Abstract

Remediation of water sources contaminated with radioactive waste products is a major environmental issue that demands new and more efficient technologies. For this purpose, we report a highly efficient ion-exchange material for the removal of radioactive nuclides from aqueous solutions. The kinetic characteristics of adsorption of uranyl ions on the surface of barium titanate were investigated using a spectrophotometric method under a wide range of conditions. By controlling the pH it was possible to exert fine control over the speciation of uranium, and by optimizing the temperature and grain size of the exchanger, almost total removal was achieved in a matter of just hours. The highest efficiency (>90 % removal) was realized at high temperature (80 °C). Moreover, the effect of competitive ion adsorption from a range of different cations and anions was quantified. Adsorption was found to follow first-order kinetics and both Freundlich and Langmuir isotherms could be applied to this system. The results of a mathematical treatment of the kinetic data combined with the observation that adsorption was independent of stirring speed and dependent on the ion-exchanger grain size, indicate that the dominant mechanism influencing adsorption is particle spreading. The adsorption behavior was not influenced by exposure to high-intensity gamma radiation, indicating potential for use of this ion-exchanger in systems containing radioactive material. These results will be of use in the development of uranium extraction systems for contaminated water sources.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Separation by ion exchange is one of the most important chemical methods to remove contaminants from waste- and contaminated water. This is typically achieved through adsorption of the analyte on inorganic oxides. For example, radionuclides have been separated in this way by adsorption on hydrous oxides [1–6]. The removal of nuclear fission products from aqueous solutions has been intensively studied over the past two decades, particularly inorganic titanate components and their selectivity toward various radionuclides [7–13]. The adsorption the uranyl, strontium, plutonium, and bismuth ions on sodium and barium titanates and iron hydroxides has been studied in detail [8–20]. Mishra et al. [7–9] studied the adsorption of barium ions on the surface of sodium titanate at concentrations between 10−2 and 10−6 M and temperature between 305 and 335 K. They found that the adsorption kinetics follow a first-order reaction rate, obeying a Freundlich isotherm.

The objective of the present research is to prepare inorganic ion exchangers that have the ability to adsorb specific radionuclides with high efficiency. Barium titanate (BaTiO3) was prepared and used to study the adsorption behavior of uranium ions from various aqueous solutions. Different factors affecting the adsorption process were investigated to optimize the ion exchange system towards adsorption of radioactive waste products and to shed light on the adsorption mechanism.

Experimental

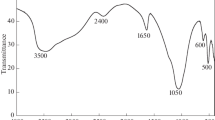

All chemicals used were of high purity (≥99 %). For the spectral analysis of gamma rays, a High Purity Germanium detector (Model, GEM 20180) (ORTEC, USA) was used, which had the ability to separate gamma-rays with energies above 1.8 keV (γ-energy = 1,332 keV) and a relative efficiency of 40 %. The high resolution was such that the spectral overlap between the peaks was very small. Lambda 20 UV/Vis spectrometer was used (Perkin-Elmer, USA) at wavelength 595 nm with FWHM (resolution) <3 nm.

The barium titanate was prepared by mixing titanium dioxide (1 mol, 81.63 g) with barium carbonate (1 mol, 201 g). This molar ratio was chosen because of the 1:1 reaction stoichiometry. The mixture was placed in a bowl containing small aluminum oxide spherules and was then flooded with 250 mL of pure methyl alcohol (methanol).

The mixture was then magnetically stirred for 2 h to ensure homogeneous mixing between the barium carbonate and titanium dioxide. The mixture was then completely dried, its weight recorded, and finally, was calcined at 1,250 °C.

