Abstract

Multifunctional, water and oil repellent and antimicrobial finishes for cotton fibres were prepared from a commercially available fluoroalkylfunctional water-born siloxane (FAS) (Degussa), nanosized silver (Ag) (CHT) and a reactive organic–inorganic binder (RB) (CHT). Two different application procedures were used: firstly, one stage treatment of cotton fabric samples by FAS sol (i), as well as by a sol mixture constituted from all three precursors (Ag–RB–FAS, procedure 1S) (ii), and secondly, two stage treatment of cotton by Ag–RB sol and than by FAS sol (Ag–RB + FAS, procedure 2S) (iii). The hydrophobic and oleophobic properties of cotton fabrics treated by procedures (i)–(iii) before and after consecutive (up to 10) washings were established from contact angle measurements (water, diiodomethane and n-hexadecane) and correlated with infrared and XPS spectroscopic measurements. The results revealed that even after 10 washing cycles cotton treated with Ag–RB + FAS (2S) retained an oleophobicity similar to that of the FAS treated cotton, while the Ag–RB–FAS (1S) cotton fibres exhibited a loss of oleophobicity already after the second washing, even though fluorine and C–F vibrational bands were detected in the corresponding XPS and IR spectra. The antibacterial activity of cotton treated by procedures (i)–(iii) was tested by its reduction of the bacteria Escherichia coli and Staphylococcus aureus following the AATCC 100-1999 standard method and EN ISO 20743:2007 transfer method. The reduction in growth of both bacteria was nearly complete for the unwashed Ag–RB and Ag–RB–FAS (S1), but for the unwashed Ag–RB + FAS (S2) treated cotton no reduction of S. aureus and 43.5 ± 6.9% reduction of E. coli was noted. After the first washing, the latter two finishes exhibited nearly a complete reduction of E. coli but for the Ag–RB treated cotton the reduction dropped to 88.9 ± 3.4. None of the finishes retained antibacterial properties after 10 repetitive washings. The beneficial and long-lasting low surface energy effect of FAS finishes in the absence of Ag nanoparticles, which led to the “passive” antibacterial properties of FAS treated cotton fabrics, was established by applying the EN ISO 20743:2007 transfer method. The results revealed a reduction in bacteria of about 21.9 ± 5.7% (FAS), 13.1 ± 4.8% (Ag–RB–FAS (S1)) and 41.5 ± 3.7% (Ag–Rb + FAS (S2)), while no reduction of the growth of bacteria was observed for cotton treated with Ag nanoparticles after 10 repetitive washings. The physical properties (bending rigidity, breaking strength, air permeability) of finished cotton samples were determined, and showed increased fabric softness and flexibility as compared to the Ag–RB treated cotton, but a slight decrease of breaking strength in the warp and weft directions, while air permeability decreased for all type of finishes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Increasing demands for comfortable, aesthetic, durable, functional and safe textile products with different properties dictates the development of new and contemporary techniques of processing and designing textiles [1, 2]. Protective textiles have to satisfy stringent standards related to their mechanical, physical, chemical and physiological properties, and to fulfil all of them simultaneously is a formidable task [3–5]. The combination of oil and water repellence with antibacterial properties seems to be particularly important for practical applications and of fundamental interest because oil and water repellence could indirectly affect antibacterial properties by influencing bacteria adhesion due to the low surface energy (<20 mN/m) [6] of cotton. However, when low surface energy finishes are used in combination with antibacterial agents, the question arises whether the reduction in growth of bacteria is diminished by impeding the release of antibacterial active agents from the textile to its surroundings, or if these finishes could beneficially influence the long-term antibacterial properties by controlling the release of antibacterial agents. Accordingly, the aim of this study was first to establish the influence of the low surface energy finish obtained by applying fluoroalkoxysilane (FAS) to cotton fabrics upon the reduction of bacterial growth, and in the second step to compare it with the antibacterial effect of cotton fabrics treated with nanosized silver particles in the presence of FAS and without it. The end result is not easy to predict because of the expected differences in the interactions of the various precursors with cotton fabrics related to their wetting, adhesion and temperature stability. Commercially available precursors (CHT, Germany and Degussa, Germany) were used throughout this work.

Even though numerous antimicrobial agents are known and have already been tested in combination with many hydrocarbon and fluorochemical [5, 7–9] and sol–gel based finishes [10–19], they have been applied with variable success. Literature data reveal that permanent and long lasting incorporation of antimicrobial agents into organic polymers could be achieved only by agents bearing an organic functionality such as halamines, e.g. monomethylol-5,5-dimethylhydantoin [20], the diphenyl ether derivative known as Triclosan [21], quaternary ammonium compounds [22], cationic dyes [23], and cationic polymers, e.g. chitosan and polyhexa methylene biguanide [8, 24], but the permanent incorporation of hard metals such as metallic silver or copper [11, 14, 25–28] into organic polymers has been difficult to achieve. The corresponding metals are active only when in the form of non-agglomerated and well dispersed nanoparticles. Nanometallic agents are not chemically bonded to the textile fibres and their antimicrobial activity is attributed to their gradual and persistent release from the textile into the surroundings, where they act as a poison to a wide spectrum of bacteria and fungi. This leads to problems related to their uniform dispersion and embedment in the polymer host, rarely achieved by nanometallic particles incorporated into organic polymers.

Sol–gel finishes based on either single-capped (R′–Si(OR)3), R′ = organic group (acryl, epoxy, isocyanato, isooctyl perfluoro...) or bis end-capped ((RO)3 Si–R″–Si(OR)3), R″ = organic polymers) silane precursors are a good alternative to organic networks, enabling the uniform dispersion, embedment and controlled release of antibacterial agents such as metallic nanoparticles. Complex silane precursors consisting of hydrophobic groups and antibacterial active quaternary ammonium moieties [29] seem to be a much better option because they could be applied to textiles in a single step, and due to their multifunctional chemical character, assure at the same time adhesion to the textile, antibacterial properties and hydrophobicity, the latter important for controlling the release of the active component to the surroundings.

