical force is reached, at which adhesion failure is detected. This critical load is used as a measurement of the adhesion between coating and substrate. In this study, adhesion strength of coatings was evaluated by using a scanning scratch tester with a 15 μm tip radius diamond stylus. The applied load was 98 mN for all samples. During the test, a stylus was drawn on coating surface with a sliding speed of 5 μm s−1 keeping scanning amplitude of 10 μm, which perpendicular to the scratching direction at the same time. Load was carried out progressively to the stylus with a loading speed of 2 μm s−1. Friction on the stylus increases with increasing load, which causes a delay in movement between cartridge body and stylus. This delay is defined as a cartridge output.

Optical properties of the produced films were evaluated using refractometer and spectrophotometer machines. Refractive indexes of thin films were measured at selected wavelengths in the VIS region by a high-accuracy Abbe refractometer at room temperature. Refractive indexes were used to determine film thickness and optical band gap values using V-530 JASCO UV/VIS Spectrophotometer. Optical band gaps of ITO films on glass substrates, it is well known that in an amorphous material like glass characterized by indirect allowed transitions, the absorption coefficient varies with the photons energy according to the Tauc’s relation [10]:

where ν is the frequency of incident photons, E opt the optical gap, h the Planck’s constant and B a constant. The variation of (αhν)1/2 as a function of the energy hν shows a linear behavior near the band gap. The value of the energy band gap is given by the intercept of the straight line with the energy axis. In addition to these, transmittance and absorbance properties of ITO thin films on glass substrates were investigated using V-530 JASCO UV/VIS Spectrophotometer with a blank piece of substrate in the reference beam.

3 Results and discussion

With turbidity experiments, whether powder precursor materials are dissolved very well in solutions is understood by looking ntu values before coating process. As mentioned before, turbidity values of solutions change in the range of 0 ntu and 1,000 ntu. It is interpreted that powder based precursors are completely dissolved as turbidity value approachs to 0 ntu and they are not dissolved and some powder particles are suspended in a solution as it approaches to 1,000 ntu. The fabrication of homogeneous, continuous and thin film is directly related to turbidity value, which is 0 ntu. In this experiment, turbidity value of the solutions were measured as 21.32 ntu. Based on the turbidity value, it can be pointed that powder based precursors are completely dissolved in the solutions. Moreover, these values present an important clue for further processing. Notably, films prepared from completely undissolved solutions are not homogeneous, continuous and thin. It is worth noticing that optimum structural, thermal, microstructural, mechanical, optical and gas sensivity properties is not obtained using undissolved solutions.

Figure 2 demonstrates pH values of the solutions depending on methanol concentration. According to this result, clearly, acidity of the solutions decreases with increasing methanol concentration. It was estimated that pH values generally increases because of Cl− ions in InCl3 and SnCl2 precursors. The pH values of the solutions with 2, 4, 6 and 8 mL methanol content were found to be 1.93, 3.16, 3.45 and 3.54, respectively. Since pH value of the solution is an important factor influencing the formation of the polymeric three-dimensional structure of the gel during the gelation process, it should be taken into consideration while preparing solutions. While ramified structure is randomly formed in acidic conditions, separated clusters are formed from the solutions showing basic characters [11]. The other factor is dilution of the solution using solvent. The excess solvent physically affects the structure of the gel, because the liquid phase during the aging procedures mainly consists of the excess solvent. The changes in the gel structure at this stage partly influence the structure of the final film [12].

Concerning wettability properties of the prepared solutions, their contact angles were measured as a function of methanol concentration. Wettability properties of the solutions give an important clue for further processes in the sol–gel technique. The properties of spreading liquid on substrate present film quality. In our experiments, the contact angles for the solutions for all methanol concentration were found to approximately 13.50° (see Fig. 3a). In Fig. 3b, contact angle image of the solutions prepared from 8 mL methanol concentration was denoted. Since the contact angles of the solutions approaches to 0°, these results are reasonable for wettability before coating process.

