Abstract

Real-time monitoring of uranium concentration in molten salt reactors (MSR) is crucial for reactor operation and safety. However, conventional analytical methods cannot provide accurate results when uranium concentrations exceed approximately 4 wt%. We report an electrochemical technique based on repeating chronoamperometry (RCA) for precise and accurate measurements of uranium concentrations > 10 wt% in a NaCl–MgCl2–UCl3 molten salt. Uranium concentration was measured in a molten salt containing 5–12.5 wt% of uranium chloride with high precision and a linearity close to 1. The RCA technique can be used for measuring the concentration of nuclear fuel in MSRs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently, next-generation nuclear reactor designs and technologies are attracting considerable global attention. The molten salt reactor (MSR) is a fourth-generation reactor system [1, 2]. The MSR uses liquid nuclear fuel, which can prevent serious accidents caused by coolant loss. The liquid nuclear fuel is an added safety measure, as the molten salt fuel solidifies at room temperature when a reactor explosion or other leakage incidents occur [3,4,5,6].

The liquid nuclear fuel used in the MSR is usually mixed with an actinide fuel salt in chloride- or fluoride-based molten salts. Among the various molten salts used, NaCl–MgCl2 (in the form of a eutectic mixture) has been identified as a promising material. The MSR molten salt contains > 10 wt% uranium chloride nuclear fuel [7]. As the MSR operates, the quantity of dissolved uranium chloride reduces gradually, and the resulting fission products dissolve in the molten salt [8]. Therefore, the total uranium concentration in the molten salt is the fundamental functional parameter needed to evaluate the operational life and efficiency of MSR reactors. Furthermore, real-time concentration monitoring of uranium is essential to the effective functioning and operation, as well as the safety protocol of the MSR [9].

Several analytical techniques, such as spectroscopy and electrochemical methods, can be used to measure the concentration of nuclear fuel in molten salts [10,11,12,13,14,15,16,17,18]. However, UCl3 in the reactors is generally used at a concentration of > 10 wt%; this concentration is difficult to probe using conventional measurement methods [7, 19, 20]. For example, for spectroscopic measurements, uranium ions (U3+) display a very large molar absorption coefficient, owing to their dark maroon color, and it is difficult to measure their absorbance at high concentrations [11, 13]. This difficulty is experienced even with conventional electrochemical methods. The electrochemical methods are problematic because of issues such as the superposition and nonlinearity of the peak currents of various components at high concentrations, which make it difficult to measure the concentration of some elements such as U3+ and Pu3+, accurately [19].

Cyclic voltammetry (CV) is the most commonly used electrochemical method [12, 14, 19,20,21,22]. Solute depletion occurs at the electrode/solution interface when an overpotential is applied, and the current is gradually reduced, resulting in a peak current. The peak current can be used to determine the concentration of the element using the Randles–Sevcik and Berzins–Delahay equations for soluble–soluble and insoluble–soluble species, respectively [23]. However, the peak current may not provide accurate information regarding the concentration of the solute in the molten salt because it varies depending on the structure of the electrodeposit, concentration of the solute, and electrodeposition mechanism [23]. In addition, when measuring a high concentration of solute using CV, an elevated concentration of solute is located very close to the electrode, which reacts during the potential application, producing a large amount of current. Therefore, the peak current at the reduction potential might not be proportional to that of the solute concentration. Hence, it is difficult to measure high concentrations of uranium using CV because the electrochemical reaction does not follow the usual mechanisms of electrodeposition and dissolution. Consequently, it is necessary to develop a new, improved, and accurate methodology for the measurement of high concentrations of uranium for long-term reactor operation and large-scale processes.

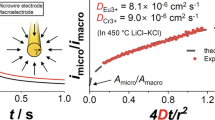

The concentrations of metal ions in a molten salt can be measured using repeating chronoamperometry (RCA) [24]. RCA is a method for reacting elements with working electrodes at regular time intervals using a specific potential (Fig. 1) [24]. The key factors in this method are the potential and current. RCA can be applied to the electrodeposition and dissolution potential regions to measure high concentrations of materials with excellent stability and accuracy because it is not affected by changes in the electrochemical environment owing to the high concentrations of analytes. Specifically, RCA is advantageous for measuring the concentrations of metal ions in molten salts [24]. RCA provides exact information on the high concentration of metal ions. Additionally, RCA can be continuously run throughout the process. Moreover, the RCA measurements do not interfere with the main operating system because solutes do not accumulate around the electrode. Finally, the RCA measurement system is compatible with the high-temperature molten salt system. In this work, we studied if the RCA could be used to quantify uranium in molten NaCl–MgCl2–UCl3 that contains > 10 wt% of the uranium salt.