The chemical reaction involving the two components is shown in Eq. (1):

Uranyl nitrate standard (0.0502 ppm) was prepared as Stock solution. The count rate of uranium was measured by spectral analysis of gamma rays using the 235U spectral line at 185 keV. This was carried out after ion exchange treatment by taking a 5-mL sample from the uranium solution after centrifuging and measuring the pH. The count rate of 235U at 185 keV was measured for 6 h. As a reference, the same volume of a uranyl nitrate solution (1 mM) was taken and measured at the same time as the sample under identical conditions. The adsorption percentage was then calculated using Eq. (2):

where A o is the count rate or the absorbance of the reference compound, and A is the count rate or absorbance of the compound after ion exchange [21].

The spectrophotometry method was used to determine the concentration of uranium by mixing 1 mL of uranyl nitrate (1 mM) and 2 mL of a compound arzenazo-1 (1 mM) in a standard 25-mL flask. The flask was filled to 25 mL with distilled water and the solution used as the reference solution. Following ion exchange, 1 mL of the uranium nitrate solution was taken. Equation (2) was used to determine the concentration of adsorbed uranium.

The results of the spectral method are compared with those obtained from the radiological method in Table 1. It is clear that there is concordance between the two measurement methods, and thus either method would be suitable. However, because of the ease and speed of the spectral method, we have used this in the present study. The obtained reproducibility was calculated to be <5 %. The data were evaluated using normality and z-score tests and the obtained results of normality and z-score showed that all data were normally distributed and the z-score was between ±2.

Results and discussion

The physical properties of barium titanate were determined as follows:

-

(1)

Surface area: 0.575 m2 g−1

-

(2)

Grain size: 39.24 μm. This is in good agreement with the value reported in the literature by Al-Hassoun (59 μm) [22] but quite low compared with the value reported by Othman (78 μm) [23]. The difference in grain size may be due to the different measurement methods used.

-

(3)

Pore size (radius): 116.88 Å.

The extent of uranium adsorption on barium titanate increases with time in the range studied from 5 min to 3 days as shown in Fig. 1. The concentration reached about 50 % in about 2 h. Thereafter, the adsorption increased slowly, by about 27 % between 2 and 24 h, reaching about 95 % after 3 days (4,680 min). 100 % removal was achieved after 6 days. This result is in agreement with that reported in the literature for the case of adsorption of barium and strontium ions on the surface of sodium titanate [9, 13, 14, 24]. We note that the speed of stirring had no effect on the extent of adsorption of uranium on barium titanate.

The pH is considered to be the most important factor affecting adsorption on ion exchange materials. Thus, we studied the effect of pH over the range pH = 0.59–5.00 to determine the optimum pH, at which the proportion of uranium adsorbed was as high as possible. The fact that uranium UO2 2+ precipitates at about pH 5.5 was taken into account; this value varied depending on the uranium concentration, decreasing at high concentrations and increasing at low concentrations. The results shown in Fig. 2 confirm that the adsorption rate is affected by the pH, with all other conditions held constant. The extent of adsorption increased with increasing pH to pHi = 4.51, where the adsorption was 69 %. Upon further increasing the pH, the adsorption increased abruptly to 100 %. It is noteworthy that pHf = 7.23, where the adsorption is almost 100 %, is within the limits of uranium precipitation. Therefore, this may be interpreted as precipitation rather than pure adsorption. This is consistent with results reported in the literature, where it was found that adsorption of barium and strontium ions on the surface of sodium titanate increased with increasing pH [9, 13, 24].

The percentage of uranium adsorption on the exchanger increased with decreasing uranium concentration in the concentration range 1 × 10−4 to 1 × 10−1 M, as shown in Table 2. The highest percentage of adsorption (ca. 100 %), was obtained at a concentration of 1 × 10−4 M, whereas this was only 3.7 % at 1 × 10−1 M. This is attributed to the saturation of active sites on the surface of the exchanger at high concentration. This result is consistent with those reported by Al-Ariefy [25] and Mishra and Srinivasu [26].

