Abstract

Nanocrystalline sol–gel derived titania doped with ceria (1, 2, 5 and 10-mole%) has been prepared from titanyl oxysulphate. The titania doped with 5-mole% CeO2 after calcining to 500 °C, possesses specific surface area of 97 m2 g−1 and has anatase phase stability up to 900 °C. Moreover it retains a surface area of 37 m2 g−1 at 700 °C. In comparison, the undoped calcined material has anatase stability only up to 700 °C and specific surface area only 48 m2 g-1 and 6 m2 g-1 at 500 °C and 700 °C, respectively. The diffuse reflectance spectra show that, as the cerium content increases, the absorption undergoes a red shift and reaches the visible range. The exceptionally high phase stability, crystallinity and high surface area are due to the extremely fine particle size and effective doping achieved by the specific synthesis method. The results based on X-ray diffraction, specific surface area and diffuse reflectance spectra indicated that the maximum threshold limit of doping is up to a value of 5-mole%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nanocrystalline anatase titania has become increasingly important because of its potential applications in catalysis, photo catalysis, as self-cleaning coating on ceramic surfaces and sensors [1–6]. Titania has three phases; anatase, rutile and brookite [7]. The low temperature anatase phase is irreversibly transformed to rutile phase on heat treatment above 450 °C [8, 9]. The phase transition temperature depends upon the grain size, presence of impurities, dopants, precursor material and synthesis method [10]. Disadvantages of titania being used as a catalyst and for catalytic support, is its relatively low surface area and the poor stability of the active anatase structure at elevated temperatures. Various metal ion dopants have been studied to synthesise high temperature stable anatase phase titania through different methods like sol–gel, hydrothermal synthesis etc. Rao et al. [11] studied the effect caused by the addition of Sb2O5, Al2O3, ZnO, PO4 3−, SO4 2− and Cl− on the anatase-to-rutile phase transformation. Ranjit et al. [12] reported an enhancement of the photocatalytic properties of titania upon doping with rare-earth ions such as Eu3+, Pr3+ and Yb3+. Yang and Ferreira [13] explained the stability of the anatase phase with respect to the ionic radius of the dopant ions such as Al3+ and Si4+. LeDuc et al. [14] synthesized lanthana-doped titania by the addition of lanthanum nitrate to a suspension of titanium oxide and studied its photocatalytic activity. Lin et al. [15] studied the photoactivity of mixed oxide TiO2 prepared by using rare earth oxide like CeO2, Y2O3 and La2O3. The addition of rare earth oxide improves the anatase-rutile transformation temperature. It was found that Y2O3 and La2O3 improve the photoactvity, but CeO2 addition decrease the photoactivity due to faster recombination rate of electron-hole pairs. The effect of CeO2 on the structure and catalyitc property of titania was also studied [16, 17]. Mohamed et al. [16] studied the effect of CeO2 doped titania on the structure and properties of TiO2 and MO3/TiO2 catalyst and characterized by XRD, BET surface area and FT-IR. In their work incorporation of ceria at low loading was found to improve the anatase stability. The titania-ceria mixed oxide sample prepared shows the anatase phase at 500 °C calcination. These materials also show the CeO2 phase in the XRD pattern along with the anatase phase. The ceria incorporation improves the bronstead acidity at the surface of titania. J. Rynkowski et al. [17] prepared titania–ceria mixed oxide at different atomic ratio like 8/2 (Ti/Ce) and 5/5 (Ti/Ce) through sol–gel method and studied the structural behaviour by XRD and XPS. At a temperature of 700 °C they obtained the rutile phase along with some ceria titania peak of CeTi4O24 and Ce2Ti2O7. These catalysts are studied for the hydrogenation of unsaturated aldehyde. In previous work [18–21], it has been reported that the addition of Ce4+/CeO2 decreases the temperature of phase transformation of sol–gel derived amorphous silica phase to cordierite product. Addition of ceria in amorphous silica depresses the growth of crystals, improves the density of cordierite ceramics and make available with unique properties [18–21].

