Abstract

The in situ current normalized particle induced gamma-ray emission method using 4 MeV proton beam was utilized for total boron concentrations in boron based neutron absorbers and borated wood based neutron shielding materials. Boron carbide samples with varying masses were analyzed to examine the effect of matrix as well as the efficacy of the in situ current normalized method. Isotopic composition of boron (10B/11B atom ratio) has been determined in natural and 10B enriched boron carbide samples as well as in four synthetically prepared enriched boron carbide samples to serve as in-house reference standard for isotopic composition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Natural boron has two isotopes namely 10B (19.8%) and 11B (80.2%). Due to the differences in neutron absorption cross section they have different uses in nuclear fields. Because of the low neutron absorption cross section of 11B it is used as neutron reflector whereas 10B is used in nuclear industry as control/shutoff materials. Boron based neutron absorbers like boron carbide (natural and enriched with respect to 10B), boron composites, transition and rare earth metal borides play a vital role as control/shutoff material, burnable poison, neutron shielding, neutron sensors, and nuclear material storage in advanced, fast and/or high temperature nuclear reactors [1]. It is due to high thermal neutron absorption cross section of 10B ((n,α) cross section 3837 barn) and having superior thermo physical and mechanical properties like high B mass fraction, refractory nature, low density, high melting point and high temperature strength, chemical inertness, resistance to radiation damage and excellent thermal and electrical characteristics. Borides have properties like high hardness and melting point and relatively low thermal expansion and conductivity to make it ideal for a number of industrial uses [2]. B4C is the third hardest material after diamond and cubic boron nitride. It finds extensive application in nuclear industry. Ability to absorb neutrons makes it popular as a material for absorbing neutron in nuclear power plants. B4C is used as a control rod in the nuclear reactor and as shut down pellets in a nuclear power plant. B4C is used as the control rod in Boiling Water Reactors (BWR) and 10B enriched pellets of B4C is a proposed control rod material in Prototype Fast Breeder Reactor (PFBR) in India [3, 4]. Boron composites like Ti–B and Ti–Cr–B are studied as the materials for control rod and/or neutron shielding applications in compact light water reactors [5]. Due to additional neutron absorption cross section of rare earth elements, hexa-borides of rare-earth elements such as LaB6 and NdB6 can replace enriched B or B4C and this would eliminate the cost of expensive enrichment process [6].

Other materials like bocarsil (boron carbide in silicon rubber) and polyboron (boric acid in polyethylene) can be used for the shielding the reactor neutrons and storing nuclear materials [7]. For many practical applications, borated paraffin and borated wood are used as neutron shielding materials, wherein higher energy/fast neutron components are first thermalized by low Z elements (like H and C) and then absorbed by boron. The gamma-ray at 478 keV obtained from 10B (n, αγ) 7Li is shielded by lead. Jabroc is a non-impregnated and densified wood laminates developed commercially for a wide range of industrial applications. Jabroc can be used along with other neutron shielding materials to form complex shielding structures. Additionally, due to light weight and cleanliness in handling, it is a suitable candidate for the standard design of neutron shielding equipment. Jabroc can also be impregnated with boron up to a maximum of 4% to control high gamma doses in the cases where gamma radiation is produced on neutron capture. Boron impregnated Jabroc wood also finds application in power reactor system. The shielding property of this material is optimized by incorporating requisite amount of boron in wood. For the Chemical Quality Control (CQC) purpose boron content in this material needs to be determined accurately prior to its use as neutron shielding material. Chemical characterization of materials is one of the most important steps under CQC which ensures the material suitability as per the specified composition [8, 9].

As a part of CQC exercise, total concentration and isotopic composition of B (10B/11B atom ratio) are very crucial parameters for practical purposes like operation of reactor effectively, assessing the thermo-physical and mechanical properties and also for ascertaining the nature of compound contains natural or enriched boron with respect to 10B, it is necessary to determine accurately total boron mass fraction as well as its isotopic composition (IC) in the finished product. The routinely used conventional wet-chemical and spectroscopic analytical methods to quantify at low or high concentration level for total boron determination for solid and aqueous samples have disadvantages like their destructive nature as samples need to be brought to solution form, involves cumbersome chemical dissolution for complex matrix samples, separation and/or pre-concentration to eliminate the matrix effect and, also, they are not free from reagent blank [10, 11]. Among various mass spectrometric methods like Thermal Ionization Mass Spectrometry (TIMS), Secondary Ionization Mass Spectrometry (SIMS) and ICP-MS which are used for isotopic composition (IC) determination of B (10B/11B atom ratio), TIMS is the best method for precise determination of IC of B [12,13,14].

