Abstract

N,N,N′,N′-tetraoctyl diglycolamide (TODGA) and bis(2-ethylhexy)phosphoric acid (HDEHP) were coated on Fe3O4 nanoparticles under different chemical conditions. The TODGA-coated magnetite nanoparticles (Fe3O4@TODGA) captured representative actinides Am(III) and Pu(IV) at 3–4 M HNO3 with high efficiency. However, the HNO3 induced pre-organization of TODGA, before coating on the magnetite nanoparticles, was found to be important for the sorption of Am(III) and Pu(IV) ions. The Fe3O4@HDEHP particles exhibited selectivity toward Pu(IV), and Am(III) did not sorb from 3 to 4 M HNO3. The quantification of Pu(IV) preconcentrated on coated particles was carried out by removing the extractant coating in dioxane based scintillator, followed by liquid scintillation counting.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Functionalized nanoparticles (NPs) have many potential applications in analytical chemistry based on their unique magnetic, optical and electrochemical properties [1]. The functionalized superparamagnetic particles offer many advantages for the sample preparation and analyte preconcentration such as higher surface area, easy dispersion in a larger volume sample, and retrieval from sample using an external magnetic field without retaining residual magnetization after withdrawal of magnetic field [2, 3]. It is important that the magnetic particles should be easy to prepare, cheaper, nontoxic, stable under ambient conditions, should be superparamagnetic with higher magnetic saturation value, and easy to functionalize for the analyte specific applications. The magnetite (Fe3O4) NPs and its products of oxidation maghemite (γ-Fe2O3) have such properties and, therefore, used extensively not only in analytical chemistry but also for hosting the NPs for many other applications [4–7]. In general, the Fe3O4 NPs can be used after coating/anchoring desired functionality directly on their surfaces [8–11], immobilization in polymer matrix [12–16], or formation of ferrofluid [17, 18]. However, the most popular method appears to be the direct functionalization of the Fe3O4 NPs by physical coating or anchoring of functional groups by covalent linking [2, 3, 19–21].

Argonne National Laboratory has developed a magnetically assisted chemical separation (MACS) process for removal of transuranic elements for the waste management objectives [22]. Thereafter, several research papers have been published for the removal of actinides using different design and strategy of MACS [23–30]. However, the quantification of actinide requires the reproducible high extraction efficiency, selectivity towards the target analyte or a group of analytes, and reusability in a prevailing chemical environment. The quantification of the analyte preconcentrated on the Fe3O4 NPs is done either subjecting directly to tailored instrumental methods [31, 32], or eluting analyte in an appropriate solution which is subjected to conventional instrumental methods such as alpha spectrometry, ICP-AES etc. [33–35]. The radiation measurement based analytical methods are highly sensitive to radionuclides but lacks chemical selectivity, require constant radiation courting geometry, and often subjected to the sample preparation steps to avoid interferences and lowering detection limit by preconcentration [36, 37].

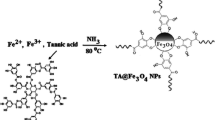

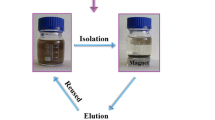

In the present work, the N,N,N′,N′-tetraoctyl diglycolamide (TODGA) and bis(2-ethylhexy)phosphoric acid (HDEHP) coated Fe3O4 NPs have been developed for the preconcentration of actinides from large volume samples followed by magnetic separation. These extractants are well known for their promising separation of lanthanides and actinides [38–40]. The coated particles are characterized by thermogravimetry, vibrating sample magnetometry, and their actinide sorption efficiencies. The amounts of actinides preconcentrated have been quantified either by decoating of the extracting phase on Fe3O4 NPs in scintillation cocktail which is subjected to alpha liquid scintillation counting, or by direct γ-spectrometry. The outline of the present work is shown in Scheme 1.