Previous research focused the preparation of nano titania through the alkoxide route by a controlled hydrolysis−condensation reaction. Recently considerable interest has been shown to identify processes where the reactions are carried out under aqueous or acidic medium [22, 23] using inorganic precursors. However, the doped titania is prepared by either precipitation followed by impregnation of dopants or hydrothermal synthesis from a mixture of precursors. Here we report a sol–gel process where nano crystalline ceria-doped titania is synthesized from titanyl oxysulphate precursor by introducing the dopant ion in the peptised sol. This method exploits the advantage of an inexpensive precursor, homogenous mixing of precursor and distribution of the dopant over titania at nano level and control over powder characteristics. We studied the influence of cerium content on the crystal size, phase transformation from anatase to rutile, diffuse reflectance spectra, specific surface area, pore volume and pore diameter of the titania samples prepared. To the best of our knowledge, no work has been reported for the study of ceria doped titanium oxide following precipitation and peptization method starting from titanyl oxysulphate, and addition of dopant ions to the nanosized sol particles. The reason for choosing the cerium ion, it was expected that the addition of cerium ion can enhance the thermal properties of the gels and promote the formation of ultrafine anatase crystals and improves the surface area of the titania. Further more cerium as a dopant, is an efficient electron acceptor, which can remove photogenerated electron from electron-hole recombination sites, increasing the quantum size yield rate [24].

2 Experimental

Titanyl oxysulphate (Aldrich 99.99% purity) was used as precursor for the synthesis of nano titanium dioxide. In a typical experiment, titanyl oxysulphate was dissolved in 500 ml of distilled water (0.2 M) and hydrolysed by slow addition of ammonium hydroxide (S.D Fine Chemicals, India. 99% purity) solution under constant stirring at room temperature (32 °C), until the reaction mixture attained pH 8.0. The precipitate obtained was separated by filtration and washed free of sulphate ions (confirmed by the BaCl2 test) with distilled water. The precipitate was further dispersed in 1,000 mL of hot distilled water and was peptised by addition of 10% HNO3 (Merck, India) solution up to a pH 2. Cerium nitrate (M/s. Indian Rare Earths Ltd., Alwaye, India, AR grade, 99.9% purity) solution corresponding to 1, 2, 5 and 10-mole% of titania was added to the titania sol and the stirring continued for further 90 min. The sols were concentrated over steam bath and subsequently dried in an oven at 70 °C to result in xerogel. These gels were further calcined at 500, 600, 700, 800 and 900 °C at a heating rate of 10 °C min−1 for 1 h. The surface area measurements and pore analysis were carried out by nitrogen adsorption using a Micromeritics Gemini 2375 surface area analyser after degassing the sample at 200 °C for 2 h. Specific surface area measured at p/p 0 = 0.3 (single point), total pore volume calculated at p/p 0 = 0.99 by BET method, BJH mesopore volume and micro pore volume which were calculated by t-method. XRD patterns of the calcined gels were obtained with a Rigaku X-ray diffracto meter in the diffraction angle range 2θ = 20 − 60° using Cu Kα radiation. The amount of anatase in the sample was estimated using the Spurr equation [25].

where FA is the mass fraction of anatase in the sample, I A (101) and I R (110) is the integrated main peak intensities of anatase and rutile respectively.

The particle diameter (crystallite size) was calculated by applying the Scherrer equation

where λ = X-ray wavelength, K is the shape factor, θ = Bragg angle, β = full width at half maxima. The absorption properties of the samples calcined at 500 °C was studied by using UV–visible spectrometer (Shimadzu, Japan, UV-2401 PC) keeping BaSO4 as standard. The powder sample (5 g) was made in the form of a pellet and scanned for a wavelength starting from 200 to 800 nm.

