Abstract

We describe a convenient and flexible solid phase radioimmunoassay for human insulin employing magnetizable cellulose particles. Anti-porcine insulin antibody was covalently linked to magnetizable cellulose particles to form a stable and economical solid phase immunosorbent system. The tracer was prepared by radioiodinating insulin with 125I using Chloramine-T oxidation method. The analytical sensitivity of assay observed was 5.5 μIU/mL. Intra-assay and inter-assay variations were found to be <12 % along with analytical recovery of 93–109 %. The developed assay can be used for the routine analysis of clinical samples. In addition, concentration of the solid phase magnetizable immunosorbent can be easily varied as per the specific requirement for research purposes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Insulin is synthesized in the β-cells of the islet of Langerhans as an immature, inactive precursor proinsulin, which undergoes enzymatic proteolysis to render mature insulin and its cleavage by product, C-peptide [1]. Glucose-stimulated insulin by the islets is a fundamental tool for studying and assessing islet function [2]. Insulin secretory defects and insulin resistance are associated with type 2 diabetes whereas type 1 diabetes, is associated with an autoimmune-mediated destruction of pancreatic β-cells resulting in insulin deficiency [3]. Reliable measurement of insulin is thereby needed to understand the pathogenesis of type 2 diabetes and transplantation of pancreas. Insulin levels are also used in studying morbidity due to cardiovascular disease [4].

Insulin immunoassay was first developed by Yalow and Berson in 1960 [5]. Since then, several modifications of the insulin immunoassay have been described for routine sample analysis. An essential requirement of reliable immunoassays is an efficient and clean method for separating the bound immune complexes from the non-reacted reagents. Solid phase separation has immensely contributed towards the reliability and simplicity of assays. Some commonly used solid supports for solid phase assays are plain cellulose, plastic tubes or plastic beads and a variety of magnetizable particles. Although solid phase separation based on antibody coated plastic tubes are most popular, they are expensive due to the requirement of large quantities of antibody along with quality tubes and sophisticated automated instrumentation. On the other hand, separation methods based on antibody coupled to magnetizable particles as solid phase are relatively inexpensive and can serve as an attractive alternative to coated tubes, without compromising on the simplicity of the assay system [6]. In addition, they are amenable to R&D needs unlike antibody coated tubes wherein the antibody concentration being fixed on the tube cannot be varied as per the specific requirement of the assay parameters such as sensitivity, range, etc. [7].

Experimental

Materials

Polyclonal anti-porcine insulin raised in guinea pig was obtained from Fitzgerald, USA. Porcine insulin for standard preparation, Bovine serum albumin (BSA) and 1, 1′ Carbonyl-di-imidazole (CDI) were from Sigma Chemical Company, USA. Magnetizable cellulose particles were prepared in-house (Indian Patent No: 193445). Bovine serum for preparation of insulin standards was purchased from Himedia, India. Na125I used for labelling was from Bhabha Atomic Research Centre, India.

Coupling of anti-porcine insulin antibody to magnetizable cellulose particles

Anti-porcine insulin antibody was purified using sodium sulphate precipitation method. Briefly, the procedure involves mixing 180 mg of anhydrous sodium sulphate with 1 mL of raw antiserum for the precipitation of IgG fraction from the serum. The resulting turbid mixture was mixed gently for half an hour at room temperature to allow complete precipitation. The contents were centrifuged at 3,000 rpm for 10 min and the supernatant was discarded. The precipitate was then suspended in 50 mL of 18 % sodium sulphate solution and mixed thoroughly. It was once again centrifuged at 3,000 rpm for 10 min and the supernatant was discarded. The above procedure was repeated once again and the resulting IgG pellet was finally dissolved in 5 mL of 0.1 M bicarbonate buffer, pH 8 (bicarbonate buffer). 1 g of in-house prepared magnetizable cellulose particles [7] were washed with double distilled water (DDW) and acetone. The washed particles were suspended in 50 mL of acetone containing 500 mg of CDI with gentle shaking for 1 h at room temperature. The activated particles were washed successively with acetone, DDW and bicarbonate buffer. The particles were then suspended in 15 mL of bicarbonate buffer and 5 mL of previously precipitated anti-porcine insulin antibody was added. The total reaction volume was maintained at 20 mL and coupling reaction was allowed to proceed overnight at room temperature with gentle shaking. Following coupling reaction, anti-porcine insulin antibody linked magnetizable cellulose particles were washed once with bicarbonate buffer and saturated with 0.2 M glycine prepared in 0.1 M bicarbonate buffer, pH 8 containing 2 % BSA. To block the residual binding sites, particles were alternatively washed several times with bicarbonate buffer and 0.1 M sodium acetate buffer, pH 4. Finally, anti-porcine insulin antibody coupled magnetizable cellulose particles were suspended in 20 mL of assay buffer (0.2 % BSA and 0.1 % Tween-20 in 0.05 M Phosphate buffer, pH 7.4) and stored at 4 °C until further use.

