Abstract

In order to separate Zr(IV) and Hf(IV) from chloride solutions, TEHA (tri 2-ethyl hexyl amine) was used as an extractant. The aqueous phase consisted of 200 ppm of Zr and Hf in strong HCl solution. In our solvent extraction system, the extractability of the constituents by TEHA was found to be in the following order, HCl > Zr(IV) > Hf(IV). The highest separation factor between the two metals was obtained from 8 M HCl solution. Based on the selectivity towards Zr over Hf with TEHA, McCabe–Thiele plot was constructed and batch simulation of counter-current extraction studies has been conducted. Scrubbing results from the loaded TEHA showed that Hf was selectively scrubbed over Zr by strong HCl solution (9 M). Complete stripping of Zr was possible from the organic phase with distilled water after scrubbing of Hf. The extraction behavior of Zr and Hf by TEHA was compared with that by TiOA and TOA. Our results can be utilized in developing a solvent extraction process to separate Zr and Hf from concentrated chloride solutions by using TEHA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Zirconium is mainly produced from two ore minerals, zirconium silicate (zircon, ZrSiO4) and baddelyite (ZrO2) [1]. Among the two minerals, zircon is the primary source of all hafnium and the ratio of zirconium to hafnium in zircon is about 50. Zirconium is mainly used for cladding nuclear reactor fuels due to its low neutron-capture cross-section and to having strong resistance to corrosion, whereas hafnium having 640 times high-neutron absorption cross-section than zirconium [2]. In fact, the concentration of hafnium in zirconium has a direct impact on the efficiency of reactor core and generation of nuclear power. Therefore, the separation of hafnium from zirconium is extremely important in nuclear science and technology. Numerous research efforts have indicated that the following three methods are effective to separate zirconium from hafnium in industry, multiple crystallization [3, 4], solvent extraction [5–7] and extractive distillation [4, 8]. Solvent extraction is one of the most remarkable technologies to the separation of metal ions from acidic aqueous solutions [5–7, 9].

Some of the research efforts have indicated that the separation of Zr from Hf is possible from different sort of acidic aqueous medium by using solvent extraction and ion-exchange methods [5–7, 9–13]. For example, Voit has patented on the separation of hafnium free nuclear grade zirconium from acidic chloride solutions in the presence of thiocyanate using MIBK extractant [14]. Hure et al. developed a process to separate zirconium from hafnium in 6 M nitric acid medium using 60 % TBP [15]. Karve et al. [16] reported that the separation of Zr from Hf could be achievable by using selective stripping method from loaded Aliquat 336 containing both Zr and Hf which was extracted at pH 4.0 in presence of ascorbic acid as a complexing reagent. The authors clearly suggested that Hf could be selectively stripped by strong HCl solution (9 M) but Zr was stripped with 2 M hydrochloric acid. Dasilva et al. [17] demonstrated that Cyanex 925 was an efficient and selective extractant for getting maximum separation factor of Zr about 37 between Zr and Hf in hydrochloric acid medium. Gupta et al. [18] investigated a process involving three consecutive steps to separate zirconium from zircon ore containing other associated elements such as cerium, titanium, thorium, aluminum and iron by using Cyanex 923 and also reported that the recovery and purity of Zr was about >98 %. Additionally, Taghizadeh et al. [19] reported that the combination of TBP and Cyanex 923 was also efficient to separate Zr from Hf in nitric acid medium. Moreover, Smolik et al. [20] have studied on the sorption and separation behavior of Zr and Hf from sulphate solutions, and the authors demonstrated that the use of Diphonix ion-exchange resin was efficient for the selective separation of Zr from Hf.