The effect of the amount of barium titanate on the extent of adsorption is demonstrated in Table 3. An increase in the amount of the exchanger led to an increase in the adsorption rate. About 5 % adsorption was obtained for 0.1 g barium titanate; this increased to about 80 % when the amount was increased to 1.5 g. In addition, there was a change in pHf with increasing amount of barium titanate.

Temperature is one of the most important parameters in chemical reactions. We varied the temperature between 0 and 80 °C to determine its effect on the extent of adsorption; the results are shown in Table 4. Cooling to a temperature of 0 °C did not dramatically affect the adsorption process, where the percentage adsorption was 32.5 %. At 25 °C, the adsorption rate increased to about 50 %. Upon heating the solution, it was observed that the extent of adsorption increased with solution temperature to 91.5 % at 80 °C. We note that there was only a slight change in the value of pHf which can be neglected. These results are consistent with those reported in the literature [25, 26], where the adsorption rate was found to increase with increasing solution temperature between 30 and 60 °C on the surface of barium titanate, and from 5 to 80 °C on the surface of nickel oxide.

To determine the effect of grain size on adsorption, a large amount of barium titanate was taken, spiral milled for an hour, and then separated into several different sizes using different sized sieves of between 45 and 850 μm pore size. The data in Table 5 show that there is a clear effect of grain size on absorption. The extent of adsorption was 33 % when the particle size was <850 μm and increased to 56 % when the particle size was between 63 and 106 μm. This indicates that the ion exchanger does not fragment and that the grain size is constant for the duration of the experiment; were this not the case, the adsorption percentage would be constant over the range of studied grain sizes. It is well known that the charge density is inversely related to the grain size. There was also an increase in pH with decreasing particle size.

Table 6 illustrates the obtained results after adding some competitor positive cations with different concentrations between 0.05 and 1 M, we can see that lithium ion improve the adsorption in this range. But, for all ions of sodium, potassium and cesium, they have a clear impact on the proportion of adsorption, where is noted that adsorption rate increase with concentration, we get 100, 95 and 100 %, respectively, when using the highest concentration of these ions 1 M. Therefore, we find that there is no effect of the size of the ion. In the second group, in the case of a double ionized magnesium ion, is observed an improvement in the rate of adsorption in the studied concentration range, where we getting about 79 % at a concentration of 1 M. In contrast, in the case of the use of double ionized barium ion, the adsorption ratio decreased to 25 % for all concentrations. In this case, the barium ion is a good competitor and disincentive for adsorption process for uranium adsorption on the surface of the exchanger. Here we can say that the size of the barium ion has a prominent role in the adsorption process and barium ion is competitor for the adsorption on barium titanate and this result agrees with what is found by Mishra and Srinivasu [14], the barium ion presents a large adsorption on the surface of barium titanate.

For the third group, concerning the three-charged ions, aluminium and iron, it is noted that they present an inhibitory effect on the adsorption process of uranium and this agrees with what is found by Al-Ariefy and Al-Suhybani [25, 27] In the light of this result both iron and aluminium are competitors for the adsorption on the surface of barium titanate.

Table 7 illustrate the obtained results after adding some competitor negative ions with different concentrations between 0.05 and 1 M, where is noted that the chloride, bromide and iodide ions increase the proportion of adsorption when increasing the concentration of each of them, so that were obtained on the proportion of adsorption are 75, 76 and 72 %, respectively, for 1 M ratio concentration, so we can say that the size of the ion careless influence in this status.

Table 8 shows influence of different solvents on the adsorption of uranium on the surface of barium titanate.

The barium titanate was irradiated with a radioactive dose of 1,000 kGy from a 60Co source to determine the effect of radiation on uranium adsorption. The results shown in Table 9 indicate that the irradiation of barium titanate had no effect on adsorption, consistent with the findings of Letho and Miettinen [24], who reported that irradiation of sodium titanate does not affect the adsorption properties of strontium ions. The inactivity of the exchanger toward radiation can be considered a positive result because this means it can be employed in systems containing radioactive elements without compromising its performance.