Experimental

Materials and methods

TODGA and Fe3O4 NPs (20–30 nm) were procured from Thermax, Pune, India and J. K. Impex, Mumbai, India, respectively, dodecane and tetra ethoxy silane (TEOS) from Sigma-Aldrich, methanol from S. D. Fine Chemicals, India, nitric acid (69–70%) received from Beaker chemicals Pvt. Ltd, Mumbai, India and liquid scintillation cocktail-O from Sisco Research Laboratory, India. JASCO 420 spectrometer was used for recording FTIR, and STARe system METLER TOLEDO instrument was used for thermo gravimetric analysis (TGA).

Coating of extractants on Fe3O4 NPs

The coating of TODGA on Fe3O4 (Fe3O4@TODGA) was carried out with and without pre-HNO3 treatment. For acid treatment, TODGA in dodecane (0.1 mol L−1) was equilibrated with equal volume of HNO3 (0.1–3 mol L−1) for 30 min prior to coating. It was then centrifuged and aqueous layer was discarded. Thereafter, Fe3O4 NPs (0.1 g) were dispersed in 10 mL of acid treated as well as in without acid treated solutions containing 0.1 mol L−1 TODGA in dodecane. These solutions containing Fe3O4 particles were subjected to constant agitation for 24 h at room temperature and 40 °C using a constant temperature shaking bath. Subsequently, the coated Fe3O4 particles were separated from solutions using an external magnet. Finally, the coated Fe3O4 particles (Fe3O4@TODGA) were washed 4–5 times with 5 mL of methanol, and dried under vacuum at room temp for overnight.

The coating of HDEHP was carried out in a similar fashion except that acid treatment was not given. Typically, 0.1 g of Fe3O4 NPs were dispersed in 10 mL of 0.1 mol L−1 HDEHP in ethanol and equilibrated under shaking condition for 24 h. Then the coated Fe3O4 was removed and washed 3 times with 5 mL methanol. It was then dried overnight at room temp.

Extraction experiments

The sorption/desorption of actinides in Fe3O4@TODGA was studied using 241Am and mixPu as representatives of actinides. Weighed amounts of Fe3O4@TODGA coated under different chemical conditions were equilibrated with 5 mL solution containing known activity of Am and Pu in 3 mol L−1 HNO3 for 2 h with a constant shaking at room temp. After equilibration, the aqueous phase and Am/Pu loaded Fe3O4@TODGA were separated by applying external magnet, and counted by γ-spectrometer consisting of NaI(Tl) detector coupled to a multichannel analyzer for 241Am, and a home built liquid scintillation counter was used for mixPu. The radioactivity of the aqueous phase before and after equilibration was used to determine the D value using following equation:

where A i and A f represent γ/α -activity of radionuclide in aqueous phase initial and after equilibration, W and V are weight of the functionalized Fe3O4 and volume of equilibrating aqueous phase (5–10 mL), respectively. The uptake efficiency was calculated using following relation:

where Ai and Af are same as given in Eq 1. To study the reproducibility of coating procedure, four batches of Fe3O4@TODGA were prepared by the same procedure and equilibrated with 241Am as described above. Standard deviation was calculated on percentage extraction from different batches. Similar extraction experiments were also carried out with HDEHP coated Fe3O4 for Plutonium extraction at 3 mol L−1 HNO3.

Analytical applications

To explore analytical applications of TODGA@Fe3O4, the known amounts of 241Am activity (5.7–57 µCi) spiked in the 3 mol L−1 HNO3 and loaded in fixed weights of TODGA@Fe3O4 (100 mg) as described above for the sorption experiments. The 241Am activity loaded in Fe3O4 was counted by γ-spectrometry. For alpha liquid scintillation counting, the mixPu loaded TODGA@Fe3O4 particles were dispersed in 5 mL of different solvents like toluene, toluene based scintillator, isopropyl alcohol (IPA) and dioxane based scintillator for 24 h to remove TODGA coating in a scintillating glass vials. Toluene based scintillator contained 5% HDEHP in cocktail-O; whereas dioxane based scintillator contained 1% TOPO in cocktail-W.