This work consisted of two parts. In the first, we focused on the assessment of the surface energy properties of (i) washed and non-washed cotton fabrics treated only by the FAS precursor; (ii) cotton fabrics treated with a solution of metallic nanoparticles (Ag) with reactive siloxane polymer (RB) and FAS (Ag–RB–FAS, a one step procedure, S1 for short); and (iii) cotton treated first by an Ag–RB antibacterial solution followed by the application of FAS (Ag–RB + FAS, a two step procedure, S2, for short). The establishment of correlations between the surface energy values of cotton and the amount of finishing agents applied through structural studies of treated cotton fabrics is important but not trivial, as could be derived from the results of many studies reported so far on the hydrophobicity and oleophobicity of various FAS single-capped silane based coatings on textiles [10, 12, 13], and their adsorption on cellulose fibres [30] and other substrates [31]. In this study we employed IR and XPS spectroscopic measurements in order to obtain evidence for the presence and structure of finishes, and their fastness on washed cotton fabrics.

The second part of this work was devoted to an assessment of the antibacterial properties of washed and non-washed cotton fabrics treated by procedures (i)–(iii). The antibacterial properties were assessed for Escherichia coli and Staphylococcus aureus by following the reduction of their growth using the EN ISO 20743:2007 transfer method and the reduction obtained after the AATCC 100-1999 standard method. The former method is rarely used but was found useful due to the strong water repellence of the investigated cotton fabrics, which made the application of the standard methods (i.e. AATCC 100-1999) difficult. By employing both methods it was possible to confirm the beneficial effect of low surface energy FAS finishes on the reduction of bacterial growth on treated cotton fabrics. Finally, the practical aspects of the treatment were addressed as well by assessment of the recovery of the finished cotton fabrics from creasing, their bending rigidity, breaking strength and air permeability.

2 Experimental

2.1 Preparation

2.1.1 Materials

Plain-weave 100% cotton woven fabric with a mass of 164 g/m2 was used in the experiments. In pre-treatment processes the fabric was bleached in an H2O2 bath, mercerised in NaOH solution and neutralised with diluted CH3COOH solution.

As a water and oil repellent agent, Dynasylan F 8815 (Degussa, Germany), which is a fluoroalkylfunctional water-born siloxane (FAS), was used. As an antimicrobial agent, iSys AG was used in combination with iSys MTX (CHT, Germany). The former is a dispersion containing nanosized silver (Ag) and the latter is a reactive organic–inorganic binder (RB). All products can be mixed with water to any desired concentration.

2.1.2 Finishing of cotton fabric

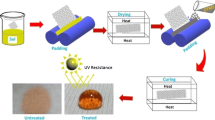

For finishing of cotton fabric Ag–RB and FAS sols were applied in different combinations to the fabric samples by the pad-dry-cure method, including full immersion at 20 °C, wet pick-up of 80 ± 1% at 20 °C, drying at 120 °C and curing at 150 °C for 1 min. Two different combinations of FAS and Ag–RB precursor solutions were used, named according to the S1 and S2 procedures. For procedure S1 a sol mixture of 10% FAS, 3 g/L Ag and 15 g/L RB (Ag–RB–FAS) was used and the mixture of all three precursors was applied in a single step to the fabrics as described above. For procedure S2, the Ag–RB sol consisting of 3 g/L Ag and 15 g/L RB was applied first and after heat treatment of the fabric, FAS (10%) was applied in the second step (Ag–RB + FAS), followed by the same treatment of the fabrics. After the application of sols the samples were left for 14 days to complete network formation of the applied finishes. FAS precursor was applied on cotton fabrics by following the same procedures as for S1 and S2.

Even though both finishes consisted of the same components, their properties could not be expected to be the same. The penetration of Ag, RB and FAS components and the ensuing wetting of the cotton fabrics, as well as the FAS layer formed on the surface of the fabrics could be different. It should be noted that the amount of sol applied to the fabric samples was about 1% by weight and its composition was 0.42% of FAS, 0.25% of Ag–RB, 0.40% of Ag–RB + FAS (1S) and 0.97% of Ag–RB + FAS (2S).

Each sol was applied to 18 fabric samples (20 cm × 30 cm) in order to provide a sufficient number of samples for statistical analysis, as well as to carry out other measurements.

2.1.3 Washing procedure

The washing fastness of coatings was determined after repetitive washing in an AATCC Atlas Launder-O-Meter Standard Instrument, which is widely used for evaluating laundry results on a laboratory scale. One wash in a Launder-O-Meter (ISO 105-C01:1989(E) standard method) provides an accelerated washing treatment corresponding to five home washings. The finished fabric samples were washed repetitive up to 10 times; the duration of the washing cycles was 30 min and was carried out in a solution of SDC standard detergent of concentration 5 g/L, previously heated to 40 °C, to give a liquor ratio of 50:1.

After washing, the samples were rinsed in cold distilled water and then held in cold tap water for 10 min, squeezed and dried at room temperature. After drying, samples were also heat-treated by ironing at 190 °C for 10 s. The quality of the coatings was assessed after the first and tenth washing cycle.

2.2 Analyses and measurements

2.2.1 Oil repellency

The oil repellency of the finished cotton samples was determined under static conditions using the AATCC test method 118-1978, where eight hydrocarbon liquids in a series of decreasing surface tension were used (Table 1). Drops of standard test liquids were placed at different spots on the fabric surface and observed for wetting. The repellency rating was expressed by the highest numbered test liquid which did not wet and penetrate the fabric in 30 s.

