Abstract

Delonix regia pods have been used to produce high-efficiency and low-cost activated carbons using different activation methods. The ability of these prepared sorbents to remove cations [137Cs, 85Sr, La(III), Eu(III), Co(II), U(VI)] and anions [75Se, Cr(VI), Mo(VI)] was evaluated in mono-component systems and the sorbents number 11, 13, 25, and 35 showed high removal efficiency. These sorbents also show the high ability to remove organic pollutants such as methylene blue and phenol. This study highlighted the extensive applicability of these low-cost sorbents in the sequestration of anionic and cationic radionuclides from real radioactive wastewaters and different environmental samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Environmental pollution is a serious problem due to increasing anthropogenic activities associated with the growth of technology. The environment is significantly affected by the radioactive contaminants that are released from nuclear fission reactors, TENORM, and medical wastes as well as nuclear accidents in Chernobyl and Fukushima, which sparked the attention of scientists to solve this problem [1, 2]. Radioactive waste includes several radioisotopes that are extremely dangerous to humans and the surrounding environment as a result of harmful ionizing radiation. The degree of risk is determined on the basis of the concentration of radioactive waste, the amount of energy released from it, the type of radiation, and the distance between the body parts and the radioactive source [2]. Organic pollutants (including phenolic derivatives, polycyclic aromatic compounds, extractants and analytical reagents) are often found in the environment as a result of their wide laboratories and industrial uses. In scientific laboratories many organic compounds (PAR, Arsenazo-III, HDEHP, Methylene blue, Surfactants, EDTA, DTPA and TBP) are used in the extractive separation and determination processes of many metals. They are common contaminants in wastewater and many of them are known to be very toxic (carcinogenic and harmful) to organisms even at low concentrations. Hard legislation on the evacuation of these toxic organic makes it then necessary to develop various efficient technologies for the extirpation of organic pollutants from wastewater [3, 4]. Although many methods have been developed to concentrate or process metal ions from aqueous solutions, few of them have been accepted because of the high cost, and low efficiency. Sorption is an effective method for treating metal ions and Organic species from wastewater, and water supplies. Activated carbon has also proven to be highly effective in treating radioactive liquid wastes due to its tendency to some ions or groups of ions from acid and alkaline solutions. Moreover, its chemical, radioactive, and thermal stability, as well as its rigid porous structure and mechanical strength, give it significant advantages over other adsorbents [5]. The use of diverse natural biomass is important for the production of activated carbon because it is the most abundant renewable raw material [6]. Biomass refers to organic matter that has ability for degradation by microorganisms and comes from plants and animals. According to another definition, biomass refers to wood, short-rotating woody crops, agricultural waste, short-cycle herbaceous species, industrial waste, paper waste, municipal solid waste, waste from processing food, algae waste and a host of other materials [7]. Despite the presence of commercial activated carbon in many countries, the prepared one by different ways has many distinctive properties, the most important ones are its renewability, easy to recycle, controlling effective surface function groups, specific surface area, pore radius and pore volume [8,9,10,11,12]. This research completely focused on preparing of different activated carbons as a low-cost sorbents from Delonix regia pods (DRP). These pods fall from the trees to the ground after they dry up, placing a heavy burden on the environment as solid waste. Environmentally friendly utilization of these wastes as starting materials in production of so-called activated carbons is an important issue. Therefore, the main objective of the current work is to prepare different activated carbons from DRP using different activation methods, and explore the efficiency of sorbents prepared towards the removal of anionic, cationic radionuclides and some organic species ions such as 137Cs, 85Sr, La(III), Eu(III), Co(II), U(VI),75Se, Cr(VI), Mo(VI), methylene blue (MB) and phenol (P).

Experimental

Materials and reagents

Delonix regia pods (DRPs) were collected, dried, and cut as agricultural waste from the area of Atomic Energy Authority environment in Abu Zaabal, Cairo, Egypt. Then use it to produce activated carbons through various activation methods. All chemicals and reagents used in this work were of an analytical grad (A.R) and were used without further purification. The solutions of metal ions under study (Cs, Co and Sr) were prepared by dissolving a known weight of chloride salts in deionized distilled water (DDW). Oxides were also used to prepare the solution of La and Eu ions. Selenium solution used in the experiments was prepared by dissolving Na2SeO3 (from Aldrich) in DDW. Sodium-dichromate and ammonium-molybdate salts were also used in the preparation of chromium and molybdenum ions solutions, respectively. In the case of uranium solution, which was obtained by dissolving a certain weight of uranium nitrate oxide (UO2(NO3)2) in DDW. 1000 mg/L of a stock solution from MB and P (purchased from Aldrich), was prepared by dissolving an appropriate amount of them in 100 mL DDW. The radio-isotopes of 85Sr and 75Se used as a tracer in the current study were prepared by neutron irradiation in the second Egyptian research reactor at Inshas site. The radiotracer of 137Cs was purchased (Institute of Radioisotopes Co., Ltd.).