Results and discussion

Characterizations of extractant coated Fe3O4 NPs

The morphology of the Fe3O4 NPs did not change after coating the extractant (TODGA/HDEHP) as shown in the representative FE-SEM image in Fig. 1. The size of particles were 20 ± 5 nm. In order to stabilise the magnetite nanoparticles in high nitric acid medium, the magnetite nanoparticles were coated with silica using tetra ethoxy silane (TEOS). The presence of extractant on Fe3O4 NPs was confirmed by FTIR spectroscopy. The absorption peaks at around 638 and 580 cm−1 observed in FTIR spectrum of the pristine Fe3O4 could be assigned to stretching mode of Fe–O. The absorption peaks at 1095 and 1210 cm−1 corresponds to Si–O bond, which shows that silica layer was successfully coated on Fe3O4 see Fig. 2. The additional absorption bands appeared at 2920 and 1375 cm−1 in Fe3O4@TODGA were due to C-H stretching and bending modes of the alkyl group, respectively, 1640 cm−1 was assigned to carbonyl group, and 1105 cm−1 assigned to stretching vibration of C–O–C groups present in TODGA see Fig. 2b. The characteristic phosphate bands were observed at 1370 and 960 cm−1 along with C–H stretching vibrations at 2926 and 1060 cm−1 in FTIR spectrum shown in Fig. 2c of the Fe3O4@HDEHP particles.

The effect of extractants coatings on the superparamagnetic properties of Fe3O4 was studied by using vibrating sample magnetometer (VSM). It is seen from the magnetization curves given in Fig. 3 that the TODGA and HDEHP coatings did not reduce the saturation magnetization to a significant extent with respect to that of the pristine Fe3O4 particles. This seems to suggest that the extractants coating on Fe3O4 was thin as expected from the FE-SEM images.

The amounts of extractants coated on the Fe3O4 particles were determined by thermo gravimetric analysis (TGA) performed under nitrogen atmosphere with the heating rate of 15 °C min−1, and thus obtained thermograms are given in Fig. 4. As can be seen from Fig. 4, 3% weight loss was observed because of adsorbed water in the pristine Fe3O4. For HDEHP and TODGA coated Fe3O4 particles, the initial weight loss about 3 wt% was observed below 200 °C attributed to the loss of water molecules and additional weight losses of 6 wt% from 200 to 600 °C for TODGA coated Fe3O4 and 8% weight loss from 200 to 700 °C for HDEHP coated Fe3O4 were observed. The organic extractants were burned to gases during analysis. Thus, 6 and 8 wt% losses could be correlated to the amounts of extractants coated on the Fe3O4 particles. The higher coating of HDEHP on the Fe3O4 particles could be due to mono acidic phosphate group in HDHEP which has higher affinity towards Fe3+/Fe2+ sites of Fe3O4.

Actinide sorptions and desorptions

The actinide extraction properties of diglycolamides are attributed to their aggregations induced by HNO3 [41–45]. These class of extractants take up tri and tetravalent actinides such as Am(III) and Pu(III,IV) from 3 to 4 mol L−1 HNO3 solutions [46, 47]. To understand effect of HNO3 induced aggregation of TODGA, 0.1 mol L−1 TODGA in dodecane was pre-equilibrated with HNO3 and then coated on the Fe3O4 particles at different temp. As can be seen from distribution coefficients values (D) given in Table 1, the pre-acid treated Fe3O4@TODGA extracted Am3+ quantitatively irrespective of coating temp but no extraction was observed for non-acid treated TODGA coated particles. It was also evident from data given in Table 2 that the Fe3O4@TODGA formed by the coatings of lower concentration of HNO3 acid pre-equilibrated TODGA did not have significant extraction efficiency toward Am3+ ions. This is in accordance with the literature which reported the critical concentration of acid required for 0.1 mol L−1 TODGA in n-alkane to form TODGA reverse micelles was 0.7 M mol L−1 HNO3 [48]. HDEHP exists normally in a dimer form without any pre-treatment [49, 50], therefore was coated as such using conditions described in experimental section. The depicted chemical structure and schematic representation of HDEHP/TODGA coatings is shown in Scheme 2. But in aqueous solution the hydrocarbon chains collapses and coils around magnetite nanoparticles.

