Abstract

The high potential of bentonites to volume changes depending on the water content is considered as their advantage for the engineered barriers in the deep geological repository of high-level radioactive waste and spent nuclear fuel because of swelling and self-healing of cracks in contact with water. On the other hand, drying may lead to opening of cracks and spaces between the bentonite blocks. This would increase the permeability and contamination risk around the hot container with high-level radioactive waste and spent nuclear fuel, especially if the host rock mass is dry. First shrinkage tests on four Slovak bentonites studied for engineered barriers were carried out. The water content at the shrinkage limit and the relative linear shrinkage are the first available shrinkage parameters received for the bentonite paste. The shrinkage hazard is higher in the best bentonites with high swelling potential—from Kopernica and Jelšový potok. The results indicated the necessity of further shrinkage tests to determine the relative linear and volume shrinkage of bentonite elements pressed of the loose bentonite powder of low water content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The swelling potential made bentonites to the most recommended material for the engineered barriers in deep geological repositories of high level radioactive waste and spent nuclear fuel, and bentonite emplaced in compacted block form is the preferred option for the clay buffer for most waste management organisations [1–19]. In swelling clays two categories of swelling are observed. The first category—the innercrystalline swelling—is caused by the hydration of the exchangeable cations of the dry clay. The second category—the osmotic swelling—results from the large difference in the ion concentrations close to the clay surfaces and in the pore water. The swelling behaviour of clay rocks depends on the type and quantity of clay minerals encountered their surface charge and the valence of the cations in the double layer [20–25]. In addition, the swelling properties depend on the initial dry density and water content of the soil specimen. The higher the initial dry density, the higher the swelling pressure or the higher the swelling strain; the swelling strain decreases with increasing initial water content, but the swelling pressure seems not to be affected by the initial water content [26, 27]. The swelling properties can be also affected by the chemical composition of the saturating fluid: the swelling capacity of the bentonite decreases with the increase in salinity of saturating fluid, although this influence becomes less significant for higher densities [28–32]. Moreover, studies on the aging effects on the swelling behavior show that the swelling potential may decrease with time due to the rearrangement of clay particles with time [33–35]. The swelling potential of bentonites from several Slovak deposits was already evaluated by the Atterberg liquid limit as indicator, and by swelling pressure tests [36]. While swelling follows wetting, drying leads to shrinkage of bentonites. This seems to be a minor problem for the long-term performance of the barrier expecting that water saturation and swelling will progress fast enough through the clay buffer to limit advective transport. Mayor et al. [37] reported that based on thermo–hydro-mechanical models, bentonite undergoes a drying process due to the sudden increase in temperature close to the canister and reduces the degree of saturation to 0.5 in the first year but then a resaturation begins due to water from the rock mass. Also Pusch et al. [38] point out the necessity of the undisturbed water access for the optimal function of the clay barrier. But gaps between the high-density bentonite blocks used in most repository concepts might open, or fissures in the blocks could appear eventually in the first period of the repository operation, especially if the host rock mass is dry. This could increase the hydraulic conductivity of the buffer and the vulnerability of the host rock mass at least for a short period. To be able to assess the risk of environment contamination by radioactive substances, nuclear fuel fission products included, data on shrinkage parameters of the applied bentonite are necessary. This initiated a pilot research of shrinkage parameters of Slovak bentonites.

Experimental

Applied methods

The volumetric shrinkage limit and the relative linear shrinkage were tested. The volumetric shrinkage limit of clays w s (%) is the water content below which clay ceases to shrink [39]. This limit should be recognized by most of clays by a change to a lighter colour [40]. The research started with a comparison of several technical standards for shrinkage tests which showed that they suggest some more or less different test procedures for w s:

-

Method A*: A method for undisturbed or remoulded cylindrical soft rock/soil specimens; their changing water content and related specimen volume are measured during drying and the shrinkage curve necessary for the shrinkage limit approximation is plotted.

-

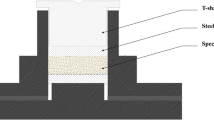

Method A: A volumetric measurement only on the soil fraction passing a specified sieve (mostly 0.5 mm); sieved clay is mixed with distilled water to a smooth homogeneous paste with a moisture content w a little above the Atterberg liquid limit w L, i.e. w = (1–1.1) × w L. The paste is placed into a shrinkage dish or ring on a glass plate (without entrapping air) and dried at the room temperature. The volume change is monitored during drying and the shrinkage curve plotted as in method A*, while a special attention is given to the colour. At the moment of the colour change, owen drying starts, first at 50 °C, then at 105 °C. Shrinkage limit is estimated from the linear part of the shrinkage curve (Fig. 1).