It is advantageous to have an alternative method for IC and total B mass fraction determination with respect to conventional methods. PIGE, an accelerator based on-line ion beam analysis (IBA) technique, is capable of simultaneous determination of mass fractions of B at major to trace concentration levels and its IC as well as other low Z elements (from Li to S) using low energy (about 2–5 MeV) proton beams non-destructively. It is isotope specific and it involves measurement of prompt gamma-rays from 10B (p,αγ) 7Be, 10B (p, p′γ) 10B and 11B (p, p′γ) 11B reactions. Particle Induced Gamma-ray Emission spectroscopy (PIGE) is a powerful technique for material characterization and it has been used since the early 1960s in different fields of applications to determine low Z elements in reactor materials to environmental samples, cultural heritage etc. [15]. As we don’t have any certified reference material for isotopic composition of enriched B4C, attempt was made to prepare in-house reference standard of enriched B4C of four different 10B atom% namely 30, 40, 50 and 60 atom%. These samples were prepared by homogeneously mixing natural (19.8 atom% of 10B) and enriched (67 atom% of 10B) B4C samples. These samples have been analysed by PIGE method for 10B/11B atom ratio calculations.

We have developed an in situ current normalised PIGE method using 4 MeV proton beam for non-destructive determination of total B concentration as well as its IC in boron based compounds having complex matrices [1]. IC values in natural B4C, 10B enriched B4C along with four synthetically in house prepared enriched B4C samples have been determined simply by taking peak area ratios of their characteristics gamma rays with boric acid standard and total boron concentrations in neutron shielding materials such as borated wood, neutron absorbers like NdB6, SiB6, Ti and Cr boride and natural B4C have been determined by in situ current normalized PIGE method non-destructively. Total boron concentration determination in refractory neutron absorbers/shielding materials is difficult by sensitive conventional wet chemical analysis techniques. The conventional analytical techniques which are destructive require cumbersome sample preparation for complex matrices like borides, carbides and composites. The accuracy of these methods also depends on complete dissolution of samples which requires HF digestion or Na2CO3 fusion method. Total B concentration for some samples is compared with ICP-OES as a part of quality assurance purpose. Results of IC of natural B4C and total B in stoichiometric compound natural B4C were used for method validation. Matrix effect study taking varying masses of B4C has been studied which shows the efficacy of the in situ current normalized method.

Experimental

Preparation of targets for PIGE

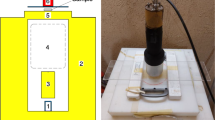

In order to prepare in house reference standards for B4C having different 10B atom %, natural B4C (19.8 atom% of 10B) and enriched B4C (67 atom% of 10B) were used to get in between enriched B4C. Four synthetic composition of B4C (30, 40, 50 and 60 atom% of 10B) were prepared by appropriate mixing of natural and enriched B4C using agate mortar and pastel. Boron standard pellets were prepared by homogeneously mixing varying amounts of boric acid (25–250 mg) with fixed amount of CaF2 (having 5 mg effective mass of F) in a cellulose matrix to get the calibration curve. Different B4C samples with varying 10B atom%, neutron absorbers (NdB6, (Ti,Cr)B2, SiB6) and neutron shielding material (borated wood) were prepared in pellet form of total weight 750 mg, diameter 2 cm, and thickness 0.2 cm in a cellulose matrix applying 2 ton pressure using hydraulic press after homogeneous mixing of sample (100 mg) for about 2 h, constant amount of CaF2 and cellulose as the matrix for the PIGE experiment. Fluorine in the form of CaF2 acts as in situ current normalizer as it is absent in the sample. Replicate samples (N = 6) were prepared to evaluate the reproducibility/precision of results. A blank pellet except the sample was prepared to check any gamma ray interference from the CaF2 and cellulose matrices. Method validation was carried out with targets of stoichiometric compounds namely borax and natural boron carbide.