Instruments and apparatus

The remaining concentrations of some sorbat species were determined spectrophotometrically (Shimadzu1601, Tokyo, Japan). The activities of different isotopes were measured using a high accuracy (7.5%) and 30% efficiency using a NaI(Tl) γ-ray spectrometry model 802-3X3 Canberra, USA. The pH value of the solutions was determined using a digital instrument Hana brand pH Meter, Italy. The functional groups on the surface of the selected activated carbon samples were investigated by Fourier transform infrared (FT-IR) using Nicolet spectrometer, Meslo, USA with an absorbance range 4000–400 cm−1. While the morphology for the same prepared samples was conducted using a scanning electron microscope (SEM), JOEL, JEM 1000CX, USA. Other parameters such as porous properties of the DRP-activated carbons was characterized by its N2 adsorption/desorption isotherm at 77 K using Quanta chrome Nova 1000e series, Model 184, USA. The specific surface area was determined by analyzing the adsorption isotherm using the Brunauer–Emmett–Teller (BET) equation and density functional theory (DFT) models, with calculations performed using Micromeritics and Quantachrome software (Version 1.01, Quantacrome Instruments, Boynton Beach, FL, USA). The elemental compositions (C, H, N) content of sorbents was analyzed using a CHNS analyzer (Perkin Elmer Series II 2400).

Preparation of DRP-activated carbon

The prepared activated carbons are divided into five groups based on the method and conditions of preparation. Group I: Carbonization process A known weight of 30 g of crushed DRPs was taken and inserted into a tube furnace model (Barnstead Thermolyne F21130). The oven temperature was raised gradually (50 °C/15 min.) until it reached the required degree between 500 and 800 °C, and the sample was left for specified periods between 30 and 120 min. The percentage yield of each carbon was calculated from Eq. 1:

Group II: Physical activation Following the same previous steps and at 350 °C, pure air, pure steam or pure carbon dioxide is allowed to bass through the heated mass and the temperature is rising continuously until 600 °C. The product is held at this temperature for 1 h and finally stored in sealed bottles for later use.

Group III, IV, and V Chemical activation DRP was activated chemically with different acids, bases or salts.

-

a.

Acid activation 30 g of the crushed precursor was immersed in 100 mL solution of different concentrations (30–70%) by weight of hydrochloric, sulfuric, nitric, or phosphoric acid with stirring to ensure the solution is penetrated throughout the origin sample (precursor). The mixture is left overnight at room temperature and transferred into the thermal reactor for treatment after that. With the same previous preparation steps, the product is washing thoroughly with hot DDW to remove the excess acid and adjust pH to ≈ 6.5. Finally, it is dried at 110 °C, and kept in suitable bottle.

-

b.

Base activation Soak a known amount of DRP in 100 mL solution of pre-diluted 5%, 10%, and 30% Wt of NaOH or KOH and follow the same previous steps to obtain a final activated carbon.

-

c.

Activation with salts By following the same previous preparation steps with changing the activation conditions, using mineral salts solutions of 2%, 5%, and 10% wt of FeCl3 or ZnCl2, except KMnO4 the percent was 0.5%, 2%, and 5% Wt. The same procedure was applied as described above with acids at the same activation temperatures.

Characterization of DRP-activated carbons

Ash content 1.0 g of the prepared carbon was placed in a clean dried pre-weighed crucible, heated in a muffle furnace at 900 °C for 1.5 h. The crucibles were removed from the muffle furnace and allowed to cool in a dryer and re-weighed. Ash percent was calculated as in Eq. 2 [13, 14].

pH measurements

For measuring the initial pH of the adsorbent, 1 g suspension is immersed in 50 mL DDW and then heated to approximately 90 °C and stirred for 20 min [15]. The suspension is allowed to cool to room temperature and the pH was measured by pH meter. The different parameters including yield, ash and burn off for the prepared DRP-activated carbons were finally determined.

Sorption process

The literatures report that the sorption of MB and P from aqueous phase is a useful tool for determining activated carbon production. MB was chosen because of its well-known strong adsorption onto solids and its recognized usefulness in characterization of sorbents [16]. MB is well known cationic dyes, which have been widely used in textile, printing, and research laboratories. Moreover, MB is the most common basic dye used in cotton, silk, and wood industries [16]. The ability of activated carbon towards the removal of P is also very important since it is one of the most frequent contaminant found in industrial wastewater, which is harmful to human health as well as the environment.