Experimental

All experiments were performed in a glove box under an Ar atmosphere while maintaining the O2 and H2O concentrations at < 1 ppm. NaCl (99.99%) and MgCl2 (99.9%) were obtained from Sigma-Aldrich. NaCl (58 wt%) and MgCl2 (42 wt%) were mixed and heated to 450 °C in a glove box to accomplish a eutectic melt.

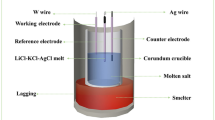

UCl3 was prepared via a chemical reaction between metallic U and NH4Cl [25]. The desired concentration 5–12.5 wt% of UCl3 was dissolved in the NaCl–MgCl2 melt (7.40 g) before each experiment. The concentration of UCl3 in the melt was confirmed using an inductively coupled plasma-atomic emission spectrometer after each experiment. The electric furnace used in this work was specially designed and installed at the bottom of the glove box. A digital temperature controller (Dae Jin instrument) was used for heating the reactor. This particular electric furnace adjusted the temperature of the furnace and prevented oxygen from entering the glove box. Figure 2 shows a schematic of the electrochemical cell used in this work.

The electrochemical studies were performed in a quartz tube (outer diameter, 20 mm, and wall thickness, 2 mm). W wires (Alfa Aesar; diameter, 0.2 mm) were used as both the working and counter electrodes. The active surface area of the working electrode was 0.063 cm2. Each W wire electrode was mechanically polished with sandpaper before use. An Ag wire in contact with 2.5 wt% AgCl in the NaCl–MgCl2 eutectic melt was used as the reference electrode. Electrochemical measurements were performed using a Gamry Reference 3000 potentiostat. The effect of the uranium concentration on the quantity and rate of electrodeposition and dissolution was investigated via electrochemical experiments. Uranium concentrations were measured at 2.5, 5, 7.5, 10, and 12.5 wt%.

Results and discussion

Figure 3 shows the results of the CV measurements in the NaCl–MgCl2 melt at 580 °C. Here, the electrochemical properties of uranium are investigated using an inert W wire working electrode. When UCl3 is not included in the molten salt, the potential window of the NaCl–MgCl2 melt ranges from + 0.50 V to − 1.46 V. The potential window is limited by the evolution of chlorine and Mg electrodeposition. Here the potential window is consistent with that in the literature [26]. The electrodeposition reaction (Fig. 3a) of U, that is, the conversion of U(III) to U(0), occurs at − 1.25 V [11] (Eq. (1)). The oxidation process, in which the electrodeposited uranium is redissolved, occurs during the reverse scan (Eq. (1)) The redox currents are shown by the U(III) and U(IV) redox reactions in the − 0.15 V region, as shown in Eq. (2). Additional currents are observed at − 0.6 V and − 1.2 V, which can be attributed to the dissolution-formation of the sub-halide complexes [27]. The peak potentials of the reactions shift in the positive direction by approximately − 0.2 V compared with that of the LiCl–KCl melt reported in the literature [27]. This difference can be attributed to the higher temperature of the melt and because a different melt is used as the electrolyte. As the uranium concentration increases, both the reaction current and the peak current of the U3+/4+ and U0/3+ redox reactions also register an increase as has been seen in previous studies (CV results in Fig. 3b) [12, 14].

The RCA experiments were designed to repeatedly apply a reduction–oxidation potential in the NaCl–MgCl2–UCl3 molten salt which contains various UCl3 concentrations. Electrodeposition was performed at − 1.4 V for 5 s and dissolution at − 1.0 V for 5 s (Fig. 1). This process was repeated to determine the effect of varying the uranium concentration (from 2.5 to 12.5 wt%).

Figure 4a shows the RCA measurements obtained at varying UCl3 concentrations in the NaCl–MgCl2–UCl3 molten salt at 580 °C. The results were obtained by the repeated application of electrodeposition-dissolution potentials. Figure 4b shows an example of the reduction and oxidation currents for a set of electrodeposition and dissolution reactions. As the concentration increases, the negative current of the uranium electrodeposition reaction increases sequentially. However, in the dissolution (oxidation) reaction, the dissolution time increases, but the magnitude of the oxidation current does not change markedly. This finding may be due to following factor: the oxidation reactions occur with the fastest reaction rate as soon as the oxidation potential is applied, resulting in a similar magnitude of the current. Additionally, the dissolution time is dependent on the quantity of the electrodeposit, i.e., the concentration dependence.