3 Results and discussion

3.1 XRD measurements

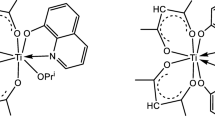

The gel was calcined at different temperatures starting from 500, 600, 700, 800 and 900 °C. From the powder XRD pattern (Figs. 1 and 2) of calcined titania gel, it was found that the anatase to rutile transformation takes place at 900 °C on doping with 5-mole% of ceria. At 900 °C, 5-mole% ceria doped sample contains 85% anatase. However, undoped titania calcined at 700 °C shows only 28% anatase where as at 600 °C it shows 71% anatase. This indicates that phase transformation occurred in undoped titania at 600 °C itself. In 5-mole% doped sample 100% anatase is obtained at 800 °C, furthermore 85% anatase is present even after calcining at 900 °C. Suzane et al. [26] reported that the phase stability of CeO2 added to titania system has phase stability up to 650 °C. Yan et al. [27] reported that the solubility of the cerium ions in the anatase type TiO2 and stability of anatase phase is only up to 700 °C for a dopant concentration of 5-mole%. Lin et al. [15] reported the 0.5% doping of ceria improves the anatase-rutile transformation temperature up to 750 °C. This sample shows 14% rutile at 700 °C and 29% rutile at 750 °C. The crystal size calculated at 700 °C shows a value 25.8 nm. The La2O3 and Y2O3 addition shows 32% and 28% of rutile at 750 °C. It should be noted that all the dopant added samples the rutile formation starts as early as 500 °C. All of them contain 14% rutile at 500 °C. In contrast we obtained the phase stability up to 900 °C for 5-mole%, which is much higher than the above reported values. The doped sample with cerium content of 1, 2 and 5-mole% were detected as a single-phase anatase type structure, and no trace of diffraction peaks due to cerium oxide, was detected. This is attributed to the high area of distribution of the dopant around the titania sol particles, which effectively results in poor titania-titania connectivity necessary for early transformation to rutile. The XRD pattern indicates (Fig. 2e and g) peaks related to cerium oxide in addition to those related to titania for composition 10-mole% of ceria while the results generally supports the reported data regarding the extent of dopant as <10 mole%. It has been reported that lanthanide doped titania sample will result in the reduction of crystallite size due to the distribution of doped cation at surface boundaries of titania which inhibit grain growth by providing a barrier between titania grains [28, 29]. When crystallite size reaches a critical value 12–20 nm [27, 29] the rutile phase formed in both the doped and undoped sample. However, this crystallite size (Table 1) is attained in the present work above 800 °C in the case of ceria doped titania while the same occurs at 600 °C in the case of undoped sample. A considerable increase in phase transformation temperature is obtained due to this decrease in reduction of crystallite size of the doped sample. This is a good advantage of the current synthesis method. The effectiveness of dopant distribution has been further explored in the present work by surface area and diffuse reflectance spectra.

XRD pattern of the samples calcined at different temperature (A Anatase phase, R Rutile phase, Ce Ceria phase) (a) Undoped at 800 °C (b) 1-mole% ceria doped at 800 °C (c) 2-mole% ceria doped at 800 °C (d) 5-mole% ceria doped at 800 °C (e) 10-mole% ceria at 800 °C (f) 5-mole% ceria doped at 900 °C (g) 10-mole% ceria at 900 °C

3.2 Surface area measurements

Textural characteristics of the samples calcined at 500 and 700 °C derived from N2-adsorption analysis. Specific surface area (SBET) measures at p/p 0 = 0.3 (single point), total pore volume calculated at p/p 0 = 0.99 by BET method, BJH mesopore volume and micro pore volume which were calculated by t-method. The results are shown in the Table 2. The surface area and total pore volume decrease with increase in calcination temperature. The results indicated that surface area of the sample was strongly dependent on the thermal treatment temperature and on the cerium doping. When TiO2 and 5-mole% ceria doped sample are calcined at 500 °C, the measured surface areas were 48 m2 g−1 and 97 m2 g−1, respectively. This indicates that the surface area was double in the case of the doped one. The pore volumes for the doped and undoped sample calcined at same temperature are 0.149 and 0.108, respectively that decreases to 0.026 and 0.099 at 700 °C. Yan et al. [27] indicated that the lattice parameter should change by the addition of cerium to the titania matrix and this effect is up to 5-mole% and therefore this will improve the surface area of the doped sample. The higher the mole% going in to the titania matrix will increase the defect and hence it will increase the surface area. Therefore, doping of ceria in titania matrix increases the surface area and total pore volume of the system. The average pore diameter measured shows all sample lies in the mesoporous range (2–50 nm). The ceria doped sample have almost constant pore diameter at 500 °C, which indicates pore stability of the system as a result of ceria doping. There is not much change in pore diameter by ceria doping when the temperature increases from 500 to 700 °C. This is an additional proof for the pore stability of ceria doped samples. As a conclusion of the surface area measurements the aqueous sol–gel method adopted here provides mesoporous titania having high surface area and doping with ceria improves the thermal pore stability and surface area of the titania.