The uptake of MB and P has been carried out using batch technique as follows; 0.1 g of different prepared sorbents was added to 25 mL aqueous solutions of 100 ppm concentration (in the case of MB or P) The suspensions were kept in a shaker at 150 rpm for 24 h to reach equilibrium. The supernatant solutions were filtered and the residual concentrations were measured spectrophotometrically at wavelengths of 664 ± 1 nm for MB and 270 ± 1 nm for P.

Generally, The sorption of cationic and anionic species was carried out by agitating 0.02 g of some prepared activated carbons (samples no. 7, 10, 11, 12, 13, 17, 19, 23, 25, 28, 31, 35, and 37, with 5 mL of cations [137Cs,85Sr, La(III), Eu(III), Co(II), U(VI)] and anions [75Se, Cr(VI) and Mo(VI)] solutions of concentration 20 mg/L in the sealed bottle (50 mL) at 25 °C for 24 h. Generally, the pH was set at about pH 3 in the case of the anion species and at a pH 5 in the case of cation species. Aqueous solutions cationic and anionic species were prepared by dissolving known amounts of corresponding salts of these species in DDW, which were labeled with [137Cs, 85Sr and 75Se in the case of Cs(I), Sr(II) and Se(IV)]. Suspensions were filtered and the remaining activities or concentrations of ions in the filtrates were determined spectrophotometrically or radiometerally. Equations 3 and 4 were used to calculate the percent efficiency of sorbents to remove 137Cs, 85Sr, La (III), Eu(III), Co (II), U (VI) cations, 75Se, Cr(VI), Mo(VI) anions and MB and P using different types of prepared activated carbons.

where Co and Ce are the initial and the equilibrium of adsorbate concentrations (mg/L−1), Ao and Ae are the initial and final activities per unit volume for the corresponding radioisotopes, respectively.

All the trials were repeated at least two separate experimental runs and the mean values have been reported. Also, blank experiments were proceeded to ensure that no sorption was taking place on the used bottles walls.

Results and discussion

The commercially available activated carbons produced from different precursors are still considered as an expensive one. Several waste and bio-mass derived sorbents are presented for the removal of organic compound, metals, and toxic pollutants from aqueous medium. To meet the wide scale application and demand of activated carbon, there is an immediate need of alternative low-cost precursor and procedure [8,9,10,11]. Table 1 indicates the number of activated carbon samples prepared from Delonix regia (DRPs) waste via different preparation methods using carbonization in varying degrees of temperatures and physical activation in the presence of oxidizing agents such as pure steam or fresh air or carbon dioxide as well as the chemical activation processes in the presence of different activating agents using different acids, bases and salts. Physical activation is a two-step process that includes the process of thermal decomposition in a neutral atmosphere and then activation in the presence of oxidizing gases such as pure air or pure steam or pure carbon dioxide with raising temperature [17]. This method is characterized by its ability to produce activated carbon of porous structure and good physical strength, which is a cheap way to obtain activated carbon and is considered a green way because it is free of chemicals [18,19,20].

The chemical activation process is known as wet oxidation and it is usually used for raw materials that contain cellulose, such as wood, sawdust, a grew waste, or fruit seeds. Organic precursors are activated in the presence of chemicals at high temperatures [21, 22]. The chemicals help to penetrate deep into the precursor structure leads to the development of small pores in the produced activated carbon, thereby increasing its surface area [23]. The properties of the final activated carbon are affected by some factors such as impregnation ratio and method, temperature, the final temperature of carbonization, carbonization time, activation space (under atmospheric conditions) [24, 25]. In comparison to the different methods of activation, chemical activation is considered more economical because it requires less activation temperature, shorter processing time to achieve higher surface areas and pore volumes [26]. Each chemical has a different effect on the precursors and thus affects sorption behavior. The main chemicals that were used possible stimulants are KOH, NaOH, and KMnO4, HCl, H2SO4, HNO3, H3PO4, FeCl3 and ZnCl2.

Characterization of the DRP-activated carbons

Some physical and chemical properties of the prepared DRP-activated carbons were investigated using the different techniques. Physico-chemical characterizations of prepared sorbents derived from local Delonix regia pods (DRPs) waste are summarized in Table 2. The data indicate a difference in their properties according to the method of preparation. The prepared sorbents from DRPs by carbonization and physical methods exhibit basic surfaces and this may be due to inorganic ash content comes from the precursor as reported by Hassler [27]. The correlation between pH and ash content values is stable. This indicates that the ash is insoluble in water, so the prepared sorbents may have good and suitable applications in water treatment. Systematic checks were carried out on the set of prepared sorbents groups to find the best sorbent that combine good sorption capacity with fast and efficient separation.