Irradiation and measurement in PIGE

Quantification of total boron in boron based neutron absorbers and shielding materials,isotopic composition of boron in natural, enriched and synthetically prepared enriched boron carbide samples have been done by in situ current normalized PIGE method using 4 MeV proton beam from FOlded Tandem Ion Accelerator(FOTIA),Mumbai,India. The 4 MeVproton beam is suitable for this experiment as a higher count rate under the peak of interest is obtained with lower counting statistical error and there is no interference from the gamma rays due to matrix at this energy. The targets of samples and standards, mounted on a stainless steel ladder, were kept under vacuum (≤ 10−6 Torr) inside a scattering chamber. The target pellets were placed at 45° to the beam direction during irradiation. HPGe detector was placed at 900 to the beam direction and target to detector distance was 7 cm. The targets were irradiated for 20–30 min with current 15–20 nA depending on the sample to accumulate counts of the order of 105 for in situ current normalizer and 20,000–80,000 for boron peaks and the dead time was kept below 5%. Energy calibration of the HPGe detector was done using standard 152Eu source and a multielement target to cover up to energy range 2125 keV of 11B placed in the target position. Gamma ray measurement was done with a 50% relative efficiency HPGe detector having energy resolution 1.9 keV at 1332 keV of 60Co. The detector was coupled to a PC based 4 k Multi Channel Analyzer (MCA). Gamma-ray spectra obtained using 4 MeV proton beam and F as in situ current normalizer for borated wood and 50 atom% of 10B enriched B4C samples are shown in Figs. 1 and 2, respectively. The acquired spectra were analyzed using peak-fit software called Pulse Height Analysis SofTware (PHAST) for peak areas (net counts) determination [16]. Efforts were taken to analyze higher degree of homogenised pellet samples and standards. To check the homogeneity of sample pellets, a few representative samples were irradiated at three different locations and the percentage differences of counts under the peak of interest of boron (429, 718 and 2125 keV) from multiple measurements were about 0.5%.

Total B concentration determination in borated wood using conventional ICP-OES method

The wood sample flakes were wetted with saturated barium hydroxide solution and dried under IR lamp. The sample was ashed in a muffle furnace at 600 °C for 2 h. The residue was dissolved in hydrochloric acid and made up to a known volume. An aliquot was titrated against standard alkali in the presence of a polyhydric alcohol to determine the boron content. The method was validated by dissolving the samples by two additional methods viz. microwave digestion and alkali fusion. The sample solutions were then analysed for boron content using Titrimetry as well as ICP-OES [17].

Calculation

Determination of total boron concentration by PIGE

Concentration of total boron was determined using relative methods of PIGE. Relative method requires a previous knowledge in the composition of sample in order to choose the standards. As we are determining boron high pure boric acid (99.5%) standards are used. In this work both samples and standards were irradiated under similar experimental conditions like fixed beam energy, target to detector distance and fixed target angle with the beam direction. In case of relative method of PIGE, it is not required to measure absolute current for sample and standard. In the present case we added F in the form of CaF2 as in situ current normalizer to the solid samples and mixed homogeneously.

The count rate of the gamma-rays of interest is normalized with the sensitivity of fluorine [count rate of F per unit concentration (in ppm or mg kg−1)] both for sample and standard, (SCN) F, Sam/Std to account for any fluctuation in beam current during irradiation. The concentration of an analyte, ‘x’ in sample (CSam,x) can be determined by using the following expression.

where (SStd,x)N is the in situ current normalized sensitivity of standard of an element (x) is obtained using the following relation,

where CStd,x represents the concentration of ‘x’(mg kg−1) in the standard pellet, \((CPS_{x} )_{Sam/Std}\) is the count rate of x in sample or standard [1, 8]. (SCN) F, Sam/Std is given by