To study the reproducibility of TODGA coating, four batches of Fe3O4@TODGA were prepared by the same procedure. Fe3O4@TODGA (0.1 g) was equilibrated with 25 mL solution containing 241Am in 3 mol L−1 HNO3 for 3 h under constant shaking at 25 °C. The extraction efficiency was found to quite reproducible as 87 ± 3%. It was also observed that Pu(III,IV) sorption in Fe3O4@TODGA was similar as expected from literature [41–47].

Unlike Fe3O4@TODGA particles, the Pu(IV) ions were selectively adsorbed in the Fe3O4@HDEHP particles at higher HNO3 concentration as shown in Table 3. Thus, it is possible to quantify Pu(IV) selectively in the presence of Am(III) using the Fe3O4@HDEHP particles. The reusability of Fe3O4@TODGA particles was tested for Am(III) ions. First the Fe3O4@TODGA particles were loaded with Am(III) ions from 25 mL of 3 mol L−1 HNO3 for 3 h; and subsequently de-loaded quantitatively (>99%) with 3 mL of 0.02 mol L−1 disodium salt of EDTA. The cycle of extraction and stripping was repeated for three times. It was observed that the percentage of extraction remains same even after three cycles. The same is also true for Fe3O4@HDEHP particles toward Pu(IV) ions. Where Pu was deloaded with 0.02 mol L−1 disodium salt of EDTA and again equilibrated with same amount of plutonium. The re-usability cycles given in Fig. 5. Which indicates the extractant coatings on Fe3O4 particles did not deteriorate after multiple uses.

Analytical applications

The quantification of 241Am, which emits 59.54 keV γ-rays with 35.9% abundance, was carried out by direct γ-spectrometry of 241Am(III) loaded Fe3O4@TODGA particles. For this, the Fe3O4@TODGA particles (0.01 g) were equilibrated with different amount of 241Am activity (5.7–57 µCi) spiked in the 3 mol L−1 HNO3 and kept under shaking condition for 2 h at room temp. As can be seen from Fig. 6, the gamma activity in Fe3O4@TODGA particles varied linearly as a function of amount of activity spiked. Thus, the direct γ-spectrometry of 241Am(III) loaded Fe3O4@TODGA particles could be used for Am(III) quantification using calibration plot or by the standard comparison method.

The isotopes of Pu are weak γ-emitters and, therefore, their quantification with γ-spectrometry at ultra trace conc is not feasible. However, the α-counting using alpha spectrometry, proportional counters and scintillation counters etc. could be used for the quantification of Pu after appropriate sample manipulation [36, 37, 51–53]. In the present work, the Pu(IV)-loaded Fe3O4@TODGA particles were dispersed in a liquid scintillation cocktail and subjected to scintillation counting. It was observed that Fe3O4@TODGA particles did not remain homogeneously distributed and settled at bottom of the vial. This made alpha scintillation counting non-reproducible and lower than that obtained by spiking the same quantity of Pu in the liquid scintillation cocktail. Therefore, the removal of coating in the liquid scintillation cocktail having different solvents was studied. For this, 241Am was used as it is good γ and α emitter which make it possible to corroborate liquid scintillation counting results with γ-spectrometry.

The known quantity 241Am(III)-loaded Fe3O4@TODGA NPs were dispersed in different organic solvents such as toluene, dioxane and isopropyl alcohol. As can be seen from Table 4, there was no decoating of the TODGA organic phase from 241Am(III)-loaded Fe3O4@TODGA after equilibration for 24 h in toluene. However, the quantitative decoating of TODGA bearing organic phase in dioxane as well as isopropyl alcohol was observed. The dioxane decoated solvent was transparent, but white coagulation was observed in isopropyl alcohol. Therefore, dioxane based liquid scintillation cocktail was tested for decoating of organic phase of 241Am(III)-loaded Fe3O4@TODGA and subsequent alpha scintillation counting. It was observed that scintillation counts rate thus obtained was within ±1% of that obtained by direct spiking of the same quantity of 241Am in the same dioxane based liquid scintillation cocktail. There was no residual γ-activity in the decoated Fe3O4, and did not sorb the Am(III) on reuse.