The electrodeposition current of the chronoamperometry becomes constant after approximately 2 s, and this is called the steady-state current (SSC) (Fig. 4b). The passed charge can be determined by integrating the plot of current versus time. In the present study, the high-concentration measurement of RCA is investigated by examining the relationship between passed charge (or SSC) and concentrations of uranium. Figure 5 illustrates the SSC of the RCA method (as shown in Fig. 4) as a function of the uranium concentration. The SSCs in the electrodeposition reactions increase linearly with an increase in the concentration of uranium. However, the SSC which is measured at a concentration of 2.5 wt% deviates slightly from the linear. The coefficient of determination, R2, is 0.9749 when 2.5 wt% uranium salt is used, but increases to 0.9993 at > 5 wt%. This may be because ion diffusion has a greater influence on the reaction at low concentrations.

Figure 6 shows the passed charge (as determined by the RCA method shown in Fig. 4) as a function of concentration. By integrating the current measured by the RCA over time, the passed charge can be calculated as shown in Eq. (3).

where I is current (C/s) and t is time(s). The charge calculated by integrating both the oxidation and reduction reactions increases linearly with an increase in concentration. The linear regression analysis of the passed charge is also shown in Fig. 6. The results of the linear regression are expressed as Eq. (4) and (5):

where y and x are the variables for the passed charge (C) and the concentration (wt%) of UCl3, respectively. Here the y-intercepts are similar, but the slope of the line for the cathodic reaction is greater than that for the anodic reaction. This trend may occur because the non-Faradaic current (charging current) flowing during the electrodeposition is higher than that for the dissolution reaction [27]. We also compared R2 values with and without the data point for 2.5 wt% uranium, as depicted in different colors. When the data point for 2.5 wt% uranium is included, the coefficient of determination of the linear regression at the anode is 0.9857 and increases to 0.9983 for uranium concentrations > 5 wt%. The cathode performance also improves from 0.9960 to 0.9999. This finding confirms that the RCA method can be used for the measurement of high uranium concentrations of ≥ 5 wt%, because the coefficient of determination is approaching 1.

Conclusion

In this study, we investigated the applicability of an electrochemical method to accurately measure the high concentration of uranium dissolved in a high-temperature molten salt, namely, NaCl–MgCl2 which may be primarily considered as a coolant in an MSR. The electrochemical measurement, repeating chronoamperometry, proved to be an effective technique for determining the real-time concentration of uranium, when it was performed with a salt containing an increasing concentration of uranium chloride. The higher concentrations of uranium chloride (i.e., ≥ 5 wt%) dissolved in a high-temperature molten salt were directly proportional to the electrochemical charge, and the R2 value of the linear regression was measured to be close to 1. These findings confirmed that RCA measurements could be used for nuclear material accountancy and could play a pivotal role in the nuclear safeguarding of MSRs.

References

Serp J, Allibert M, Beneš O, Delpech S, Feynberg O, Ghetta V, Heuer D, Holcomb D, Ignatiev V, Kloosterman JL, Luzzi L, Merle-Lucotte E, Uhlíř J, Yoshioka R, Zhimin D (2014) The molten salt reactor (MSR) in generation IV: overview and perspectives. Prog Nucl Energy 77:308–319

Locatelli G, Mancini M, Todeschini N (2013) Generation IV nuclear reactors: current status and future prospects. Energy Policy 61:1503–1520

Badawy ME (2013) Safety assessment of molten salt reactors in comparison with light water reactors. J Radiat Res Appl Sci 6(2):63–70

Cottrell W, Hungerford H, Leslie J, Meem J (1955) Operation of the aircraft reactor experiment; Technical Report; Oak Ridge National Lab., Tenn., Oak Ridge, TN

Luo R, Liu C, Macián-Juan R (2021) Investigation of control characteristics for a molten salt reactor plant under normal and accident conditions. Energies 14(17):5279–5302

Porter T, Vaka MM, Steenblik P, Della Corte D (2022) Computational methods to simulate molten salt thermophysical properties. Commun Chem 5(1):69–84

Yeon J-W et al (2014) Research on the actinide chemistry in molten salt. KAERI/RR-3778/2014, Korea Atomic Research Institute

Ignatiev V, Merzlyakov A, Afonichkin V, Khokhlov V, Salyulev A (2002) Transport properties of molten-salt reactor fuel mixtures: the case of Na, Li, Be/F and Li, Be, Th/F salts. In: Proceedings of the seventh information exchange meeting on actinide and fission product partitioning and transmutation, Jeju, pp 14–16

Cumberland RM, Yim M-S (2014) Development of a 1D transient electrorefiner model for pyroprocess simulation. Ann Nucl Energy 71:52–59

Park Y-J, Bae S-E, Cho Y-H, Kim J-Y, Song K (2011) UV–vis absorption spectroscopic study for on-line monitoring of uranium concentration in LiCl–KCl eutectic salt. Microchem J 99:170–173

Lambert H, Kerry T, Sharrad CA (2018) Preparation of uranium(III) in a molten chloride salt: a redox mechanistic study. J Radioanal Nucl Chem 317(2):925–932