3.3 Diffuse reflectance spectra

The UV Visible spectrum was used to obtain the optical absorption properties of the doped and undoped sample. Figure 3 shows the spectra of the undoped and ceria doped precursor gel calcined at 500 °C. With the increase of cerium content, the absorption shifted to the longer wavelength side (red shift). This absorption clearly increases from undoped titania to 5-mole% ceria doped titania. Beyond this level there is no significant change, thus limiting the advantage of dopant addition up to a maximum of 5-mole%. The increase in absorption by the addition of ceria can be explained on the basis of previous studies [27]. Particles formed from large TiO2 crystals have smoother surface than the particle made from smaller crystals [27]. The incident photons are scattered and lost by reflection, the rate at which the loss take place will increase as the particle size increases. Because of the reduction in crystallite size (Table 1) due to doping, the absorption increases. However, the optical absorption decreases when the cerium content increases from 5 to 10 mole%. This is due to following reasons. When the dopant concentration goes from 5 to 10 mole% the amount of cerium content increases in the solid solution, which crystallizes out as CeO2 phases as the calcination temperature increases. This is evident from the XRD (Fig. 2e and g) in the case of 10-mole% ceria doped sample. The presence of large amount of cerium content in the lattice of titania affects the optical properties of transmission of titania. Also the crystal size calculated for 10-mole% doped sample doesn’t shows much decrease in value when we compare the crystal size reduction from 1 to 5 mole%.

Titanyl oxysulphate precourser has been recently reported for the preparation of highly photoactive TiO2 support [30]. They achieved a high photonic efficiency for the mineralization of glucose for a supported photocatalytic TiO2. It is an inexpensive inorganic chemical compared to the metal alkoxide chemicals like titanium butoxide, titanium isopropoxide etc used for the preparation of nanocrystalline titania through sol–gel process. This method of preparation using titanyl oxysulphate is an alkoxide free route to synthesise nanocrystalline titania. The advantage of this aquoes colloidal synthesis is, it ensures homogenous mixing of the precourser, a uniform distribution of the dopant over titania at nano level and control over power charasticstics. Here we prepared ceria doped titania (1, 2, 5 and 10-mole%) by the addition of cerium nitrate to the titania sol, which is prepared through precipitation–peptisation method from titanyl oxysulphate. This method of addition of dopant solution to already dispersed in situ formed hydrous titanium ensures effective adsorption of the dopant over the hydrous titania oxide. The influence of the dopant on the structural and textural properties of the sample can be explained on the basis of changes caused by the dopant on the defect structure of the TiO2 lattice. The solid solution and solid-state diffusion of Ce4+ ion in anatase is referred to the mechanism of high temperature anatase stability [31, 32]. The X-ray pattern indicates that cerium oxide peaks are formed in the gel matrix (Fig. 2e and g), evidence for the solid solution formation [31]. Further more the ionic size of Ce4+ (0.092 nm) is larger than that of Ti4+ (0.064 nm) but smaller than oxygen (0.132 nm) [27]. The cerium ion can be introduced substitutionally into the matrix, producing some deformation of the lattice structure and deformation energy retards the transformation from anatase to rutile. The rate of diffusion of Ce4+ is rather slow because of its larger radius [27]. Thus, the cerium ions are enriched around the anatase crystals. As a result, the particle growth is slowed down and anatase phase achieves higher temperature stability.

The threshold limit of doping (5 mole%) can be explained on the basis of the solid-state diffusion of Ce4+ in anatase. Anatase is a typical n-type semiconductor, in which there are oxygen vacancies. The calcination temparature increases the crystallinity increases as a result the solubility of Ce4+ ion in anatase decreases compared to that in the amorphous TiO2. The amount of cerium ion in lattice will increases as the dopant concentration increases from 5 to 10 mole%. As the anatase crystals grow, extra Ce4+ ions have to be discharged from the crystals through solid diffusion and it crystallises out as CeO2 phase. This extra cerium ions will help in the growth of anatase crystal and there by the early formation of rutile titania. The amount of extra ceria ions will be high for 10-mole% sample and this will appear as a separate peak for cerium in X-ray diffraction studies (Fig. 2e and g). The peak of CeO2 phase is not appearing for up to 5-mole% doping. This shows the effective doping is only up to 5 mole%. However, the diffusion of Ce4+ is rather slow because of its larger radius. Thus, Ce4+ ions are enriched around the anatase crystals, suppressing Ti4+ diffusion towards the crystals. As a result, the growth is slowed down or completely terminated leads to the high temperature stability of anatase phase.

4 Conclusions

Ceria doped titania has been prepared from titanyl oxysulphate through the aqueous sol–gel method and was characterized using X-ray diffraction, diffuse reflectance spectra and surface area measurements. The preparation method consists of addition of the dopant to a sol of the titania, which resulted in a homogenous distribution of dopant in the tiatnia matrix. The surface area of the doped titania after heating to 500 °C is 97 m2 g−1 where as undoped one under identical conditions shows only 48 m2 g−1. The crystallite size of the titania is also considerably reduced by doping, further and there by the dopant increases the anatase phase stability of titania up to 900 °C. The diffuse reflectance spectrum shows that the absorption values undergo red shift and maximum shift are for 5-mole% doping. The present study resulted in a novel process of doping cerium oxide to nano titania where for a critical dopant composition of 5-mole%, the specific surface area was 97 m2 g−1, anatase phase stability upto 900 °C and the UV absorption shifted to longer wavelengths which could leads to final use as a high temparature catalyst and also as photocatalyst.