Finally, the fixed amount (0.1 g) of Fe3O4@TODGA and Fe3O4@HDEHP particles were equilibrated with solution containing varying amount of Pu(IV) ions and fixed amount of 241Am at 3 mol L−1 HNO3. The scintillation counts rates obtained after decoating in the dioxane based liquid cocktail varied linearly with the Pu(IV) amount spiked in the equilibrating solutions. The scintillation counts rate obtained by using the Fe3O4@TODGA particles were systematically higher than that obtained using the Fe3O4@HDEHP particles corresponding to fixed amount of 241Am, see Fig. 7. This was attributed to a fact that the Fe3O4@HDEHP particles sorbed Pu(IV) ions only, while Fe3O4@TODGA takes of both Am(III) and Pu(IV) ions.

a Variation in α-scintillation count rate of mixPu loaded on Fe3O4@TODGA nanoparticles as a function of Pu(IV) amount spiked in the solution. Fe3O4@TODGA nanoparticles were equilibrated with different amount of 239Pu activity (20–114 nCi) spiked in the 3 mol L−1 HNO3 for 2 h under shaking conditions at room temp. Pu loaded Fe3O4@TODGA nanoparticles were then dispersed in 5 mL dioxane based scintillation cocktail and then counted. b Variation in α-scintillation count rate obtained by equilibrating Fe3O4@TODGA and Fe3O4@HDEHP particles in solution having varying amount of Pu(IV) and fixed amount of 241Am (scintillation count rate 35,000 counts min−1) under similar conditions described for Fig. 6a

Conclusions

TODGA and HDEHP extractants were successfully coated on superparamagnetic Fe3O4 nanoparticles using the optimized chemical conditions. The TODGA coated Fe3O4 nanoparticles showed quantitative uptake of Am3+ and Pu4+ ions. However, HDEHP coated Fe3O4 nanoparticles were found to take up Pu4+ ions only from the solution having 3 mol L−1 HNO3, which are normally encountered in the nuclear reprocessing plants. For liquid scintillation counting, the removal of coating in dioxane based scintillator was found to be suitable for the quantification of preconcentrated actinides on the extractant coated Fe3O4 nanoparticles. This provides a potential application of this method for monitoring the ultra-trace concentration of radioactivity in large volume of aqueous sample discharges from nuclear facilities using magnetically assisted separation followed by quantification by alpha scintillation counting.

References

de Dios AS, Díaz-García ME (2010) Multifunctional nanoparticles: analytical prospects. Anal Chim Acta 666:1–22

Huang D, Deng C, Zhang X (2014) Functionalized magnetic nanomaterials as solid-phase extraction adsorbents for organic pollutants in environmental analysis. Anal Methods 6:7130–7141

Chen L, Li B (2012) Application of magnetic molecularly imprinted polymers in analytical chemistry. Anal Methods 4:2613–2621

Decun S, Jiaxiu S, Sha L, Qingsh L, Youfeng H, Yuxiao W, Huijuan C (1996) Preparation of magnetic particle antibodies for radioimmunoassay and immunoradiometric assay of thyroid related hormones. J Radioanal Nucl Chem 206:189–200

Rathi AK, Gawande MB, Pechousek J, Tucek J, Aparicio C, Petr M, Tomanec O, Kirkavova R, Travnicek Z, Varma RS, Zboril R (2016) Maghemite decorated with ultra-small palladium nanoparticles (γ-Fe2O3–Pd): applications in the Heck-Mizoroki olefination, Suzuki reaction and allylic oxidation of alkenes. Green Chem 18:2363–2373

Gawande MB, Luque R, Zboril R (2014) The rise of magnetically recyclable nanocatalysts. ChemCatChem 6:3312–3313