Masset P, Bottomley D, Konings R, Malmbeck R, Rodrigues A, Serp J, Glatz J-P (2005) Electrochemistry of uranium in molten LiCl-KCl eutectic. J Electrochem Soc 152(6):A1109–A1115

Polovov IB, Volkovich VA, Charnock JM, Kralj B, Lewin RG, Kinoshita H, May I, Sharrad CA (2008) In situ spectroscopy and spectroelectrochemistry of uranium in high-temperature alkali chloride molten salts. Inorg Chem 47(17):7474–7482

Hoover RO, Shaltry MR, Martin S, Sridharan K, Phongikaroon S (2014) Electrochemical studies and analysis of 1–10 wt% UCl3 concentrations in molten LiCl-KCl eutectic. J of Nucl Mater 452(1–3):389–396

Fujii T, Uda T, Fukasawa K, Uehara A, Sato N, Nagai T, Kinoshita K, Koyama T, Yamana H (2013) Quantitative analysis of trivalent uranium and lanthanides in a molten chloride by absorption spectrophotometry. J Radioanal Nucl Chem 296:255–259

Shaltry MR, Allahar KN, Butt DP, Simpson MF, Phongikaroon S (2020) Electrochemical impedance spectroscopy and cyclic voltammetry methods for monitoring SmCl3 concentration in molten eutectic LiCl-KCl. J Nucl Fuel Cycle Waste Technol 18(INL/JOU-15-34095-Rev000):1–18

Kim T-J, Jung Y, Kim S-H, Paek S-W, Ahn D-H, Lee H-S (2011) Elucidation of electrode reaction of EuCl3 in LiCl-KCl eutectic melts through CV curve analysis. Bull Korean Chem Soc 32:863–866

Wang CS, Liu Y, He H, Gao FX, Liu LS, Chang SW, Guo JH, Chang L, Li RX, Ouyang YG (2013) Electrochemical separation of uranium and cerium in molten LiCl-KCl. J of Radioanal and Nucl Chem 298:581–586

Zhang C, Wallace J, Simpson MF (2018) Electrochemical measurement of high concentrations of UCl3 and GdCl3 in molten LiCl-KCl eutectic. Electrochim Acta 290:429–439

Elgrishi N, Rountree KJ, McCarthy BD, Rountree ES, Eisenhart TT, Dempsey JL (2018) A practical beginner’s guide to cyclic voltammetry. J Chem Educ 95(2):197–206

Kim D-H, Park T-H, Bae S-E, Lee N, Kim J-Y, Cho Y-H, Yeon J-W, Song K (2016) Electrochemical preparation and spectroelectrochemical study of neptunium chloride complexes in LiCl–KCl eutectic melts. J Radioanal Nucl Chem 308(1):31–36

Yoon D, Pormatikul J, Shaltry M, Phongikaroon S, Allahar K (2019) Determination of kinetic properties of Sm(III)/Sm(II) reaction in LiCl–KCl molten salt using cyclic voltammetry and electrochemical impedance spectroscopy. J Radioanal Nucl Chem 322(2):1031–1037

Williams T, Shum R, Rappleye D (2021) Review—concentration measurements in molten chloride salts using electrochemical methods. J Electrochem Soc 168:123510–123523

Kim D-H, Bae S-E, Park T-H, Kim J-Y, Lee C-W, Song K (2014) Real-time monitoring of metal ion concentration in LiCl–KCl melt using electrochemical techniques. Microchem J 114:261–265

Yoon D, Paek S, Lee C (2022) Chlorination of uranium metal to uranium trichloride using ammonium chloride. J Radioanal Nucl Chem 331(5):2209–2216

Ding W, Bonk A, Gussone J, Bauer T (2018) Electrochemical measurement of corrosive impurities in molten chlorides for thermal energy storage. J Energy Storage 15:408–414

Kim D-H, Bae S-E, Park T-H, Kim J-Y, Park Y-S, Park YJ, Cho YH, Yeon J-W, Song K (2014) electrochemical reactions of uranium trichloride on a graphene surface in LiCl-KCl molten salts. Electrochem 82(6):462–466

Acknowledgements

This work was supported by the Molten Salt Reactor Development Agency grant funded by the Korea government (the Ministry of Science and ICT) (Project No. RS-2023-00261146). This work was also supported by the Korea Atomic Energy Research Institute Program (Project No. 522330-22). CJ acknowledges the National Research Foundation of Korea (NRF) for grants (2021M2E1A1085202).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jung, CY., Kim, TH. & Bae, SE. Real-time monitoring of uranium concentration in NaCl–MgCl2–UCl3 molten salt. J Radioanal Nucl Chem 332, 5233–5238 (2023). https://doi.org/10.1007/s10967-023-09000-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-023-09000-5