Abstract

Carboxymethyl cellulose (CMC)/sodium alginate (SA) hydrogel beads were successfully prepared by Ca2+ ions crosslinking followed by gamma irradiation. The factors affecting beads formation are the composition of SA in the blend and concentration of calcium chloride as a crosslinking agent. The results indicated that the addition of CMC to SA increases the swelling (%) upto (1:3) (CMC:SA) ratio. The effect of different irradiation doses (2.5, 5, and 10 kGy) on swelling (%) was studied. At low doses, swelling (%) decreases upto 5 kGy then starts to increase at 10 kGy. The degree of the swelling (%) and release (%) of ammonium nitrate salt from beads were investigated under different pH (1.2, 5 and 7). The beads were characterized by FTIR, SEM and TGA to investigate molecular structure, morphology and thermal stability of beads.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polymeric beads based on natural polymers are unique class of materials for controlled release, due to their inherent properties such as non-toxic and potentially biodegradable etc. [1].

Although various polymeric carriers have been used for controlled release of pesticides [2], agrochemicals [3], and pharmaceutical [4], however, biodegradable matrix are especially preferred as carriers to prevent different kind of pollution created by residues of depleted, non-degradable carriers. Agriculture represents one of the important areas of international requirement for health, nutrition, and economic development. Agrochemicals are bioactive agents concerned with the utilization of chemicals to control either plant or animal life that is disadvantageous to humans and animals, and to improve production of crops both in quality and quantity. Hence, a great increase in the quantities of these chemicals is necessary for enhancing any substantial increase inform production of food-stuff [5]. Depending on the method of application and climatic conditions, as much as 90 % of applied agrochemicals never reach their target, to produce the desirable biological response.

Sodium alginate (SA) and carboxymethyl cellulose (CMC) are biocompatible, biodegradable polymers and have finding widespread applications in pharmaceutical area [6], tissue engineering [7–9], and food industry [10] and so on. SA, compared of linear chains of α-l-guluronic acid (G) and B-d-mannuronic acid (M) residues joined by 1,4-glucosidic linkages, is a naturally occurring anionic polymer that is extracted from marine brown algae [11]. The most attractive property 0f alginate is its gel formation simply induced by cross-linking with various divalent cations except Mg2+ [12]. Usually calcium alginate beads are formed by dropping soluble SA solution with certain concentration into an aqueous solution of Ca2+ ions made from calcium chloride (CaCl2). Because of SA’s ability to form a stable and bioadhesive gel with calcium ions [13], some sensitive drugs [14, 15], protein [16], living cells [17], etc. could be encapsulated and released through alginate beads. CMC, a water-soluble polysaccharide prepared by chemical modification of cellulose, also has tremendous potential for use in site- and low immunogenicity [18–20].

Highly water absorbing and homogeneous binary biopolymer blends in bead form were prepared from calcium alginate and CMC by solution cast method. The prepared blends were evaluated for controlled delivery of KNO3 which taken as a model agrochemical. The beads characterized by FTIR and SEM were used to investigate the molecular structure and morphology of beads [21].

Gamma irradiation has been found to be effective for degradation of carbohydrate such as alginate, CMC, starch and chitosan. Cleavage of molecular chain ascribed to decay processes of free radicals generated at the primary stage of gamma irradiation. It was found that gamma radiation at low doses can conveniently improve the swelling properties of alginate beads [22].

The present study aims to develope a hydrophilic matrix of binary polymeric blend of SA and CMC and evaluates their potential as controlled release device using a model agrochemical.

Experimental

Materials

A sodium salt of CMC (pure polymer) in the form of granules, molecular weight 1,80,000 was supplied by El-Nasr Pharmaceutical Chemical-Prolabo (Egypt). SA was purchased from shanghai chemical reagents company, chemical grade. Calcium chloride (dihydrates) (Loba Chemie Mumbai, India) was used as a crosslinker for both CMC and SA.

Preparation of beads

SA and CMC in ultrapure water were prepared by weighting respective solids to give (3 % wt/v) for CMC and (5 % wt/v) for SA. Different compositions (1:1, 1:2, 1:3, and 1:4 (CMC/SA) were prepared by mixing the two polymers under continuous stirring until the solution become viscous and homogeneous. The formation of the hydrogel beads was based on the ionic gelation technique. Using a 10 ml syringe the viscous solution was transferred dropwise from a distance of 10 cm into different concentrations of CaCl2·2H2O (1, 3, 5, 7, and 10 % wt/v) which was under magnetic stirring. Hydrogel beads were formed instantly and they were left in contact with the solution for 30 min. in order to complete the gelation. Finally, they were rinsed gently with ultrapure water and dried at 37 °C [23].