The activation energy \( \left( {E_{\text{a}}^{ * } } \right) \) was calculated using the Arrhenius equation (3), plotting ln k as a function of the inverse temperature (1/T). The activation energy of adsorption can be calculated from the slope of this line. The kinetic parameters are listed in Table 10.

The value of activation enthalpy can be found from Eq. (4) [28], taking into consideration that \( \Updelta H^{ * } \) and \( \Updelta S^{ * } \) do not change with temperature:

where N o is Avogadro’s number, R is the gas constant, h is the Planck constant, \( \Updelta S^{ * } \) is the entropy of activation, n is the reaction order, and C is the conc. of radium ions. \( \Updelta H^{ * } \) and \( \Updelta S^{ * } \) are calculated from the slope and intercept, respectively, of the graph obtained using Eq. (4) of ln (k/T) versus (1/T). The change in Gibbs free energy for activation can be calculated from the relationship:

The value of the activation energy provides an indication of the dominant mechanism involved. For example, the activation energy for the film diffusion-controlled mechanism of membrane spreading is in the range of 12.6–25.1 kJ mol−1 [29], whereas for the particle diffusion-controlled mechanism of particle spreading it is in the range of 25.1–41.8 kJ mol−1 [29]. This does not, however, mean that the activation energy must fall within these limits. A value of as high as 173 kJ mol−1 has been reported [30, 31], depending on the type and nature of the ion exchanger as well as the adsorbed ions. Al-Ariefy [25] reported an activation energy of 96 kJ mol−1 for the adsorption of uranium on nickel oxide, and Yamanaka [32] reported a value of about 100 kJ mol−1 for the adsorption of lithium, sodium, potassium ions on the crystalline zirconium phosphate. From Table 10, it is clear that the activation energy for adsorption of uranium on barium titanate is located within the range for membrane mechanical spreading.

The following kinetic equations, Eqs. (6) and (7) [33], can be applied:

which can be simplified to:

The value of F should be between 0 and 0.8.

As shown in Fig. 3, a linear relationship is obtained between Bt and time (t).

Together with the finding that the adsorption rate is independent of stirring speed and dependent on the grain size, the applicability of the relationship between Bt and t provides strong evidence that particle spreading is the dominant mechanism in this system, and that there is only a limited contribution from mechanical spreading of the membrane.

From Eq. (8) [7], which is shown in Fig. 4, a linear relationship for uranium adsorption on barium titanate is found, indicating that adsorption follows first order kinetics.

Here, a e is the concentration of adsorbed ions at equilibrium, a t is the concentration of adsorbed ions at a given time, t, and k is the rate constant for the adsorption process.The important thermodynamic values obtained in this study are presented in Table 11. Langmuir and Freundlich isotherms [3] were applied to the system using Eqs. (9) and (10):

Here, C b is the concentration of ions in solution at equilibrium, M and b are constants, x is the amount of adsorbed uranium at a certain concentration and m is the weight of ion exchanger in grams.

Here, C ads is the concentration of adsorbed ions on the exchanger, C bulk is the concentration of ions in the solution before adsorption, and A is the Freundlich constant.

The Langmuir and Freundlich isotherms are shown in Figs. 5 and 6, respectively; both isotherms are linear. The values of the two Freundlich constants (1/n and A) are calculated from the slope and the intercept of the straight line as: 1/n = 0.4 mol g−1 and A = 7.4 × 10−3 mol g−1.

Capacity of barium titanate used in our study was 7.4 mmol/100 g, and in similar previous studies reported capacity of magnesium titanate, nickel oxide and sodium titanate were 12.4 mmol/100 g [34], 90 mmol/100 g [25] and 140 mmol/100 g [24] respectively, depending on the type and nature of the ion exchanger as well as the adsorbed ions. For example the capacity change with change of oxidation state of adsorbed ions, such as change of selenite ions to selenate ions on goethite exchanger [35, 36].