References

Brikefield LD, Azad AM, Akbar SA (1992) J Am Ceram Soc 75:2964

Regan BO, Gratzel M (1991) Nature 353:737

Lawandy NM, Balachandran RM, Gomes ASL, Sauvaln E (1994) Nature 368:436

Beck DD, Siegel RW (1992) J Mater Res 7:2840

Wei ZB, Yan W, Zhang H, Ren T, Xin Q, Li Z (1998) Appl Catal A: Gen 167:39

Alejandre AG, Cruz MG, Trombetta M, Busca G, Ramirez J (1998) Microporous Mesoporous Mater 23:265

Kostov I (1973) Minerology, 3rd ed. Nauka, Izkustia, Sofia

Zzanderna AW, Rao CNR, Honig JM (1958) Trans Faraday Soc 54:1069

Yoganarasimhan SR, Rao CNR (1962) Trans Faraday Soc 58:1579

Hirano M, Nakahara C, Ota K, Tanaike O, Inagaki M (2003) J Solid State Chem 170:39

Rao CNR, Turner A, Hanig JM (1959) J Phys Chem 11:173

Ranjit KT, Willner I, Bossmann SH, Braun AM (2001) Environ Sci Technol 35:154

Yang J, Ferreira JMF (1998) Mater Lett 36:320

LeDuc CA, Campbell JM, Rosssin JA (1996) Ind Eng Chem Res 35:2473

Lin J, Yu JC (1998) J Photochem Photobio A: Chem 116:63

Mohamed MM (2004) Applied Catal A: Gen 267:135

Rynkowski J, Farbotko J, Touroude R, Hilaire L (2000) Appl Catal A: Gen 203:335

Shi ZM, Liang KM, Zhang Q, Gu SR (2001) J Mater Sci 36:1

Shi ZM, Liu Y, Yang WY, Liang KM, Gu SR (2002) J Eur Ceram Soc 22:1251

Shi ZM, Liang KM, Gu SR (2001) Mater Lett 51:68

Shi ZM, Pan F, Liu DY, Liang KM, Gu SR (2002) Mater Lett 57:409

Sivakumar S, Krishnapillai P, Mukundan P, Warrier KGK (2002) Mater Lett 57:330

Zhang Y, Xiong GX, Yao N, Yang W, Fu XZ (2001) Catal Today 68:89

Bai W, Choy KL, Sytelzer NHJ, Schoonman J (1999) Solid State Ionics 116:225

Spurr RA, Myers H (1957) Anal Chem 29:760

Suzana M, Francisco P, Valmer Mastelarno R (2002) Chem Mater 14:2518

Yan QZ, Xin TS, Huang ZY, Ge C (2006) J Eur Ceramic Soc 26:915

Sibu CP, Rajesh kumar S, Mukundan P, Warrier KGK (2002) Chem Mater 14:2876

Baiju KV, Sibu CP, Rajesh K, Krishna Pillai P, Mukundan P, Warrier KGK, Wunderlich W (2005) Mater Chem Phys 90:123

Hidalgo MC, Bahmann D (2005) Appl Catal B: Environ 61:359

Shi ZM, Yu WG, Bayer X (2004) Scripta Mater 50:885

Baiju KV, Periyat P, Pillai PK, Mukundan P, Warrier KGK, Wunderlich W (2007) Mater Lett 61:1751

Acknowledgments

The authors acknowledge the members of Materials and Minerals division for providing general assistance. One of the authors, Pradeepan Periyat is grateful to CSIR, India, for providing financial support. Special thanks to Dr. Hugh Hayden, Dr. Suresh Pillai and Dr. S. K. Ghosh for their valuable suggestions during the manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Periyat, P., Baiju, K.V., Mukundan, P. et al. Aqueous colloidal sol–gel route to synthesize nanosized ceria-doped titania having high surface area and increased anatase phase stability. J Sol-Gel Sci Technol 43, 299–304 (2007). https://doi.org/10.1007/s10971-007-1583-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-007-1583-1