Phenomena associated with the extraction and separation of Zr from various sort of aqueous acidic solutions containing Hf with amine based extractants have been widely investigated for many years [21–26]. For instance, MacDonald [27] has patented on the separation of zirconium from hafnium in the presence of α-hydroxy carboxylic acid as water soluble complexing reagent with tertiary amine based extractant in sulfuric acid medium. El-Yamini and co-workers described that the primary amine and Aliquat 336 were efficient to separate Zr from Hf in sulfuric and hydrochloric acid, respectively and that the efficiency of quaternary ammonium halide was higher than the other amine based extractants [28, 29]. Additionally, combination of Aliquat 336/Alamine 336 and TBP gave a synergistic extraction of Zr from acidic aqueous chloride solutions [30]. Other investigations exhibited that it was possible to separate Zr from Hf with Aliquat 336 in presence of high concentrated acidic thiocyanate media and also described that the efficient synergistic extraction of Zr and Hf was achievable with a mixture of Aliquat 336 and TOPO [31]. Recently, Poriel et al. [32] have investigated the extraction characteristics of Zr and Hf from HCl solutions with Aliquat 336 and the stoichiometry of the extracted Zr and Hf with Aliquat 336 from single metal ion solution seemed to be different from that obtained with mixture of Zr and Hf solutions.

In this work, solvent extraction experiments have been done to separate Zr and Hf from concentrated hydrochloric acid medium, particularly for the generation of hafnium free nuclear grade zirconium. For this purpose, using TEHA as an extractant, the extraction behavior of the two metals was investigated by varying the concentration of HCl and extractant.

Experimental

Reagents

Tri 2-ethylhexyl amine (TEHA) was purchased from BASF Chem Co. Ltd., South Korea and 1-Decanol (Acros Organics) was used as a modifier. These reagents were used as such without any further purification. Throughout the experiments, kerosene was used as a diluent and all the other chemicals used were of reagent grade.

Procedure

The aqueous feed binary solution consisting 200 mg/L of each Zr and Hf was prepared by dissolving respective chemicals (ZrOCl2.8H2O, HfOCl2.8H2O, Alfa Aesar, Johnson Matthey Company) in hydrochloric acid solutions. The concentration of HCl in the feed solution was varied from 1 to 10 M. The required concentration of organic phase containing TEHA extractant was generally prepared in kerosene diluent. It is important to mention here that the feed solution containing both Zr and Hf metals used during extraction studies was freshly prepared in each time.

The general extraction and stripping experiments were conducted at room temperature by mixing equal volumes (20 mL) of the aqueous and organic phases (A/O = 1) for 30 min [32] by using wrist action shaker (Burrell model 75 USA). After shaking experiments, two phases were placed into a separating funnel, afterwards both phases were separated and subsequently the concentration of metals in the aqueous phase, before and after extraction, was measured by using ICP-OES (Spectro arcos) and the metal contents in the organic phase were determined by mass balance. The distribution ratio (D) was calculated as the ratio of the concentration of metal present in the organic phase to that part in the aqueous phase at equilibrium. From the D values, the percent extraction was obtained by using %E = D × 100/[D + (V aq/V org)] where V aq and V org are the volume of aqueous and organic phases, respectively. The separation factor (β) (β = D M1/D M2) was calculated from the value of distribution coefficient where M1 represents Zr and M2 represents Hf, respectively. Additionally, in extraction experiments, the concentration of HCl in the aqueous phase was analysed volumetrically by acid–base titration method as mentioned in Vogel [33] and the concentration of HCl in the organic phase was measured by mass balance. In majority cases, two replicate experiments were carried out simultaneously and the errors associated with the extraction, scrubbing and stripping percentages were varied more or less ± 5 %.

Results and discussion

Dependence of Zr and Hf extraction on the HCl, HNO3 and H2SO4 concentrations with TEHA in kerosene

The dependence of Zr and Hf extraction efficiency on the HCl, HNO3, H2SO4 concentration has been investigated with 0.05 M TEHA, and the results on the metal extraction in the HCl concentration range from 1 to 9 M are shown in Fig. 1 and Table 1. The obtained results denote that no significant extraction of Zr and Hf was noticed for the studied concentration range of HNO3 and H2SO4. Similar extraction behavior was noticed for HCl concentrations only less than 7 M. Afterwards, the extraction trend of Zr and Hf increased drastically and attained a maximum percent extraction of Zr and Hf 98.3 and 67.3 % at 9 M HCl, respectively. The same types of studies have already been reported by Poriel et al. [32] in acidic hydrochloric acid media by using Aliquat 336. Our results indicate that the concentration of TEHA and HCl can play a significant role on the selective extraction of Zr and Hf.