Gelation occurs when aggregation of particles or molecules takes place in a liquid, under the action of Van der Walls forces or via the formation of covalent or noncovalent bonds. The process can be investigated using rheological measurement techniques [13]. This evaluation is extremely important, since the microstructure and therefore the optical properties of the film are obtained in this part of the process. Figures 4 and 5 show rheological properties such as viscosity, shear stress, viscous and elastic modulus for the solutions prepared from 8 mL methanol as a function of temperature and time. Figure 4 depicts viscosity and shear stress values of the solutions as a function of time at 30 °C for 150 s in air. Viscosity and shear stress values of the solution were found to be 1.4 mPa s and 0.4 Pa, respectively. The relative viscosity of obtained solution was 1.4 Pas after its preparation. However, the viscosity of the same solution was increased because of evaporation of solvent. Figure 5 denotes viscous and elastic modulus of the solution prepared from 8 mL methanol at different temperatures such as 30, 40 and 50 °C for 4,500 s in air. Here, the experiment was performed at 30 °C for 1,500 s and then at 40 °C for period between 1,500 and 3,000 s. After that, experiment was completed at 50 °C for period between 3,000 and 4,500 s. As clearly seen from Fig. 5, elastic and viscous moduli were determined as 2 and 1.2 Pa, respectively. It can be indicated that viscous and elastic moduli do not change depending on time and temperature for our cases.

Thermal behaviour of In- and Sn-based powders dried at 300 °C for 3 h in air is depicted in Fig. 6. DTA curve revealed that thermal behaviours of the powders are observed at temperatures between 25 and 625 °C as shown in Fig. 6a. It was caused by physical water and solvent in the gel evaporated and carbon based materials coming from alkoxide, solvent and chelating agent burnt out as explain in Ref. [12]. The first thermal phenomenon was the solvent removal at temperature of approximately 75 °C. In this phenomenon, endothermic reaction started at 39 °C and completed at 126 °C. At these temperatures, the endothermic reaction is mostly owing to evaporation of volatile organic components. The second phenomenon was combustion of OR groups at temperatures between 225 and 325 °C. A small exothermic peak was determined at this temperature range because of combustion of carbon based materials because the obtained xerogel powder dried at 300 °C for 3 h in air before putting it in the furnace of DTA–TG machine. It was also seen that an exothermic reaction was occured at 551 °C. The last stage was the formation of pyrochlore structure at 589 °C. The TGA curve (see Fig. 6b for details), illustrated in the present case for In- and Sn-based powders, shows a weight loss of about 25.9% for temperatures from 25 up to 620 °C. In this range of the thermal treatment, the weight decrease is due to solvent removal and combustion of carbon-based materials. As seen in TG curve, the largest weight lost is occurred at 530 °C.

Figure 7 indicates the FTIR absorbance spectra of In- and Sn-based powders, which were dried 25, 300, 500 and 600 °C for 30 min in air. The spectra show characteristic vibrations in the region of 400–4,000 cm−1. The bands at 3,200 and 4,000 cm−1 are due to O–H species in the In- and Sn-based xerogel, which was heat treated at 25 and 300 °C, respectively and those at 2,200–2,800 cm−1 is due to C–H stretching frequencies. Notably, a broad band between 3,200 and 4,000 cm−1 for all dried and heat treated samples was possible due to residual water present in the samples. The band seen in 1,600 cm−1 is due to C=O arising due to bridging type metal-acetate bonding (M–OCOO–M). The band at 1,444 cm−1 is the C–O streching frequencies and that at 1,040 cm−1 is due to weakly bound acetic acid molecule (HOOC–R). The spectra of the samples, which was heat treated at 25 and 300 °C were nearly similar. However, the OH band has shifted slightly toward lower frequencies as seen in Fig. 7. Upon increasing heat treatment temperature from 25 to 600 °C, the frequencies of O–H, C–H, C=O and M–OCOO–M bands decreased. The spectrum of ITO precursor film annealed at 500 and 600 °C, which shows an absence of absorption bands corresponding to organics and hydroxyls indicating complete removal of organics and hydroxyls. The common features that appear below 900 cm−1 corresponds to the stretching vibrations of In=O and Sn=O, and also to the contributions of In–O and Sn–O bonds. In the spectrum of 500–600 °C, the band at ≈500 cm−1 may be assigned to the vibration of ITO bands appear at high temperatures [14].