2.2.2 Contact angle measurements

Contact angle measurements of water, diiodomethane and n-hexadecane on the finished cotton samples were made on a DSA 100 contact angle goniometer (Krüss, Germany), which works on the principle of the goniometer-sessile drop technique. The contact angle, θ, of a liquid drop is determined from the video camera images of the drop in the course of its formation on a solid surface. Using the DSA 100, the drop contour was analysed with the circle fitting method and the contact angle was determined as tan θ at the intersection of the drop contour line with the base line created on the fabric surface. In order to avoid deformation of the liquid drop form due to gravity, a drop volume of 2 μL was chosen. Ten measurements, in which liquid drops were placed on different spots all over the fabric samples, were used for the determination of the average contact angle values with a precision of ±3°. All the values reported here correspond to contact angles obtained under stationary conditions, i.e. 60 s after the liquid drops were applied to the fabric.

2.2.3 Antimicrobial activity

The antimicrobial activity of the coatings was estimated for the Gram-positive bacteria S. aureus (ATCC 6538) and the Gram-negative bacteria E. coli (ATCC 25922) according to the AATCC 100–1999 standard method. In this method, circular swatches (4.8 cm in diameter) of finished cotton samples were put into a 250 mL container and inoculated with 1.0 mL of a nutrient broth culture containing 1–2 × 105 colony forming units of bacteria. An unfinished cotton sample was used as a control. After incubation at 37 °C for 24 h, the bacteria were eluted from the swatches by shaking in 100 mL of neutralizing solution for 1 min. After making serial dilutions with sterilized water, the suspensions were plated on nutrient agar and incubated at 37 °C for 24 h. Afterwards the number of bacteria was counted and the reduction of bacteria, R, was calculated as follows:

where A is the number of bacteria recovered from the inoculated swatch of cotton sample in the jar incubated over the desired contact period (24 h) and B is the number of bacteria recovered from the inoculated swatch of cotton sample in the jar immediately after inoculation (at “0” contact time). For every finished cotton fabric three treatments were performed on two samples.

In addition, the reduction of bacterial growth on the finished samples was also estimated using the EN ISO 20743:2007 transfer method. This method enables assessment of the bacterial reduction which is caused not only by the presence of antibacterial active agents (i.e. nanosilver particles) in the finishes, but could stem from the low surface energy of the oleophobic finished cotton (caused by FAS), which prevents or at least hinders the adhesion of bacteria and their consequent growth and formation of a biofilm on the finished fabrics. The latter effect we called ‘passive antimicrobial activity’ to distinguish it from the inherent antibacterial effect of various chemical agents embedded in finishes such as the silver nanoparticles used in this study. According to the EN ISO 20743:2007 transfer method, the agar plates were inoculated with 1 mL of the nutrient broth culture containing 1–3 × 106 colony forming units of Gram-negative bacteria E. coli (ATCC 25922). Afterwards the swatch of the test sample (3.8 cm in diameter) was plated on the agar surface and pressed down with a 200 g cylindrical weight for 60 ± 5 s. The test sample was then removed from the agar surface, placed in a 100 mL container with the transferred surface face up and incubated at 37 °C for 24 h in a humidity chamber. After incubation 20 mL of neutralizing solution was poured on the test sample and shaken vigorously for 1 min. After making serial dilutions with sterilized water, the suspensions were plated on nutrient agar and incubated at 37 °C for 24 h. The reduction of bacteria growth, R A, on the finished sample in comparison to the unfinished one was calculated as follows:

where U is the number of bacteria forming units on the untreated sample after 24 h incubation and T the number of bacteria forming units on the treated samples under the same conditions. For every fabric sample three treatments were performed on two samples.

2.2.4 Scanning electron microscopy (SEM)

A microscopic evaluation of the morphological changes occurring after the finishing of cotton samples was carried out using a JEOL JSM 6060 LV scanning electron microscope, where samples were coated with a thin layer of gold before observation.

2.2.5 Fourier transform infrared (FT-IR) spectroscopy

FT-IR spectra were obtained on a Bruker IFS 66/S spectrophotometer, equipped with Silver gate ATR cell (45° angle incidence) employing a cylindrical Ge crystal (n = 4.0) with a diameter of 7 mm and single reflection. (SpectraTech). The samples were tightly pressed against a Ge crystal and the spectra were recorded over the range 4,000–600 cm−1, with a resolution of 4 cm−1 and averaged over 128 spectra. Before measurement, the studied samples were dried to constant mass.

2.2.6 X-ray photoelectron spectroscopy (XPS)

X-ray photoelectron spectroscopy (XPS or ESCA) analyses were carried out on a PHI-TFA XPS spectrometer (Physical Electronics Inc.). The analysed area was 0.4 mm in diameter and about 3–5 nm in depth. This high surface sensitivity is a general characteristic of the XPS method. Sample surfaces were excited by X-ray radiation from a monochromatic Al source at a photon energy of 1,486.6 eV. C 1s, F 1s, O 1s, N 1s and Si 2p spectra were acquired with an energy resolution of about 1.0 eV with an analyser pass energy of 58 eV. Quantification of surface composition was performed from XPS peak intensities measured on three different spots of the sample, taking into account the relative sensitivity factors provided by the instrument manufacturer [32].

2.2.7 Recovery from creasing

Recovery from creasing was determined according to the ISO 2313 Standard. After the specimen had been loaded with a load of 1 kg for 5 min, the crease recovery angle was measured 5 min after the removal of the load. The mean value of the angle, α, was calculated from the mean values of 10 measurements in warp and weft directions as follows:

where α1 in α2 are the mean values of the angles obtained in warp and weft directions, respectively.