Hydrous oxides of compounds are characterized by the existence of hydroxyl groups on their surfaces. Their chemical formulae can be written as X–OH, where X represents the oxide that dissolves in aqueous solution. The dissolution, which depends on the pH can be written as:

For barium titanate, the dissolution reaction is:

The uranyl ion is the adsorbing ion in this system, thus, the following reaction with the exchanger takes place:

Additionally, the mechanism can be written as follows:

Adsorption on hydrous oxides can be described by a hydrolytic adsorption mechanism [37]. Assuming that this mechanism applies to the present system, the following reaction will take place:

UO2(OH)+ is produced from the hydrolysis of uranyl ions in accordance with the reaction shown in Eq. (17). It should be noted that there are some examples in the literature that follow this kind of mechanism, such as the adsorption of Co2+ ions on the surface of ferric iron oxide [36], as well as the adsorption of Co2+, Zn2+, and Sr2+ ions on the surface of manganese dioxide [38–41].

We have shown that the pH has a large effect on adsorption. The pH will also affect the reaction mechanism, affecting both the adsorbent and adsorbed body alike. Its effect on the adsorbed body is clear from the adoption of the hydrous oxides at the zero charge point, which is defined as the pH value at which the adsorbed surface is electrically neutral, and depends on both the oxide itself and the medium. Depending on the pH, a proton will either be gained or lost as indicated in following reaction equation:

For an adsorbing material such as uranium, the pH determines which form of the uranyl ion and which hydration reaction dominates. In the case of low pH, the dominant form of the uranyl ion will be UO2 2+, but at the high pH, the following equilibria become important [42]:

The ratio of the species UO2 2+, UO2(OH)+, (UO2)2(OH) 2+2 , (UO2)3(OH)5+ produced depends both on the pH and the concentration of uranyl ions. At pH 3, UO2 2+, is the predominant form; at pH 4, the relative amount of UO2 2+ is 50 % and the percentage of (UO2)2(OH) 2+2 is 25 % [43]. At pH 5, effectively only (UO2)3(OH)5+ is formed. In other studies, it has been shown that the uranyl ion and nitrate do not complex to form UO2NO3 + except at very high concentrations [44, 45].

For the barium titanate used in the present study, the speciation can be predicted based on existing data and using the value pHi = 3.83. Accordingly, the dominant species in our system are UO2 2+ and (UO2)2(OH) 2+2 . This is similar to previous studies investigating the adsorption of more than one species on the same oxide, for example, the adsorption of (Co(II)EDTA)− and EDTA on silicon dioxide [46] and sulfate and chromate on iron oxide [47].

Conclusion

Barium titanate ions were shown to adsorb uranium (in the form of uranyl) with high efficiency, especially at high temperatures where adsorption exceeded 90 % at 80 °C. Control of the experimental variables, such as pH, grain size and temperature, makes it possible to control the separation process of a mixture of isotopes, and most importantly permits speciation and competitive ion adsorption to be controlled. The results will be of great use in the extraction of uranium from waste- and contaminated water sources.

References

Cvjeticanin D (1957) Separation of uranium(VI), plutonium(VI) and plutonium(IV) from zirconium and niobium on a column of silica gel. Nucl Sci Abstr 12:17000

Ahrland S, Grenthe I, Noren B (1960) The ion exchange properties of silica gel. The sorption of Na+, Ca2+, Ba2+, Uo2+, Gd3+, Zr(IV), Nb(V), U(IV), and Pu(IV). Acta Chem Scand 14:1059–1077

His C-KD, Langmuir D (1985) Adsorption of uranyl onto ferric oxyhydroxide application of the surface complexation site-binding model. Geochim Cosmochim Acta 49:1931–1941

Ames LL, McGarrah JE, Waker BA, Salter PF (1983) Uranium and radium sorption an amorphous ferric oxyhydroxide. Chem Geol 40:135–148