The pore structure parameters, including the BET surface area, pore volume and pore diameter of the adsorbents, played a crucial role in the process of the adsorption. The result of proximate analysis of the selected sorbents no. 11, 13, 25, and 35 according to Table 3 was determined. Characteristics of prepared four sorbents were illustrated in Table 3 where higher specific surface area and pore volume were observed which indicates the four activated carbons as an efficient sorbents. Moreover, H3PO4 activation process made more porous structure.

FTIR spectrum revealed the chemical functionalization of sorbent surface. The surface functional group is a significant characteristic of the carbonaceous sorbents since it determines the surface properties of the sorbents and has very important role on their behaviors. The FTIR spectra of the DRP-activated carbons were presented in Fig. 1. It is noted that the four sorbent samples correspond in most of the bands that appear and this is because the origin of the starting material (precursor) used in the preparation processes from the same source. The appearance of very strong peaks (3500–3300 cm−1) for all samples is attributed to the O–H stretch vibrations [28].The bands from 3000 to 2800 cm−1 show the presence of an aliphatic –CH stretching peak. The band at 1740 cm−1 indicates the existence of the stretching vibrations peak of the C=O group. The peak noted in the range 1625–1610 cm−1 could be attributed to the presence of C=C aromatic skeletal stretching [29, 30]. The peak detected at 1570 cm−1 could be attributed to the carboxylic, and carboxylate anion stretching mode. The peaks detected at 1450 and 1420 cm−1 were assigned to C–H asymmetric bending bands. The peaks detected at 1375 and 1300 cm−1 were assigned to C–H asymmetric and symmetric bending bands. The peaks between 1260 and 1000 cm−1 were associated with –C–O stretching and –OH bending modes of alcoholic, phenolic, carboxylic, ester, or the P=O bond in phosphate esters in the case of activation with H3PO4 acid [31]. These observations indicate that the carboxylic group had been successfully introduced on the surface of sorbents. The peak was appeared at 600–550 cm−1 to distinguish sorbent prepared with iron chloride as a result of Fe–O bond formation [32, 33].

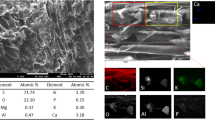

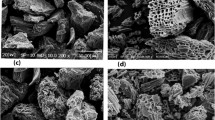

SEM was applied to deduce the surface physical morphology of the prepared carbon samples. The SEM micrographs of the prepared activated carbon samples obtained from DRPs by physical and chemical methods are investigated. Figure 2 shows the effect of the preparation method and the activating agents used on the surface morphology of the prepared sorbents. More rough and porous surface morphology is noticeable in the case of chemical activations than physical activation. It seems that the observed changes in pores and their size are fully consistent with those obtained from the surface area measurement device. Figure 2 also confirmed the large porous structure of samples.

Adsorbent having large pore size has the higher sorption capacity. Furthermore highly porous sorbents which have organic functional groups have the higher ions capturing capacity The SEM images confirming the porous nature of prepared DRP-activated carbons which could reinforce the sorption of different ion species.

CHNS elemental analyses supply a means for the fast determination of carbon, hydrogen, nitrogen and sulphur in different activated carbons. CHNS values of the prepared DRP-activated carbons by different activation (with acids, bases and salts) shown in Table 3. Generally, the relative % of C, H and N elements increased after base treatment because of the removal of silica from the starting material. Then, the % of C element was increased after activation process. However, H and N elements followed the opposite variation trend. The decrease in H and N may be attributed to the formation of vapor, NH3 or other substance. The rest components of the sorbents were oxygen and ash.

Sequestration of organic species

According to Figs. 3, 4, 5, 6 and 7, it can be noticed that increasing temperature from 500 to 800 °C has increased the methylene blue index, which may be attributed to an increasing % mesopore volume. It was reported, that higher activation temperature can lead to a reduction in microporosity, while the mesopore proportion was drastically increased [34]. Figure 3 shows in its three images a, b and c the effect of different burning factors such as raising the temperature and increasing the holding time on removing methylene blue, phenol from their aqueous solutions. Where, the removal rate reached 85% and 78% in the case of MB, P, respectively, as shown in Fig. 3c. Figure 4 turns out the effect of steam and fresh air as well as carbon dioxide as physical catalysts on removing MB and P from their aqueous solutions. Where, the removal % reached a maximum of about 99.3% for MB in the presence of water vapor, and the removal % of phenol was 94.6% using the fresh air. Looking carefully at Fig. 5 in its four forms, (a, b, c, and d) it was noted that the clear positive effect of using different acids, such as H3PO4, H2SO4, HCl, and HNO3 as chemical activating agents has a great effect to prepare carbon to remove MB and P. Where, the removal ratio was in the range (95.7–99.7%) in the case of MB and (69.8–94.1%) in the case of phenol. The percentage of removal of MB and P from its solution is positively affected by the chemical agents used in the preparation process, as is the case with (NaOH, KOH) as in Fig. 6. Also, Fig. 7 which shows the positive effect of using different salts such as Zncl2, Fecl3, and KMnO4, as a chemical activator on the properties of the resulting carbon and it greatly, confirms its effectiveness in removing the above organic compounds. According to the previous Figs. 3, 4, 5, 6 and 7 the selectivity of samples number (7, 10, 11, 12, 13, 17, 19, 23, 25, 28, 31, 35, and 37) is due to its great ability to remove organic matter. One of the proposed mechanisms of phenol adsorption on activated carbon depends on the formation of a hydrogen bond within the group between the phenolic hydroxyl group and the surface oxygen groups mainly located on the outer surface or at the edges of the graphene layers [35]. Another mechanism involves the interaction between the basic sites of the ACs (electron donor) and the aromatic ring of phenol (electron acceptor) [36].