During the disengagement of the two phases, after equilibration between 0.05 M TEHA and 7–9 M HCl of aqueous solution, a kind of third phase was detected in the organic phase and also it was observed that the organic phase became very thick and syrupy solution. Additionally, it should be mentioned here that after allowing prolonged period of time, the color of organic solution became colorless to light pink.

The influence of TEHA concentration on the extraction of Zr and Hf at various HCl concentration range from 7 to 10 M

The data concerning the influence of TEHA concentration on the extraction of Zr and Hf at various HCl concentrations from 7 to 10 M is necessary to get an optimum condition to separate the two metals. The results obtained for Zr and Hf extraction with various TEHA and HCl concentrations are displayed in Fig. 2. At 7 M HCl concentration, it was relevant to observe that the percent extraction of Zr increased regularly from 50.3 to 75 % with increasing TEHA concentration up to 0.3 M and afterwards it was decreased to 33.3 % with increasing TEHA concentration up to around 1 M. The more significant and selective extraction of Zr was noticed at 7 M HCl concentration and rather nil extraction of Hf was observed with studied TEHA concentrations. For the similar experimental conditions adopted at 8 M HCl concentration, it was observed that the percent extraction of Zr and Hf was higher even at initial concentration range around 0.05 M TEHA and afterwards a significant decrease of Hf extraction from 27.7 to 7.8 % was noticed with increasing TEHA concentration up to 1 M, whereas the percent extraction of Zr remained unchanged. However at 9 M HCl, Zr and Hf extraction increased as the TEHA concentration increased to 0.5 M, thereafter, the percent extraction of Zr and Hf was constant but the percent extraction of Hf abruptly decreased to 55.1 % with increasing TEHA concentration up to about 1 M. The results of Zr and Hf extraction obtained at 10 M HCl denote that the quantitative extraction of those metals was attained with the entire studied concentration range.

In Fig. 2, it is seen that percent extraction of Zr decreased with increasing TEHA concentration at 7 M HCl. In the case of Hf, its extraction percentage decreased with increasing TEHA concentration when HCl concentration was 8 and 9 M in aqueous medium. There was little change in the percent extraction of the two metals at 10 M HCl. The decrease in metal extraction with the increase of extractant concentration may be ascribed to the formation of third phase, to the increase in the viscosity of the organic phase, and additionally to the competitive extraction between the HCl and metals (Zr and Hf) for the binding sites of TEHA. Therefore, some studies should be attempted to explain the decrease in percent extraction of metals with increasing TEHA concentration which was observed in Fig. 2. Similar type of competitive extraction studies has been described earlier by the El-Yamani et al. [28] with amine based extractant in kerosene diluent. We will discuss the decrease of metal extraction with TEHA concentration in “Effect of phase ratio on the separation of Zr with TEHA” section.

In order to find an optimum condition for the separation of Zr from Hf, additional information on the separation factor values (see in Fig. 3) has been obtained from the extraction data shown in Fig. 2. As can be seen in Fig. 3, the separation factor of Zr increased effectively from 54.1 to 316.5 with increasing TEHA concentration from 0.05 to 1 M at 8 M HCl. Furthermore at 9 M HCl concentration, it is observed that there was some fluctuation in the separation factor values. These results might be due to the co-extraction of Hf and abrupt decrease in percent extraction of Hf. Regarding the separation factor values obtained at 10 M HCl concentration, the results showed that the separation factor of Zr was very low, which was almost around 10 in the entire investigated concentration range.

According to preliminary extraction experiments and separation factor values, it can be said that the results obtained at 7 and 8 M HCl are the significant conditions to separate Zr from Hf. In all the experiments conducted in this present extraction study, the formation of third phase was observed; as a result 2 % decanol was added to prevent the appearance of the third phase in organic solution. Our results imply that the separation of Zr and Hf can be achievable from acidic aqueous chloride solutions by 0.3 and 1 M TEHA at 7 and 8 M HCl concentrations, respectively.