Loading of ammonium nitrate

Beads containing ammonium nitrate salt were prepared by dissolving different concentrations of this salt (2 and 5 %) in an aqueous solution containing CMC/SA (1:3). After mixing ammonium nitrate salt with the polymeric solution, beads were fabricated as described above using 3 % CalCl2·2H2O as a crosslinking agent as shown in Fig. 1.

Swelling percentage

Conventional gravimetric procedure [24] was adopted for monitoring the progress of water sorption process. In a typical experiment, preweighed quantity of beads were immersed in a definite volume of water at definite pH and taken out at 24 h. The swollen beads so taken out were gently pressed in between the two filter papers to remove excess water and finally weighed. The swelling (%) was calculated by the following equation.

where W1and W2 represents the weight of the dry and wet beads, respectively.

Release of ammonium nitrate

To study the release of ammonium nitrate, the loaded beads of known weights were placed in a measured volume (20 ml) of distilled water (release medium) under unstirred condition. The released amount of ammonium nitrate after 24 h was determined by measuring the conductivity of the release medium using a conductivity meter (Model Adwa 8000).

IR spectroscopic analysis

FTIR spectrophotometer model Mattson 100, made by Unicam, (UK) was used for FTIR measurements over the range 500–4,000 cm−1.

Scanning electron microscope (SEM)

The surface morphology of unloaded and ammonium nitrate loaded beads were performed by SEM. The micrographs were taken with JSM-5400 instrument manufactured by Joel, Japan.

Thermogravimetric analysis (TGA)

TGA studies were carried out using a TGA-30 apparatus (Shimadzu, Kyoto, Japan), at a heating rate of 10 °C min−1 in air, over a temperature range from room temperature to 600 °C.

Results and discussions

The formation of crosslinked alginate–CMC beads depends on the composition of SA in (CMC/SA) blend and concentration of calcium chloride solution which acts as crosslinking agent and consequently plays an important role on swelling (%) beside the effect of pH on swelling (%).

Effect of SA on beads formation

SA plays an important role in the formation of beads. Addition of CMC will affect the beads formation and its swelling %. The optimum composition for beads formation is 1:3 (CMC/SA). In case of other composition 1:1 and 1:2 (CMC/SA) there are no uniform beads shape. As a conclusion all other factors will be studied for the beads composed of 1:3 (CMC/SA).

Effect of calcium chloride (CaCl2·2H2O)

Calcium chloride, a known crosslinking agent of alginate, is assumed to act as complexing carboxylate anions of alginate by its bivalent calcium ion. In this work, the effect of crosslinker concentration on swelling (%) of blend has been studied by varying the concentration of CaCl2 in the range (1–10 %). The results are summarized in Table 1 that clearly indicates swelling % decreases with increasing concentration of CaCl2. From these results, it was found that CaCl2 solution with concentration 3 % gives suitable swelling % especially from handling the sample.

It is known that with increasing concentration of calcium chloride, the amount of Ca2+ ion per unit volume of the liquid increases and more Ca2+ will bond to the SA chains. This will result in a diminished net work space, so less water can enter the beads. On the other hand, the number of –COO− groups decreased due to the combination of Ca2+ and –COOH group of SA. Therefore, the electrostatic repulsion between –COO− groups becomes weak, and this also gave rise to the decreasing of swelling (%) of the beads.

Effect of pH on swelling (%)

The effect of pH on the swelling (%) of the beads has been investigated in the pH range 1.2, 5 and 7. The results are indicating that the swelling (%) increases with the increase pH of the swelling medium at all concentrations of CaCl2 solution as shown in Fig. 2. The increase in the swelling (%) that can be explained by the fact that with rising pH of the swelling medium, the ratio COO–/COOH on CMC also increases because of increasing ionization of carboxylic groups and this results in a greater repulsion among the –COO– bearing CMC chains. The results may also be explained by the fact that with increasing pH of the swelling medium the extent of ionization of carboxylate groups of alginate also increases which produce greater number of carboxylate ions along the alginate molecule. These anionic charged centers repel each other and produce a rapid relaxation in the network. This clearly results in a rise in the swelling (%).

Effect of gamma irradiation on swelling (%)

Effect of gamma irradiation on the swelling (%) of crosslinked alginate–CMC beads prepared from different concentration of CaCl2 as crosslinking agent is presented in Fig. 3. From this figure, it was found that the swelling (%) decreased up to 5 kGy then considerable increasing was observed at 10 kGy. At 2.5 and 5 kGy, the swelling (%) decreased from 791 % for unirradiated beads to 382 and 268 % respectively, then swelling (%) increases at 10 kGy which was significantly lower than the unirradiated beads where the swelling (%) increased from 268 to 277 % [22].