Himstedt HH, Yang Q, Dasi LP, Qian X, Wickramasinghe SR, Ulbricht M (2011) Magnetically activated micromixers for separation membranes. Langmuir 27:5574–5581

Wang Y, Qi Y, Li Y, Wu J, Ma X, Yu C, Ji L (2013) Preparation and characterization of a novel nano-absorbent based on multi-cyanoguanidine modified magnetic chitosan and its highly effective recovery for Hg(II) in aqueous phase. J Hazard Mater 260:9–15

Zhan S, Yang Y, Shen Z, Shan J, Li Y, Yang S, Zhu D (2014) Efficient removal of pathogenic bacteria and viruses by multifunctional amine-modified magnetic nanoparticles. J Hazard Mater 274:115–123

Rezaei A, Khani H, Masteri-Farahani M, Rofouei MK (2012) A novel extraction and preconcentration of ultra-trace levels of uranium ions in natural water samples using functionalized magnetic-nanoparticles prior to their determination by inductively coupled plasma-optical emission spectrometry. Anal Methods 4:4107–4114

Rathod PB, Pandey AK, Meena SS, Athawale AA (2016) Quaternary ammonium bearing hyper-crosslinked polymer encapsulation on Fe3O4 nanoparticles. RSC Adv 6:21317–21325

Varve Z, Lai EPC, Li C, Li C, Sadi BB, Kramer GH (2012) Polymer-coated magnetic nanoparticles for rapid bioassay of 90Sr in human urine samples. J Radioanal Nucl Chem 292:1411–1415

Majidnia Z, Idris A, Majid M, Zin RM, Ponraj M (2015) Efficiency of barium removal from radioactive waste water using the combination of maghemite and titania nanoparticles in PVA and alginate beads. Appl Radiat Isot 105:105–113

Akl ZF, El-Saeed SM, Atta AM (2016) In-situ synthesis of magnetite acrylamide amino-amidoxime nanocomposite adsorbent for highly efficient sorption of U(VI) ions. J Ind Eng Chem 34:105–116

Bée A, Talbot D, Abramson S, Dupuis V (2011) Magnetic alginate beads for Pb(II) ions removal from wastewater. J Colloid Interface Sci 362:486–492

Bagheri H, Roostaie A, Daliri R (2014) An electrospun magnetic nanocomposite for a facile micro-scaled analysis approach. Anal Methods 6:5838–5846

Ballesteros-Gómez A, Rubio S (2009) Hemimicelles of alkyl carboxylates chemisorbed onto magnetic nanoparticles: study and application to the extraction of carcinogenic polycyclic aromatic hydrocarbons in environmental water samples. Anal Chem 81:9012–9020

Ngomsik A-F, Bee A, Talbot D, Cote G (2012) Magnetic solid–liquid extraction of Eu(III), La(III), Ni(II) and Co(II) with maghemite nanoparticles. Sep Purif Technol 86:1–8

He FF, Wang HQ, Wang YY, Wang XF, Zhang HS, Li HL, Tang JH (2013) Magnetic Th(IV)-ion imprinted polymers with salophen schiff base for separation and recognition of Th(IV). J Radioanal Nucl Chem 295:167–177

Chen L, Wang T, Tong J (2011) Application of derivatized magnetic materials to the separation and the preconcentration of pollutants in water samples. TrAC, Trends Anal Chem 30:1095–1108

Lu A, Salabas E, Schüth F (2007) Magnetic nanoparticles: synthesis, protection, functionalization, and application. Angew Chemie Int Ed 46:1222–1244

Nuñez L, Kaminski M, Bradley C, Buchholz BA, Nunez L, Landsberger S, Aase SB, Tuazon HE, Vandegrift GF et al (1995) Magnetically assisted chemical separation (MACS) process: preparation and optimization of particles for removal of transuranic elements. Argonne National Laboratory Argonne, Lemont

Navratil J (2001) Pre-analysis separation and concentration of actinides in groundwater using a magnetic filtration/sorption method I. Background and concept. J Radioanal Nucl Chem 248:571–574