Akyil S, Aslani MAA, Oelmez S, Eral M (1996) Kinetic studies of uranium(VI) adsorption on a composite ion exchanger. J Radioanal Nucl Chem 213:441–450

Burclova J, Prasilova J, Benes P (1973) The state and adsorption behavior of traces of molybdenum(VI) in aqueous solutions. J Inorg Chem 35:909–919

Mishra SP, Srinivasu N (1992) Ion exchangers in radioactive waste management: part II. Radiotracer studies on adsorption of barium ions on sodium titanate. Indian J Technol 30:409–412

Mishra SP, Srinivasu N (1991) Adsorption of barium ions on sodium titanate: radiotracer studies. (Preprint no. RC 46). India p 2

Mishra SP, Dixit RK (1992) Effect of pH on uptake of Ba2+ and Sr2+ ions on inorganic ion exchangers: radiotracer study. 482:300–301

Chitra S, Viswanathan S, Rao SVS, Sinha PK (2011) Uptake of cesium and strontium by crystalline silicotitanates from radioactive wastes. J Radioanal Nucl Chem 287(3):955–960

Chitra S, Sudha R, Kalavathi S, Mani AGS, Rao SVS, Sinha PK (2013) Optimization of Nb-substitution and Cs+/Sr+2 ion exchange in crystalline silicotitanates (CST). J Radioanal Nucl Chem 295(1):607–613

Mishra SP, Srinivasu N (1990) Adsorption of iodide ions on barium titanate powder using radio-tracer technique. Bhabha Atomic Res Center, Nagpur, India 2:5–8

Heinoen OJ, Lehto J, Miethinen JK (1994) Sorption of strontium(II) and radio-strontium ions on sodium titanate. Radiochim Acta 28:93–96

Mishra SP, Srinivasu N (1992) Removal of barium ions from aqueous solution by barium titanate using radiotracer technique. Bombay 482:321–322

Tripathi VS (1984) Uranium(VI) transport modeling. Geochemical data and submodels. Ph. D. Dissertation, Stanford University, Stanford, California, USA

Guin R, Das SK, Saha SK (2002) Adsorption studies of zinc ions on barium titanate from aqueous solution. Radiochim Acta 90:53–56

Barnes MJ, Edwards TB, Hobbs DT, Marshall KM (2001) Strontium and actinide removal testing with monosodium titanate and other sorbents. Westinghouse Savannah River Company, TR-2001-00436

Hobbs DT, Blume MS, Thacker HL (2000) Phase V simulant testing of monosodium Titanate adsorption kinetics. Westinghouse Savannah River Company, TR-2000-00142

Hobbs DT, Blume MS, Thacker HL (2000) Screening evaluation of sodium nonatitanate for strontium and actinide removal from alkaline salt solution. Westinghouse Savannah River Company, TR-2000 00361

Duff MC, Hunter DB, Hobbs DT, Fink SD, Dai Z, Bradley JP (2003) Mechanisms of strontium and uranium removal from high-level radioactive waste simulant solutions by the sorbent monosodium titanate. Westinghouse Savannah River Company, MS-2003-00588

Fritz JS, Johnson-Richard M (1959) Colorimetric uranium determination with arsenazo. Anal Chim Acta 20:164–171

Al-Hassoun FAA (1992) Study of the physical and electrical properties of BaTiO3 doped with praseodymium oxide. Physics Department, King Saud University, Riyadh

Othman NMH (1992) Electrical properties of Ho-doped polycrystalline Sr0.35 Ba0.65 Ti1.03 O3. Physics Department, King Saud University, Riyadh

Lehto J, Miettinen JK (1985) Sodium titanate. A highly selective inorganic ion exchange for strontium. in: Inorganic ion exchangers and adsorbents for chemical processing in the nuclear fuel cycle, IAEA–TECDOC–337. Int Atomic Energy Agency Vienna 282:9–17