Cationic and anionic species removal

The first examination was performed to clarify the adsorption power of the selected activated carbon prepared towards anionic and cationic radionuclides. Tables 4 and 5 represent sorption of some cations [137Cs,85Sr, La(III), Eu(III), Co(II), U(VI)] and some anions [75Se, Cr(VI), Mo(VI)] onto DRP-system prepared by different activation methods. Based on the results in Tables 4 and 5, it was found that the prepared activated carbon samples 11 (DRPA6), 13 (DRPP6a), 25 (DRPNa6a) and 35(DRPFe6b) can exclusively sorb the cations and anions under study with high efficiency, sometimes reaching to about 98.6%. Figures 8 and 9 show the preference of the sorbent samples that were selected to remove the selected anions [75Se, Cr(VI) and Mo(VI)] and cations [137Cs, 85Sr, La(III), Eu(III), Co(II), U(VI)]. It has been found that most of the sorbents that have been prepared achieve a good sorption rate, which confirms the effectiveness and efficiency of these prepared sorbents, according to Figs. 8 and 9. Also, these types of sorbents have the advantage that they have one origin, but they are prepared by different activating ways. From the totality of these results, we can conclude that the sorbents prepared by different activation methods are very suitable for recovery and removing different species of radionuclides from the radioactive wastewater, whether they are positively charged or negatively charged.

Mechanism of different species sorption

There are many mechanisms by which different species may sorb onto the DRP-activated carbons. (1) Ion exchange Replacement of counter ions sorbed onto the DRP-activated carbons from the solution by similarly charged species. (2) Ion pairing sorption of some species from their solutions onto oppositely charged sites unoccupied by counter ions. (3) Hydrophobic bonding: sorption occurs by this mechanism when there is an attraction between a hydrophobic group of sorbed species and species present in the aqueous media. (4) Sorption by polarization of π electrons When some species contains electron-rich aromatic nuclei; the sorbent has strongly positive sites, attraction between electron rich aromatic ring of the sorbate and positive sites on the DRP-activated carbon results in sorption. v. Sorption by dispersion forces: Sorption by London–van der Waals force between some species and DRP-activated carbon increases with the increasing molecular weight of the sorbate species [5, 37,38,39].

Comparison with other sorbents

The carbonaceous materials are now used as sorbents in many industrial applications due to their high specific surface area and porous structure (a consequence of their large mesopore and micropore contents). Activated carbon has a strong affinity for many sorbate species (anions, cations and organic species) because it has different functional groups, e.g. carbonyl, carboxyl, phenol, lactone, quinine groups, etc.) on their graphite layers, giving these sorbents a wide range of sorption targets. Table 6 shows the high efficiency of activated carbon prepared from Delonixregia pods over carbons prepared from other materials when used to remove cations and anions from contaminated solutions. Furthermore, our prepared activated carbons have high chemical, radiological and thermal stability, rigid porous structure and mechanical strength, which give them great advantages. These sorbents, due to its high radiation stability and high purity is often used for the separation of ions [5, 7, 8]. The results revealed that the low-cost prepared carbonaceous sorbents exhibited good sorption capacities compared with other materials as reported in the literatures. The results also indicated that the prepared sorbents can be considered as a promising sorbents for the removal and recovery of different radionuclides species, even compared to some other low cost sorbents and activated carbons previously suggested for the uptake of different radionuclides from aqueous solutions [48,49,50].

Finally, through the results obtained, it was found that:

-

1.

H3PO4-activated carbon is the most efficient in removing of [85Sr, La(III), Eu(III), Co(II),U(VI),75Se and Cr(VI)] ions, where a removal percent reached to (67.6, 97.0, 96.4, 82.0, 98.6, 19.7 and 61.1) respectively. This is explained by the fact that phosphoric acid plays a major role in increasing the surface porosity and creating surface groups of an acidic nature. The specific surface area and total pore volume obtained from H3PO4 acid activated carbon is also higher than the corresponding values for other carbon types obtained with other activators such as pure air, NaOH, and FeCl3.