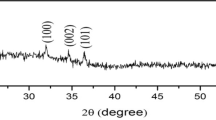

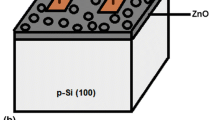

The phase identification of ITO films on glass slide substrates was performed by XRD techniques after annealing process at 600 °C for 1 h in air. The results are depicted in Fig. 8, where one observes the evolution of the XRD profiles as a function of the solvent concentration. Their patterns of 2θ scan mode and θ–2θ mode indicate the diffraction from the surface part of the film and entire part of the film, respectively. In2Sn2O7−x and SnO2 phases were found from XRD patterns. It is clear that the intensity of diffraction peaks changed depending on methanol concentrations. These diffraction peaks match those of the separated In2Sn2O7−x crystalline pyrochlore phase with (222), (400), (622) and (301) orientations corresponding to 30.8°, 35.7°, 51.2° and 60.8° of 2θ angles, respectively. Cassiterite phase of SnO2 with low intensity was observed and the characteristic 2θ lines appeared at 26.5° and 32°. Furthermore, no peaks assignable to the SiO2 crystalline phase are observed in ITO films.

Figure 9 shows SEM micrographs of ITO films on glass slide substrate with different solvent content. In this observation, effect on film morphology of methanol can be easily seen in Fig. 9a, which represents the microstructure prepared from the solution with the 2 mL methanol content. Owing to increasing thickness with decreasing solvent concentration, the coating islands can be formed in production period. Figure 9a reveals the cracks in coating like coating island on substrate. As we explained in detail elsewhere [15], the cracks are firstly formed in the coating layers and subsequently canals corresponding to long uncoated regions between two coating islands depending on the contact angle, coating thickness and drying stresses. Furthermore, some pores emerge at surface of the films, probably at intersections of the large surface crystalline. The morphologies observed in the different regions of the films can be explained by different diffusion mechanisms acting during the formation and crystallization of ITO film. As demonstrated in Ref. [2], at bottom part of the film, only bulk diffusion into the growing film is active. The atom diffusion is limited at the interface with the amorphous SiO2 layer and homogeneous growth of ITO crystalline nuclei takes place. At the top of the film, surface diffusion works very fast and only some ITO nuclei are selected for growth, resulting in larger crystallites, which develop in the directions parallel to the film surface. This forms a dense crust at the surface of the film, which encloses a porous zone in the middle of the film. As seen in Fig. 9b, c and d, the same magnification with Fig. 9a, because of increasing solvent concentration from 2 to 8 mL, coating thickness were decreased and microstructures were changed. In particular, SEM micrograph in Fig. 9c is different from other ones because the basic structure with wavy consists in small and large domes. It is believed that the small domes are in the fact the topsides of the component grains of the films. Besides this base morphological structure, large domes and pores can be observed on the surface if the films are formed with rapid increase of the temperature to the first drying step of 300 °C [2]. When highly diluted solution with low viscosity and low contact angle was used to coat glass substrates, the homogeneous, crack-free and continuous films were produced as clearly seen from Fig. 9c and d. We have a good agreement with research of Jiao et al. [1]. As shown from microstructural observations, a regular surface morphology forms as solvent concentration increase until 8 mL. These thin films are obtained for the coatings, which applied six cycles on glass substrates. The film thickness and surface defects increase in accordance with the same number of layers and as mentioned above, decreasing solvent concentration. Microstructural observations and measuring film thickness show that this characterization parameters are changed depending on solvent concentration of solution. Minimum coating thickness was obtained while increasing solvent concentration but microstructural observation of minimum thickness samples did not have the required properties. In addition, thermal processes carried out at high temperatures result in some cracks inside the coating. However, coating layers in 8 mL solution was flaked off in some region. It can be stated that not only coating thickness but also solution viscosity and wettability influence film structures.