Al-Ariefy AM (1993) Master Thesis Preparation and use of some metal oxides for the separation of some radioisotopes. King Saud University, Riyadh

Mishra SP, Srinivasu N (1991) Adsorption of barium ions on sodium titanate: radiotracer studies. Preprints 685:9700548

Al-Suhybani A (1984) Use of local natural clays for radioactive waste treatment. Project No. AT-7-32 KACST

Aronson S, Roof RB Jr, Belle J (1957) Kinetic study of the oxidation of uranium dioxide. J Chem Phys 27:137–144

Helfferich F (1962) Ion exchange. McGraw Hill Book Co. Inc., New York

Barrer RM, Falconer JD (1956) Ion exchange in felspathoids as a solid state reaction. Proc R Soc Lond 236:227–249

Heitner-Wirguin C, Markovits G (1963) Kinetics of ion exchange in the chelating resin bio-chelex 100. J Phys Chem 67:2263–2266

Yamanaka S (1980) Ionic conductivity in anhydrous zirconium phosphates, Zr(HPO4)2 (M = Li, Na, K), with layered structures. J Inorg Nucl Chem 42:717–720

Reichenberg D (1953) J Am Chem Soc 75:589–597

AL-Hobaib AS, Al-Suhybani AA, Al-Homaidy KA (2006) Removal of uranyl ions from aqueous solutions by magnesium titanate. J Saudi Chem Soc 10(3):621–638

Carter M (1975) Some aspects of the geochemistry of liquid waste disposal. Ph. D. Thesis, Aslon University Birmingham, England

Wu CL, Yang MH, Lin CC (1983) Radiochim Acta 33:57

Fricke R, Blaschke F, Schmitt C (1938) Über die chemische Spezifität verschieden energiereicher Formen ein und derselben Krystallart, I. Mitteil.: Verschieden energiereiche Formen von α-Fe2O3. Chem Berichte 71:1738

Balistrieri LS, Murry JW (1982) The adsorption of copper, lead, zinc and cadmium on goethite from major ion Sea-water. Geo-chim Cosmochim Acta 46:1253–1265

Hasany SM, Chaudhary MH (1981) Adsorption studies of strontium on manganese dioxide from aqueous solutions. Int J Appl Radiat Isot 32:899–904

Hasany SM, Qureshi MA (1981) Adsorption studies of cobalt(II) on manganese dioxide from aqueous solution. Int J Appl Radiat Isot 32:747–752

Grano JP, Etienne P, Laurnet JF (1965) Etude des proprietes de surface du bioxyde de manganese. J Electrochim Acta 10:947–963

Baes CF Jr, Meyer NJ (1962) Acidity measurements at elevated temperatures: I. Uranium(VI) hydrolysis at 25 and 94. Inorg Chem 1:780–789

Mlkaml N, Sasakl M, Hachlya K, Yasunaga T (1983) J Phys Chem 87:5478

Komar INP, Trel’yak ZA (1955) Zh Anal Khim 10:236

Pant DD, Khandelwal DP (1954) The absorption and fluorescence spectra of uranyl nitrate solutions at room temperature. Proc Indian Acad Sci 50:323

Huang CP, Lin YT (1981) In: Tewari P (ed) Adsorption from aqueous solutions. Plenum Press, New York, p 65

Benjamin MM, Bloom NS (1981) In: Tewari P (ed) Adsorption from aqueous solutions. Plenum Press, New York, p 41

Acknowledgments

Authors are grateful to the King Abdulaziz City for Science and Technology, Riyadh, Saudi Arabia, for the financial support of this work and the facilities in its labs.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Hobaib, A.S., Al-Suhybani, A.A. Removal of uranyl ions from aqueous solutions using barium titanate. J Radioanal Nucl Chem 299, 559–567 (2014). https://doi.org/10.1007/s10967-013-2772-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-013-2772-8