Preparation of radiolabelled insulin

Porcine insulin was radioiodinated with 125I using Chloramine-T oxidation method as described by Greenwood et al. [8]. The labelled insulin was purified by gel filtration over a Sephadex G-75 column previously saturated with 1 % BSA. Purified 125I labelled insulin was aliquoted and stored at −20 °C. At the time of the assay, the aliquot was reconstituted with assay buffer to get approximately 50,000 CPM per tube. The radioiodination yield and radiochemical purity (RCP) were determined by paper chromatography method.

Insulin calibrators (standards)

A set of six insulin standards in the range of 0–200 μIU/mL (0, 7.5, 12.5, 25, 50, 100 and 200 μIU/mL) were prepared by dissolving porcine insulin in bovine serum depleted of insulin by activated charcoal method as described by Carter [9] with minor modifications. Insulin standards were calibrated against WHO International Reference preparation (NIBSC 83/500). Sodium azide (1 g/L) was added as a preservative and standards were stored frozen at −20 °C.

Assay procedure

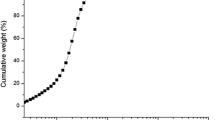

The optimised assay procedure was established after optimization of various assay parameters such as reaction kinetics, concentration of antibody coupled to magnetizable cellulose, the amount of 125I labelled insulin (tracer), volume of standard/samples etc. to achieve optimal sensitivity and assay range. The final assay procedure involved the incubation of 200 µl of standards/sample along with 100 µl of anti-porcine insulin antibody coupled to magnetizable cellulose particles overnight at room temperature with gentle stirring. This was followed with the further addition of 100 µl of tracer with second incubation for 4 h at room temperature under gentle stirring. At the end of incubation, 1 mL of wash buffer (0.05 M Phosphate buffer containing 0.9 % sodium chloride and 0.5 % Tween-20) was added and the assay tubes containing reaction mixture were placed on a magnetic rack for 15 min. The particles were allowed to form a firm pellet. The supernatant was discarded by gently inverting the rack. The radioactivity associated with the solid phase particles were measured using multi-well gamma counter calibrated for 125I. A standard curve was constructed by plotting % B/B0 (Y-axis) versus insulin concentration (X-axis) on a logit-log graph sheet. The insulin concentrations in test samples were estimated from a standard curve by interpolation. A typical standard curve is shown in Fig. 1.

Results and discussion

Chloramine-T method used for the preparation of 125I labelled insulin as described by Greenwood et al. [8] was found to be consistent and reproducible with a labelling yield of 80 ± 4 % (n = 8) as determined by paper electrophoresis corresponding to specific activity of 150 ± 8 µCi/µg. Radiochemical purity of labelled insulin as determined by the paper electrophoresis was found to be not less than 95 %. The labelling yield and RCP was also confirmed by trichloroacetic acid (TCA) precipitation method. The method of coupling anti-porcine insulin antibody to magnetizable cellulose using CDI was found to be simple, reproducible and resulted in a stable immunosorbent. The immunosorbent suspension stored at 4 °C retained immunoreactivity for not less than 2 years.

One of the methods followed in immunoassay procedure to enhance the sensitivity is the sequential addition of the assay reagents. Anti-insulin coupled magnetizable cellulose particles and standard insulin was incubated overnight followed by the late addition of 125I labelled insulin. Second incubation was allowed to proceed for different duration of time (3, 4 and 5 h) and corresponding standard curves were plotted as shown in Fig. 2. Assay was found to be most sensitive, under given reagent concentrations, as determined by the standard methods. It was found to be 5.5 μIU/mL for overnight + 4 h incubation.

Cross-reactivity (CR) of the related peptide hormones were evaluated in the developed assay system to assess the specificity of insulin antiserum (Table 1). The percentage CR was calculated as the ratio of ED50 of insulin concentration to ED50 of the cross reactant. Cross reactivity of the insulin antiserum determined as above for human proinsulin (assay range 0.125–2 ng/mL) and C-peptide (assay range 0.3–18 ng/mL) was found to be <0.05 %. Undetectable cross reactivity was observed in case of glucagon (assay range 0.0125–0.125 ng/mL), somatostatin (assay range 0.00625–0.1 ng/mL) and pancreatic polypeptide (assay range 0.025–1 ng/mL) eventhough presented in their supraphysiological concentrations in the assay system (Fig. 3).

Reproducibility of the assay was checked by intra-assay and inter-assay variations using standard methods. Intra-assay and inter-assay variations were found to be <10 and <12 % respectively indicating acceptable precision in immunoassays (Table 2). Matrix identity and accuracy of the assay system was confirmed by recovery studies and linearity of dilution studies. For recovery studies, human serum samples containing insulin were spiked with a known amount of insulin standards. The native sample and spiked sample were analyzed in the same assay (Table 3). Percentage recovery ranged from 93 to 109 %. Linearity was assessed by determination of dilution parallelism. For linearity of dilution studies, human samples containing high insulin concentrations were diluted twofold, fourfold and eightfold with zero standard and both native samples as well as diluted samples were analyzed in the same assay. Parallelism between standard reference serum and serially diluted human serum samples was evident as depicted supporting the antibody binding characteristics to allow determination of insulin levels in diluted samples. Percentage recovery for dilution parallelism ranged from 87 to 124 % (Table 4).