Sadeghi S, Azhdari H, Arabi H, Moghaddam AZ (2012) Surface modified magnetic Fe3O4 nanoparticles as a selective sorbent for solid phase extraction of uranyl ions from water samples. J Hazard Mater 215:208–216

Matthews SE, Parzuchowski P, Garcia-Carrera A, Grüttner C, Dozol JF, Böhmer V (2001) Extraction of lanthanides and actinides by a magnetically assisted chemical separation technique based on CMPO-calix[4]arenes Electronic supplementary information (ESI) available: full synthetic procedures and extraction studies. Chem Commun 5:417–418, http://www.rsc.org/suppdata/cc/b0/b009679m

Li D, Egodawatte S, Kaplan DI et al (2016) Functionalized magnetic mesoporous silica nanoparticles for U removal from low and high pH groundwater. J Hazard Mater 317:494–502

El-Maghrabi HH, Abdelmaged SM, Nada AA, Zahran F, El-Wahab SA, Yahea D, Hussein GM, Atrees MS (2017) Magnetic graphene based nanocomposite for uranium scavenging. J Hazard Mater 322:370–379

Nuñez L, Kaminski MD (1999) Transuranic separation using organophosphorus extractants adsorbed onto superparamagnetic carriers. J Magn Magn Mater 194:102–107

Ambashta RD, Wattal PK, Singh S, Bahadur D (2006) Magnetic carrier for radionuclide removal from aqueous wastes: parameters investigated in the development of nanoscale magnetite based carbamoyl methyl phosphine oxide. Sep Sci Technol 41:925–942

Kaur M, Zhang H, Martin L, Todd T, Qiang Y (2013) Conjugates of magnetic nanoparticle: actinide specific chelator for radioactive waste separation. Environ Sci Technol 47:11942–11959

Banerjee R, Katsenovich Y, Lagos L, Senn M, Naja M, Balsamo V, Pannell KH, Li CZ (2010) Functional magnetic nanoshells integrated nanosensor for trace analysis of environmental uranium contamination. Electrochim Acta 55:7897–7902

Li N-N, Kang T-F, Zhang J-J, Lu L-P, Cheng S-Y (2015) Fe3O4@ ZrO2 magnetic nanoparticles as a new electrode material for sensitive determination of organophosphorus agents. Anal Methods 7:5053–5059

Khayatian G, Hassanpoor S, Azar ARJ, Mohebbi S (2013) Spectrophotometric determination of trace amounts of uranium(VI) using modified magnetic iron oxide nanoparticles in environmental and biological samples. J Braz Chem Soc 24:1808–1817

O’hara MJ, Carter JC, MacLellan JA, Warner CL, Warner MG, Addleman RS (2011) Investigation of magnetic nanoparticles for the rapid extraction and assay of alpha-emitting radionuclides from urine: demonstration of a novel radiobioassay method. Health Phys 101:196–208

Cui C, He M, Chen B, Hu B (2014) Chitosan modified magnetic nanoparticles based solid phase extraction combined with ICP-OES for the speciation of Cr(III) and Cr(VI). Anal Methods 6:8577–8583

Vajda N, Kim C-K (2011) Determination of transuranium isotopes (Pu, Np, Am) by radiometric techniques: a review of analytical methodology. Anal Chem 83:4688–4719

Qiao J, Hou X, Miró M, Roos P (2009) Determination of plutonium isotopes in waters and environmental solids: a review. Anal Chim Acta 652:66–84

Nayak PK, Kumaresan R, Venkatesan KA et al (2014) Extraction behavior of Am(III) and Eu(III) from nitric acid medium in tetraoctyldiglycolamide-bis(2-ethylhexyl)phosphoric acid solution. Sep Sci Technol 49:1186–1191

Sengupta A, Murali MS, Mohapatra PK (2013) A comparative study of the complexation of Am(III) and Eu(III) with TODGA in room temperature ionic liquid. J Radioanal Nucl Chem 298:405–412