-

Method B: Specimen preparation and drying as in method A, but without continuous measurement, the volume and weight are measured only after full drying. Shrinkage limit is calculated as w s = (V d/m d − 1/ρ s) × ρ w, where V d (cm3) is the volume of the dry specimen, m d (g) is the dry mass, ρ s (g cm−3) is the particle density and ρ w (g cm−3) is the density of water.

-

Method C: No volume measurement; specimen preparation as in method A, drying at the room temperature, monitoring of the specimen weight; here, shrinkage limit is considered as the water content at the moment when the weight lost by drying is lower than 1 % of the previous weight measurement after 24 h.

Table 1 shows types of methods allowed by those national technical standards. There are also different attempts to the shrinkage curve construction within the methods A* and A (different parameters on the y-axis), while water content is always on the x-axis—read remarks. The practical comparison of the different methods was one of the research aims.

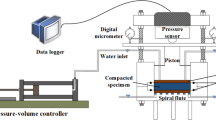

Because bentonite powders were tested (i.e. no undisturbed or compacted samples), the shrinkage limit w s was measured by the fully monitored method A, that allowed also a calculation according to simplier methods B and C from the measured data and a comparison of results. Specimen dimensions were close to DIN 18122-2 [40] ÖNORM B 4411 [41].

Due to the dimensions of available moulds, the relative linear shrinkage was tested according to BS 1377: Part 2 [39] and ÖNORM B 4411 [41]. Sample preparation was the same as in the shrinkage limit test. The relative linear shrinkage L s was calculated as L s = (1 − L d/L o) × 100, where L o is the initial length of the sample and L d is the length of the dry sample.

Bentonite samples

Four bentonites from deposits in Slovakia were tested: J250 from Jelšový potok, K45 from Kopernica, L45 from Lieskovec and LA45 from Lastovce. Many authors give their exact geological, mineralogical and geochemical characteristics, the most recent review of those publications was set up by Šucha, Andrejkovičová, Stríček, Osacký, Melichová and Galamboš et al. [42–54]. The number in the bentonite symbol gives the grain size, e.g. J250 means grains passing the sieve mesh 0.250 mm. Data on Atterberg consistency limits and particle density were taken from publication [55].

Results and discussion

The results of the shrinkage tests are given in Fig. 2 and Table 2. If the shrinkage limit w s is lower than the equilibrium vapour content at room conditions w, bentonite blocks might shrink and gaps between them open due to high temperature around the radwaste containers until water from the host rock mass intrudes and bentonite swells. This could happen to the blocks of bentonites J250 and K45 according to test methods A and C, while no hazard was indicated by the method B. Bentonites L45 and LA45 show no shrinkage hazard. Because of different results by different methods, further shrinkage tests are necessary. Shrinkage of the compacted high-density bentonite should be studied, because shrinkage limit of all studied bentonites is very similar, but the relative linear shrinkage L s shows differences. Bentonites K45 and J250 showed the highest relative linear shrinkage, as these bentonites have also the highest swelling potential, i.e. the potential to volume changes [55].

The experience with the different tests methods was summed up as follows. The determination of the relative linear shrinkage L s showed very high values, but it does not indicate the ultimate shrinkage of compacted bentonite blocks. This test is suitable explicitly for comparative studies when searching for material less sensitive to shrinkage. In tests on compacted bentonites (as in method A*), shrinkage depends not only on the current water content, which is far below the liquid limit required as starting moisture in standard tests, but also on the grain size distribution and porosity (pore number and size).

It is to point out that different interpretation (methods A, B and C) of the same shrinkage limit tests with the same specimens brought different results. One should be aware of this and always ask about the exact description applied for w s determination. The application of the method B is questionable, because results are highly dependent on the accuracy of the problematic particle density determination. Small deviation makes big difference in the shrinkage limit.

The colour change observation does not work well as indicator of reaching the shrinkage limit. Some bentonites (J250, L45—Figs. 3, 4) became lighter than the liquid paste (method A), but the daily mass decrease by drying was still above the 1 % defined as indicator of the shrinkage limit in the method C. On the other hand, slowly dried K45 was still darker than the fresh paste, even after drying at 50 °C (Fig. 5). Finally, its colour got lighter only after drying at 105 °C.