The aim of scratch test is to evaluate the adhesion between coating and substrate. In the test, increasing normal load is applied to the diamond stylus. Simultaneously, diamond stylus is scratched over the surface of the coating with a constant speed. The load at which failure occurs on the coating is defined as critical load. The test load versus cartridge output (%) curves for ITO films on glass substrates were given in Fig. 10. During the scratch test, with increasing applied load, friction of the stylus becomes large, therefore delay in movement of the stylus from that of the cartridge body also becomes large. This delay is given as a cartridge output. Critical load values of ITO films were found from Fig. 7, when sudden increase takes place at the cartridge output. The critical load values of the ITO films prepared from the solutions including 2, 4, 6 and 8 mL methanol content were found to be 12, 15, 24 and 31, respectively. This is why the residual stresses, which cause mechanical failures increase with increasing film thickness of ITO on glass substrate. Therefore, the films prepared from the solutions with 8 mL methanol have better adhesion strength to the glass substrate among other coatings. As seen from these results, critical load values of the coatings increase with the increasing amount of the methanol. Generally speaking, improvement in adhesion properties was determined depending on coating thickness. Adhesion is directly related to wettability, solution viscosity and coating thickness.

Optical properties of ITO film on glass substrate are listed in Table 1. Refractive index and film thickness of ITO films on glass substrates were measured by using spectrophotometer. Refractive index of ITO thin films was 1.3171. The film thicknesses of ITO films were determined as 0.625 μm by using measured refractive indexes. The thickness deduced from the fit of the optical transmission data. Using refractive index and film thickness, band gap of the films was calculated in the range of 3.64–3.71 eV as shown in Fig. 11. It is important to remark that ITO films indicate semiconducting properties. It can be observed that the transmission value continuously increased depending on increasing wavelength (see Fig. 12).

4 Conclusion

Summarizing the results of this work, ITO based thin films were synthesized on glass substrate from the solutions prepared from InCl3, SnCl2 precursors, different methanol concentrations and glacial acetic acid using sol–gel process for gas sensor applications. Turbidity value of the solutions was measured as 21.32 ntu. Acidity of the solutions decreases with increasing methanol concentration. The contact angles for the solutions for all methanol concentration were found to approximately 13.50°. In solution characterization, viscosity and shear stress values of the solution were found 1.4 mPa s and 0.4 Pa at 30 °C for 150 s in air, respectively. When the films were deposited after a few days from solution preparation, its relative viscosity slightly increased. Modulus of viscous and elastic did not change depending on time and temperature.

The first thermal phenomenon was the solvent removal at temperature of approximately 75 °C. The second phenomenon was combustion of OR groups at temperatures between 225 and 325 °C. The third and fourth stages were the formations of oxide layer and pyrochlore structure. A weight loss of the xerogel sample is about 25.9% for temperatures from 25 up to 620 °C. Depending on these temperatures, the structures of the films were changed as explained in FTIR results. The spectra of the samples, which was heat treated at 25 and 300 °C were nearly similar. In the spectrum of 500 and 600 °C, the band at ≈500 cm −1 may be assigned to the vibration of ITO bands appear at high temperatures.

In2Sn2O7−x and SnO2 phases were found from XRD patterns. It is clear that the intensity of diffraction peaks changed depending on methanol concentrations. In microstructural observation, the coating islands can be formed in production period due to increasing thickness with decreasing solvent concentration. Some pores emerge at surface of the films, probably at intersections of the large surface crystalline. Because of increasing solvent concentration from 2 to 8 mL, coating thickness were decreased and microstructures were changed. When highly diluted solution with low viscosity and low contact angle was used to coat glass substrates, the homogeneous, crack-free and continuous films were produced. The films prepared from the solutions with 8 mL methanol have better adhesion strength to the glass substrate among other coatings.