2.2.8 Bending rigidity

The handle of the finished cotton samples was determined by the ‘Shirley’ stiffness test according to ASTM Standard D-1388-64. The bending rigidity, G, as a measure of stifness associated with handle, was determined from the bending length, l, which was obtained when a fabric sample was bent under its own weight to a definite extent. G is defined as:

where G 1 and G 2 are the bending rigidities in warp and weft directions equal to:

where T is the fabric weight per unit area. The results represent the mean values of 10 measurements.

2.2.9 Breaking strength

Breaking strength was measured with an Instron 5567 dynamometer in accordance with SIST ISO 5081:1996. The relative reduction in breaking strength, q red, of the finished cotton samples compared with the unfinished one was calculated from the mean value of the breaking strength of 10 specimens, using the following relationship:

where F f and F un are the breaking strength of the finished and unfinished cotton samples, respectively. Measurements were made in warp and weft directions. Before testing, the samples were conditioned at 65 ± 2% relative humidity and 20 ± 1 °C for 24 h.

2.2.10 Air permeability

Air permeability measurements were carried out according to the SIST EN ISO 9237:1999 Standard. From the amount of air passing through the sample under a pressure of 20 mm H2O, the air permeability was determined as Q given by:

where q is the volume of air flowing through the sample of area, a, expressed in L/h and Q is the volume of air in m3 passing through 1 m2 of the fabric per minute at the required pressure. The results represent the mean values of 20 measurements.

2.2.11 Statistical analysis

The large number of samples belonging to a particular coating allowed us to measure each examined parameter not only on different spots of one sample (representing replicates) but also on different samples (representing treatments) which enabled statistical analysis by the use of analysis of variance (ANOVA). Water contact angle measurements on different points of the samples were used for determination of sample-to-sample variations. Accordingly, only those fabric samples where sample-to-sample variations did not significantly influence the results of the water contact angle measurements were used for further observations.

3 Results and discussion

3.1 SEM and contact angle measurements

SEM measurements (Fig. 1) showed that the surface roughness of the treated fabric samples was higher than that of untreated fabric. This has been already reported by others [18, 29]. No detectable differences were noted for fabric samples treated by different sols.

The results presented in Table 2 revealed that the application of FAS and Ag–RB/FAS coatings to fabrics expectedly increased the oleophobicity of the unfinished textile (UN), and that the same level (i.e. 6) of oleophobicity was obtained for the Ag–RB–FAS (1S) and Ag–RB + FAS (2S) fabrics, indicating that the different procedures 1S and 2S did not affect the olephobicity of the fabrics. However, greater differences were noted for washed fabric samples. While the FAS treated textile retained its high oleophobicity (i.e. 6), the oleophobicity of Ag–RB–FAS (1S) decreased to 4 after the first and further dropped to 2 after the tenth washing cycle. A less pronounced drop of oleophobicity was noted for the Ag–RB + FAS (2S) fabrics which after 10 washings still retained a relatively high oleophobicity (i.e. 4).

A much better insight into how the oleophobic properties varied with washing for the Ag–RB + FAS (2S), Ag–RB–FAS (1S) and FAS fabric samples was obtained from the water (Fig. 2a), diiodomethane (Fig. 2b) and n-hexadecane (Fig. 2c) contact angle measurements. A closer look at the results in Fig. 2 revealed that the washing fastness of the Ag–RB + FAS (2S) fabric was superior with respect to Ag–RB–FAS (1S) and was very similar to the properties of the fabric treated with FAS alone. It should be pointed out that the washing fastness estimated from the water contact angles for Ag–RB + FAS (2S) was even higher than that for the FAS treated textile. This suggested that pre-application of RB–Ag followed by the application of FAS beneficially affected the overall washing fastness of the Ag–RB + FAS (2S) textile. We could speculate that the presence of RB silane or even Ag nanoparticles acted as anchoring sites for FAS which is known to exhibit poor wetting of hydrophilic surfaces.

Another interesting result could be obtained from Fig. 2c, which showed that n-hexadecane completely wetted the Ag–RB–FAS (1S) fabric already after the second washing (Fig. 3), while Ag–RB + FAS (2S) still exhibited contact angles of ∼105°, similar to those of FAS treated cotton fabrics. The results of the contact angle measurements fully supported those of the oil repellency ratings shown in Table 2.

3.2 Infrared spectra measurements

Infrared spectra provide valuable information about the molecular groups and species which are present on the surface or in the interior of textile fabrics. Due to the inherent surface roughness of cotton fabrics, the ATR technique [33] was preferred to the more common transmission technique where strong scattering of infrared light makes the spectra unreliable. As demonstrated below, the vibrational bands of the perfluoro groups attributable to the cotton finishes were easily detected in the corresponding ATR spectra. Accordingly, we used them as a probe to follow the removal of finishes from fabrics in a course of repetitive washings [33]. Because the chemical composition of FAS was not known, the spectra of chemically similar perfluorooctylpropylsilane (PFOTES) (Fig. 4) were analysed in detail in order to strengthen the credibility of the conclusions inferred from the ATR spectra of cotton finishes.