Some bentonites (e.g. J250) cracked during free drying. But if the drying rate is controlled by containers as in STN 72 1019 [56], method C cannot be used.

Conclusion

A comparison of Slovak, Austrian, German and British Standards for shrinkage test methods showed that Slovak Technical Standards (STN) pertain to undisturbed soil samples, where shrinkage depends not only on the current moisture, but also on the grain size distribution and porosity. Shrinkage limit w s (%) and relative linear shrinkage L s (%) determined according to the foreign technical standards are independent from those properties, because sample preparation brings all soils to equal starting conditions: sieved to grain size below 0.5 mm, water added to reach moisture w near the liquid limit w L, suspension smeared without bubbles into standard moulds. Applied Austrian ONORM B 4411 2009 offers three test procedures for w s. First, w s was determined by manifold measuring of the sample weight and volume during drying. Calculation followed from the water content versus relative volume plot with a linear trend line. Results were compared to data from the other two methods. The highest L s (up to 33.3 % of the initial length) was observed in the bentonite K45 from Kopernica and in J250 from the Jelšový potok deposit (32.3 %), the best Slovak bentonites because of their swelling potential and excellent adsorption properties for radionuclides. Reaching of the shrinkage limit (w s = 13 %) of J250 was indicated also by a colour change from light brownish grey (2,5Y 6/2) to light grey (2,5Y 7/1—Munsell Soil-Color Charts, 2009). Because w s obtained by two test methods is lower than the equilibrium moisture of the bentonite J250 under room conditions, which is 14 %, bentonite blocks might shrink and gaps between them open due to high temperature around the containers with high-level radioactive waste and spent nuclear fuel in the deep geological repository, until water from the host rock mass intrudes and bentonite swells. The same conclusion about the shrinkage hazard was drawn for the bentonite K45 from Kopernica. Results indicated the necessity of further shrinkage tests, but on bentonite powder compacted to high-density blocks/segments. Methods described in STN 72 1019 [56] are recommended as relevant for the assessment of their total linear and volumetric shrinkage.

References

Wilson Savage D, Bond A, Watson S, Pusch R, Bennett D (2011) Bentonite: a review of key properties, processes and issues for consideration in the UK context. Quinteesa report QRS-1378ZG-1.1

Shaefers A, Fahland S (2014) In: Proceedings of the international conference on the performance of engineered barriers. Physical and chemical properties, behaviour and evolution. BGR, Hannover, Feb 6–7, p 522

Slaninka I, Hók J, Franzen J (2007) Status and development of deep geological repository in Slovak Republic from geological point of view. Acta Montan Slovaca 1(12):17–23

Bauer V, Šofranko M, Stavnikovič M (2007) Research of the multibarrier system for an underground deposition of radioactive wastes. Acta Montan Slovaca 1(12):217–225

Galamboš M, Rosskopfová O, Rajec P (2011) Geotechnické požiadavky na bentonitové bariéry v hlbinných úložiskách pre rádioaktívny odpad a vyhoreté jadrové palivo. Bezpečnost jaderné energie 19(57) 7/8:38–44

Galamboš M, Daňo M, Rosskopfová O, Šeršeň F, Kufčáková J, Adamcová R, Rajec P (2012) Effect of gamma-irradiation on adsorption properties of Slovak bentonites. J Radioanal Nucl Chem 292(2):481–492

Galamboš M, Magula M, Daňo M, Osacký M, Rosskopfová O, Rajec P (2012) Comparative study of cesium adsorption on dioctahedral and trioctahedral smectites. J Radioanal Nucl Chem 293(3):829–837

Galamboš M, Osacký M, Rosskopfová O, Krajňák A, Rajec P (2012) Comparative study of strontium adsorption on dioctahedral and trioctahedral smectites. J Radioanal Nucl Chem 293(3):889–897

Krajňák A, Galamboš M, Rosskopfová O, Viglašová E, Rajec P (2012) Slovak bentonites as engineering barriers in radioactive waste management. In: European nuclear conference (ENC 2012), pp 135–139

Galamboš M, Krajňák A, Rosskopfová O, Viglašová E, Adamcová R, Rajec P (2013) Adsorption equilibrium and kinetic studies of strontium on Mg-bentonite, Fe-bentonite and illite/smectite. J Radioanal Nucl Chem 298(2):1031–1040

Jesenák K, Galamboš M, Daňo M, Kurek M, Rosskopfová O (2013) Determination of hydraulic properties of bentonite rocks. [Stanovenie hydraulických vlastností bentonitových hornín.] Bezpečnost jaderné energie 21(59) 11/12:332–336