Determination of isotopic composition of boron by PIGE

The prompt γ-rays of 10B (429 keV, 718 keV),11B (2125 keV), and 19F (197 keV) from 10B(p,αγ)7Be, 10B(p, p′γ)10B, 11B(p, p′γ)11B and19F(p, p′γ)19F reactions, respectively, were detected by High Purity Germanium (HPGe) detector both for samples and standards. Boron peaks at 429, 718 and 2125 keV not interfered in the present case due to absence of Li, Cl, and S. If they are present in the sample, the 2125 keV γ-ray of 11B(p, p′γ) 11B will be interfered from34S(p, p′γ) 34S and 37Cl(p, αγ)34S whereas 429 keV of 10B(p, αγ)7Be will be interfered from7Li (p, nγ)7Be. Interferences from Cl and S are less at 4 MeV proton beam compared to Li as per the proton induced thick target γ-ray yield data. A blank pellet except the sample was prepared to check any gamma ray interference from the CaF2 and cellulose matrices. No gamma ray interferences from the above isotopes have been observed. The absence of 478 keV gamma ray from 7Li (p, p′γ) 7Li having high thick target yield at the 4 MeV proton beam in the samples ensures the absence of Li. The IC of B was calculated using Eq. (3) by taking simply peak area (PA) ratio of sample to standard [1, 8]. IC determination does not require peak areas of the in situ current normalizer.

where the isotopic abundance (\(\uptheta\)) ratio in boric acid standard \(\left( {\uptheta\left( {^{10} B} \right)/\uptheta\left( {^{11} B} \right)} \right)_{\text{Reference}}\) is 0.2473 ± 0.0002.

The 10B at% can be calculated from \(\left( {^{10} B/^{11} B} \right)_{\text{Atom ratio}}\) using Eq. (4) as follows

Results and discussion

Total boron concentration determination

The total boron concentrations of the samples were determined by in situ current normalized PIGE using Eq. 1 for 718 keV of 10B and 2125 keV of 11B and are given in Table 1.

The uncertainties (± 2 s) at 95.5% confidence level reported in Table 1 for total boron concentration from three replicates are in the range of 1.9–3.3% using 718 keV of 10B, 0.8–3.8% using 2125 keV in PIGE and 2.2–3.1% in ICP-OES. Combined uncertainty at ± 1 s was calculated by propagating individual uncertainty components like uncertainties (counting statistics) on peak areas of sample, standard and in situ current normalizer, uncertainty due to pellet homogeneity and uncertainties on their corresponding absolute masses. Finally, the expanded uncertainty at ± 2 s (k = 2, at 95.5% confidence level) was calculated and values are 2.3–3.1% for 718 keV and 2.0–2.9% for 2125 keV. The individual uncertainties are: counting statistics error of sample in the range of 0.6–1.2% at 718 keV and 0.5–1.1% at 2125 keV and of standard about 0.7% at 718 keV and 0.5–0.7% at 2125 keV, counting statistics error for in situ current normalizer F at 197 keV is 0.2%, uncertainties due to masses of samples, standard and current normalizing standard are in the range of 0.05–0.2% and the uncertainty on pellet homogeneity was about 0.5%. Total boron concentrations for natural composition samples obtained independently from 10B (using 718 keV) and 11B (using 2125 keV) are in good agreement. The B concentrations using conventional ICP-OES method for borated wood and natural B4C have also been performed and given in Table 1. The results obtained from both PIGE and ICP-OES method are in good agreement with an absolute error below 2.5%. The results of total boron concentration in natural B4C by PIGE and ICP-OES can be treated as the method validation and the obtained results are in good agreement within ± 2% of their expected or calculated values.

Matrix effect study in B4C samples by in situ current normalized PIGE method

PIGE analysis is usually performed with the help of the standards but for better result the standard matrix should be similar to the sample being analysed [18]. Hence study on matrix effect is required for determination of B in different matrices. In situ current normalized PIGE method has been established by us for quantification of total B in various boron compounds using boric acid as the standard. Samples are prepared with cellulose as the major matrix (90% or more). Thus, the matrix effect is negligible in order to have appreciable effect on results as the stopping power of sample and standard for 4 MeV proton beam has been assumed as the same. In order to study the matrix effect of boron determination keeping constant amount of boron standard in cellulose matrix, PIGE experiment was carried out for varying masses of samples (50–250 mg, effective boron atoms different in samples compared to standard) of B4C. The count rates of all three peaks at 429 and 718(10B) and 2125 keV(11B) per unit mass of the sample normalized with cps of 197 keV(19F) were determined and the results are shown in Table 2. It is interesting to note that the matrix effect is not seen for total boron concentration determination using in situ current normalized PIGE method. The results indicated the variation (% RSD) of the mass and current normalized cps in in situ method are 10.0% (429 keV), 6.9% (718 keV) and 4.3% (2125 keV) indicating a very good agreement of the values and stopping power effect is negligible, which is due to presence of in situ current normalizer. As expected the 2125 keV (11B) which is higher in energy has got least variations due to lower matrix effect (attenuation) compared to 429 and 718 keV. Thus for samples like B4C, variation in sample masses to get total B is not an issue with in situ current normalized PIGE as linearity holds good for 10 fold differences in masses of the sample (25–250 mg).