Around 50 clinical samples were analyzed using developed assay. Insulin values obtained were compared with those values obtained by using an established commercial kit supplied by BRIT based on the second antibody/polyethylene glycol (PEG) separation system with acceptable correlation (r = 0.99; Y = 0.99x + 0.41 μIU/mL).

Validation data presented clearly demonstrates the suitability of magnetizable cellulose particle separation system for determination of insulin by radioimmunoassay (RIA). Basically, success of most immunoassay procedures lies in the efficient separation of the Ag–Ab complex from free Ag. Earlier methods employed cumbersome procedures like charcoal separation [10] and double antibody technique using anti-guinea pig γ-globulin [11] for insulin radioimmunoassay. The developed magnetizable cellulose particles separation for the insulin radioimmunoassay employs simple, one-step efficient and complete separation thereby providing more sensitive and accurate quantification of insulin levels. Magnetizable cellulose particles have been preferred over similar other polymer coated magnetizable particles as they offer stable solid supports with reduced non specific binding. Several assays for T3, T4, PTH and testosterone have been developed using this technique [7, 12, 13]. It is seen from validation studies that consistency of assay was comparable to the binding observed in the liquid phase separation system (conventional method). The method retains all the technical excellence of the conventional liquid phase assay method and possesses other practical advantages of economy, ease of operation and time saving.

Although amino acid sequence of insulin varies among species, certain segments of the molecule are strongly conserved among vertebrates. The strong homology leads to a three dimensional conformation of insulin that is very similar across species. Thus, insulin from one species is often biologically active in other species. Bovine insulin differs from human in only three amino acids, and porcine insulin in one amino acid. The amino acid sequence of human insulin is very much identical to that of porcine insulin differing only in the replacement of threonine for human and alanine at residue B30 in porcine insulin. Porcine insulin is preferred for the preparation of assay standards as well as for the preparation of the tracer as cross reactivity of anti-porcine insulin antibody with human insulin is almost 100 %. In addition, it is economical and widely available in purified form [14]. Recovery/dilution linearity studies employing standards and 125I labelled insulin prepared using porcine insulin along with human samples demonstrate the same (Tables 3 and 4).

Conclusions

The developed assay procedure can be adopted for large-scale production of Insulin RIA kits. Ready to use standards along with minimal pipetting steps make this assay protocol very attractive and can be compared with assays based on tubes. The developed assay has an added advantage of flexibility in use of solid phase magnetisable immunosorbent as per the requirement in research.

References

Chan SJ, Keim P, Steiner DF (1976) Proc Natl Acad Sci USA 73:1964–1968

Heyduk E, Moxley MM, Salvatori A, Corbett JA, Heyduk T (2010) Diabetes 59:2360–2365

Bouchea C, Lopeza X, Fleischmana A, Cypessa AM, Sheila O’Sheaa, Stefanovskie, Bergmane DR, Rogatskyf E, Steinf DT, Kahna CR, Kulkarnia RN, Goldfine AB (2010) Proc Natl Acad Sci USA. doi:10.1073/pnas.1000002107

Pyolara M, Miettinen H, Laakso M, Pyolara K (1998) Circulation 98:398–404

Yalow RS, Berson SA (1960) J Clin Invest 39(7):1157–1175

Paradkar S, Vrinda C, Jyotsna N, Sivaprasad N (1998) J Radioanal Nucl Chem 241(3):561–567

Kadwad VB, Jyotsna N, Sivaprasad N, Sinha PK (1996) J Radioanal Nucl Chem 210:27–33

Greenwood FC, Hunter WM, Glover JS (1963) Biochem J 89:114–123

Carter P (1978) Clin Chem 24(2):362–364

Albano JDM, Ekins RP, Maritz G, Turner C (1972) Acta Endocrinol 1(70):487–509

Dalpé-Scott M, Heick HM, Bégin-Heick N (1982) Can J Biochem 60(10):962–966

Prasad UV, Krishna Mohan R, Samuel G, Harinarayan CV, Sivaprasad N, Venkatesh M (2012) Indian J Med Res 136(6):963–970

Mohan RK, Kadwad V, Samuel G, Venkatesh M, Sivaprasad N (2006) J Radioanal Nucl Chem 268:461–466

Reimers TJ, Cowan RG, McCann JP, Ross MW (1982) Am J Vet Res 43(7):1274–1278

Acknowledgments

We thank Dr. A. K. Kohli, Chief Executive, BRIT and Shri. S. S. Sachdev, Senior General Manager, RPhP for their keen interest and support throughout course of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rasmi, R.R., Bhasker Shenoy, K., Sarnaik, J. et al. Standardisation of radioimmunoassay for human insulin employing magnetizable cellulose particles. J Radioanal Nucl Chem 302, 1271–1275 (2014). https://doi.org/10.1007/s10967-014-3539-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-014-3539-6