Adamcová R, Galamboš M, Durmeková T, Rosskopfová O, Krajňák A, Ekkertová P (2013) Pilot research on diffusion parameters of U-235 fission products in Slovak bentonites. In: XV international clay conference, 7–11 July

Krajňák A, Viglašová E, Galamboš M (2014) Disposal, storage and deposit of spent nuclear fuel and high-level radioactive waste in Slovak republic. Bezpečnost jaderné energie (in press)

Galamboš M, Krajňák A, Viglašová E (2014) Th final part of nuclear power engineering in Slovak Republic. Beuzpečnost jaderné energie (in press)

Švandová J, Videnská K, Přikryl R (2013) Experimental evaluation of the influence of saturation media on the mineralogical and physicochemical stability of bentonites. Appl Clay Sci 86:1–10

Mockovčiaková A, Orolínová Z, Škvarla J (2010) Enhancement of the bentonite properties. J Hazard Mater 180:274–281

Kolaříková I, Přikryl R, Hanus R, Jelínek E (2005) Thermal loading of smectite-rich rocks: natural processes vs. laboratory experiments. Appl Clay Sci 29:215–223

Přikryl R, Weishauptová Z (2010) Hierarchical porosity of bentonite-based buffer and its modification due to increased temperature and hydration. Appl Clay Sci 41:163–170

Kolaříková I, Švandová J, Přikryl R, Vinšová H, Jedináková-Křižová V, Zeman J (2010) Mineralogical changes in bentonite barrier within Mock-Up-CZ experiment. Appl Clay Sci 47(1–2):10–15

Madsen FT, Müller-Vonmoos M (1989) The swelling behaviour of clays. Appl Clay Sci 4(2):143–156

Bucher F, Müller-Vonmoos M (1989) Bentonite as a containment barrier for the disposal of highly radioactive wastes. Appl Clay Sci 4(2):157–177

Montes HG, Duplay J, Martinez L, Geraud Y, Rousset-Tournier B (2003) Influence of interlayer cations on the water sorption and swelling-shrinkage of MX80 bentonite. Appl Clay Sci 23:309–321

Přikryl R, Ryndová T, Boháč J, Weishauptová Z (2003) Microstructures and physical properties of “backfill” clays: comparison of residual and sedimentary montmorillonite clays. Appl Clay Sci 23:149–156

Montes-H G, Duplay J, Martinez L, Mendoza C (2003) Swelling-shrinkage kinetics of MX80 bentonite. Appl Clay Sci 22:279–293

Montes-H G (2005) Swelling-shrinkage measurements of bentonite using coupled environmental scanning electron microscopy and digital image analysis. J Colloid Interface Sci 284(1):271–277

Pusch R (1982) Mineral-water interactions and their influence on the physical behavior of highly compacted Na bentonite. Can Geotech J 19(3):381–387

Komine H, Ogata N (1994) Experimental study on swelling characteristics of compacted bentonite. Can Geotech J 31(4):478–490

Pusch R (1980) Swelling pressure of highly compacted bentonite. SKBF/KBS technical report no. 80-13

Vejsada J, Jelínek E, Řanda Z, Hradil D, Přikryl R (2005) Sorption of cesium on smectite-rich clays from the Bohemian massif (Czech Republic) and their mixtures with sand. Appl Radiat Isot 62:91–96

Xiaodong L, Přikryl R, Pusch R (2011) THMC-testing of three expandable clays of potential use in HLW repositories. Appl Clay Sci 52:419–427

Wang Q, Tang AM, Cui Y-J, Delage P, Gatmin B (2012) Experimental study on the swelling behaviour of bentonite/claystone mixture. Eng Geol 124:59–66

Hanuláková D, Zeman J, Vašíček R, Přikryl R, Kuchovský T (2013) Determination of pore water composition during long term interaction of bentonite substrates with water media: comparative study. Appl Clay Sci 80–81:69–75

Subba Rao KS, Tripathy S (2003) Effect of aging on swelling and swell-shrink behaviour of a compacted expansive soil. ASTM Geotech Test J 26(1):36–46

Delage P (2006) Some microstructure effects on the behaviour of compacted swelling clays used for engineered barriers. Chin J Rock Mech Eng 25:721–732

Delage P, Cui YJ, Tang AM (2010) Clays in radioactive waste disposal. J Rock Mech Geotech Eng 2:111–123