Determination of IC ratios in in-house prepared enriched B4C samples

The homogenized enriched B4C powder samples with 10B atom% of 30, 40, 50 and 60 were analysed by PIGE method using 4 MeV proton beam to determine the IC. The results obtained for different B4C samples are given in Table 3. The isotopic composition of boron (10B/11B atom ratio) was determined by comparing peak area ratios of 429 and 2125 keV of sample to boric acid standard using Eq. 3 and 10B atom% was calculated from the atom ratio using Eq. 4. The IC values from six replicates were in between 0.248 and 2.022 that corresponds to 19.9–67 atom% of 10B. The IC values obtained from two gamma energies of 10B at 429 keV and 718 keV and 2125 keV of 11B are in good agreement (within ± 1%) and it gives the self-validation using PIGE [1]. The uncertainties (± 2 s) at 95.5% confidence level reported in Table 3 for IC of boron from six replicates are 0.8–2.4% and 1.0-2.7% for 429/2125 keV and 718/2125 keV of 10B/11B peaks, respectively. We have also calculated the expanded uncertainty at ± 2 s (k = 2, at 95.5% confidence level) by propagating individual uncertainty components like uncertainty (counting statistics) on peak areas of sample and standard. The advantage of PIGE for IC determination of boron is that the uncertainties due to mass and current normalizer are not input parameters as the peak areas of two peaks of 10B and 11B are used for calculation from same sample. The corresponding expanded uncertainties on IC values are found to be 1.7–2.0% and about 2.4% for 429/2125 keV and 718/2125 keV of 10B/11B peaks, respectively, which are found to be similar compared to that obtained due to uncertainties from un-weighted standard deviation from replicate samples as given in Table 3. The obtained results will be considered as the in house prepared values rather than the calculated or added isotopic concentration values. This is the first step for preparations of in-house reference standard for IC of B using PIGE method and the results are found encouraging.

Method validation

We have used borax, B4C and synthetic samples for in situ current normalized PIGE method validation in the case of total boron concentration determination in the absence any CRMs/SRMs. On the other hand, boric acid isotopic SRM 951a from National Institute of Standards and Technology (NIST) was used for method validation for the IC of boron, wherein the 10B/11B atom ration is 0.2473 ± 0.0002 with 10B(atom%) 19.827 ± 0.013 and 11B(atom%) 80.173 ± 0.013. Our determined values by PIGE for IC and total 10B atom% in SRM 951a are found to be 0.2473 ± 0.002 and 19.85 ± 0.12, respectively, and are in good agreement with certified values.

Conclusions

The work carried out using PIGE is a unique one having promising application to boron based neutron absorbers. PIGE method has been advantageously applied to samples which could be analyzed without chemical dissolution for obtaining intended results of either total B concentration and/or IC of boron. The developed method has been extended to prepare in-house reference standard for isotopic composition of boron and the feasibility run has shown promising results in the range of 30–60 atom%. Matrix effect study taking varying masses of B4C has been studied which shows the efficacy of the in situ current normalized method. This work is the first step of preparation of in house reference materials for IC of enriched boron carbides. The results of total boron data were in good agreement with two gamma-rays 10B (718 keV) and 11B (2125 keV) for all samples and also in good agreement with conventional ICP-OES method for borated wood and B4C samples. The main advantage of the standardized PIGE method is that it is an online method for quick quantitative analysis for determination of total B and its isotopic composition in solid samples directly, i.e., without any chemical dissolution/destruction.