The bulk of the information about the vibrational bands attributed to –CF2 and –CF3 groups has been gathered from the IR reflection–absorption (IR RA) spectra of perfluoro compounds on metallic substrates such as copper [34, 35], gold [36, 37], aluminium [38], glass [31, 39], silicon and germanium [40], but much less information has been obtained from the spectra of treated textile fabrics [41, 42]. The interpretation of the vibrational spectra of perfluoro compounds is based on the Raman-active longitudinal acoustic spectra of n-alkanes and perfluoroalkanes, the IR RA spectra of semifluorinated amidethiol alkanephosphonic acid monolayers [38], different fluorinated alkanethiols [36, 37] and also the perfluorosilanes [34, 35]. Most perfluoro compounds as well as the analogous silanes (CF3–(CF2) n –CH2CH2–Si–OEt, n = 3, 5, 7, 9) exhibit bands at approximately the same frequencies, distinguished by the direction of the vibrating dipole with respect to the chain axis (or helix). Bands with dipole moments parallel (∥) to the chain axis appear at 1,378, 1,324 cm−1 (ν (CF2)-progression mode of the infinite fluorocarbon helix at the centre of the Brillouin zone activated due to the finite length of the chain) and perpendicular (⊥) modes at 1,232 cm−1 (νa (CF2) mixed with rocking (CF2)), 1,208 cm−1 (νa (CF2) + νa (CF3)), 1,150 cm−1 (νs (CF2), and deformation modes νa (CF2)) [37].

The bands attributed to the (∥) ν (CF2) progression modes of the chain expected at 1,378 and 1,324 cm−1 were barely seen in the spectra of perfluorooctylpropyltriethoxysilane (PFOTES) (Fig. 4), agreeing with the fact that these bands become strong in the P-polarized IR RA spectra of monolayers, but are rather weak in the spectra of bulk samples. The bands with a vibrating dipole perpendicular (⊥) with respect to the perfluoro chain axis perfectly matched the bands observed in the spectra of PFOTES (Fig. 4) and were observed at 1,240 cm−1 (νa (CF2) mixed with rocking (CF2)), 1,209 cm−1 (νa (CF2) + νa (CF3) and 1,144 cm−1 νs (CF2) modes. [37], but the band assigned to (νs (CF2), deformation νa (CF2)) at 1,150 cm−1 was red-shifted to 1,144 cm−1.

A closer look at the ATR spectra of FAS (Fig. 4) revealed that the bands of the perfluoro groups were slightly shifted with respect to those of PFOTES and appeared at 1,238, 1,207 cm−1 and at 1,143 cm−1. However, some bands appeared with different intensities, suggesting that the length of the perfluoro chains differed for FAS and PFOTES [43]. The ATR spectra of FAS and PFOTES also differed regarding the bands at 1,672 and 1,603 cm−1, and some other bands in the spectral region from 1,000 to 1,100 cm−1. Overall, the frequency agreement was surprisingly good, important for performing spectra subtraction (see below).

After the addition of acidified water, the spectra of PFOTES (Fig. 4) changed, showing a partial loss of Si-OEt bands at 820 and 778 cm−1 and a complete disappearance of the bands at 1,105, 1,083 and 962 cm−1 suggesting fast (15 min) and complete hydrolysis. The latter band became substituted by a band at 910 cm−1ascribed to the silanol groups. The expected silanol band in the spectra of FAS was not observed because of its weak intensity.

Definitely no sign of the Ag nanoparticles was detected in the spectra of Ag–RB and RB (Fig. 5), showing bands of the Si–O–Si linkages at 1,130, 1,075 and 1,025 cm−1 (shoulder). It is important to note that the Si–O–Si bands at 1,075 and 1,025 cm−1 coincided with the strong bands of cotton and were not suitable for the detection of the presence of RB binder from the subtraction spectra (see below).

The ATR spectra of finished and bare cotton fabrics are shown in Fig. 6. As expected, all the bands attributed to FAS were broadened due to the contribution from the bands of cotton itself and slightly shifted [33, 44, 45]. Comparison of the corresponding spectra (Fig. 6), revealed only bands attributable to the modes of the –CF2 and –CF3 groups (1,245 cm−1, 1,237 cm−1, Fig. 4) but the band at 1,208 cm−1 (νa (CF2) + νa (CF3)) was blurred by the cellulose –OH deformational mode at ∼1,200 cm−1 [45, 46]. Practically no useful information could be extracted from a direct comparison of the spectra of finished and bare cotton fabrics, which led us to perform ATR spectra subtraction [33].

In the first step, the ATR spectra of bare cotton were subtracted from the finished cotton (Fig. 7) in order to identify the presence of the corresponding finishes on the cotton fabrics. The subtraction spectra revealed surprisingly good agreement with the spectra of Ag–RB and FAS (Fig. 4). Practically all the bands of FAS were observed in the subtractive spectra, having nearly the same relative intensities as obtained from Fig. 4. In addition, the band at 1,075 cm−1 attributable to the Si–O–Si modes of RB was observed as well, but it showed stronger intensity in the S2 than in the S1 spectra. The presence of some other bands, albeit having low intensity and slight shifts of the prominent bands of the finishes, could not be avoided but they did not affect the conclusions extracted from the spectral analysis.

In the next step, the washing fastness of the Ag–RB–FAS (1S) and Ag–RB + FAS (2S) finishes was assessed by subtraction of the spectra of cotton washed 10 times from the spectra of bare non-washed cotton (Fig. 7).

From the subtractive spectra it could be inferred that the washing fastness of Ag–RB + FAS (2S) was much better than that of Ag–RB–FAS (1S) cotton fabrics. In both subtraction ATR spectra—they practically coincided with those shown in Fig. 5: the bands attributed to the C–F modes of FAS (1,245, 1,237, 1,204 and 1,144 cm−1) could be easily identified, but their intensity was not the same. While the subtraction spectra of Ag–RB + FAS (2S) showed the intensity of the most prominent bands up to 0.04 absorbance units, the intensity of the same bands in the spectra of Ag–RB–FAS (1S) reached only 0.02 absorbance units, indicating that the latter finish was washed off more during the 10 consecutive washings. To conclude, even though the subtractive ATR spectra gave evidence for the presence of FAS, agreeing also with the residual C–F groups identified from the XPS spectra (see below), they supported the loss of oleophobicity for the S1 cotton fabrics noted from the contact angle measurements (Fig. 2).