Adamcova R, Haasova Y (2005) Selected physical properties of bentonite for the deposit of radioactive waste. Mineralia Slovaca 37:387–389

Mayor JC, Villar MV, Martin PL, Gens A, Velasco M (2014) Water uptake in the bentonite buffer—PEBS case 1. In: Shaefers A, Fahland S (eds) Proceedings of the international conference on the performance of engineered barriers. Physical and chemical properties, behaviour and evolution. BGR, Hannover, Feb 6–7, pp 15–22

Pusch R, Knutsson S, Al-Taie L, Mohammed MH (2012) Optimal ways of disposal of highly redioactive waste. Nat Sci 4:906–918

BS 1377: Part 2 (1990) British standard methods of tests for soils for civil engineering purposes. Part 2. Classification tests

DIN 18122-2 (2000) Deutsche Norm Baugrund. Zustandsgrenzen (Konsistenzgrenzen). Teil 2: Bestimmung der Schrumpfgrenze

ONORM B 4411 (2009) Geotechnik - Untersuchung von Bodenproben. Bestimmung von Fliess-, Plastizitäts- und Schrumpfgrenze unter Einbeziehung der Vornorm ÖNORM CEN ISO/TS 17892-12

Šucha V (2001) Íly v geologických procesoch. Acta Geologica, Universitas Comenianae, Bratislava

Andrejkovičová S, Madejová J, Czímerová A, Galko I, Dohrmann R, Komadel P (2006) Mineralogy and chemistry of Fe-rich bentonite from the Lieskovec deposit (Central Slovakia). Geol Carpathica 57(5):371–378

Stríček I, Šucha V, Uhlík P, Madejová J, Galko I (2009) Mineral stability of Fe-rich bentonite in the Mock-Up-CZ experiment. Geol Carpathica 60(5):431–436

Osacký M, Šucha V, Czímerová A, Madejová J (2010) Reaction of smectites with iron in a nitrogen atmosphere at 75 °C. Appl Clay Sci 50:237–244

Osacký M, Šucha V, Miglierini M, Madejová J (2012) Reaction of bentonites with pyrite concentrate after wetting and drying cycles at 80ºC: relevance to radioactive waste (Radwaste) storage. Clay Miner 47:465–479

Brtáňová A, Melichová Z, Komadel P (2012) Removal of Cu2+ from aqueous solution by Slovak bentonites. Ceram Silik 56(1):55–60

Melichová Z, Hromada L (2013) Adsorption of Pb2+ and Cu2+ ions from aqueous solutions on natural bentonites. Pol J Environ Stud 22(2):457–464

Galamboš M, Kufčáková J, Rajec P (2009) Sorption of strontium on Slovak bentonites. J Radioanal Nucl Chem 281(3):347–357

Galamboš M, Kufčáková J, Rajec P (2009) Adsorption of cesium on domestic bentonites. J Radioanal Nucl Chem 281(3):485–492

Galamboš M, Kufčáková J, Rosskopfová O, Rajec P (2010) Adsorption of cesium and strontium on natrified bentonites. J Radioanal Nucl Chem 283(3):803–813

Galamboš M, Paučová V, Kufčáková J, Rosskopfová O, Rajec P, Adamcová R (2010) Cesium sorption on bentonites and montmorillonite K10. J Radioanal Nucl Chem 284(1):5–64

Galamboš M, Rosskopfová O, Kufčáková J, Rajec P (2011) Utilization of Slovak bentonites in deposition of high-level radioactive waste and spent nuclear fuel. J Radioanal Nucl Chem 288(3):765–777

Galamboš M, Suchánek P, Rosskopfová O (2012) Sorption of anthropogenic radionuclides on natural and synthetic inorganic sorbents. J Radioanal Nucl Chem 293(2):613–633

Adamcova R, Frankovska J, Durmekova T (2009) Engineering geological clay research for a radioactive waste repository in Slovakia. Acta Geol Solvaca 1,2:71–82

STN 72 1019 (1989) Slovak technical standard. Laboratory determination of shrinkage of soils

Acknowledgments

This research was partly granted by the Ministry of Education, Science, Research and Sports of the Slovak Republic (project VEGA 1/0828/13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adamcová, R., Suraba, V., Krajňák, A. et al. First shrinkage parameters of Slovak bentonites considered for engineered barriers in the deep geological repository of high-level radioactive waste and spent nuclear fuel. J Radioanal Nucl Chem 302, 737–743 (2014). https://doi.org/10.1007/s10967-014-3292-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-014-3292-x