Shimojo K, Kurahashi K, Naganawa H (2008) Extraction behavior of lanthanides using a diglycolamide derivative TODGA in ionic liquids. Dalt Trans 37:5083–5088

Yaita T, Herlinger AW, Thiyagarajan P, Jensen MP (2004) Influence of extractant aggregation on the extraction of trivalent f-element cations by a tetraalkyldiglycolamide. Solvent Extr Ion Exch 22:553–571

Abécassis B, Testard F, Zemb T, Berthon L, Madic C (2003) Effect of n-octanol on the structure at the supramolecular scale of concentrated dimethyldioctylhexylethoxymalonamide extractant solutions. Langmuir 19:6638–6644

Nave S, Modolo G, Madic C, Testard F (2004) Aggregation properties of N, N, N′, N′-tetraoctyl-3-oxapentanediamide (TODGA) in n-dodecane. Solvent Extr Ion Exch 22:527–551

Chavan V, Thekkethil V, Pandey AK, Iqbal M, Huskens J, Meena SS, Goswami A, Verboom W (2014) Assembled diglycolamide for f-element ions sequestration at high acidity. React Funct Polym 74:52–57

Chavan V, Patra S, Pandey AK, Thekkethil V, Iqbal M, Huskens J, Sen D, Mazumder S, Goswami A, Verboom W (2014) Understanding nitric acid-induced changes in the arrangement of monomeric and polymeric methacryloyl diglycolamides on their affinity toward f-element ions. J Phys Chem B 119:212–218

Ansari SA, Pathak P, Mohapatra PK, Manchanda VK (2011) Chemistry of diglycolamides: promising extractants for actinide partitioning. Chem Rev 112:1751–1772

Sasaki Y, Tachimori S (2002) Extraction of actinides(III),(IV),(V),(VI), and lanthanides(III) by structurally tailored diamides. Solvent Extr Ion Exch 20:21–34

Jensen MP, Yaita T, Chiarizia R (2007) Reverse-micelle formation in the partitioning of trivalent f-element cations by biphasic systems containing a tetraalkyldiglycolamide. Langmuir 23:4765–4774

Tkac P, Vandegrift GF, Lumetta GJ, Gelis AV (2012) Study of the interaction between HDEHP and CMPO and its effect on the extraction of selected lanthanides. Ind Eng Chem Res 51:10433–10444

Grimes TS, Jensen MP, Debeer-Schmidt L, Littrell K, Nash KL (2012) Small-angle neutron scattering study of organic-phase aggregation in the TALSPEAK process. J Phys Chem B 116:13722–13730

Paul S, Pandey AK, Kumar P, Kaity S, Aggarwal SK (2014) Tailored bifunctional polymer for plutonium monitoring. Anal Chem 86:6254–6261

Paul S, Pandey AK, Shah RV, Aggarwal SK (2015) Chemically selective polymer substrate based direct isotope dilution alpha spectrometry of Pu. Anal Chim Acta 878:54–62

Paul S, Pandey AK, Shah RV, Bhushan KS, Aggarwal SK (2016) Polymer based sorbent materials for thermal ionization mass spectrometric determination of uranium (VI) and plutonium (IV) ions. J Anal At Spectrom 31:985–993

Acknowledgements

Shashikala Ojha is thankful to Dr Pradeepkumar K. S., Associate Director, HS&EG and Head RSSD, BARC and R. K. Gopalakrishnan, Head RHCS, RSSD, BARC for giving permission to carry out doctoral work and their keen interest in the present work. Authors are also thankful to Dr P. K. Pujari, Head Radiochemistry Division, BARC for his keen interest in the present work. Vivek Chavan is supported by Korea Research Fellowship Program through the National Research Foundation of Korea (NRF) funded by Ministry of Science, ICT and Future Planning (NRF-2015H1D3A1066285).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ojha, S., Chappa, S., Mhatre, A.M. et al. Actinides selective extractants coated magnetite nanoparticles for analytical applications. J Radioanal Nucl Chem 312, 675–683 (2017). https://doi.org/10.1007/s10967-017-5246-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-017-5246-6