Fourier transform infrared measurements (FTIR)

Infrared spectra of crosslinked Alginate–CMC beads were studied before and after loading with ammonium nitrates. As shown in Fig. 4 the characteristic bands of both Alginate and CMC were appeared, where some bands were overlapped, as for example the band attributed to O–H group that appeared at (3,521–3,610) cm−1. The characteristic bands of Alginates are two bands at 1,427 and 1,646 cm−1 for the COO− group, and one sharp band at 1,141 cm−1, which is for the C–O group. The characteristic band appeared at 821 cm−1 this may be attributed to the Ca-alginate linkage. By examining the IR spectra of loaded crosslinked-alginate–CMC beads the main characteristic bands of both polymers were appeared but the wavenumber shifted to lower values due to the adsorption and interaction between the ammonium nitrates and the prepared polymer beads.

Scanning electron microscope (SEM)

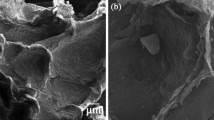

The surface morphology of unirradiated and irradiated crosslinked alginate–CMC beads at 5 and 10 kGy is shown in Fig. 5a, b, c. Randomly aggregated structure through unirradiated beads was observed as shown in Fig. 5a. Figure 5b clearly illustrates the formation of fine macromolecular structure all over the surface of beads networks due to crosslinking of beads at 5 kGy. By increasing radiation dose up to 10 kGy, the macromolecular structure disappear and surface become more smooth due homogeneity of the two polymers as shown in Fig. 5c.

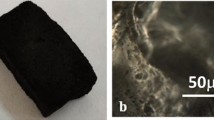

The morphological surface of the unloaded and ammonium nitrate loaded beads have been investigated by recording their SEM as shown in Fig. 6a, b, respectively. In Fig. 6a, it was found that the surface of unloaded beads is quite heterogeneous and possesses a multilayer morphology containing agglomerated cluster of crosslinked alginate–CMC. On other hand, a clear and flat surface crosslinked morphology was observed for the ammonium nitrate loaded beads as shown in Fig. 5b. CMC, SA and ammonium nitrate are assessed in order to understand the stability of ammonium nitrate salt in the matrix system.

Thermal gravimetric analysis (TGA)

TGA was employed to characterize the thermal stability of the unloaded and loaded beads. TGA curves of unloaded and loaded beads are shown in Fig. 7. From this figure, it was found that the thermal stability is approximately the same for loaded and unloaded beads. As for example at 280 °C the weight loss is equal to 35 and 25 % for loaded and unloaded beads respectively. Finally, these results show that the loaded or unloaded beads posse good thermal stability suitable for all the domain of practical application in which these beads are used.

Effect of percent loading on release (%)

The effect of percent loading of ammonium nitrate on its release by the polymeric beads has been studied by varying the amount of percent loading 2, 5, 10 % ammonium nitrate. The results are shown in Fig. 8 which clearly indicate that the amount of released ammonium nitrate from beads increases with increasing percent loading. The accumulative release (%) of the beads containing 10 % ammonium nitrate showed 85 % release at pH7 within 24 h, where as the beads containing 2 % ammonium nitrate showed 60 % release at the same pH and time. Higher initial loading of the salt causes the faster movement of water penetration on surface of beads, this further facilitate the relaxation of the polymer chains. Similar observations were also reported by Johnsen et al. [25].

Conclusion

Addition of CMC affects the beads formation and its swelling %. The optimum composition for beads formation is 1:3 (CMC/SA) which displays suitable swelling (%) using 3 % CaCl2 solution as a crosslinking agent. The swelling (%) decreases with increasing irradiation dose up to 5 kGy, then increased at 10 kGy. Moreover, The accumulative release of ammonium nitrate increases with increasing the percent loading of ammonium nitrate and pH of the medium. This matrix can be used for controlled release of ammonium nitrate that used as agrochemical.

References

Chavidi VP, Bala YS, Chanda LNR, Kokkarachedu VP, Posa S, Subha MCS (2012) Formulation and characterization of sodium alginate g-hydroxy ethylacrylate bio-degradable polymeric beads: in vitro release studies. J Polym Environ 20:344–350

Shukla PG, Kalidhass B, Snah A, Palaskar DV (2002) Preparation and characterization of microcapsules of water-soluble pesticide monocrotophos using polyurethane as carrier material. J Microencapsul 19:293–304

Bajpai AK, Giri A (2003) Water sorption behavior of highly swelling (carboxy methylcellulose-g-polyacrylamide) hydrogels and release of potassium nitrate as agrochemical. Carbohydr Polym 53:271–279

Peppas NA, Bures P, Leobandung W, Ichikawa H (2000) Hydrogels in pharmaceutical formulations. Eur J Pharm Biopharm 50:27–46