Effect of phase ratio on the separation of Zr with TEHA

In order to estimate the number of counter-current stages required for acquiring maximum loading of metal into the organic phase in continuous experiment at chosen phase ratio, extraction isotherm was obtained by varying the volume ratio of organic to aqueous and vice versa at constant temperature. In these experiments, the volume ratio of aqueous to organic was varied from 1 to 9 and the volume ratio of organic to aqueous was varied from 1 to 7 with 0.3 and 1 M TEHA at 7 and 8 M HCl concentrations, respectively. Subsequently, under the given set of experimental conditions, abnormal result were obtained that the percent extraction of Zr decreased drastically when the volume ratio of organic to aqueous increased with the selected concentration of TEHA extractant (see Table 2). This anomalous behavior may be due to preferential extraction of HCl over Zr and Hf into the organic phase. In order to verify the preferential extraction of HCl by TEHA, the concentration of HCl in the aqueous phase before and after the extraction was measured by acid–base titration. The obtained HCl concentration results (see Table 2) exhibited that the percent extraction of HCl increased from 25 to 80 % with increasing O/A ratio from 2 to 7. When an O/A ratio of 7 was employed at 8 M HCl solution, the equilibrium HCl concentration was 1.6 M. According to the data shown in Fig. 1, the extraction of Zr and Hf was negligible when HCl concentration was below 5 M. In addition, when the volume ratio of organic to aqueous was varied from 5 to 7 at 1 M TEHA without phase modifier, the formation of third phase was completely disappeared in organic solution. These results support the preferential extraction of HCl over Zr and Hf by TEHA in our experimental range.

Under the present experimental conditions, the extraction isotherm was constructed at 7 and 8 M HCl with 0.3 and 1 M TEHA, respectively. The plots (Fig. 4) suggest that more than two and three stages are necessary to get quantitative extraction of Zr from Hf at 7 and 8 M HCl, respectively.

Counter-current extraction simulation studies for separation of Zr

Based on the data obtained from McCabe–Thiele plots, a batch simulation of three and two stage counter-current extraction studies have been carried out to check the McCabe–Thiele predictions to separate Zr from Hf in 7 and 8 M HCl concentrations at A/O ratio 2 and 10 with 0.3 and 1 M TEHA, respectively. The results of three stage counter-current extraction simulation studies showed that the raffinate contained 2.4 mg/L of Zr and 173.6 mg/L of Hf, corresponding to 99.8 and 13.2 % extraction efficiency, respectively. On the other hand, the results obtained at two stage counter-current simulation studies indicated that the extraction percent of Zr and Hf was 99.6 and 41.8 %, respectively. It is clear that the co-extraction percent of Hf was more pronounced in two stage-simulation studies, when compared with the three stage-simulation extractions. Under comparable conditions, Zr was effectively separated from Hf with low TEHA concentration (0.3 M) at an A/O ratio 2 in three stage batch simulations studies. For high concentration TEHA (1 M) at an A/O ratio 10, the exhibited extraction performance of TEHA towards both Zr and Hf was much greater. Moreover, it should be mentioned here that the co-extracted HCl was nil along with Zr and Hf in three counter-current extraction simulation studies at an A/O ratio of 2.

Considering better utilization of solvent and selectivity of Zr over Hf, a three stage counter-current simulation studies data is promising and more efficient to separate Zr over Hf. Therefore, finally these results clearly suggest that the scrubbing step is necessary to obtain hafnium free nuclear grade zirconium from loaded TEHA organic phase.