-

2.

FeCl3-activated carbon has a high removal efficiency of Mo(VI) ions due to the presence of iron particles well distributed on the surface of the developed carbon, in addition to the high stability of the iron which appears to be closely related to the carbon matrix during the preparation stage. Based on the propagation of ferric ions on the surface of the prepared activated carbon, it becomes positively charged. This results in an ionic interaction between the positive and negative ions of the molybdate species.

-

3.

NaOH-activated carbon has a high efficiency in removing radioactive cesium ions. This is due to the fact that NaOH is one of the strongest stimulants known to produce high-quality carbon.

Conclusion

Producing of different sorbents from environmental debris is of a great advantage as it can be exploited for removing of different radionuclide species from wastewaters. Delonixregia pods as an example was used to prepare Activated Carbons by different activation methods. These prepared sorbents were used successfully in this investigation to sorb many radionuclides with good efficiency. Also, these activated carbons are very efficient for sorption of some organic species. The studies showed that the prepared activated carbons could be applied as a promising sorbents for the removal of different anionic and cationic radionuclides such as 129I, 99Tc, 79Se, 36Cl, 93Mo, 137Cs, 85Sr, lanthanides (or trivalent actinides such as 241, 242m,243Am), Co(II) and U(V) from different environmental samples and real radioactive wastewaters.

References

Yakout SM, Hassan HS (2014) Adsorption characteristics of sol gel-derived zirconia for cesium ions from aqueous solutions. J Mol 19(7):9160–9172. https://doi.org/10.3390/molecules19079160

Hamed MM, Hilal MA, Borai EH (2016) Chemical distribution of hazardous natural radionuclides during monazite mineral processing. J Environ Radioact 162–163:166–171. https://doi.org/10.1016/j.jenvrad.2016.05.028

El-Sayed AA, Hamed MM, El-Reefy SA (2010) Determination of micro amounts of zirconium in mixed aqueous organic medium by normal and first derivative spectrophotometry. J Anal Chem 65:1113–1117. https://doi.org/10.1134/S1061934810110043

Gad HMH, Hamed MM, Abo Eldahab HMM, Moustafa ME, El-Reefy SA (2017) Radiation-induced grafting copolymerization of resin onto the surface of silica extracted from rice husk ash for adsorption of gadolinium. J Mol Liq 231:45–55. https://doi.org/10.1016/j.molliq.2017.01.088

Hamed MM (2014) Sorbent extraction behavior of a nonionic surfactant, Triton X-100, onto commercial charcoal from low level radioactive waste. J Radioannal Nucl Chem 302:303–313

Tiryaki B, Yagmur E, Banford A, Aktas Z (2014) Comparison of activated carbon produced from natural of biomass and equivalent chemical composition. J Anal Appl Pyrol 105:276–283. https://doi.org/10.1016/j.jaap.2013.11.014

Yakout SM, Hamed MM, Hassan HS (2012) Solid phase extraction of nitrate and nitrite anions using naturallyand available sorbent. J Radioannal Nucl Chem 295:697–708. https://doi.org/10.1007/s10967-012-1896-6

El-Sayed AA, Hamed MM, Hmmad HA, El-Reefy SA (2007) Collection/concentration of trace uranium for spectrophotometric detection using activated carbon and first-derivative spectrophotometry. Radiochim Acta 95:43–48. https://doi.org/10.1524/ract.2007.95.1.43

Tan IAW, Ahamad AL, Hameed BH (2008) Adsorption of basic due on high surface area activated carbon prepared from coconut husk: equilibrium, kinetic and thermodynamic studies. J Hazard Mater 154(1–3):337–346. https://doi.org/10.1016/j.jhazmat.2007.10.031

Zhao XT, Zeng T, Hu ZJ, Gao HW, Zou CY (2012) Modeling and mechanism of the adsorption of proton onto natural bamboo sawdust. Carbohydr Polym 87(2):1199–1205. https://doi.org/10.1016/j.carbpol.2011.08.098

Rizk HE, Hamed MM, Ahmed IM (2018) Adsorption behavior of zirconium and molybdenum from nitric acid medium using low-cost adsorbent. J Mol Liq 249:361–370. https://doi.org/10.1016/j.molliq.2017.11.049

Zhao XT, Zeng T, Li XY, Hu ZJ, Gao HW, Xie Z (2012) Modeling and mechanism of the adsorption of copper ion onto natural bamboo sawdust. Carbohydr Polym 89(1):185–192. https://doi.org/10.1016/j.carbpol.2012.02.069