Rehab A, Akelah A, Kandil S (1994) Modification of poly(methyl methacrylate)resins with herbicide moities. J Appl Polym Set Appl Polym Symp 55:185–196

Yang Y, He Q, Duan L, Cui Y, Li JB (2007) Assembled alginate/chitosan nanotubes for biological application. Biomaterials 28:3083–3090

Kim IY, Seo SJ, Moon HS, Yoo MK, Park IY, Kim BC, Cho CS (2008) Chitosan and its derivatives for tissue engineering applications. Biotechnol Adv 26:1–21

Shi GQ, Chen YW, Wan CX, Yu XX, Feng T, Ding YL (2008) Study on the preparation of chitosan–alginate complex membrane and the effects on adhesion and activation of endothelial cells. Appl Surf Sci 255:422–425

Li ZS, Ramay HR, Hauch KD, Xiao DM, Zhang MQ (2005) Chitosan-alginate hybrid scaffolds for bone tissue engineering. Biomaterials 26:3919–3928

Capela P, Hay TKC, Shah NP (2007) Effect of homogenisation on bead size and survival of encapsulated probiotic bacteria. Food Res Int 40:1261–1269

Johnson FA, Craig DQM, Mercer AD (1997) Characterization of the block structure and molecular weight of sodium alginates. J Pharm Pharmacol 49:639–643

Liu XX, Qian LY, Shu T, Tong Z (2003) Rheology characterization of sol–gel transition in aqueous alginate solutions induced by calcium cations through in situ release. Polym 44:407–412

Yellanki SK, Nerella NK (2010) Stomach-specific drug delivery of riboflavin using floating alginate beads. Int J Pharmacy Pharm Sci 2:160–163

Grassi M, Colombo I, Lapasin R (2001) Experimental determination of the theophylline diffusion coefficient in swollen sodium-alginate membranes. J Cont Rel 76:93–105

Kim MH, Kim JC, Lee HY, Kim JD, Yang JH (2005) Release property of temperature-sensitive alginate beads containing poly(N-isopropylacrylamide). Coll Surf B 46:57–61

Xu YM, Zhan CY, Fan LL, Wang L, Zheng H (2007) Alginate chitosan blend gel beads and in vitro controlled release in oral site-specific drug delivery systems. Int J Pharm 336:329–337

Stabler C, Wilks K, Sambains A, Constantinidis I (2001) The effects of alginate composition on encapsulated bTC3 cells. Biomaterials 22:1301–1310

Rokhade AP, Agnihotri SA, Patil SA, Mallikarjuna NN, Kulkarni PV, Aminabhavi TM (2006) Semi-interpenetrating polymer network microspheres of gelatin and sodium carboxymethyl cellulose for controlled release of ketorolac tromethamine. Carbohydr Polym 65:243–249

Liu Z, Jiao Y, Wang Y, Zhou C, Zhang Z (2008) Polysaccharides-based nanoparticles as drug delivery systems. Adv Drug Deliv Rev 60:1650–1657

Jo H, Kim DS, Hong MS, Kim HL, Cho WH, Lee D, Khang G (2011) Influence of the viscosity properties on drug release rate from hydroxymethylcellulose and carboxymethylcellulose matrix tablets. Int J Tiss Regen 2:21–28

Bajpai J, Mishra S, Bajpai AK (2007) Dynamics of controlled release of potassium nitrate from a highly swelling binary polymeric blend of alginate and carboxymethyl cellulose. J Appl Polym Sci 106:961–972

Tanzina H, Avik K, Dominic D, Stephane S, Ruhul AK, Monique L (2012) Effect of gamma radiation on the physico-chemical properties of alginate-based films and beads. Rad Phys Chem 81:945–948

Salmieri S, Lacroix M (2006) Physicochemical properties of alginate/polycaprolactone-based films containing essential oils. J Agric Food Chem 54:10205–10214

Bajpai AK, Shrivastava M (2002) Enhanced water sorption of a semi-interpentrating polymer network of poly (2-hydroxyethyl methacrylate) and poly (ethylene glycol). J Macromol Sci Pure Appl Chem A 39:667–672

Johnsen K, Kirkhorn S, Olafsen K, Redford K, Stori A (1996) Modification of polyolefin surfaces by plasma-induced grafting. J Appl Polym Sci 59:1651–1657

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ibrahim, S.M., Abou El Fadl, F.I. & El-Naggar, A.A. Preparation and characterization of crosslinked alginate–CMC beads for controlled release of nitrate salt. J Radioanal Nucl Chem 299, 1531–1537 (2014). https://doi.org/10.1007/s10967-013-2820-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-013-2820-4