Scrubbing of Hf and stripping of Zr from loaded TEHA organic phase

In view of information reported in the literature on the scrubbing of Hf from different kind of loaded organic phase, it is anticipated that concentrated HCl solution is a good reagent to scrub Hf efficiently from loaded organic phases [16]. Subsequently, in the present study HCl concentration was varied from 1 to 9 M to check the influence of its concentration on the scrubbing of Hf from loaded 0.3 M TEHA. The obtained results (see Table 3) exhibited that the scrubbing of both Zr and Hf was decreased from 99.1 to 0.5 and 99.9 to 39.2 % with increasing HCl concentration from 1 to 9 M respectively at unit phase ratio. As can be seen from Table 3, the selective scrubbing of Hf was noticed at 9 M HCl concentration at an A/O ratio of 2. In order to obtain quantitative scrubbing of Hf from loaded TEHA organic phase, a batch simulation of three stage counter-current scrubbing studies has been conducted at an A/O ratio of 2. The scrubbed TEHA organic phase contained 5 mg/L of Hf corresponding to >90 % scrubbing efficiency and 379.4 mg/L of Zr, corresponding to 4 % loss of Zr. Finally the complete stripping of Zr was achieved from loaded TEHA phase by simple contact with distilled water.

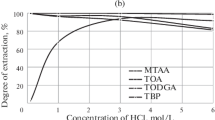

Comparison of the TEHA extraction behavior towards Zr and Hf with its other already studied structural/or chain isomers

In our previous work reported recently, both structural/or chain isomers namely tri-iso-octyl amine (TiOA) and tri n-octyl amine (TOA) have already been examined regarding their extraction affinity towards Zr and Hf in acidic aqueous chloride medium. From the reported data, it can be observed that the exhibited extraction performance of Alamine 308 towards Zr was higher than that of Alamine 300 [34]. In the present study, TEHA was used as an extractant for the separation of Zr over Hf. However, it is true that the TEHA is also a chain isomer of TiOA and TOA. The effect of chemical structure arrangement of tertiary amine based extractant and their basicity on the extraction efficiency of Zr over Hf was considered as a significant subject. Therefore, the extraction efficiency of Zr exhibited by the different tertiary amine based extractants (TEHA, TiOA and TOA) should be compared with the data obtained in the present and previous studies. Under comparable conditions, it is clear that the TEHA extraction efficiency towards Zr was higher than that of TiOA and TOA in the studied investigated range of extractant and HCl concentrations. According to the phenomena associated with the steric hindrance afforded by the ethyl groups located at the 2-position of the alkyl chain in the weakly tertiary amine based system such as TEHA, it was expected that TEHA would show lower extraction tendency towards Zr than other amine based extractants (TiOA and TOA). However, rather quite opposite behavior was noticed with the entire investigated range. The reason for this greater extraction efficiency of TEHA may be ascribed to the decrease in preferential extraction of HCl over Zr and Hf, subsequently which may provide relatively greater extraction of TEHA towards Zr. A similar result has already been reported by Sato and Watanabe on the greater extraction tendency of branched aliphatic tertiary amine based extractants towards metals when compared with the straight chain aliphatic tertiary amine based extractant [35]. However, further studies should be required to elucidate the mechanism concerning the greater extraction efficiency of TEHA towards Zr when compared with its chain isomers as TOA and TiOA in concentrated HCl media.

Conclusion

Solvent extraction experiments have been performed to separate Zr and Hf from strong HCl solutions. TEHA, a sort of amine based extractant, was used in the present experiments and the effect of the concentration of HCl and extractant on the extraction of the two metals was investigated. Extraction data clearly showed that Zr was selectively extracted by TEHA. The selectivity of TEHA over the constituents in our extraction system was found to be the following order, HCl > Zr > Hf. The highest separation factor was obtained from 8 M HCl solution. In order to obtain better conditions to separate Zr and Hf efficiently, extraction experiments, separation factor, McCabe–Thiele plots and eventually the most practical batch simulation of counter-current extraction studies have been performed. Moreover, Hf was selectively scrubbed from the loaded TEHA by strong HCl solutions and finally successive Zr stripping tests were conducted. Additionally the extraction behavior of TEHA was compared with the other structural isomers as TiOA and tri-octyl amine (TOA). The present approach can verify that TEHA can be employed for the separation of Zr and Hf from strong HCl solutions.