Angelina M, Thanga A, Rajagopal K (2015) Fluoride removal study using pyrolyzed Delonixregia pod, an unconventional adsorbent. Int J Environ Sci Technol 12:223–236. https://doi.org/10.1007/s13762-013-0485-8

Hosain L (2011) Ph.D. thesis, Ain Shams University, Cairo, Egypt

Mckay G (1996) Use of adsorbent for the removal of pollutants from wastewaters. CRC Press, New York

Yakout SM (2006) Treatment of waste effluents using active carbon prepared from Agro-residues. Ph.D. thesis, Ain Shams University, Egypt

Itodo AU, Abdulrahman FW, Hassan LG, Maigandi SA, Itodo HU (2010) Application of methylene blue and iodine adsorption in the measurement of specific surface area by four acid and salt treated activated carbons. J New York Sci 3(5):25–33

Bouchelta C, Medjram MS, Bertrand O, Bellat JP (2008) Preparation and characterization of activated carbon from date stones by physical activation with steam. J Anal Appl Pyrolysis 82:70–77. https://doi.org/10.1016/j.jaap.2007.12.009

Byamba-Ochir N, Shim WG, Balathanigaimani M, Moon H (2016) Highly porous activated carbons prepared from carbon rich Mongolian anthracite by direct NaOH activation. J Appl Surf Sci 379:331–337. https://doi.org/10.1016/j.apsusc.2016.04.082

Pallarés J, González-Cencerrado A, Arauzo I (2018) Production and characterization of activated carbon from barley straw by physical activation with carbon dioxide and steam. Biomass Bioenergy 115:64–73. https://doi.org/10.1016/j.biombioe.2018.04.015

Yahya MA, Al-Qodah Z, Ngah CZ (2015) Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: a review. Renew Sustain Energy Rev 46:218–235. https://doi.org/10.1016/j.rser.2015.02.051

Njoku V, Foo K, Asif M, Hameed B (2014) Preparation of activated carbons from rambutan (Nepheliumlappaceum) peel by microwave-induced KOH activation for acid yellow17dye adsorption. J Chem Eng 250:198–204. https://doi.org/10.1016/j.cej.2014.03.115

Samsuri A, Sadegh-Zadeh F, Seh-Bardan B (2014) Characterization of biochars produced from oil palm and rice husks and their adsorption capacities for heavy metals. Int J Environ Sci Technol 11:967–976. https://doi.org/10.1007/s13762-013-0291-3

Gratuito MKB, Panyathanmaporn T, Chumnanklang RA et al (2008) Production of activated carbon from coconut shell: optimization using response surface methodology. Bioresour Technol 99:4887–4895. https://doi.org/10.1016/j.biortech.2007.09.042

Cui X, Jia F, Chen Y, Gan J (2011) Influence of single-walled carbon nanotubes on microbial availability of phenanthrene in sediment. Ecotoxicology 20:1277–1285. https://doi.org/10.1007/s10646-011-0684-3

Wang B, Zhu C, Zhang Z et al (2016) Facile, low-cost, and sustainable preparation of hierarchical porous carbons from ion exchange resin: an improved potassium activation strategy. J Fuel 179:274–280. https://doi.org/10.1016/j.fuel.2016.03.088

Rambabu N, Rao B, Surisetty V et al (2015) Production, characterization, and evaluation of activated carbons from de-oiled canolameal for environmental applications. Ind Crops Prod 65:572–581. https://doi.org/10.1016/j.indcrop.2014.09.046

Hassler JW (1963) Active carbon. Chemical Publishing Company, New York

Fu K, Yue Q, Gao B, Wang Y, Li Q (2017) Activated carbon from tomato stem by chemical activation with FeCl2. Colloids Surf A Physicochem Eng Asp 529:842–849. https://doi.org/10.1016/j.colsurfa.2017.06.064

Xu Z, Sun Z, Zhou Y, Chen W, Zhang T, Huang Y, Zhang D (2019) Insights into the pyrolysis behavior and adsorption properties of activated carbon from waste cotton textiles by FeCl3-activation. Colloids Surf A Physicochem Eng Asp 582:123934. https://doi.org/10.1016/j.colsurfa.2019.123934

Cazetta AL, Pezoti O, Bedin KC, Silva TL, Paesano Junior A, Asefa T, Almeida VC (2016) Magnetic activated carbon derived from biomass waste by concurrent synthesis: efficient adsorbent for toxic dyes. ACS Sustain Chem Eng 4:1058–1068. https://doi.org/10.1021/acssuschemeng.5b01141

Deng H, Zhang G, Xu X, Tao G, Dai J (2010) Optimization of preparation of activated carbon from cotton satalks by microwave assisted phosphoric acid-chemical activation. J Hazard Mater 182:217–224. https://doi.org/10.1016/j.jhazmat.2010.06.018