3.3 Antibacterial properties

Results for the antibacterial activity of Ag–RB, Ag–RB–FAS (1S) and Ag–RB + FAS (2S) coatings are presented in Table 3 and in Fig. 8. The data represent average values obtained from two repeated experiments. As expected, no reduction of the bacteria S. aureus and E. coli was found on the unfinished cotton sample. On the contrary, there was even an increase in the number of bacteria recovered from the inoculated sample after 24 h of incubation in comparison to “0” contact time. In the case of the Ag–RB and Ag–RB + FAS (1S) coatings, a high reduction of both bacteria occurred on the finished unwashed cotton samples. The reason for the antimicrobial properties of the coating was attributed to the presence of Ag nanoparticles. According to literature data [47−50], the antibacterial activity of Ag is due to the high affinity of silver towards sulphur and phosphorus. Due to the abundance of sulphur-containing proteins on the bacterial cell membrane, silver nanoparticles can react with sulphur-containing proteins inside or outside the cell membrane, which in turn affects bacterial cell viability. It was also proposed that silver ions (particularly Ag+) released from silver nanoparticles (Ag0) can interact with phosphorus moieties in DNA, resulting in inactivation of DNA replication, as well as with sulphur-containing proteins, leading to the inhibition of enzyme functions.

The number of bacteria recovered from the inoculated swatches of cotton samples and after 24 h of incubation. Coating: UN, unfinished sample; Ag–RB, antimicrobial coating; Ag–RB–FAS (1S), water and oil repellent and antimicrobial coating applied in one stage; Ag–RB + FAS (2S), water and oil repellent and antimicrobial coating applied in two stages

Our results (Table 3, Fig. 8) showed that the bacterial colonies of E. coli were almost completely killed in contact with the unwashed Ag–RB and Ag–RB–FAS (1S) cotton, while the reduction of bacteria was much smaller for the cotton treated with Ag–RB + FAS (2S). Surprisingly, the antibacterial activity of Ag–RB + FAS (2S) cotton fabrics was greatly enhanced after the first washing cycle was performed. This could be explained by the screening effect of FAS on Ag nanoparticles, since FAS was deposited in the S2 procedure after the deposition of Ag–RB. However, just a single washing was enough to restore high antibacterial activity, reaching that of Ag–RB–FAS (1S) where FAS was not applied separately. Obviously, the antibacterial activity dropped in the course of repetitive washing due to the leaching of Ag nanoparticles. As a result of this gradual leaching, no reduction of bacteria was noted after the tenth washing cycle for all the investigated cotton fabrics (Table 3). To conclude, although the cotton fabrics treated with Ag–RB/FAS silane mixtures displayed antibacterial activity regardless of the procedure employed (S1 or S2), their antibacterial activities were still inferior with respect to those reported by Xing [18], probably due to the fact that in the latter case the silver nitrate solution was applied to silica-treated cotton fabric by the exhaustion method for 30 min, enabling the adsorption of a higher concentration of silver compared to that obtained by the pad-dry-cure method used in this study. We verified this by soaking the cotton fabrics for 30 min in Ag–RB sol, resulting in a much better antibacterial activity as compared to that reported in Table 3. It is obvious that a higher concentration of silver increases the antibacterial effect of any type of finish.

It is clear that the antibacterial effect, closely related to the adhesion and colonization of bacteria on the cotton fabrics, is indirectly influenced by the low surface energy of the cotton fabrics. Zhao et al. [6] demonstrated that by using a graded nickel-perfluoroethylene (PTFE) composite coating technique it is possible to tailor the surface energy of membrane diffusers to optimum values, resulting in stable membrane filtration achieved by the retention of membrane permeability, which is usually decreased due to the growth of biofilm formation. Like membrane diffusers, cotton also has a porous structure and both substrates suffer problems of poor durability, lack of resistance to cleaning agents and are prone to leaching [51]. It has been shown that particularly the low dispersive part (σLW) of the surface energy has a tremendous effect on reducing the attachment of E. coli. Undoubtedly, the high oil numbers (Table 2) of FAS and S2 treated cotton fabrics obtained even for washed fabrics (Fig. 2) could have a dramatic effect on the antibacterial properties. In order to evaluate the low surface energy effect on the antibacterial properties and to distinguish it from the inherent antibacterial effect of the Ag nanoparticles, an alternative procedure for the assessment of bacterial growth was applied.

Namely, the main problem encountered with the standard method lies in the need for complete wetting of the cotton fabrics when the antibacterial properties have to be assessed. We avoided this problem by using the EN ISO 20743:2007 transfer method, which gives the possibility of establishing at least qualitatively the contribution of the hydrophobicity to the antibacterial properties achieved.

Inspection of the results shown in Table 4 revealed that the bacteria did not grow on the finished cotton. Importantly, even cotton treated just with FAS alone exhibited bacteria reduction up to 21.9 ± 5.7% after 10 consecutive washings, suggesting the effective prevention of bacterial adhesion on low surface energy cotton fabrics. The synergetic effect of the application of Ag–RB followed by the application of FAS was inferred as well, which led to the increased bacterial reduction of up to 41.5 ± 3.7% even for washed fabrics. Expectedly, the effect of the presence of FAS in the S1 solution was less strong because of the less pronounced water repellent effect of the Ag–RB–FAS finish. It was clear that the presence of FAS controlled the leaching of Ag nanoparticles, since no antibacterial effect was noted for cotton treated with Ag–RB after 10 repetitive washings (Table 4).