References

Elvers B, Hawkins S, Ravenscroft M, Rounsaville JF, Sculz G (1989) Ulmann’s encyclopedia of industrial chemistry. VCH, Weinhein

Prohit R, Devi S (1997) Talanta 44:319–326

Vinarov IV (1967) Russ Chem Rev 36:522–536

Moulin L, Thouvenin P, Brun P (1984) ASTM Spec Tech Publ 824:37–44

Da Silva ABV, Distin PA (1988) CIM Bull 91:221–224

Nandi B, Das NR, Battacharya SN (1983) Solvent Extr Ion Exch 1:141–202

Guccione E (1963) Chem Eng 70:128

Sathiyamurthy D, Shetty SM, Bose DK, Gupta CK (1999) High Temp Mater Process 18:213–226

Das NR, Lahiri S (1991) Solvent Extr Ion Exch 9:337–381

Hubicki Z (1988) Solvent Extr Ion Exch 6:183–205

Trubet D, Monroy Guzman F, Le Naour C, Brillard L, Hussonnois M, Constantinescu O (1998) Anal Chimica Acta 374:149–158

Pin C, Joannon S (2002) Talanta 57:393–403

Kraus KA, Moore GE (1949) Separation of zirconium and hafnium with anion exchange resins. J Am Chem Soc 71:3263

Voit OD (1992) US Patent, No. 5132016

Hure J, Rastoix M, Sanit-James R (1961) Anal Chim Acta 25:118–128

Karve MA, Khopkar SM (1992) Anal Sci 8:237–241

Dasilva A, El-ammouri E, Distin PA (2000) Can Metall Q 39:37–42

Gupta B, Malik P, Madhur N (2005) Solvent Extr Ion Exch 23:345–357

Taghizadeh M, Ghanadi M, Zolfonoun E (2011) J Nucl Mater 412:334–337

Smolik M, Jakobik-Kolon A, Poranski M (2009) Hydrometallurgy 95:350–353

Cerrai E, Testa C (1959) Energia Nucl 6:707 and 768 Chem Abstr 54:10713h

Sato T, Good ML, Watanabe H, Kotani S, Yamamoto M (1976) Anal Chim Acta 84:397–408

Vibhute CP, Khopkar SM (1987) Anal Chim Acta 193:387–392

Yang XJ, Pin C (1999) Anal Chem 71:1706–1711

Yang XJ, Pin C, Fane AG (1999) J Chromatogr Sci 37:171–179

Yang XJ, Fane AG, Pin C (2002) Chem Eng J 88:45–51

MacDonald DJ (1980) US Patent, No. 4231994

El-Yamani IS, Farah MY, El-Aleim FA (1978) Talanta 25:523–525

El-Yamani IS, Farah MY, El-Aleim FAA (1978) Talanta 25:714–716

Mishra PK, Chakravortty V, Dash KC, Das NR, Bhattacharya SN (1989) J Radioanal Nucl Chem Art 134:259–264

Mishra PK, Chakravortty V, Dash KC, Das NR, Bhattacharya SN (1992) J Radioanal Nucl Chem Art 162:289–298

Poriel L, Favre-Reguillon A, Pellet-Rostaing S, Lemaire M (2006) Sep Sci Technol 41:1927–1940

Vogel AI (1989) A text book of quantitative chemical analysis, 5th edn. ELBS, Longman, p 376

Raju B, Lee HY, Lee MS (2012) Ind Eng Chem Res (accepted)

Sato T, Watanabe H (1971) Anal Chim Acta 54:439–446

Acknowledgments

This study was financially supported by a grant from the fundamental R&D Program for Core Technology of Materials funded by the Ministry of Knowledge Economy, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Banda, R., Lee, H.Y. & Lee, M.S. Separation of Zr and Hf from strong hydrochloric acid solution by solvent extraction with TEHA. J Radioanal Nucl Chem 295, 1537–1543 (2013). https://doi.org/10.1007/s10967-012-1941-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-012-1941-5