Refractive index, thickness and band gap of ITO thin films were found to be 1.3171, 0.625 μm and 3.67, respectively. The transmission value continuously increased depending on increasing wavelength. Since ITO films exhibited very good semiconducting behaviours, our future plan is to investigate its sensing mechanism.

References

Jiao Z, Wu M, Gu J, Sun X (2003) The gas sensing characteristics of ITO thin film prepared by sol–gel method. Sens Actuators B 94:216–222

Stoica TF, Gartner M, Losurdo M, Teodorescu V, Blanchin M, Stoica T, Zaharescu M (2004) Spectroellipsometric study of the sol–gel nanocrystalline ITO multilayer films. Thin Solid Films 455–456:509–512

Mbarek H, Saadoun M, Bessaïs B (2006) Screen-printed tin-doped indium oxide (ITO) films for NH3 gas sensing. Mater Sci Eng C 26:500–504

Yoo KS, Park SH, Kang JH (2005) Nano-grained thin-film indium tin oxide gas sensors for H2 detection. Sens Actuators B Chem 108:159–164

Sako T, Ohmi A, Yumoto H, Nishiyama K (2001) ITO-film gas sensor for measuring photodecomposition of NO2 gas. Surf Coat Tech 142–144:781–785

Vaishnav VS, Patel PD, Patel NG (2005) Indium tin oxide thin film gas sensors for detection of ethanol vapours. Thin Solid Films 490:94–100

Vaishnav VS, Patel PD, Patel NG (2005) Preparation and characterization of indium tin oxide thin films for their application as gas sensors. Thin Solid Films 487:277–282

Zhang J, Hu JQ, Zhu FR, Gong H, O’Shea SJ (2002) ITO thin films coated quartz crystal microbalance as gas sensor for NO detection. Sens Actuators B Chem 87:159–167

Lee S-M, Lee Y-S, Shim C-H, Choi N-J, Joo B-S, Song K-D, Huh J-S, Lee D-D (2003) Three electrodes gas sensor based on ITO thin film. Sens Actuators B Chem 93:31–35

Ech-chamikh E, Essafti A, Azizan M, Ijdiyaou Y (2006) Sol Energy Mater Sol Cells 90:1424–1428

Brinker CJ, Scherer GW (1990) Sol–gel science: the physics and chemistry of sol gel processing. Academic Press, San Diego, p 2, 656

Pierre AC (1998) Introduction to sol–gel processing. Kluwer, Boston, p 36

Phonthammachai N, Rumruangwong M, Gulari E, Jamieson AM, Jitkarnka S, Wongkasemjit S (2004) Colloids Surf A Physicochem Eng Asp 247:61–68

Pramanik NC, Das S, Biswas PK (2002) The effect of Sn(IV) on transformation of co-precipitated hydrated In(III) and Sn(IV) hydroxides to indium tin oxide (ITO) powder. Mater Lett 56:671–679

Celik E, Avci E, Hascicek YS (2004) Growth characteristics of ZrO2 insulation coatings on Ag/AgMg sheathed Bi-2212 superconducting tapes. Mater Sci Eng B 110:213–220

Acknowledgments

The authors are indebted to State Planning Foundation (DPT) and Dokuz Eylul University for financial support. Also, we would like to thank Ms. Nurhan Onar for helping about measurement of contact angles of solutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Celik, E., Aybarc, U., Ebeoglugil, M.F. et al. ITO films on glass substrate by sol–gel technique: synthesis, characterization and optical properties. J Sol-Gel Sci Technol 50, 337–347 (2009). https://doi.org/10.1007/s10971-009-1931-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-009-1931-4