3.4 XPS analysis

Encouraged by the results of the antibacterial activity testing, XPS analysis was performed in order to identify the composition of the coatings and in particular, the presence of Ag nanoparticles, which seem to be essential for the observed antibacterial activity of the textiles. Even though there were no doubts about the presence of Ag nanoparticles, their identification with the help of XPS measurements had not been persuasive [18] and the support of ICP AES analysis was sought for confirmation of the presence of Ag in the textiles. Our XPS analysis fully confirmed previous results, showing only a weak signal attributed to Ag on the samples. Accordingly, we focused on the identification of other components expected to be present.

XPS spectra of cotton fabrics treated with Ag–RB–FAS (1S), Ag–RB + FAS (2S) and Ag–RB revealed five characteristic peaks which we ascribed to carbon (C 1s) (285 eV), oxygen (O 1s) (533 eV), silicon (Si 2p) (102 eV), fluorine (F 1s) (689 eV) and zirconium (Zr 3d) (182 eV) (XPS analysis of the FAS treated cotton fibres is not discussed here and will be presented in a separate study elsewhere). It should be noted that the XPS spectra of untreated cotton fabric revealed only two characteristic peaks belonging to C 1s and O 1s. For the Ag–RB samples, beside the expected signals of C 1s, O 1s and Si 2p, also a weak Zr 3d signal was detected, likely stemming from the RB organic–inorganic siloxane. Siloxanes usually need an additional cross linker to enable their better bonding on cotton fibres [52].

Application of sols to the cotton surface caused a decrease of carbon and oxygen concentrations (equal to 59.9% and 40.1% for the untreated cotton sample), indicating that the coatings covered the cotton fibre surface. The results shown in Fig. 9 revealed that the concentrations of fluorine and silicon decreased with repetitive washing of cotton fabrics treated with Ag–RB–FAS (1S) and Ag–RB + FAS (2S), agreeing with the observed drop in the oleophobicity (Fig. 2). For example, the fluorine concentration decreased from 53.2% (unwashed) to 39.2% (the tenth washing) for the Ag–RB + FAS (2S) coating and, as expected, this concentration fall was lower than that obtained for the Ag–RB–FAS (1S) coating. The results in Fig. 9a and b also revealed that during repetitive washing the concentration fall of fluorine was much higher than that of silicon. The reason for this was attributed to the structure of the coating where the fluorine-containing side groups are much more sensitive to the action of turbulence during washing in comparison to the siloxane backbone. Interestingly, the concentrations of C 1s and O 1s signals suggested modification of the surface of the cotton fabrics, indirectly proving the observed loss of oleophobicity. Ag–RB treated cotton also showed the effect of washing which was inferred from the decrease of the Zr 3d signal. However, the changes were not so clear since the Si 2p and Zr 3d signals were of low intensity. In all respects, the XPS results were in agreement with the results of the infrared spectra analysis and the contact angle measurements. At this point it should be stressed that the contact angle values were not so influenced by the coating thickness in comparison to the results of XPS and infrared spectra analysis.

3.5 The physical properties of cotton fabrics

Finally, we checked how the sol–gel finishes and the ensuing repetitive washings influenced the physical properties of the cotton fabrics. It was found that the application of all four sols decreased their bending rigidity, which was accompanied by an increase in the crease recovery angles (Fig. 10a). While the decreased bending rigidity resulted from the improved fabric flexibility and softness, the increased crease recovery angles indicated that the fabric is more crease and wrinkle resistant. These changes were higher in the presence of FAS than of the Ag–RB coating. Treatment of cotton samples slightly decreased the fabric breaking strength in warp and weft directions (Fig. 10b). For all four samples it was also found that the sol–gel finishes caused a significant decrease of sample air permeability (Fig. 10c). Statistical analysis showed that neither the fabric breaking strength nor its air permeability was significantly influenced by the composition of the coating. The decrease of air permeability of the finished cotton samples was attributed to the polysiloxane network formed on the fibre surface which partly covered the pores in the fabric structure, resulting in the impaired porosity. This could be detrimental in the case of samples intended for use as protective clothing.

Crease recovery angle, α (a), bending rigidity, G (a), the relative reduction in breaking strength, q red (b), and air permeability, Q (c) of the finished cotton samples. Coating: FAS: water and oil repellent, Ag–RB: antimicrobial, Ag–RB–FAS (1S): water and oil repellent and antimicrobial coating applied in one stage, Ag–RB + FAS (2S): water and oil repellent and antimicrobial coating applied in two stages. UN: unfinished sample

4 Conclusions

The results of this work confirmed the expected advantages of sol–gel processing for achieving multifunctional properties of cotton fabrics, expressed in their simultaneous oleophobicity and antibacterial activity, which led to long lasting antibacterial activity of the treated cotton fabrics. A significant difference in the antibacterial activity was noted as regards the application procedure. Separate deposition of antibacterial Ag nanoparticles followed by the application of oelophobic and antibacterially non-active FAS seemed to be important, causing better adherence of FAS on cotton fabrics pre-treated by Ag–RB (2S procedure). The corresponding coatings exhibited a distinctively higher washing fastness of the finish than those where the solution mixture was applied in one step (1S procedure). The results showed that synergy between the antibacterial effect of the Ag nanoparticles and the oleophobic FAS was attained, particularly reflected in the washing fastness of the sol–gel finish and the ensuing “passive” antibacterial effect.