Yang J, Zhao Y, Ma S, Zhu B, Zhang J, Zheng C (2016) Mercury removal by magnetic biochar derived from simultaneous activation and magnetization of sawdust. Environ Sci Technol 50:12040–12047. https://doi.org/10.1021/acs.est.6b03743

Ömer S, Cafer S (2013) Preparation and characterization of activated carbon from acorn shell by physical activation with H2O–CO2 in two-step pretreatment. Biores Technol 136:163–168. https://doi.org/10.1016/j.biortech.2013.02.074

Jin Z, Zhao G (2014) Porosity evolution of activated carbon fiber prepared from liquefied wood. Part II: water steam activation from 850 to 950°C. BioResources 9(4):6831–6840. https://doi.org/10.15376/biores.9.2.2237-2247

Lorenc-Grabowska E, Diez MA, Gryglewicz G (2016) Influence of pore size distribution on the adsorption of phenol on PET-based activated carbons. J Colloid Interface Sci 469:205–212. https://doi.org/10.1016/j.jcis.2016.02.007

Gokce Y, Aktas Z (2014) Nitric acid modification of activated carbon produced from waste tea and adsorption of methylene blue and phenol. Appl Surf Sci 313:352–359. https://doi.org/10.1016/j.apsusc.2014.05.214

Hamed MM, Holiel M, El-Aryan YF (2017) Removal of selenium and iodine radionuclides from waste solutions using synthetic inorganic ion exchanger. J Mol Liq 242:722–731. https://doi.org/10.1016/j.molliq.2017.07.035

Rizk SE, Hamed MM (2015) Batch sorption of iron complex dye, naphthol green B, from wastewater oncharcoal, kaolinite, and tafla. Desalin Water Treat 56:1536–1546. https://doi.org/10.1080/19443994.2014.954004

Caccin M, Giacobbo F, Da Ros M, Besozzi L, Mariani M (2013) Adsorption of uranium, cesium and strontium onto coconut shell activated carbon. J Radioannal Nucl Chem 297:9–18. https://doi.org/10.1007/s10967-012-2305-x

Khandaker S, KubaT KamidaS, Uchikawa Y (2017) Adsorption of cesium from aqueous solution by raw and concentrated nitric acid-modified bamboo charcoal. J Environ Chem Eng 5:1456–1464. https://doi.org/10.1016/j.jece.2017.02.014

Orhan Y, Buyukgungur H (1993) The removal of heavy metals by using agricultural wastes. Water Sci Technol 28:247–255. https://doi.org/10.2166/wst.1993.0114

Rovira M, Giménez J, Martínez M, Martínez-Lladó X, de Pablo J, Martí V (2008) Sorption of selenium(IV) and selenium(VI) onto natural iron oxides: goethite and hematite. J Hazard Mater 150:279–284. https://doi.org/10.1016/j.jhazmat.2007.04.098

Mary Gladis J, Prasada Rao T (2002) Anal Lett 35:501

Choi JH, Kim SD, Kwon YJ, Kim WJ (2006) Microporous Mesoporous Mater 96:157–167

Sepehriana H, Cheraghalib R, Rezaeib P, Abdi HA (2011) Int J Ind Chem 2(4):235–241

Namasivayam C, Sangeetha D (2006) Recycling of agricultural solid waste, coir pith: removal of anions, heavy metals, organics and dyes from water by adsorption onto ZnCl2 activated coir pith carbon. J Hazard Mater B 135:449–452. https://doi.org/10.1016/j.jhazmat.2005.11.066

Holiel M, Hamed MM, Ismail ZH (2016) Removal of 134Cs and 152+154Eu from liquid radioactive waste using Dowex HCR-S/S. Radiochim Acta 104:399–413. https://doi.org/10.1515/ract-2015-2514

Hamed MM, Attallah MF, Metwally SS (2014) Simultaneous solid phase extraction of cobalt, strontium and cesium from liquid radioactive waste using microcrystalline naphthalene. Radiochim Acta 102:1017–1024. https://doi.org/10.1515/ract-2013-2200

Ahmed IM, Aglan RF, Hamed MM (2017) Removal of Arsenazo-III and Thorin from radioactive waste solutions by adsorption onto low-cost adsorbent. J Radioannal Nucl Chem 314:2253–2262. https://doi.org/10.1007/s10967-019-06669-5

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Elgazzar, A.H., Ali, M.M.S., El-Sayed, A.A. et al. Preparation of various sorbents from agro waste to remove some radionuclides and organic species from aqueous solutions. J Radioanal Nucl Chem 326, 1733–1748 (2020). https://doi.org/10.1007/s10967-020-07476-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-020-07476-z