References

Acharya R, Raja SW, Sumit Chhillar, Gupta J, Sonber JK, Ch Murthy TSR, Sasi Bhushan K, Rao Radhika M, Majumdar S, Pujari PK (2018) Non-destructive quantification of total boron and its isotopic composition in boron based refractory materials by PIGE and inter-comparison study using TIMS and titrimetry. J Anal At Spectrom 33:784–791

Cline CF, Sands DE (1960) A new silicon boride, SiB4. Nature 185:456

Sonber JK, Murthy TCSR, Subramanian C, Fotedar RK, Hubli RC, Suri AK (2013) Synthesis, densification and characterization of boron carbide. Trans Ind Cerm Soc 72(2):100–107

Sonber JK, Murthy TSRC, Sairam K, Bedse RD, Hubli RC, Chakravartty JK (2015) Development and production of 10B enriched boron carbide (B4C) pellets for control rod application in PFBR. BARC News Lett Spec Issue 259–264

Kumar S, Sairam K, Sonber JK, Murthy TSRC, Reddy V, Rao GNVS, Rao TS (2014) Hot-pressing of MoSi2 reinforced B4C composites. Ceram Int 40:16099–16105

Sonber JK, Sairam K, Murthy TSRC, Nagaraj A, Subramanian C, Hubli RC (2014) Synthesis, densification and oxidation study of lanthanum hexaboride. J Eur Ceram Soc 34:1155–1160

Subramanian C, Suri AK, Murthy TSRC (2010) Development of Boron-based materials for nuclear applications. BARC News Lett 313:14–22

Chhillar S, Acharya R, Sodaye S, Pujari PK (2014) Development of particle induced gamma-Ray emission methods for nondestructive determination of isotopic composition of boron and its total concentration in natural and enriched samples. Anal Chem 8:11167–11173

Acharya R, Pujari PK (2018) Development and applications of In Situ current normalized PIGE method using proton beams for quantification of low Z elements. J Radioanal Nucl Chem 318:1727–1735

Sah R, Brown P (1997) Boron determination—a review of analytical methods. Microchem J 56:285–304

Farhat A, Ahmad F, Arafat H (2013) Analytical techniques for boron quantification supporting desalination processes: a review. Desalination 310:9–17

Barth S, Fresenius J (1997) Comparison of NTIMS and ICP-OES methods for the determination of boron mass fractions in natural fresh and saline waters. Anal Chem 358:854–855

Christie WH, Eby RE, Warmack RJ, Landau L (1981) Determination of boron and lithium in nuclear materials by secondary ion mass spectrometry. Anal Chem 53:13–17

Deyhle A (2001) Improvements of boron isotope analysis by positive thermal ionization mass spectrometry using static multi-collection of Cs2BO2 + ions. Int J Mass Spectrom 206:79–89

Dimitriou P, Becker H-W, Bogdanovic´-Radovic´ I, Chiari M, Goncharov A, Jesus AP, Kakuee O, Kiss AZ, Lagoyannis A, Räisänen J, Strivay D, Zucchiatti A (2016) Development of a reference database for particle induced gamma ray emission spectroscopy. Nucl Instr Meth Phys Res B 371:33–36

Mukhopadhyay PK (2001) Proceedings of the symposium on Intelligent Nuclear Instrumentation. Bhabha Atomic Research Centre, Mumbai, p 307

Venkatesh K, Chhillar S, Kamble GS, Pande SP, Venkatesh M, Kumar SA, Kumar S, Acharya R, Pujari PK, Reddy AVR (2014) Determination of boron concentration in borosilicate glass, boron carbide and graphite samples by conventional wet-chemical and nuclear analytical methods. J Radioanal Nucl Chem 302:1425–1428

Mateus R, Jesus AP, Ribeiro JP (2004) Quantitative analysis of light elements in thick samples by PIGE. Nucl Instr Meth Phys Res B 219–220:519–523

Acknowledgements

Authors thank Head, MP & CED, BARC & his colleagues for providing the samples. Authors thank Head, IADD, BARC, Mr. A. Agarwal, Officer-in-Charge, FOTIA, IADD, BARC and FOTIA Operation Crews for their help during the experiment on PIGE. Authors thank ACD, BARC for analytical support using ICP-OES work. This manuscript is the part of the PhD thesis work of Mr. Sk Wasim Raja under HBNI, DAE.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Raja, S.W., Acharya, R. & Pujari, P.K. Application of PIGE method for quantification of total boron in neutron absorbers and shielding materials and isotopic composition in in-house prepared enriched boron carbide samples. J Radioanal Nucl Chem 323, 1359–1366 (2020). https://doi.org/10.1007/s10967-020-07011-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-020-07011-0