References

Heywood D (ed) (2003) Textile finishing. Society of Dyers and Colourists, Bradford

Schindler WD, Hauser PJ (2004) Chemical finishing of textiles. Woodhead Publishing Ltd., Cambridge

Černe L, Simončič B (2004) Text Res J 74:426

Simončič B, Černe L (2004) Tekstilec 47:6

Simončič B, Tomšič B, Wechtersbach H, Bračko S, Radišek S, Simončič A (2005) Tekstil 54:1

Zhao Q, Wang S, Müller-Steinhagen H (2004) Appl Surf Sci 230:371

Shao H, Meng WD, Qing FL (2004) J Fluor Chem 125:721

Lee S, Cho JS, Cho GS (1999) Text Res J 69:104

Isquith AJ, Abbott EA, Walters PA (1972) Appl Microb 24:859

Mahltig B, Böttcher H (2003) J Sol–Gel Sci Technol 27:43

Mahltig B, Fiedler D, Böttcher H (2004) J Sol–Gel Sci Technol 32:219

Mahltig B, Haufe H, Böttcher H (2005) J Mater Chem 15:4385

Mahtig B, Audenaert F, Böttcher H (2005) J Sol–Gel Sci Technol 34:103

Haufe H, Thron A, Fiedler D, Mahltig B, Böttcher H (2005) Surf Coat Int Pt B-C 88:55

Chen CC, Wang CC (2006) J Sol–Gel Sci Technol 40:31

Brückmann R, Koch M, Lutz H (2006) Textilveredlung 11/12:4

Pipatchanchai T, Srikulkit K (2007) J Sol–Gel Sci Technol 44:119

Xing Y, Yang X, Dai J (2007) J Sol–Gel Sci Technol 43:187

Haufe H, Muschter K, Siegert J, Böttcher H (2008) J Sol–Gel Sci Technol 45:97

Sun G, Xu XJ (1998) Text Chem Color 30:26

Yang YQ, Corcoran L, Vorlicek K, Li SQ (2000) Text Chem Color Am Dyestuff Rep 32:44

Purwar R, Joshi M (2004) AATCC Rev 4:22

Ma MH, Sun G (2004) Dyes Pigments 63:39

Zhang ZT, Chen L, Ji JM, Huang YL, Chen DH (2003) Text Res J 73:1103

Jeon HJ, Yi SC, Oh SG (2003) Biomaterials 24:4921

Cheng QL, Li CZ, Pavlinek V, Saha P, Wang HB (2006) Appl Surf Sci 252:4154

Parikh DV, Fink T, Rajasekharan K, Sachinvala ND, Sawhney APS, Calamari TA, Parikh AD (2005) Text Res J 75:134

Lee HJ, Jeong SH (2004) Text Res J 74:442

Yu M, Gu GT, Meng WD, Qing FL (2007) Appl Surf Sci 253:3669

Salon MCB, Abdelmoulen M, Boufi S, Belgacem MN, Gandini A (2005) J Colloid Interface Sci 289:249

Jeong HJ, Kim DK, Lee SB, Kwon SH, Kadono K (2001) J Colloid Interface Sci 235:130

Moulder JF, Stickle WF, Sobol PE, Bomben KD (1995) Handbook of X-ray photoelectron spectroscopy, Eden Prairie Physical Electronics Inc

Vince J, Orel B, Vilčnik A, Fir M, Šurca Vik A, Jovanovski V, Simončič B (2006) Langmuir 22:6489

Hoque E, DeRose JA, Houriet R, Hoffmann P, Mathieu HJ (2007) Chem Mater 19:798

Hoque E, DeRose JA, Hoffmann P, Mathieu HJ (2006) Surf Interface Anal 38:62

Chidsey CED, Loiacono DN (1990) Langmuir 6:682

Lenk TJ, Hallmark VM, Hoffmann CL, Rabolt JF, Castner DG, Erdelen C, Ringsdorf H (1994) Langmuir 10:4610

Pellerite MJ, Dunbar TD, Boardman LD, Wood EJ (2003) J Phys Chem B 107:11726

Monde T, Fukube H, Nemoto F, Yoko T, Konakahara T (1999) J Non-Cryst Solids 246:54

Hoffmann PW, Stelzle M, Rabolt JF (1997) Langmiur 13:1877

Jiang WC, Meng WD, Qing FL (2005) J Appl Polym Sci 98:222

Church JS, Evans DJ (1995) J Appl Polym Sci 57:1585

Rabolt JF, Russell TP, Twieeg RJ (1984) Macromolecules 17:2786

Fir M, Vince J, Šurca Vuk A, Vilčnik A, Jovanovski V, Mali G, Orel B, Simončič B (2007) Acta Chim Slov 54:144

Tomšič B, Simončič B, Orel B, Vilčnik A, Spreizer H (2007) Carbohydr Polym 69:478

Hulleman SHD, van Hazendonk JM, van Dam JEG (1994) Carbohydr Res 261:163

Gupta A, Maynes M, Silver S (1998) Appl Environ Microb 64:5042

Matsumura Y, Yoshikata K, Kunisaki S, Tsuchido T (2003) Appl Environ Microb 69:4278

Lee HY, Park HK, Lee YM, Kim K, Park SB (2007) Chem Commun 28:2959

Kim YH, Lee DK, Cha HG, Kim CW, Kang YS (2007) J Phys Chem 111:3629

Hamza A, Pham VA, Natsuura T, Santerre JP (1997) J Membr Sci 131:217

Kissa E (1984) Repellent finishes. In: Lewin, SB Sello (Eds) Handbook of fiber science and technology: volume II, chemical procesing of fibers and fabrics: functional finishes, Part B. Marcel Dekker, New York

Acknowledgments

This work was supported by the Slovenian Research Agency (Programme P2-0213 and Project M2-0104) and the Slovenian Ministry of Defence (Project M2-0104). B.T. thanks the Ministry of Higher Education, Science and Technology for a Ph.D. grant.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Tomšič, B., Simončič, B., Orel, B. et al. Sol–gel coating of cellulose fibres with antimicrobial and repellent properties. J Sol-Gel Sci Technol 47, 44–57 (2008). https://doi.org/10.1007/s10971-008-1732-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-008-1732-1